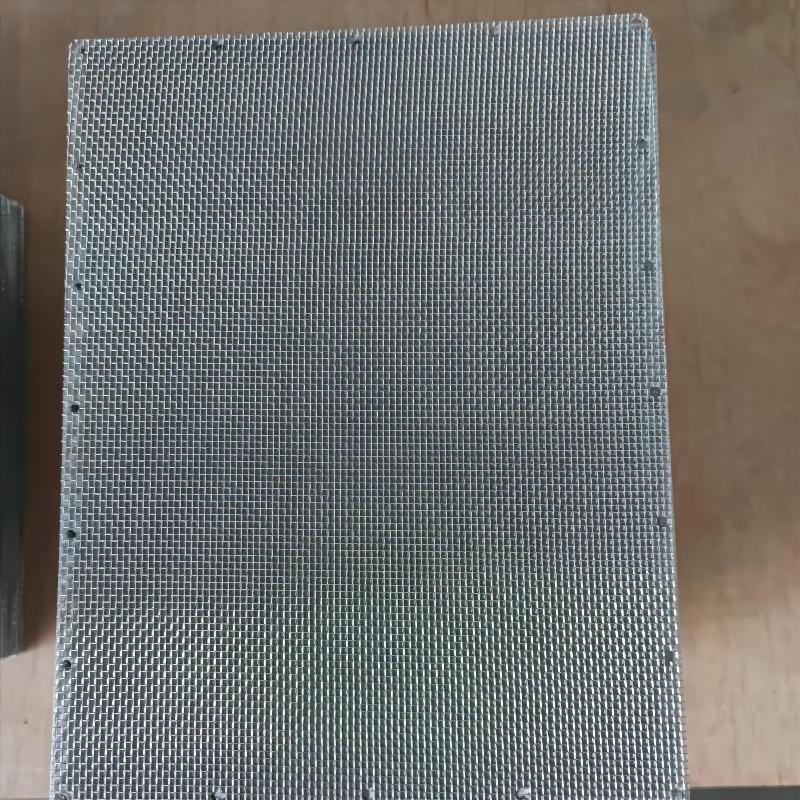

| Specification - Two or three - layer sintered mesh | |||||

| Description | filter fineness | Structure | Thickness | Porosity | Weight |

| μm | mm | % | kg / ㎡ | ||

| SSM-T-0.5T | 2-200 | filter layer+80 | 0.5 | 50 | 1 |

| SSM-T-1.0T | 20-200 | filter layer+20 | 1 | 55 | 1.8 |

| SSM-T-1.8T | 125 | 16+20+24/110 | 1.83 | 46 | 6.7 |

| SSM-T-2.0T | 100-900 | filter layer+10 | 1.5-2.0 | 65 | 2.5-3.6 |

| SSM-T-2.5T | 200 | 12/64+64/12+12/64 | 3 | 30 | 11.5 |

| Remarks:Other layer structure available on request | |||||

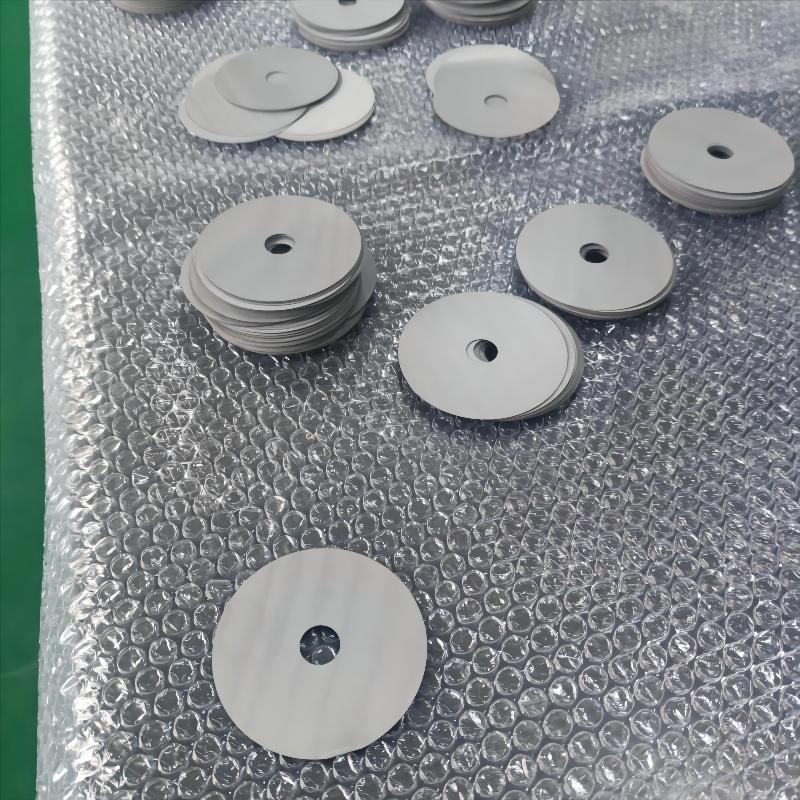

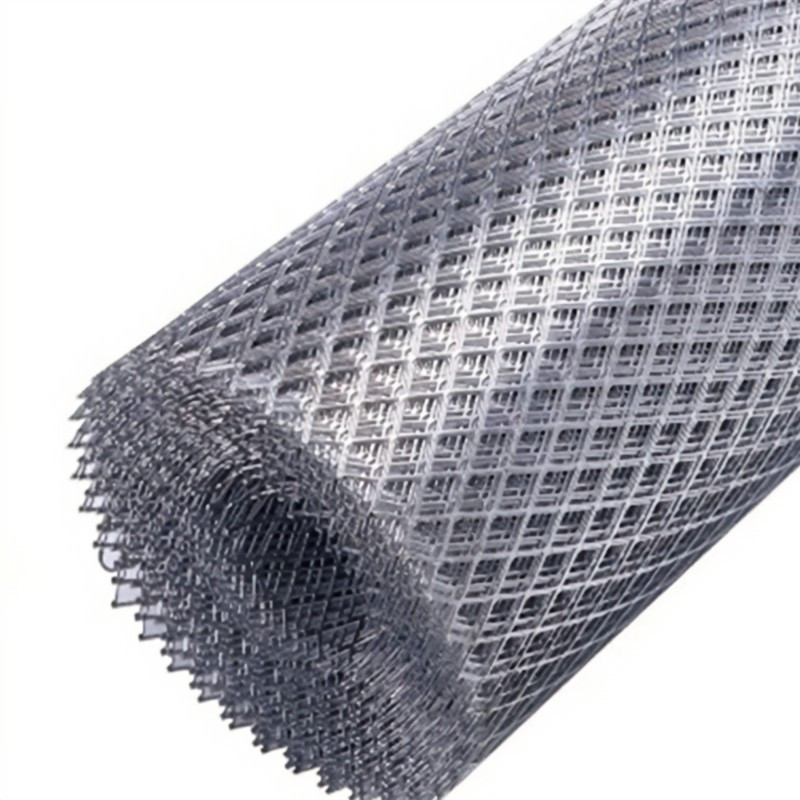

Model one

Model oneModel two

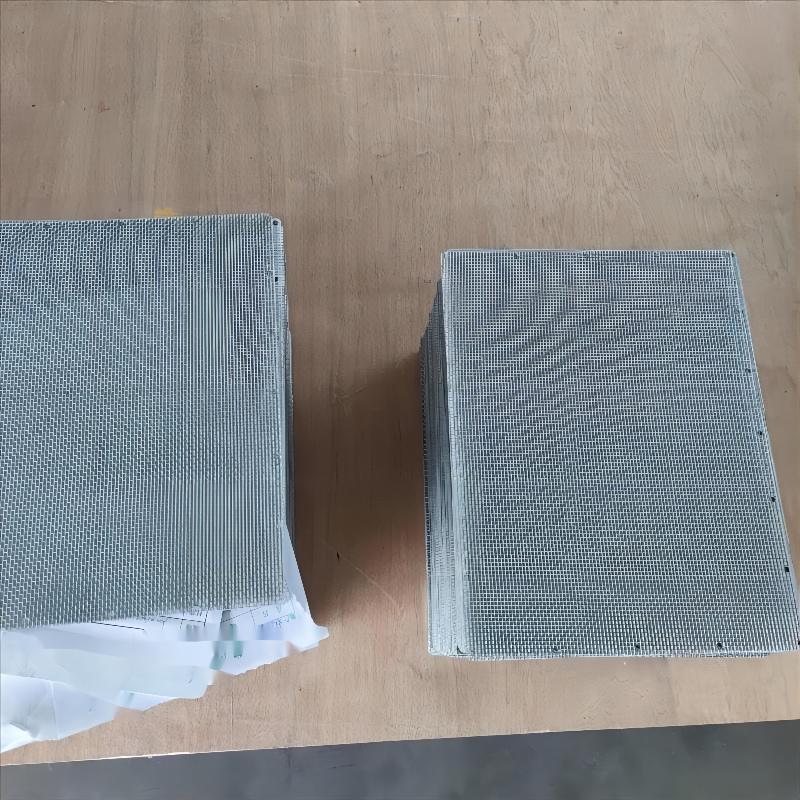

Two or Three same mesh sintered into on piece

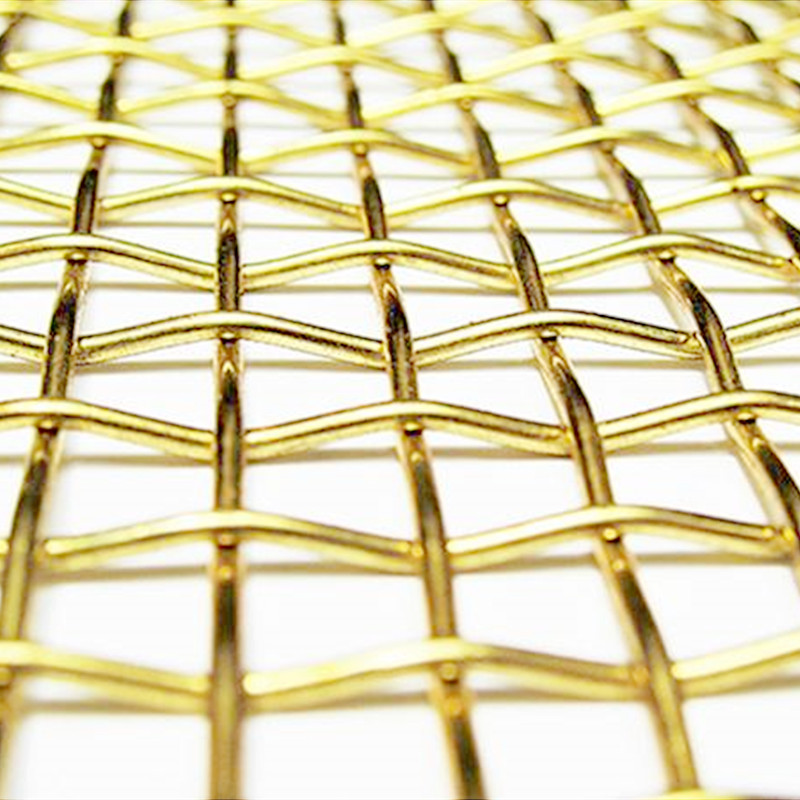

Two or Three same mesh sintered into on piece Model three

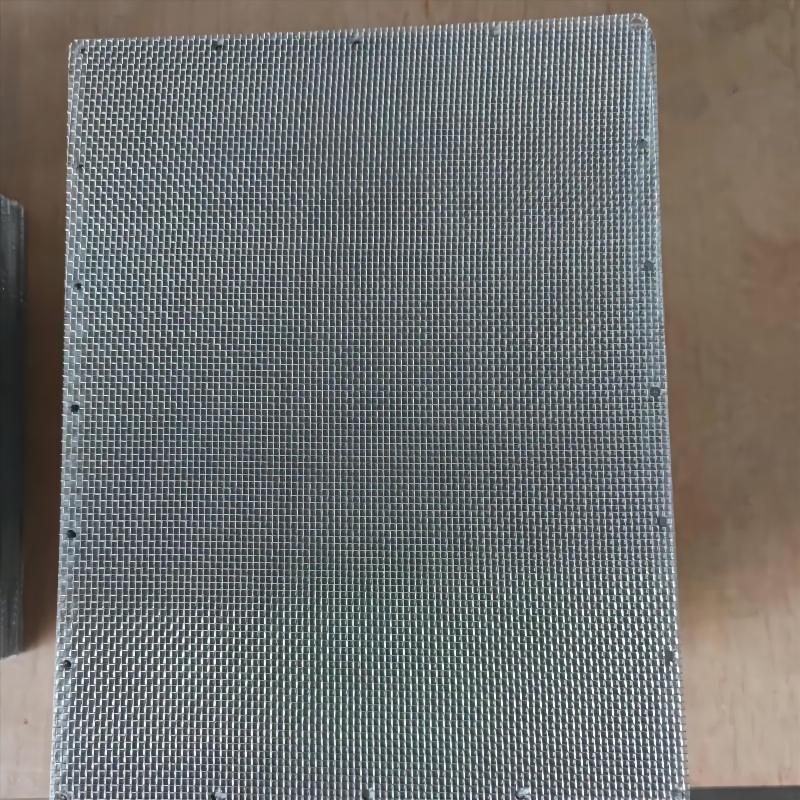

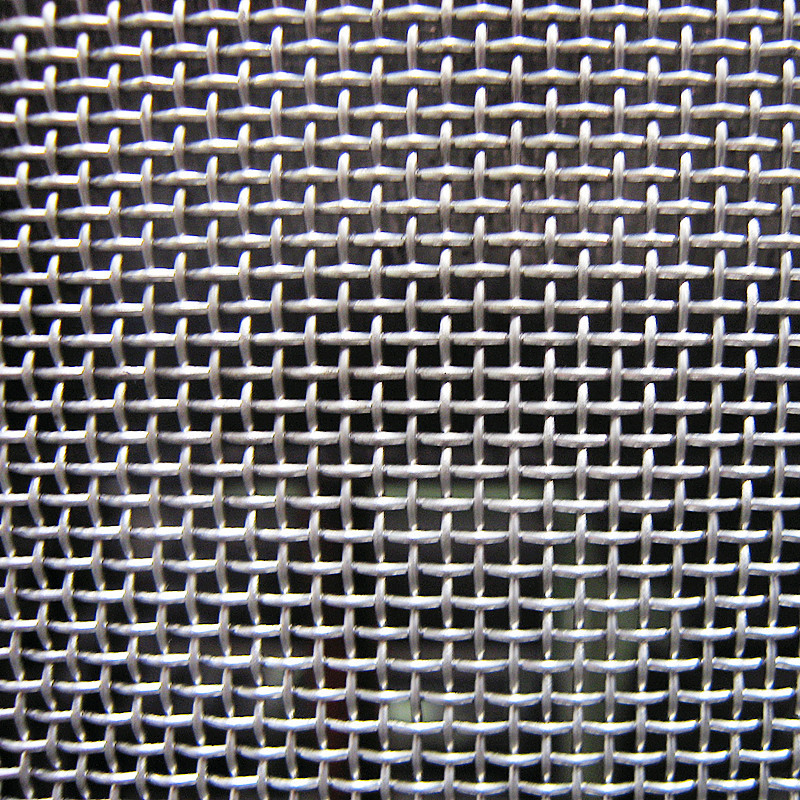

Model threeMulti-layer sintered mesh, which is suitable for complex environments with high corrosion and high temperature characteristics, such as power plant water supply system and steam generation pipe filtration, seawater deslagging in seawater desalination plants, sulfuric acid and hydrochloric acid filters, oil mist removal in crude oil distillation towers, seawater desalination Equipment pre-filtration, refining and separation of nuclear energy, etc. It has good stability in many corrosive media such as hydrofluoric acid, alkali, H2S, H2SO4, H3PO4, organic acid, etc., especially in hydrofluoric acid and alkali solution. The product is widely used in petrochemical industry, nuclear industry, national defense industry and other industries.

Features:

1. High porosity, good permeability and low flow resistance;

2. It can be designed according to the needs of users, and the filtration accuracy is 1-300µm;

3. High mechanical strength, high rigidity, convenient assembly and maintenance;

4. There is little residue when the granular objects are removed, and it is easy to clean;

5. It is easy to process and form, and can easily realize the production of single and special-shaped parts.