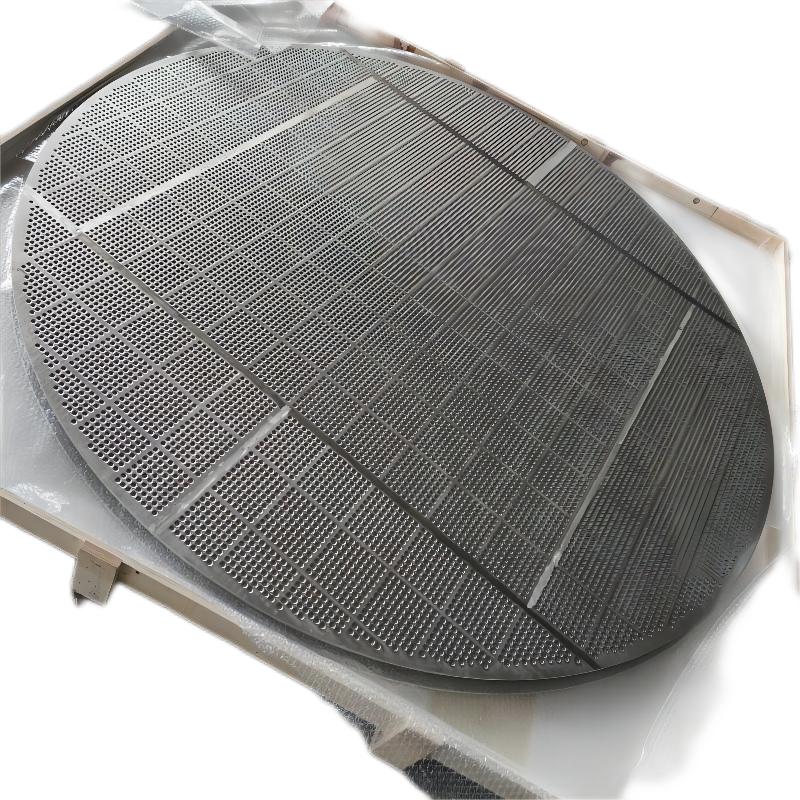

| Specification - Square weave sintered mesh | |||||

| Descriptsion | filter fineness | Structure | Thickness | Porosity | Weight |

| μm | mm | % | kg / ㎡ | ||

| SSM-S-0.5T | 2-100 | filter layer+60 | 0.5 | 60 | 1.6 |

| SSM-S-0.7T | 2-100 | 60+filter layer+60 | 0.7 | 56 | 2.4 |

| SSM-S-1.0T | 20-100 | 50+filter layer+20 | 1 | 58 | 3.3 |

| SSM-S-1.7T | 2-200 | 40+filter layer+20+16 | 1.7 | 54 | 6.2 |

| SSM-S-1.9T | 2-200 | 30+filter layer+60+20+16 | 1.9 | 52 | 5.3 |

| SSM-S-2.0T | 20-200 | filter layer+20+8.5 | 2 | 58 | 6.5 |

| SSM-S-2.5T | 2-200 | 80+filter layer+30+10+8.5 | 2.5 | 55 | 8.8 |

| Remarks:Other layer structure available on request | |||||

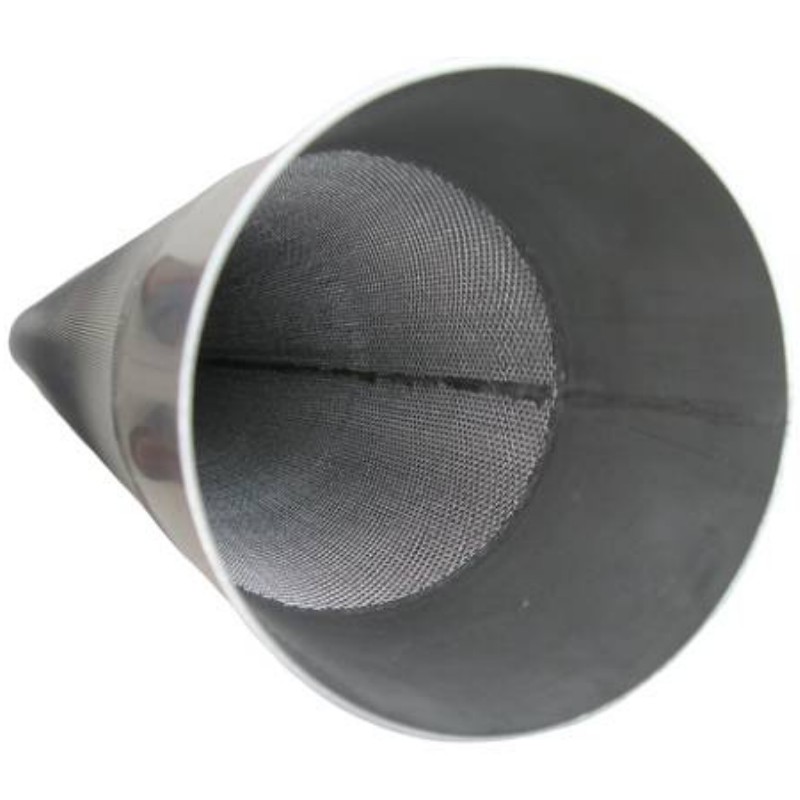

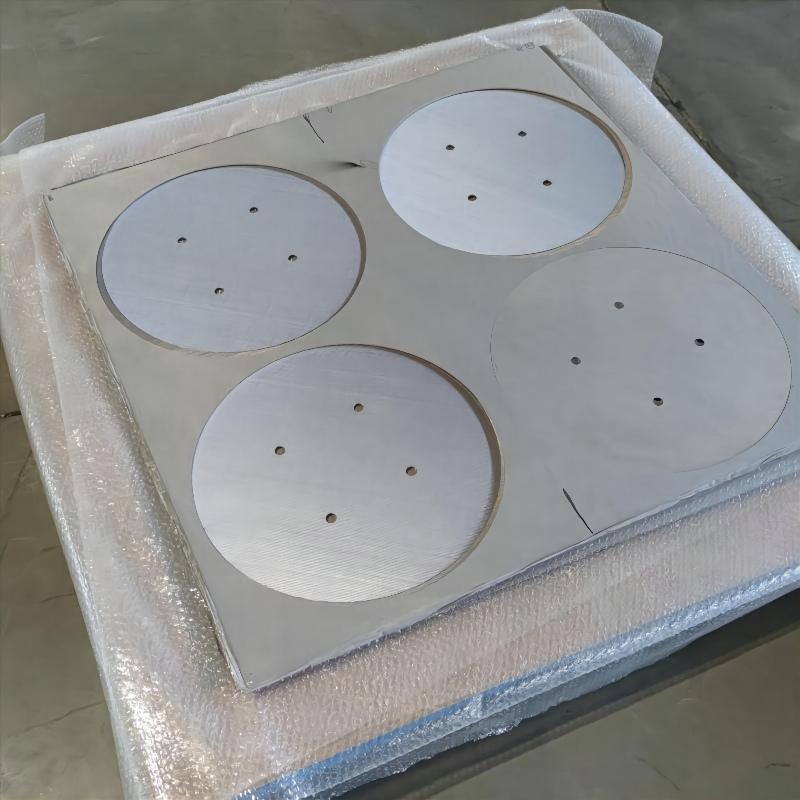

Model one

Model oneModel two

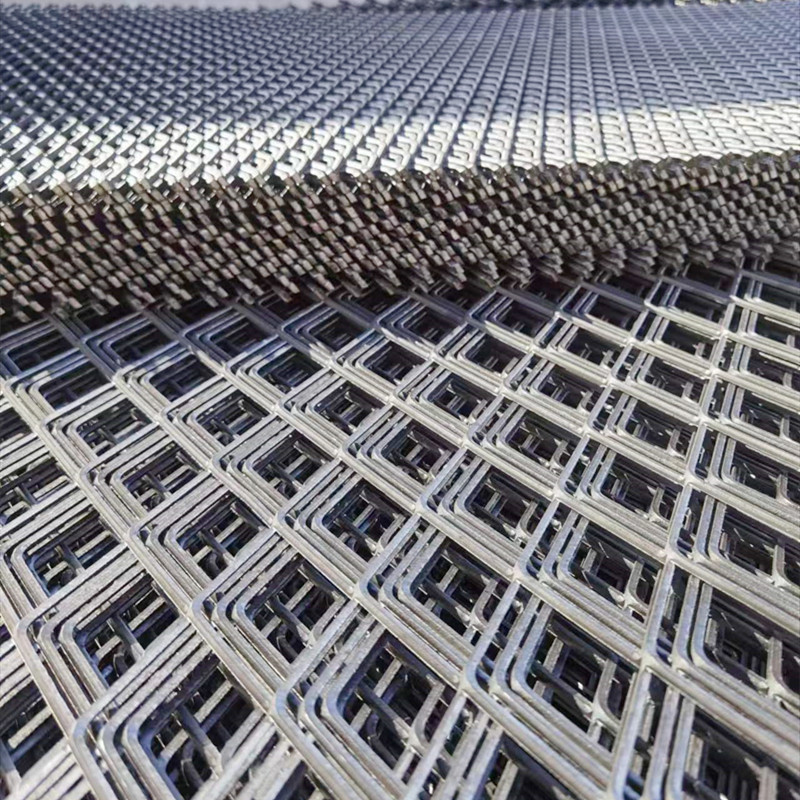

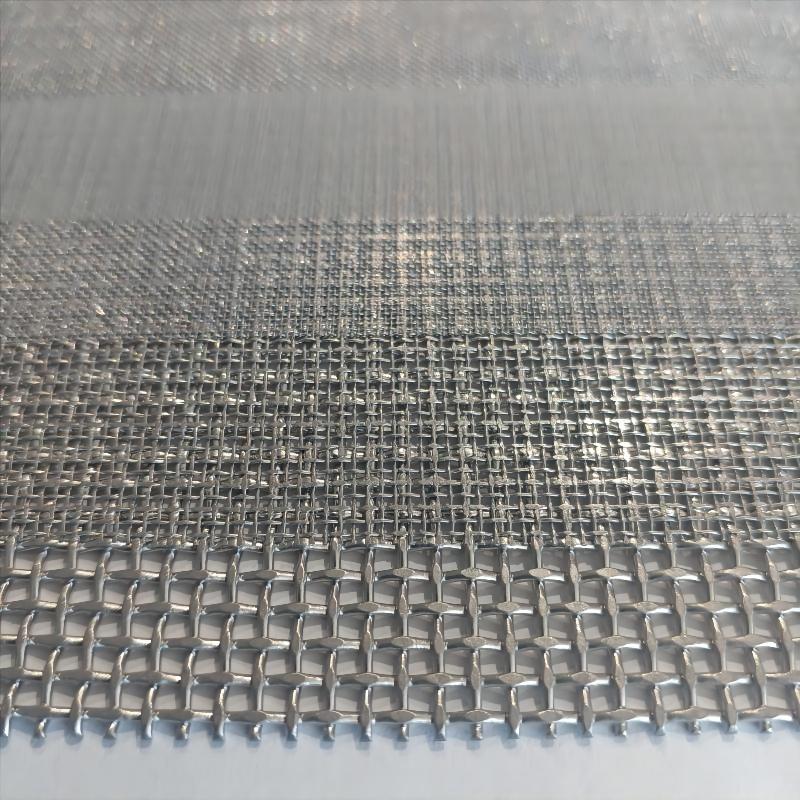

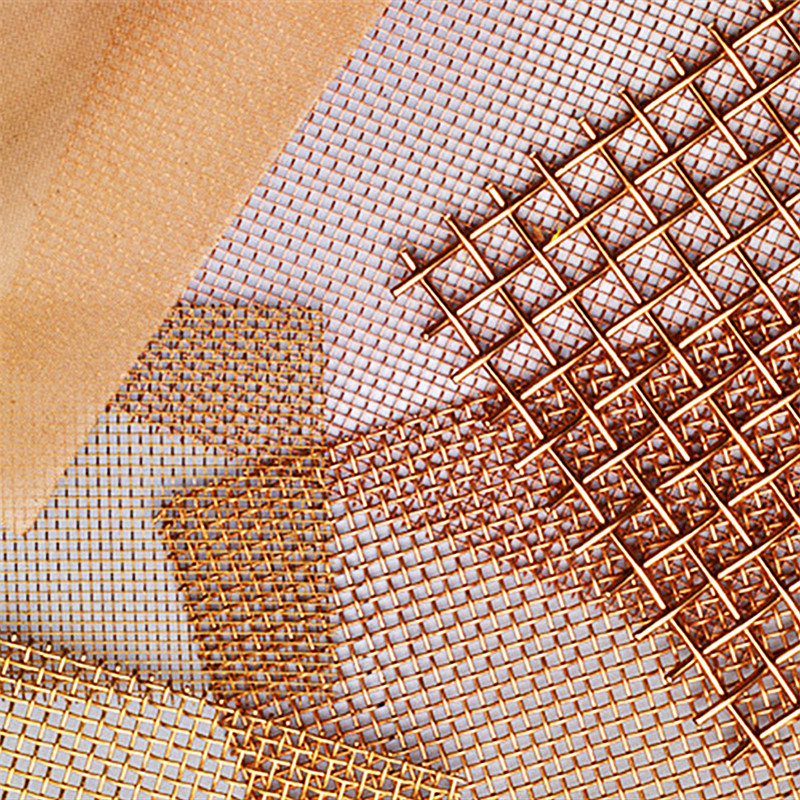

Sintered metal mesh is a new type of filter material with high mechanical strength and overall rigid structure, which is made of multi-layer metal woven wire mesh through special lamination pressing and vacuum sintering processes. The meshes of each layer of wire mesh are interlaced to form a uniform and ideal filtering structure, which not only overcomes the shortcomings of ordinary wire mesh such as low strength, poor rigidity, and unstable mesh shape, but also can adjust the pore size, Reasonable matching and design of permeability and strength characteristics, so that it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability, and its comprehensive performance is obviously better than that of sintered metal powder, ceramics, Fiber, filter cloth, filter paper and other types of filter materials.

Sintered metal mesh is a new type of filter material with high mechanical strength and overall rigid structure, which is made of multi-layer metal woven wire mesh through special lamination pressing and vacuum sintering processes. The meshes of each layer of wire mesh are interlaced to form a uniform and ideal filtering structure, which not only overcomes the shortcomings of ordinary wire mesh such as low strength, poor rigidity, and unstable mesh shape, but also can adjust the pore size, Reasonable matching and design of permeability and strength characteristics, so that it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability, and its comprehensive performance is obviously better than that of sintered metal powder, ceramics, Fiber, filter cloth, filter paper and other types of filter materials.