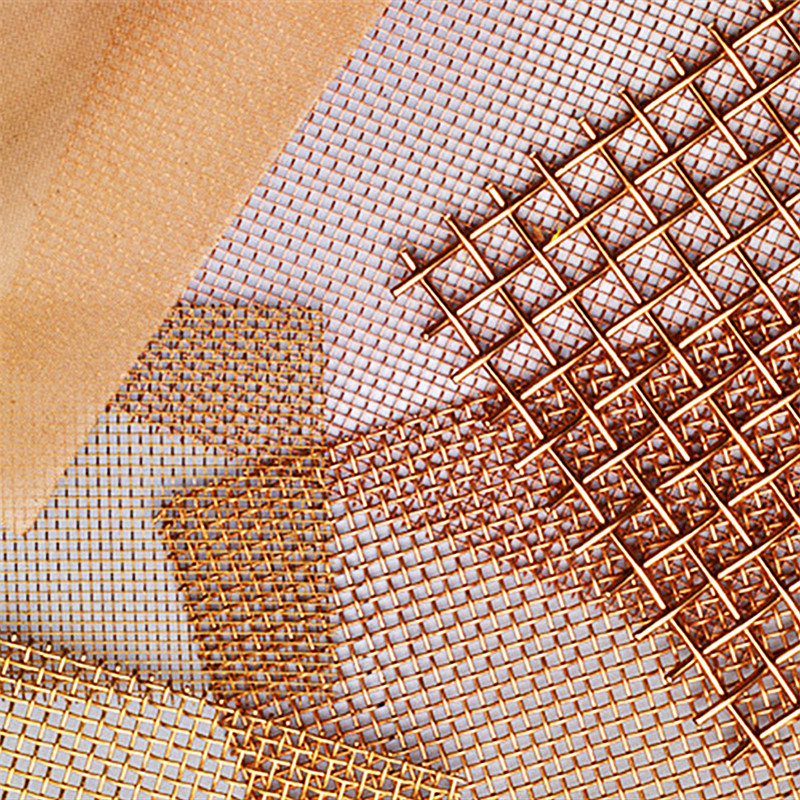

| Specification - Square weave sintered mesh | |||||

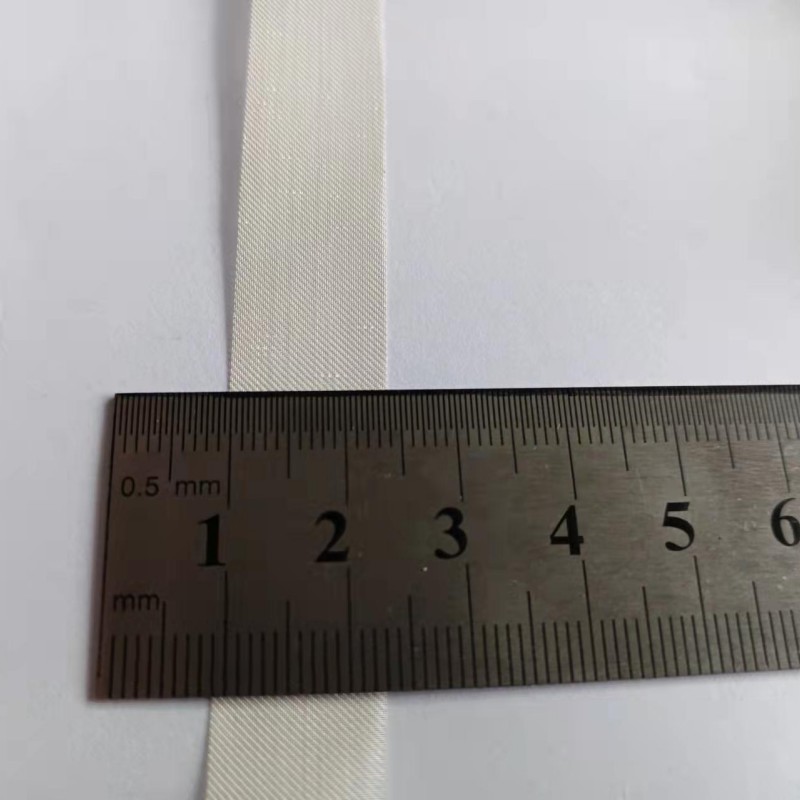

| Descriptsion | filter fineness | Structure | Thickness | Porosity | Weight |

| μm | mm | % | kg / ㎡ | ||

| SSM-S-0.5T | 2-100 | filter layer+60 | 0.5 | 60 | 1.6 |

| SSM-S-0.7T | 2-100 | 60+filter layer+60 | 0.7 | 56 | 2.4 |

| SSM-S-1.0T | 20-100 | 50+filter layer+20 | 1 | 58 | 3.3 |

| SSM-S-1.7T | 2-200 | 40+filter layer+20+16 | 1.7 | 54 | 6.2 |

| SSM-S-1.9T | 2-200 | 30+filter layer+60+20+16 | 1.9 | 52 | 5.3 |

| SSM-S-2.0T | 20-200 | filter layer+20+8.5 | 2 | 58 | 6.5 |

| SSM-S-2.5T | 2-200 | 80+filter layer+30+10+8.5 | 2.5 | 55 | 8.8 |

| Remarks:Other layer structure available on request | |||||

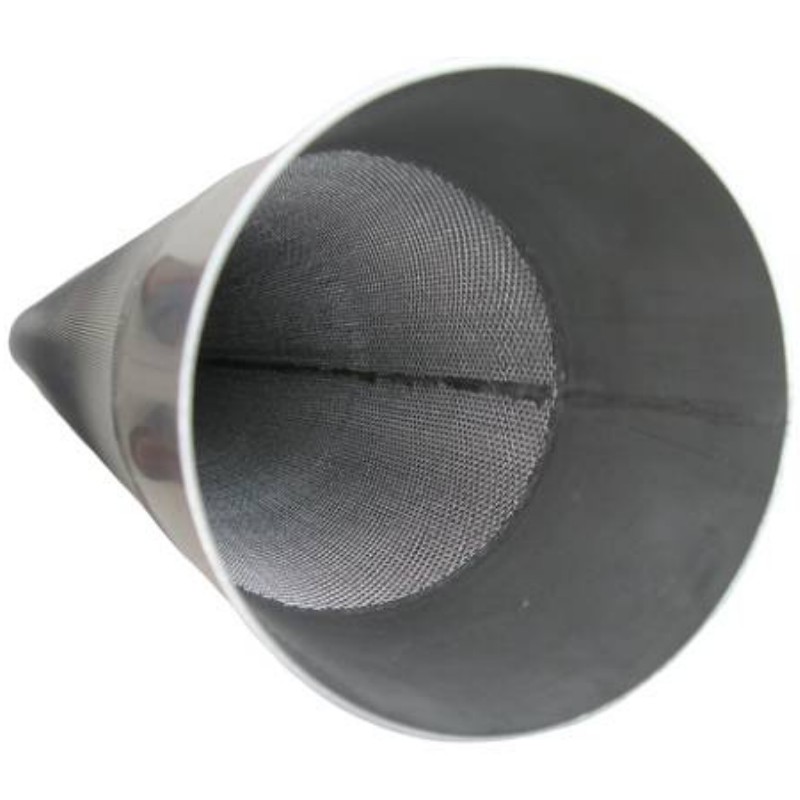

Model one

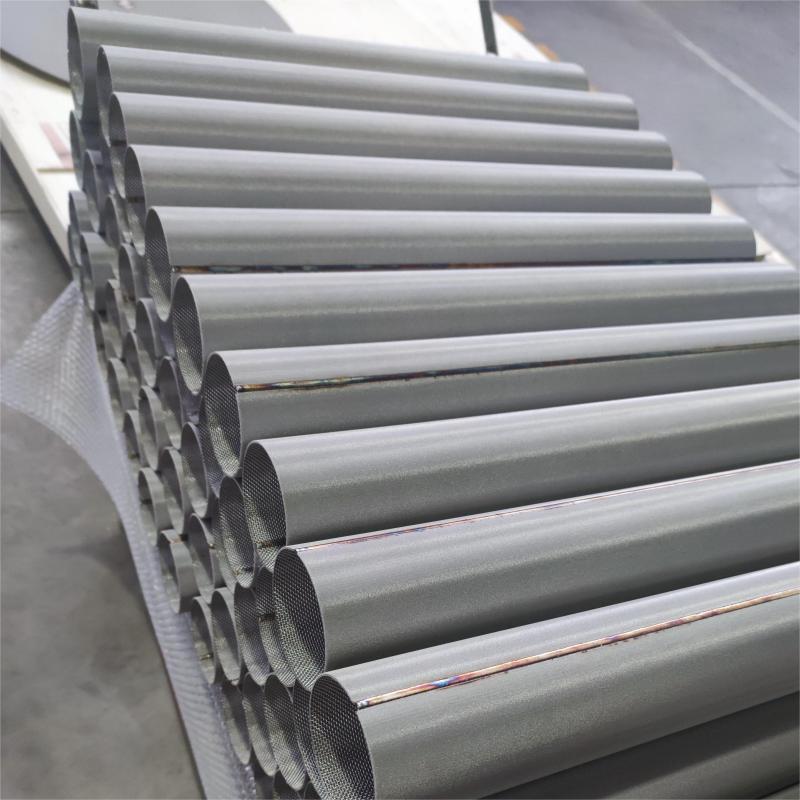

Model oneModel two

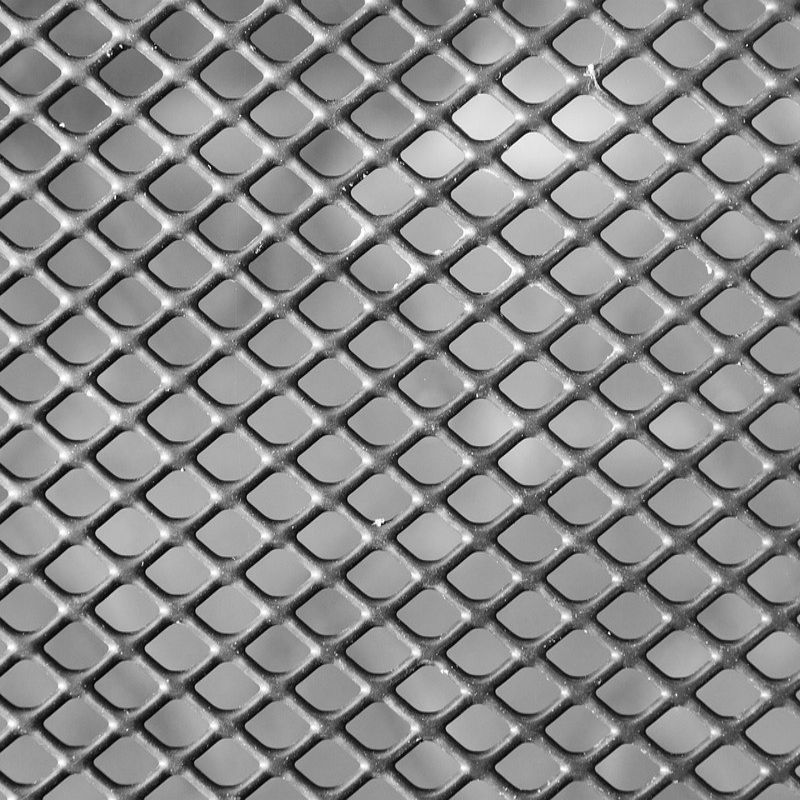

As the name suggests, the conical filter element is in the shape of a cone, which belongs to the pipeline coarse filtration series. Its form is simple, remove impurities in the medium in the pipeline to make the equipment work and run normally, and ensure the safe production of the equipment. Working principle: The working principle of the stainless steel conical filter element is that after the fluid enters the conical filter element, its impurities are blocked, and the clean fluid flows out of the outlet. When cleaning is required, just remove the conical filter element and clean it. Just load it.

As the name suggests, the conical filter element is in the shape of a cone, which belongs to the pipeline coarse filtration series. Its form is simple, remove impurities in the medium in the pipeline to make the equipment work and run normally, and ensure the safe production of the equipment. Working principle: The working principle of the stainless steel conical filter element is that after the fluid enters the conical filter element, its impurities are blocked, and the clean fluid flows out of the outlet. When cleaning is required, just remove the conical filter element and clean it. Just load it.