Innovative Porous Sintered Metal Technology: What You Need to Know

By:Admin

The metal industry has always been at the forefront of technological innovation, constantly seeking to improve the properties and performance of metal products. One such innovation that is making waves in the industry is Porous Sintered Metal, a revolutionary material that is changing the way metal is used in various applications. This innovative material is being produced by the leading company in the industry, {}, and is poised to revolutionize the metal industry.

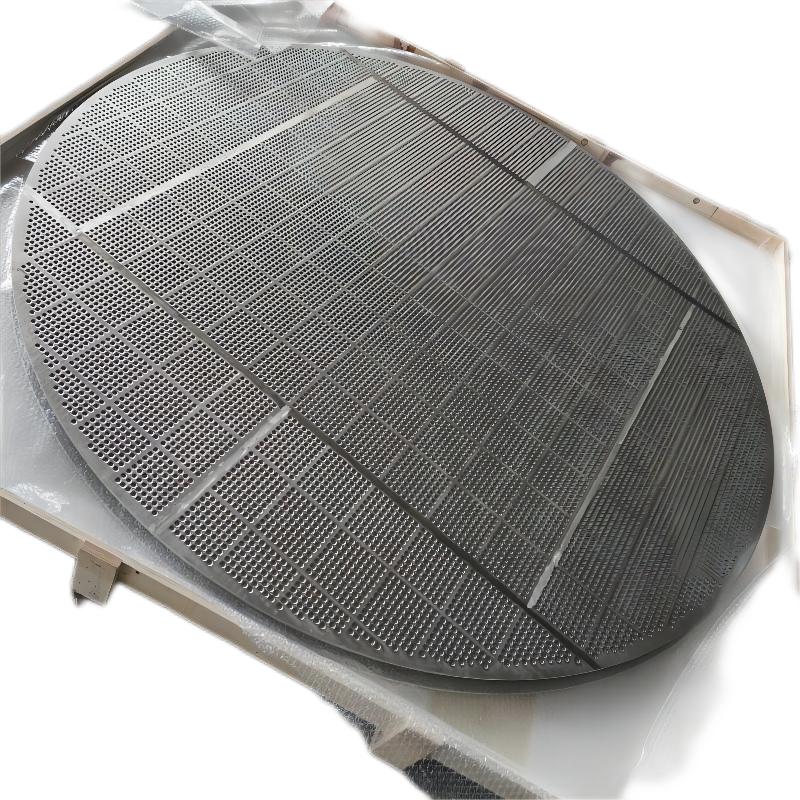

Porous Sintered Metal is a unique material that is produced through a process called sintering, in which metal powders are compacted and heated to form a solid piece. What sets Porous Sintered Metal apart from traditional metal products is its unique microstructure, which consists of interconnected pores that are distributed throughout the material. This unique microstructure gives Porous Sintered Metal a number of distinct advantages over traditional metal products, making it an ideal choice for a wide range of applications.

One of the key advantages of Porous Sintered Metal is its excellent mechanical properties. The interconnected pores in the material provide a high level of porosity, which in turn gives the material a high strength-to-weight ratio. This means that Porous Sintered Metal is incredibly strong and durable, yet lightweight and easy to work with. This makes it an ideal material for applications where weight and strength are important factors, such as in the automotive and aerospace industries.

In addition to its impressive mechanical properties, Porous Sintered Metal also offers excellent thermal and electrical conductivity. This makes it an ideal material for applications where heat dissipation or electrical conduction is important, such as in heat exchangers and electrical contacts. The unique microstructure of Porous Sintered Metal also makes it highly resistant to corrosion, making it an ideal choice for applications where the material will be exposed to harsh environments.

{} is at the forefront of Porous Sintered Metal production, leveraging its extensive experience and expertise in the metal industry to produce high-quality Porous Sintered Metal products. The company utilizes advanced sintering techniques and state-of-the-art equipment to produce Porous Sintered Metal with precise microstructures and tailored properties, ensuring that the material meets the exacting requirements of its customers.

The company's commitment to quality and innovation has earned it a reputation as a leader in the metal industry, and its Porous Sintered Metal products are already making a significant impact in a wide range of applications. From automotive and aerospace to energy and electronics, {}'s Porous Sintered Metal is being used to create innovative and high-performance products that are pushing the boundaries of what is possible in the metal industry.

Looking to the future, {} is committed to further advancing the capabilities of Porous Sintered Metal, with a focus on developing new and improved materials that offer even greater performance and versatility. The company is actively collaborating with industry partners and research institutions to explore new applications and technologies for Porous Sintered Metal, with the ultimate goal of driving innovation and advancement in the metal industry.

In conclusion, Porous Sintered Metal is a revolutionary material that is changing the way metal is used in various applications. With its unique microstructure and exceptional properties, Porous Sintered Metal is poised to revolutionize the metal industry, and {} is leading the charge with its high-quality Porous Sintered Metal products. As the company continues to push the boundaries of what is possible with Porous Sintered Metal, the industry can look forward to even more exciting developments that will shape the future of metal technology.

Company News & Blog

Versatile and Stylish Black Coated Wire Mesh: A Must-Have for Homes and Offices

Title: Innovative Black Coated Wire Mesh Revolutionizes the IndustryIntroduction:As the demand for reliable and durable wire mesh continues to rise across multiple sectors, the introduction of revolutionary black coated wire mesh by a prominent company promises to deliver exceptional performance and aesthetics. This innovative product boasts a range of features that make it a game-changer in the wire mesh industry. With its unique composition and cutting-edge technology, this mesh offers unparalleled strength, versatility, and longevity. In this article, we delve into the exceptional attributes of this black coated wire mesh and its potential applications across various industries.Paragraph 1:Black coated wire mesh, developed by the renowned manufacturer, is an innovative product designed to overcome the limitations associated with traditional wire meshes. Crafted from high-quality materials and coated with a durable black finish, this wire mesh offers not only superior functionality but also an impressive aesthetic appeal. The black color provides a modern and sleek appearance, making it an ideal choice for a range of applications.Paragraph 2:One of the key advantages of this black coated wire mesh lies in its exceptional strength and resilience. Manufactured using advanced techniques, this mesh can withstand heavy impact and high tension, making it suitable for demanding applications such as security fencing, animal enclosures, and industrial usage. The strength of this wire mesh ensures that it can effectively contain and protect without compromising on its structural integrity.Paragraph 3:Furthermore, the innovative composition of this black coated wire mesh exhibits outstanding resistance to corrosion, making it highly durable even in harsh environmental conditions. This unique feature allows the wire mesh to maintain its structural integrity for an extended period, reducing the need for frequent maintenance and replacement. Consequently, this black coated mesh offers long-term cost savings and increased operational efficiency, making it an economical choice for various industries.Paragraph 4:The versatility of this black coated wire mesh is another commendable aspect. Its applications extend beyond traditional uses, finding immense usability in architectural and interior design projects. From decorative wall panels to stylish room dividers, the sleek black finish adds a touch of elegance and modernity to any space. This opens up new possibilities for designers and architects to incorporate this black coated wire mesh in their creative endeavors.Paragraph 5:The implementation of this black coated wire mesh does not compromise on safety. With its tightly woven design and robust construction, it effectively prevents animals or objects from passing through while maintaining optimal visibility. This makes it an ideal choice for zoos, parks, and outdoor recreational areas, ensuring the safety of both animals and visitors.Paragraph 6:As sustainability and eco-friendliness increasingly become a priority, this black coated wire mesh aligns with these principles. Manufactured using environmentally friendly materials and employing responsible manufacturing processes, this wire mesh reduces its carbon footprint without compromising on quality or performance. This aspect makes it an attractive solution for eco-conscious projects and organizations.Conclusion:The introduction of this innovative black coated wire mesh has revolutionized the wire mesh industry. Its exceptional strength, durability, versatility, and aesthetic appeal have opened up new avenues for usage across various sectors. Whether it is for security, decorative, or architectural purposes, this black coated wire mesh offers a modern and reliable solution. With its efficient functionality, this wire mesh is set to transform industries and enhance safety and design options for years to come.

Understanding the Definition and Applications of Wire Mesh

and Fine Wire Mesh.Wire mesh is a versatile material that finds applications across various industries due to its structural strength, durability, and low cost. It consists of intertwined wires that form a grid-like pattern with uniform gaps between each wire. These gaps can range from small to large, depending on the type of wire mesh used.Coarse Wire Mesh, as the name suggests, has relatively larger gaps as compared to other wire mesh variants. It is commonly used for industrial purposes such as filtration, reinforcement, and security fencing. Coarse Wire Mesh is made using thicker wires, which offer higher stability and strength, ensuring that it can withstand heavy loads.Fine Wire Mesh, on the other hand, has smaller gaps and thinner wire diameters, making it more flexible and pliable. This type of wire mesh is mainly used for architectural purposes such as interior design, decorative components, and artistic installations. Fine Wire Mesh is available in various materials such as stainless steel, brass, aluminum, and copper, making it suitable for different design requirements.Wire mesh finds applications in diverse industries such as agriculture, construction, automotive, and food processing. It is commonly used for insect screening, air filtration, safety guards, and insulation. Wire mesh is also used in the production of concrete, where it acts as a reinforcement material, helping to increase its strength.Apart from its industrial and architectural applications, wire mesh is also used in the creation of innovative products such as wire mesh baskets and wire mesh shelves. These products are widely used in retail stores for displaying merchandise and organizing storage spaces.In conclusion, wire mesh is a versatile material that has found widespread usage across various industries due to its strength, durability, and low cost. Its ability to adapt to different applications and design requirements makes it a popular choice for architects, engineers, and designers. Whether it's Coarse Wire Mesh or Fine Wire Mesh, wire mesh continues to play an essential role in our daily lives.

Get Tantalum Aluminide at Competitive Prices and Fast Delivery Times

Introduction:Tantalum Aluminide is a popular material in the manufacturing industry due to its unique chemical and physical properties. It is a corrosion-resistant metal that is commonly used in a wide range of applications, including aerospace, chemical processing, and medical implants. In this blog, we will discuss the properties, applications, and benefits of Tantalum Aluminide in detail. We will also take a brief look at Tantalum Wire Mesh, another popular material used in various industrial applications.Properties of Tantalum Aluminide:Tantalum Aluminide is a silvery grey, ductile, and metallic alloy composed of tantalum and aluminum. The combination of tantalum and aluminum provides excellent mechanical strength, high-temperature stability, and corrosion resistance. Tantalum Aluminide has a low density of 8.4 g/cm³, making it a suitable material for lightweight applications. It has a melting point of 2250 °C and a Young’s modulus of around 330 GPa. Additionally, Tantalum Aluminide has a low coefficient of thermal expansion, which makes it an ideal material for high-temperature environments.Applications of Tantalum Aluminide:Tantalum Aluminide has numerous applications due to its unique properties. It is commonly used in aerospace components such as turbine blades, heat shields, and exhaust nozzles. It is also used in chemical processing as a catalyst support or coating. In the medical industry, Tantalum Aluminide is used in implants and prosthetic devices due to its biocompatibility and corrosion resistance. Moreover, Tantalum Aluminide is used as a protective coating in nuclear power plants and other high-temperature environments.Benefits of Tantalum Aluminide:Tantalum Aluminide has numerous benefits that make it popular in the manufacturing industry. Some of the benefits of using Tantalum Aluminide include:1. Corrosion Resistance: Tantalum Aluminide is highly resistant to corrosion and can withstand harsh chemical environments. This property makes it ideal for use in chemical processing and medical implants.2. High-Temperature Stability: Tantalum Aluminide can withstand high temperatures without losing its strength or ductility. This property makes it an excellent material for use in aerospace and nuclear power plants.3. Lightweight: Tantalum Aluminide has a low density, making it lightweight and a suitable material for applications where weight is a concern.4. Biocompatibility: Tantalum Aluminide is biocompatible and can be used in medical implants and prosthetic devices without causing any adverse reactions.Tantalum Wire Mesh:Tantalum wire mesh is another popular material used in the manufacturing industry that is made up of pure tantalum wire. Tantalum wire mesh has many unique properties that make it ideal for various applications. Some of the properties of Tantalum wire mesh include:1. Excellent Corrosion Resistance: Tantalum wire mesh is highly resistant to corrosion and can withstand harsh chemical environments.2. High-Temperature Stability: Tantalum wire mesh can withstand high temperatures without losing its strength or ductility.3. Lightweight: Tantalum wire mesh has a very low density, making it ideal for lightweight applications.4. Good Electrical Conductivity: Tantalum wire mesh has a high electrical conductivity, making it suitable for electrical and electronic applications.Conclusion:In conclusion, Tantalum Aluminide and Tantalum wire mesh are two popular materials used in the manufacturing industry. Both materials possess unique properties that make them ideal for various applications. Tantalum Aluminide is commonly used in aerospace, chemical processing, and medical implants, while Tantalum wire mesh is used in electrical and electronic applications. The benefits of using Tantalum Aluminide and Tantalum wire mesh include high-temperature stability, corrosion resistance, and lightweight. SAM is a leading supplier of Tantalum Aluminide, including Tantalum wire mesh, with competitive pricing and excellent lead times.

Aluminum Alloy Expandable Electric Folding Gate with Mesh Screen

Screen Electric Retractable Gate, Expandable Electric Retractable Gate, Folding Electric Retractable Gate, Quality Electric Retractable Gate, Aluminium Alloy Electric Retractable Gate.Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen - A Perfect Solution for Safety and SecurityAre you tired of traditional gates that require a lot of effort to open and close? Do you want to upgrade your home or office security with a modern gate that is both functional and stylish? Look no further than the Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen.This gate is the ultimate solution for convenience, safety, and security. It is made of high-quality aluminium alloy, which makes it durable and strong. It is also expandable, which means it can fit any size of the entrance, making it perfect for homes, businesses, and institutions.The gate is designed with a foldable feature that allows for easy opening and closing. You don't have to worry about getting out of your car to manually open and close the gate. With just a click of a button, the gate will fold and unfold automatically, giving you easy access.Another outstanding feature of this gate is the mesh screen. The mesh screen adds an extra layer of security to your entrance, ensuring that no unwanted visitors can enter your property. The mesh screen also allows for proper air circulation, making your space well ventilated.At (remove brand name), we are committed to providing high-quality electric retractable gates that meet the needs of our customers. Our Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen has undergone rigorous testing to ensure that it meets the highest quality standards.Our gate is easy to install and maintain. With proper care and maintenance, this gate will last you for years to come, providing you with maximum security and convenience.In conclusion, if you are looking for a modern, stylish, and functional gate that provides maximum security and convenience, the Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is the perfect solution. It is made of high-quality materials, easy to install and maintain, and has a mesh screen for added security. Contact us today and upgrade your security with this amazing gate.

Discover the Wide Range of Expanded Wire Mesh Sizes Available

Expanded Wire Mesh Sizes: A Leader in Quality Wire Mesh ProductsWith the increasing demand for high-quality wire mesh products in various industries, it is important for companies to provide a wide range of options to meet the diverse needs of their customers. Expanded Wire Mesh Sizes has been at the forefront of providing top-of-the-line wire mesh products for a wide range of applications. Established in [year], Expanded Wire Mesh Sizes has quickly become a leader in the industry, known for its commitment to quality, innovation, and customer satisfaction. The company offers a comprehensive range of wire mesh products, including expanded metal mesh, welded wire mesh, woven wire mesh, and perforated metal mesh, among others.Expanded Wire Mesh Sizes prides itself on using the latest technology and state-of-the-art manufacturing processes to ensure that its wire mesh products meet the highest standards of quality and performance. The company's team of skilled engineers and technicians are dedicated to developing and producing wire mesh products that are not only durable and reliable, but also tailored to specific industry requirements.One of the key strengths of Expanded Wire Mesh Sizes is its extensive range of wire mesh sizes. The company understands that different applications require different specifications, and thus offers a wide variety of wire mesh sizes to accommodate the needs of its customers. Whether it's for architectural, industrial, or agricultural purposes, customers can rely on Expanded Wire Mesh Sizes to provide the right size and type of wire mesh for their projects.In addition to its wide range of sizes, Expanded Wire Mesh Sizes also offers customization options to meet unique customer specifications. The company's team of experts is committed to working closely with customers to develop customized wire mesh solutions that perfectly fit their requirements. This level of flexibility and attention to detail has earned Expanded Wire Mesh Sizes a reputation for being a trusted partner in the industry.Expanded Wire Mesh Sizes is also known for its commitment to sustainability and environmental responsibility. The company adheres to strict environmental standards in its manufacturing processes, ensuring that its wire mesh products are produced in an eco-friendly manner. This dedication to sustainability has not only earned Expanded Wire Mesh Sizes the trust of its customers, but also solidified its position as a responsible industry leader.The company's dedication to quality, innovation, and customer satisfaction has not gone unnoticed. Expanded Wire Mesh Sizes has received numerous accolades and certifications for its wire mesh products, further establishing its reputation as a reliable and reputable supplier in the industry. With a strong track record of delivering superior products and exceptional customer service, Expanded Wire Mesh Sizes continues to set the bar high for wire mesh manufacturers.In conclusion, Expanded Wire Mesh Sizes has cemented its position as a leader in the industry by offering a comprehensive range of high-quality wire mesh products, combined with a commitment to innovation, sustainability, and customer satisfaction. With its extensive range of wire mesh sizes and customizability options, the company remains at the forefront of meeting the diverse needs of its customers. As the demand for quality wire mesh products continues to grow, Expanded Wire Mesh Sizes stands ready to meet the challenges and exceed the expectations of its customers.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.

Expert Guide to Cutting Expanded Metal: Tips and Techniques

Cutting Expanded Metal is a process that involves removing metal material from a larger piece of material to create a pattern of openings. This method is often used in manufacturing, construction, and industrial applications to create lightweight but strong materials for various purposes. The process of Cutting Expanded Metal requires precision and expertise to ensure that the desired pattern is achieved without compromising the structural integrity of the material.One company that specializes in the Cutting Expanded Metal process is {}. Founded in 1990, {} has become a leading provider of metal processing and fabrication services. With state-of-the-art facilities and a team of highly skilled professionals, {} has gained a reputation for delivering high-quality products and exceptional customer service.The Cutting Expanded Metal process at {} involves using advanced machinery to accurately cut and shape metal materials according to the specific requirements of each project. Whether it's creating custom patterns, intricate designs, or standard shapes, {} has the capabilities to meet the diverse needs of its clients. The company's commitment to precision and excellence has made it a trusted partner for businesses in various industries, including construction, architecture, automotive, and aerospace.One of the key advantages of Cutting Expanded Metal is its versatility. By being able to remove material in a controlled manner, {} can produce expanded metal sheets with a wide range of open area percentages, strand widths, and pattern designs. This flexibility allows the company to cater to the unique demands of different applications, whether it's for filtration, ventilation, security, or decorative purposes.Moreover, the Cutting Expanded Metal process allows for the creation of lightweight materials that maintain high strength and durability. This makes expanded metal an ideal choice for applications where weight reduction is crucial without sacrificing structural integrity. In addition, the open design of expanded metal sheets allows for excellent airflow and visibility while providing security and protection.The skilled technicians at {} are dedicated to meeting the specific requirements of each project, whether it's a small-scale custom job or a large-scale industrial order. Their expertise in the Cutting Expanded Metal process ensures that the final products meet the highest standards of quality and precision. By utilizing advanced technology and industry best practices, {} is able to deliver efficient and cost-effective solutions that exceed client expectations.Furthermore, {} is committed to sustainability and environmental responsibility in its operations. The company strives to minimize waste and optimize material usage in the Cutting Expanded Metal process, contributing to a more environmentally friendly approach to metal fabrication. By prioritizing eco-friendly practices, {} aims to reduce its carbon footprint and promote a greener manufacturing industry.As {} continues to expand its capabilities and reach new milestones, the company remains dedicated to delivering innovative solutions and superior products to its clients. With a focus on quality, precision, and customer satisfaction, {} is a reliable partner for businesses seeking Cutting Expanded Metal and other metal fabrication services. Whether it's for architectural design, industrial equipment, or specialized applications, {} is poised to meet the evolving needs of the market with its expertise and commitment to excellence.

Understanding the Benefits of Backwashing Filters for Cleaner Water

Title: Advanced Backwashing Filters Revolutionize Water Filtration TechnologiesIntroduction:Backwashing filters have revolutionized the field of water filtration, providing an efficient and effective solution for removing impurities and ensuring clean water supply. One company at the forefront of this innovative technology is **Company X**, a renowned leader in producing high-quality water filtration systems. With their cutting-edge backwashing filters, **Company X** has transformed the way we approach water treatment, ensuring the safety and purity of our water resources.Body:1. Background and Importance of Water FiltrationWater is a valuable resource, and access to clean and safe water is essential for human health and wellbeing. However, water sources are often contaminated with various impurities such as sediment, bacteria, and chemicals. Failure to remove these contaminants can have severe health consequences, making water filtration a critical process. Backwashing filters offer an efficient and reliable solution to this challenge, enabling the removal of impurities and ensuring our water is clean and safe for consumption.2. Understanding Backwashing FiltersBackwashing filters employ a unique filtration process that involves reversing the flow of water through the filtration media. This technique enhances the cleaning and filtering capabilities of the system, improving the overall effectiveness of water treatment. By backwashing, the filters remove accumulated impurities and prevent the formation of biofilms, which can potentially host harmful bacteria and other pathogens.3. Advancements in Backwashing Filter Technology**Company X**, a renowned pioneer in the water filtration industry, has introduced several groundbreaking advancements in backwashing filter technology. Their filters incorporate innovative materials and designs that offer superior filtration efficiency compared to traditional filtration systems. The advanced filtration media can effectively remove particles as small as a fraction of a micron, ensuring the utmost purity of the filtered water.4. Features and Benefits of **Company X**'s Backwashing FiltersOne of the key features that sets **Company X**'s backwashing filters apart is their self-cleaning capability. The filters automatically initiate the backwashing process at preset intervals, guaranteeing continuous and efficient filtration without the need for manual intervention. This not only saves time and effort but also improves the longevity and performance of the filtration system.Moreover, **Company X**'s filters boast a compact design, allowing for easy installation even in limited spaces. The filters are also highly customizable, addressing various filtration requirements, including residential, commercial, and industrial applications. With their modular design, **Company X**'s filters are easily scalable, ensuring flexibility in accommodating different water volumes and treatment needs.5. Applications of Backwashing FiltersThe applications of backwashing filters span across various industries and sectors. In households, these filters provide clean drinking water, safeguarding the health of families. In agricultural and irrigation systems, backwashing filters ensure the removal of contaminants, preventing clogging and damage to irrigation equipment. Industrial facilities can benefit from backwashing filters by eliminating impurities and improving the efficiency of processes. Additionally, backwashing filters play a crucial role in water treatment plants, ensuring the delivery of safe and potable water to communities.6. Environmental Impact and Sustainability**Company X** is dedicated to sustainability, and their backwashing filters align with this commitment. The filters reduce water wastage by utilizing efficient backwashing techniques and conserving water resources. By preventing the need for frequent filter replacements and maintenance, **Company X**'s filters also contribute to reducing waste generation while maintaining optimal performance.Conclusion:With their state-of-the-art backwashing filters, **Company X** continues to drive innovation in the field of water filtration. These advanced systems offer effective and efficient removal of contaminants, ensuring clean and safe water for various applications. Through their commitment to sustainability and technological excellence, **Company X** is shaping the future of water treatment and securing our access to a vital resource - clean water.

Durable Stainless Steel Metal Mesh for Various Applications

Stainless Steel Metal Mesh, a New Breakthrough in Industrial MaterialIn recent years, industrial material technology has experienced significant advancements and innovations. One of the latest breakthroughs in this field is the development of stainless steel metal mesh, a versatile and durable material that has a wide range of applications in various industries. The development of this innovative material has been made possible through the dedicated efforts of skilled engineers and experts at [Company Name], a leading manufacturer and supplier of industrial materials.[Company Name] has been at the forefront of industrial material innovation, constantly striving to develop and incorporate state-of-the-art technologies in its products. The development of stainless steel metal mesh is a testament to the company's commitment to pushing the boundaries of what is possible in the realm of industrial materials. This new material promises to revolutionize the way various industries approach their manufacturing processes and product development. Through its exceptional strength, durability, and versatility, stainless steel metal mesh has quickly become a highly sought-after material in the industrial sector.Stainless steel metal mesh is a woven material made from high-quality stainless steel wires. The construction of the mesh involves intricate weaving patterns that ensure its strength and stability. This unique construction allows the metal mesh to withstand high temperatures, corrosion, and impact, making it suitable for a wide range of industrial applications. The material is available in various weave patterns and wire diameters, allowing for customization to meet specific project requirements.One of the key features of stainless steel metal mesh is its exceptional durability. Unlike traditional materials, such as plastics or non-metallic meshes, stainless steel metal mesh is highly resistant to wear and tear, ensuring a longer service life and reducing the need for frequent replacements. This makes it an ideal material for applications that require reliability and longevity, such as filtration, screening, and sieving.Furthermore, the versatility of stainless steel metal mesh makes it suitable for diverse industrial applications. It can be used in the construction of architectural facades, interior design elements, and industrial partitions. Additionally, the material is widely employed in the food and beverage, pharmaceutical, and chemical industries for filtration, sieving, and separation processes. Its resistance to corrosion and high temperatures makes it an ideal choice for applications that demand hygienic and sterile conditions.The development of stainless steel metal mesh has opened up new possibilities for engineers, designers, and manufacturers, allowing them to explore innovative solutions in their respective fields. The material’s unique properties enable the creation of lightweight yet robust structures, offering new design possibilities for architects and builders. In the manufacturing sector, stainless steel metal mesh has become an essential material for process optimization, enhancing productivity and efficiency.[Company Name] takes pride in its commitment to quality and innovation. The company's advanced manufacturing facilities and stringent quality control processes ensure that its stainless steel metal mesh meets the highest industry standards. With a focus on sustainability and environmental responsibility, [Company Name] is dedicated to developing materials that are not only durable and reliable but also eco-friendly.In conclusion, the development of stainless steel metal mesh represents a significant milestone in the field of industrial materials. This versatile and durable material has the potential to revolutionize various industries and bring about new opportunities for innovation and growth. With [Company Name] at the forefront of this technological advancement, the industrial sector can look forward to a future filled with resilient, sustainable, and high-performance materials.

Update: Latest Wire Netting Mesh News and Insights

Wire Netting Mesh, a leading manufacturer of high-quality wire mesh products, is proud to announce the launch of their latest innovative wire netting mesh products. With over [number] years of experience in the industry, Wire Netting Mesh has built a reputation for delivering top-notch products that meet the highest standards of quality and durability.The new wire netting mesh products are designed to cater to a wide range of applications, including industrial, agricultural, commercial, and residential uses. They are available in various sizes, materials, and specifications to meet the diverse needs of customers. Whether it's for fencing, construction, filtration, or reinforcement, Wire Netting Mesh has the perfect solution for every requirement.One of the key highlights of the new wire netting mesh products is their superior strength and durability. Constructed from high-quality materials, they are built to withstand harsh environmental conditions and heavy-duty usage. This makes them ideal for demanding applications where reliability is crucial.In addition to strength and durability, the wire netting mesh products also offer excellent flexibility and versatility. They can be easily customized to suit specific requirements, making them suitable for a wide range of projects. Whether it's a small DIY project or a large-scale industrial application, Wire Netting Mesh has the capability to deliver tailor-made solutions to meet individual needs.The launch of these new wire netting mesh products further consolidates Wire Netting Mesh's position as a market leader in the wire mesh industry. With a strong focus on innovation and customer satisfaction, the company continues to push the boundaries of product development, offering cutting-edge solutions that exceed industry standards.In addition to their commitment to quality and innovation, Wire Netting Mesh also places great emphasis on sustainability and environmental responsibility. The company adheres to strict environmental standards in all stages of the manufacturing process, ensuring that their products are eco-friendly and sustainable. This environmentally conscious approach has earned Wire Netting Mesh the trust and respect of customers who prioritize sustainability in their operations.To complement their high-quality products, Wire Netting Mesh also offers exceptional customer service and support. Their team of experienced professionals is dedicated to providing expert advice, technical assistance, and prompt delivery to ensure a seamless experience for customers. This commitment to customer satisfaction has been a key driving force behind Wire Netting Mesh's success and continued growth in the industry.As Wire Netting Mesh continues to expand its product range and reach new milestones, the company remains focused on upholding its core values of quality, innovation, and customer satisfaction. With a strong foundation built on expertise, reliability, and integrity, Wire Netting Mesh is well-positioned to meet the evolving needs of the wire mesh market and emerge as the preferred choice for customers around the world.