High-Quality Woven Wire Mesh for Various Applications

By:Admin

Nickel woven wire mesh is a type of woven wire mesh that is made from high-quality nickel alloy materials. It is commonly used in applications where high strength, corrosion resistance, and thermal stability are important. This versatile material can be used in various industries, including aerospace, chemical processing, and electronics.

The nickel woven wire mesh is made from a combination of nickel, copper, and other elements, which gives it its unique properties. The mesh is woven using advanced manufacturing techniques, which ensures that it has a uniform and consistent structure. This makes it ideal for applications that require precise filtration and separation.

With its high tensile strength and excellent thermal stability, nickel woven wire mesh is ideal for use in high-temperature applications. It can withstand extreme temperatures without losing its structural integrity, making it suitable for use in industrial furnaces, ovens, and other high-heat environments.

In addition to its thermal stability, nickel woven wire mesh also offers excellent corrosion resistance. It can withstand exposure to harsh chemicals and environments without corroding or degrading, making it a suitable material for use in chemical processing and refining applications.

The nickel woven wire mesh is available in a range of different mesh sizes and thicknesses, allowing for customization to suit specific application requirements. It can be used for filtration, sieving, and separation of various materials, making it a versatile solution for a wide range of industrial processes.

Company Introduction

{Company Name} is a leading manufacturer and supplier of high-quality nickel woven wire mesh. With years of experience in the industry, we have developed a reputation for producing reliable and high-performance wire mesh products.

Our manufacturing facility is equipped with state-of-the-art machinery and equipment, allowing us to produce nickel woven wire mesh that meets the highest standards of quality and precision. We work closely with our customers to understand their specific requirements and provide customized solutions to meet their needs.

At {Company Name}, we are committed to delivering excellence in both product quality and customer service. Our team of skilled technicians and engineers ensures that every roll of nickel woven wire mesh is manufactured to the highest standards, and our quality control processes guarantee that each product meets our strict quality criteria.

We understand the importance of reliable and durable materials in industrial applications, which is why we have invested in developing advanced manufacturing techniques to produce nickel woven wire mesh that is not only high-performing but also cost-effective.

As a trusted supplier to a wide range of industries, we are dedicated to providing our customers with the highest level of satisfaction. We offer comprehensive technical support and guidance to assist our customers in selecting the right nickel woven wire mesh for their specific applications.

Conclusion

Nickel woven wire mesh is an essential material in various industrial applications, offering superior strength, corrosion resistance, and thermal stability. As a leading manufacturer and supplier of high-quality nickel woven wire mesh, {Company Name} is committed to delivering reliable and cost-effective solutions to meet the needs of our customers.

With our advanced manufacturing capabilities and dedication to quality, we are proud to provide our customers with a wide range of options for their specific nickel woven wire mesh requirements. Whether it is for filtration, separation, or sieving, our nickel woven wire mesh is designed to perform in the most demanding industrial environments.

At {Company Name}, we understand the importance of providing our customers with the highest level of service and support. Our team is committed to ensuring that every customer receives the right nickel woven wire mesh solution for their unique needs, backed by our expertise and technical guidance.

For more information about our nickel woven wire mesh products and how they can benefit your industrial applications, please contact us at {contact information}. We look forward to working with you to meet your wire mesh needs.

Company News & Blog

Top Sintered Mesh Filter Disc: Enhance Filtration Efficiency with Advanced Technology

Title: Leading Manufacturer Unveils Cutting-Edge Sintered Mesh Filter Disc, Revolutionizing Filtration SystemsIntroduction:In the rapidly evolving world of filtration technology, renowned industry leader, Manufacturing Co., is making waves with its latest breakthrough - the groundbreaking Sintered Mesh Filter Disc. With an unwavering commitment to innovation and excellence, the company has once again raised the bar by revolutionizing filtration systems across various industries.Body:1. Unveiling the Sintered Mesh Filter Disc:Manufacturing Co. proudly presents the highly-anticipated Sintered Mesh Filter Disc, a cutting-edge product set to transform the way particles are filtered across numerous applications. This advanced filter disc combines superior materials, precision manufacturing, and innovative design to deliver unmatched performance, improved efficiency, and prolonged service life.2. Unparalleled Filtration Efficiency:The Sintered Mesh Filter Disc boasts an exceptionally high level of filtration efficiency, enabling it to remove even the tiniest particles with remarkable accuracy. The tightly-knit mesh structure ensures an optimal flow rate, allowing for efficient filtration while maintaining minimal pressure drop. This remarkable feature makes it an ideal choice for industries such as pharmaceuticals, petrochemicals, food and beverage, and wastewater treatment.3. Enhanced Durability and Longevity:Manufacturing Co.'s Sintered Mesh Filter Disc is built to withstand harsh conditions and extreme temperatures, making it a highly durable and reliable filtration solution. The carefully selected sintered mesh materials enable the disc to resist corrosion and oxidation, ensuring a prolonged service life compared to traditional filters. This longevity translates into significant cost savings for industries that heavily rely on filtration systems.4. Versatile Applications:The versatility of the Sintered Mesh Filter Disc is a standout feature, as it can be seamlessly integrated into various applications across diverse industries. Its exceptional filtration efficiency, coupled with the ability to withstand high pressure and temperature, makes it an excellent choice for applications such as gas and liquid separation, catalyst recovery, polymer filtration, and more. The adaptability and wide range of applications make this filter disc a truly indispensable component in numerous industrial processes.5. Quality Manufacturing Process:Manufacturing Co. employs state-of-the-art manufacturing techniques to ensure the highest level of quality and precision during the production of the Sintered Mesh Filter Disc. Relying on advanced sintering technology, the company achieves a perfectly uniform and robust mesh structure, resulting in consistent performance and exceptional product reliability. Additionally, a stringent quality control process is implemented at every stage to guarantee that each filter disc meets or exceeds industry standards.6. Commitment to Sustainability:As a responsible manufacturer, Manufacturing Co. prioritizes sustainability in every aspect of its operations. The Sintered Mesh Filter Disc reflects this commitment, as it is designed for ease of maintenance and cleaning, effectively reducing waste and minimizing the need for frequent replacements. With its exceptional durability and longevity, the filter disc plays a pivotal role in promoting eco-friendly practices within the industry.Conclusion:Manufacturing Co's introduction of the state-of-the-art Sintered Mesh Filter Disc marks a significant milestone in the evolution of filtration technology. Combining exceptional filtration efficiency, enhanced durability, and unmatched versatility, this groundbreaking product is set to revolutionize filtration systems across a wide range of industries. With a steadfast commitment to innovation and sustainability, Manufacturing Co. continues to be at the forefront of delivering cutting-edge solutions that address the evolving needs of global industries.

New Woven Wire Mesh Filter Offers Efficient Filtration Solution

Woven Wire Mesh Filter Revolutionizing Filtration ProcessesIn modern industries, filtration plays an essential role in maintaining efficiency, quality, and safety. One company, renowned for its innovative solutions, has introduced a groundbreaking product - the Woven Wire Mesh. This filter, without compromise in performance and durability, has garnered significant attention from various sectors.The Woven Wire Mesh filter is engineered to meet the diverse filtration needs across industries such as oil and gas, pharmaceuticals, water treatment, and many others. This revolutionary filter provides efficient and reliable separation of solids from liquids, offering unmatched durability and longevity compared to traditional filtration methods.One of the key features that make this filter stand out is its design. The Woven Wire Mesh filter is constructed using a diverse range of materials, such as stainless steel, copper, bronze, and nickel alloys. This allows for customization to suit specific filtration requirements, making it an ideal choice for a wide array of applications. Additionally, its unique weave pattern enhances strength, ensuring long-lasting performance even under extreme conditions.Notably, the Woven Wire Mesh filter successfully eliminates the limitations imposed by conventional filters. Its precise design and manufacturing process enable it to trap and retain particles of varying sizes, down to sub-micron levels. Thanks to its superior filtration capabilities, it ensures excellent product quality, prevents equipment damage, and increases overall operational efficiency.The Woven Wire Mesh filter's applications are seemingly endless. In the oil and gas sector, it effectively separates impurities from crude oil, lubricants, and hydraulic fluids, reducing equipment wear and energy consumption. In the pharmaceutical industry, it is utilized for sterilizing liquids, thus ensuring the safety and purity of medications. Moreover, this versatile filter is employed in wastewater treatment plants to remove solids, improving water quality and environmental sustainability.To accommodate the demanding needs of various industries, the company behind the Woven Wire Mesh filter offers a range of customization options. Customers can select the filter's material, aperture size, and wire diameter to perfectly match specific filtration requirements. This flexibility enables seamless integration into existing systems and maximizes filtration efficiency.Furthermore, the company's commitment to quality is exemplified by its rigorous testing procedures. Every Woven Wire Mesh filter undergoes comprehensive performance tests to meet international standards. Additionally, the company adheres to strict quality control protocols throughout the manufacturing process, ensuring consistent and reliable products.Apart from its superior filtration capabilities and stringent quality control, the Woven Wire Mesh filter also offers distinct economic advantages. Due to its exceptional durability and longevity, it significantly reduces maintenance and replacement costs compared to conventional disposable filters. Additionally, its high filtration efficiency minimizes production downtime and maximizes productivity, yielding substantial cost savings over time.In conclusion, the Woven Wire Mesh filter is a game-changer in the field of filtration. Its innovative design, customized solutions, and exceptional performance have ushered in a new era of efficiency and reliability. With its vast array of applications, this revolutionary filter is set to transform filtration processes across industries. As the demand for superior filtration solutions continues to rise, the Woven Wire Mesh filter stands at the forefront, providing unmatched quality and innovation.

Durable Stainless Steel Metal Mesh for Various Applications

Stainless Steel Metal Mesh, a New Breakthrough in Industrial MaterialIn recent years, industrial material technology has experienced significant advancements and innovations. One of the latest breakthroughs in this field is the development of stainless steel metal mesh, a versatile and durable material that has a wide range of applications in various industries. The development of this innovative material has been made possible through the dedicated efforts of skilled engineers and experts at [Company Name], a leading manufacturer and supplier of industrial materials.[Company Name] has been at the forefront of industrial material innovation, constantly striving to develop and incorporate state-of-the-art technologies in its products. The development of stainless steel metal mesh is a testament to the company's commitment to pushing the boundaries of what is possible in the realm of industrial materials. This new material promises to revolutionize the way various industries approach their manufacturing processes and product development. Through its exceptional strength, durability, and versatility, stainless steel metal mesh has quickly become a highly sought-after material in the industrial sector.Stainless steel metal mesh is a woven material made from high-quality stainless steel wires. The construction of the mesh involves intricate weaving patterns that ensure its strength and stability. This unique construction allows the metal mesh to withstand high temperatures, corrosion, and impact, making it suitable for a wide range of industrial applications. The material is available in various weave patterns and wire diameters, allowing for customization to meet specific project requirements.One of the key features of stainless steel metal mesh is its exceptional durability. Unlike traditional materials, such as plastics or non-metallic meshes, stainless steel metal mesh is highly resistant to wear and tear, ensuring a longer service life and reducing the need for frequent replacements. This makes it an ideal material for applications that require reliability and longevity, such as filtration, screening, and sieving.Furthermore, the versatility of stainless steel metal mesh makes it suitable for diverse industrial applications. It can be used in the construction of architectural facades, interior design elements, and industrial partitions. Additionally, the material is widely employed in the food and beverage, pharmaceutical, and chemical industries for filtration, sieving, and separation processes. Its resistance to corrosion and high temperatures makes it an ideal choice for applications that demand hygienic and sterile conditions.The development of stainless steel metal mesh has opened up new possibilities for engineers, designers, and manufacturers, allowing them to explore innovative solutions in their respective fields. The material’s unique properties enable the creation of lightweight yet robust structures, offering new design possibilities for architects and builders. In the manufacturing sector, stainless steel metal mesh has become an essential material for process optimization, enhancing productivity and efficiency.[Company Name] takes pride in its commitment to quality and innovation. The company's advanced manufacturing facilities and stringent quality control processes ensure that its stainless steel metal mesh meets the highest industry standards. With a focus on sustainability and environmental responsibility, [Company Name] is dedicated to developing materials that are not only durable and reliable but also eco-friendly.In conclusion, the development of stainless steel metal mesh represents a significant milestone in the field of industrial materials. This versatile and durable material has the potential to revolutionize various industries and bring about new opportunities for innovation and growth. With [Company Name] at the forefront of this technological advancement, the industrial sector can look forward to a future filled with resilient, sustainable, and high-performance materials.

Premium Quality Cartridge Filter Element for Sale

Cartridge Filter Element: Ensuring Clean and Pure Industrial Liquid FiltrationCartridge filtration solutions are popular among industries as they offer several advantages over other filtration options. It is an effective method to remove contaminants from industrial liquids, gases and other fluids. It is a vital element in processes such as wastewater treatment, food and beverage processing, chemical processing, and pharmaceutical manufacturing. Cartridge filter elements have high demand in the market due to their efficiency and durability.The cartridge filter element manufacturer has been providing cartridge filter elements for more than 20 years. They have extensive experience in this field and cater to various industries such as food and beverage, automotive, chemical, and healthcare. They manufacture different types of filter elements, including industrial cartridge filters, spun-bonded filter cartridges and other specialty cartridges that suit a variety of applications.The company has a team of experienced and skilled professionals. They work in tandem to ensure the quality and reliability of the final product. The team comprises engineers, technicians, and quality controllers, and they use the latest techniques and equipment to manufacture high-quality filtration products.The cartridge filter element manufacturer uses a variety of filter media that include cellulose, polyester, polypropylene, and others to make their filter elements. The filter media have different properties and are suitable for different processes.The filter media used by the manufacturer is of the highest quality, ensuring maximum filtration efficiency. The filters are designed to remove a wide variety of impurities, including particles of different sizes, air, oil, and water droplets.The company offers a range of filter cartridges to suit different industrial applications, including air, gas, and liquid filtration. The filtration products are available in a range of micron ratings, and the company also provides custom micron ratings for specific applications.Cartridge filter elements are easy to install and maintain. They are also cost-effective compared to other filtration systems. The replacement of filter cartridges is simple and can be done quickly, ensuring minimal downtime in production processes.In addition, the company provides technical support to customers who require assistance in selecting the right filter element for their application. They also provide training to the maintenance and operation teams of the customers to ensure the long-term effectiveness of the filtration systems.The cartridge filter element manufacturer complies with the highest industry standards, including ISO 9001, ensuring the products are of the highest quality. They also regularly upgrade their manufacturing processes to keep up with the latest filtration technology.The company strongly believes in customer satisfaction and ensures that their products meet the needs and requirements of customers. They offer flexible payment options, on-time delivery, and excellent after-sales service.In conclusion, cartridge filter elements are essential for industries that require clean and pure liquids in their processes. The cartridge filter element manufacturer is a reliable and experienced supplier of filtration products, catering to various industries. Their products are of high quality and have a long lifespan, ensuring maximum filtration efficiency. They offer cost-effective solutions and excellent technical support to their customers. The company's commitment to customer satisfaction makes them a preferred supplier of filtration products in the market. Contact them today to know more about their products and services.

Durable and Protective Zirconia Ceramic Coating for Enhanced Performance

Introducing Zirconia Ceramic Coating: The Revolutionary Solution for Durable and High-Performance SurfacesIn the world of advanced ceramics, Zirconia Ceramic Coating is making significant waves with its innovative and game-changing properties. This cutting-edge coating is designed to provide unmatched durability, high-performance, and protection for a wide range of surfaces, making it the go-to solution for industries such as automotive, aerospace, medical, and more.With a strong focus on research and development, the company behind Zirconia Ceramic Coating has been at the forefront of ceramic technology for over a decade. Their expertise and commitment to excellence have led to the creation of a revolutionary coating that outperforms traditional alternatives in every aspect.One of the most remarkable features of Zirconia Ceramic Coating is its exceptional hardness and resistance to wear. The coating is formulated using zirconia, a high-performance ceramic material known for its remarkable strength and toughness. This gives the coating an unparalleled ability to withstand abrasion, impact, and harsh environmental conditions, making it ideal for applications that require long-term durability and reliability.Furthermore, Zirconia Ceramic Coating offers outstanding thermal and chemical resistance, providing an effective barrier against extreme temperatures, corrosive substances, and harsh chemicals. This makes it an excellent choice for protecting surfaces that are exposed to demanding operating conditions, ensuring long-lasting performance and reduced maintenance requirements.In addition to its exceptional protective properties, Zirconia Ceramic Coating also offers superior aesthetics, with a smooth and lustrous finish that enhances the appearance of the coated surface. This makes it an attractive option for various applications where both performance and aesthetics are essential, such as luxury automotive finishes, high-end consumer electronics, and architectural surfaces.The versatility of Zirconia Ceramic Coating extends to its application methods, with options for both liquid spray and powder coating. This allows for seamless integration into existing production processes, making it a convenient and cost-effective solution for manufacturers and industries looking to upgrade their surface protection capabilities.The company's commitment to quality and innovation is evident in its state-of-the-art manufacturing facilities and rigorous quality control measures. Every batch of Zirconia Ceramic Coating undergoes thorough testing and inspection to ensure that it meets the highest standards of performance and reliability, providing customers with the peace of mind that they are investing in a superior and dependable product.Beyond its technical prowess, the company behind Zirconia Ceramic Coating is dedicated to providing exceptional customer service and support. With a team of experienced professionals and technical experts, they are able to offer comprehensive assistance and guidance to customers, from product selection and customization to application and after-sales support.With its unmatched combination of durability, performance, and aesthetics, Zirconia Ceramic Coating is poised to redefine the standards for surface protection across various industries. Whether it's for enhancing the performance of automotive components, increasing the longevity of medical implants, or protecting critical aerospace structures, this revolutionary coating offers a compelling solution for businesses looking to elevate the durability and reliability of their products.In conclusion, Zirconia Ceramic Coating represents a significant advancement in the field of advanced ceramics, offering a compelling solution for businesses and industries seeking superior surface protection. With its exceptional durability, high-performance properties, and commitment to quality, it is set to become the go-to choice for manufacturers and businesses looking to elevate the longevity and performance of their products.

How to Choose the Best Mesh Stainer for Your Needs

Title: Innovative Mesh Strainer Revolutionizes Culinary ExperienceIntroduction:In today's rapidly evolving world, every industry is witnessing groundbreaking innovations, and the culinary industry is no exception. Introducing a revolutionary mesh strainer (brand name removed), a remarkable product that is set to redefine how we strain and sieve various cooking elements. This cutting-edge kitchen tool combines innovative design and impeccable functionality to deliver an unparalleled culinary experience. Developed by the esteemed company {}, this mesh strainer is poised to become an indispensable accessory in kitchens worldwide.1. Background:The concept behind this state-of-the-art mesh strainer stems from the need for a more efficient and user-friendly tool in the culinary realm. Traditional mesh strainers often fall short in terms of durability, precision, and ease of use. With years of research and development, the visionary minds at {} were able to identify these pain points and create the ultimate solution to address them.2. Superior Design and Construction:This mesh strainer redefines the standard with its unparalleled design and construction. Made from a high-quality, food-grade stainless steel material, it guarantees durability and longevity, ensuring it becomes a staple in every kitchen for years to come. The ergonomic handle provides a comfortable grip, minimizing strain during prolonged use.Moreover, the carefully engineered mesh design offers exceptional sieving precision. With strategically placed fine mesh wires, it effectively strains out even the smallest particles, ensuring a flawless end product. Whether it's draining pasta, rinsing vegetables, or sifting dry ingredients, this mesh strainer will effortlessly deliver immaculate results every time.3. Versatility at Its Finest:One of the key features of this mesh strainer is its versatility. With a range of diameters available, it caters to different cooking needs, from smaller portions to larger quantities. Its adaptability makes it suitable for straining liquids, separating pulp from juice, and even sifting powdered sugar over baked goods. The options are endless, making it an indispensable tool for both professional chefs and home cooks.4. Easy to Clean and Store:As cooking should be a delight from start to finish, this mesh strainer eases the burden of cleaning up afterwards. The seamless edges and non-stick surface simplify the cleaning process, ensuring no residue is left behind. Additionally, its compact design allows for easy storage, taking up minimal space in already overcrowded kitchen cabinets.5. Customer Satisfaction and Safety:{} places customer satisfaction and safety at the forefront of their priorities. This is reflected in this mesh strainer's commitment to meeting the highest industry standards. It is FDA-approved, BPA-free, and dishwasher-safe, ensuring peace of mind for consumers while preparing their meals. This dedication to customer safety further solidifies {}'s reputation as a leading innovator in the culinary industry.6. Availability and Future Prospects:The cutting-edge mesh strainer is now available for purchase online through multiple platforms, ensuring worldwide accessibility. Alongside its launch, {} has also promised continuous upgrades and enhancements based on customer feedback and technological advancements. This commitment to improvement further strengthens its position as a pioneer in kitchen tools and appliances.Conclusion:In an era where efficiency and convenience are paramount, the innovative mesh strainer (brand name removed) is poised to change the way we approach cooking and straining. With its impeccable design, outstanding functionality, versatility, and commitment to customer satisfaction, it is set to become a staple in kitchens worldwide. This groundbreaking product is a testament to {}'s dedication to revolutionizing the culinary experience and cementing its position as a leading company in the industry.

The Latest Advancements in Sintered Metal Candle Filter Technology Revealed

Sintered Metal Filter: The New Standard for Candle FiltrationCandle filtration is a popular and effective method of filtering liquids. In recent times, the use of sintered metal candle filters has revolutionized the filtration industry by setting a new standard of efficiency and effectiveness. Sintered metal candle filters are made from fine metal powders that are formed into a filter element under high temperature and pressure conditions. These filters are used in various industries including petrochemical refineries, oil and gas production, food and beverage processing, and pharmaceutical manufacturing.Sintered metal candle filters are designed to remove impurities from liquids by trapping them in the pores of the filter element. These filters have a high dirt-holding capacity and offer excellent purification efficiency. They can filter out particles as small as 0.5 microns. Additionally, sintered metal candle filters operate at low pressure drop, which means that they save energy and reduce operating costs.One company that has been at the forefront of producing sintered metal candle filters is {company name}. They have been supplying sintered metal filters to various industries for more than a decade. Their filters are known for their high quality, durability, and reliability. The company has invested heavily in research and development to improve the performance of their filters, and as a result, their products are highly sought after in the market.In addition to producing sintered metal candle filters, {company name} also provides filter cleaning and reconditioning services. This is important because filters that are not cleaned and maintained properly can become clogged with dirt and other impurities. This can lead to reduced filter efficiency or even filter failure. {Company name}’s cleaning and reconditioning services help to prolong the lifespan of the filter element and ensure that it operates at optimal efficiency.Sintered metal candle filters from {company name} have been used in various applications across different industries. For example, they have been used in the petrochemical industry to remove impurities from the oil before it is processed further. They have also been used in the food and beverage industry to remove solids, bacteria, and other contaminants from liquids such as juice, beer, and wine. In the pharmaceutical industry, sintered metal candle filters have been used to remove impurities from drugs, vaccines, and other medical products.One of the benefits of using sintered metal candle filters from {company name} is that they are customizable. The company can produce filters of different sizes, shapes, and specifications to meet the specific needs of different customers. This ensures that their filters can be used in a wide range of applications.Sintered metal candle filters from {company name} have been well received by their customers. One of their clients, a large oil and gas company, reported that the filters improved their production efficiency by reducing the downtime caused by frequent filter changes. Another customer, a pharmaceutical manufacturing company, reported that {company name}’s filters helped them to meet the regulatory requirements for purity and quality of their products.In conclusion, sintered metal candle filters have set a new standard for filtration efficiency and effectiveness. Companies such as {company name} have been instrumental in producing high-quality sintered metal candle filters that are used in various industries. The durability, reliability, and customizability of their filters have made them a popular choice for many customers. With their commitment to research and development, {company name} is poised to continue supplying the market with innovative sintered metal candle filters that meet the evolving needs of different industries.

Discover the Benefits of Utilizing Industrial Gas Filters

Industrial Gas Filter: Improving Air Quality and Ensuring a Clean EnvironmentIn today's fast-paced industrial world, it is crucial to prioritize clean and safe working environments. With the ever-increasing concerns about air pollution and its adverse effects on human health, companies worldwide are taking steps to minimize their environmental impact. One such solution is the Industrial Gas Filter, a cutting-edge technology that effectively removes harmful pollutants from industrial gases, ensuring cleaner air and contributing to a healthier planet.(Company Introduction)Founded several decades ago, our company has been at the forefront of developing innovative filtration solutions for a range of industries. With an unwavering commitment to research and development, we have consistently pushed boundaries to create high-quality products that fulfill the evolving needs of our customers.Our industrial gas filters are no exception. Designed with state-of-the-art technology, they efficiently eliminate a wide array of pollutants and particulate matter commonly found in industrial gases. By integrating advanced filtration materials and techniques, our filters effectively capture harmful substances, safeguarding the well-being of both employees and the surrounding environment.The need for Industrial Gas Filters arises due to the diverse range of industries that produce potentially harmful gases. From manufacturing plants to chemical refineries, these industrial processes can release pollutants such as volatile organic compounds (VOCs), sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter into the air. These pollutants can have severe consequences on air quality and human health if left uncontrolled.Our Industrial Gas Filters employ a multistage filtration process that combines various filtration mechanisms to maximize efficiency. Firstly, a pre-filtration stage removes larger particles, preventing them from entering the subsequent filtration steps. Once the gas passes through the initial stage, it undergoes absorption, adsorption, or catalytic conversion processes, depending on the targeted pollutants.Absorption involves dissolving pollutants into a liquid, effectively removing them from the gas stream. Adsorption utilizes activated carbon or other porous materials to trap pollutants onto their surface, preventing their release into the atmosphere. Lastly, catalytic processes employ catalysts to convert harmful compounds into less hazardous substances through chemical reactions.To ensure our filters operate at the highest efficiency, we employ advanced technologies, including electrostatic precipitation and high-pressure drop filtration. The former employs an electrical charge to attract and collect particulate matter, whereas the latter forces gas through a filter medium under high pressure, providing exceptional filtration of fine particles.Moreover, our Industrial Gas Filters are designed with durability and ease of maintenance in mind. With a robust construction and easily replaceable filter elements, our filters offer reliable operation and cost-effectiveness. Regular maintenance, including filter replacement and cleaning, ensures proper functioning and extends the lifespan of the filters, making them a sustainable and environmentally-conscious choice.By implementing Industrial Gas Filters, companies can significantly reduce air pollution and create a healthier working environment for their employees. In addition to meeting environmental regulations and compliance standards, businesses can enhance their corporate image by showcasing their commitment to sustainable practices and responsible manufacturing.As global consciousness towards environmental concerns grows, the demand for industrial gas filters is expected to rise. By investing in these advanced filtration systems, companies can take an active role in safeguarding the environment and protecting human health.In conclusion, Industrial Gas Filters play a vital role in improving air quality and ensuring a clean working environment in various industries. With their exceptional filtration capabilities and advanced technologies, these filters effectively remove harmful pollutants and contribute to a healthier planet. By adopting these innovative solutions, companies can demonstrate their commitment to sustainability while complying with environmental regulations.

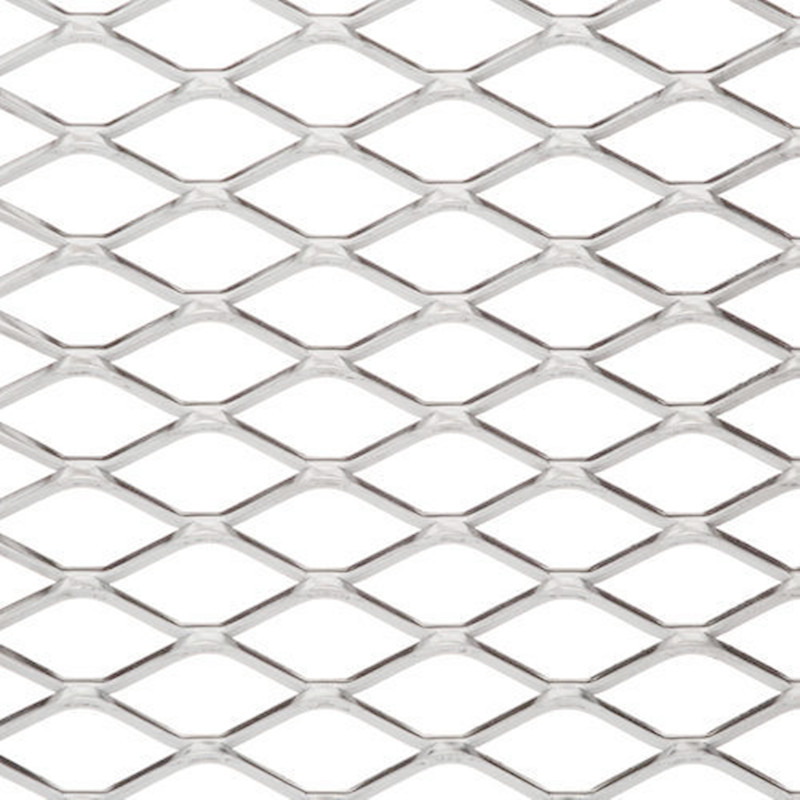

The Advantages of Using Expanded Wire Mesh for Industrial Applications

Expanded Metal Wire Mesh: A Versatile and Reliable Solution for Various Applications[City, Date] - Expanded Metal Wire Meshs have been gaining significant popularity in recent years due to their versatility and durability. With a wide range of applications across different industries, this innovative product has become a go-to choice for architects, engineers, and construction professionals.An Expanded Metal Wire Mesh, also known as expanded metal or expanded metal mesh, is made by expanding a sheet of metal into a three-dimensional pattern. This process creates a series of diamond-shaped openings in the metal, resulting in a lightweight and strong material. The expanded metal is typically made from materials such as steel, aluminum, stainless steel, or copper, offering different levels of strength and corrosion resistance.One of the key advantages of Expanded Metal Wire Mesh is its versatility. It can be customized to meet specific project requirements, including varying mesh sizes, open areas, and thicknesses. This adaptability makes it suitable for a wide range of applications, both indoors and outdoors. Common applications include façade cladding, security fencing, walkways, stair treads, filtration systems, and much more.The Expanded Metal Wire Mesh is widely used in the architectural and construction industries. Architects appreciate its aesthetic appeal, as it can be used to create unique patterns and designs on building facades. Moreover, it offers both sun shading and privacy while allowing sufficient airflow and natural light to penetrate. This makes it an ideal choice for creating visually appealing and energy-efficient structures.Additionally, Expanded Metal Wire Mesh is widely used as security fencing due to its strength and durability. The mesh design makes it difficult for intruders to penetrate, enhancing the security of residential, commercial, and industrial properties. It is often used in prisons, military bases, airports, and other high-security areas, providing an effective barrier against unauthorized access.In the industrial sector, Expanded Metal Wire Mesh is commonly used for walkways, stair treads, and platforms. Its non-slip surface ensures the safety of workers in high-traffic areas or challenging environments. Furthermore, the open design allows liquids, debris, and gases to pass through, making it suitable for use in drainage systems, filtration devices, and ventilation equipment.The durability and corrosion resistance of Expanded Metal Wire Mesh make it a long-lasting solution even in harsh environments. Whether exposed to extreme temperatures, high humidity, or corrosive chemicals, this product maintains its structural integrity and performance, reducing maintenance costs over time.Company Introduction{Company Name}, one of the leading manufacturers of Expanded Metal Wire Mesh, has been at the forefront of supplying high-quality products to industries worldwide. With decades of experience, our company takes pride in delivering durable and reliable solutions that meet the unique needs of our clients.Our state-of-the-art manufacturing facilities and skilled workforce allow us to produce a wide range of Expanded Metal Wire Mesh products. We prioritize quality assurance and ensure that each product undergoes rigorous testing to guarantee its strength, durability, and adherence to industry standards.At {Company Name}, we understand that every project is unique, which is why we offer customized solutions tailored to specific requirements. Our team of experts works closely with clients to understand their vision and provide technical support throughout the entire process – from design to installation.As a socially responsible company, we prioritize sustainable manufacturing practices. We are committed to minimizing our environmental impact by utilizing eco-friendly materials, optimizing energy consumption, and implementing waste management strategies.ConclusionExpanded Metal Wire Mesh has revolutionized various industries, offering a versatile and reliable solution for a range of applications. The durability, strength, and customization options provided by this innovative product make it a preferred choice for architects, engineers, and construction professionals. With its vast possibilities and aesthetic appeal, Expanded Metal Wire Mesh is poised to continue shaping the future of architectural design, infrastructure, and security systems.For more information about {Company Name}'s Expanded Metal Wire Mesh products, visit their website or contact their customer service team.Press Contact:[Contact Name][Company Name][Phone Number][Email Address]

High-Quality Filter Cartridge for Efficient Filtration Systems

Filter Cartridge Company Introduces Innovative Product to Enhance Water PurificationFilter Cartridge Company, a leading provider of water filtration solutions, has announced the release of their latest innovation in water purification technology. The new filter cartridge has been designed to remove impurities and contaminants from drinking water, ensuring that consumers have access to clean and healthy water.The new filter cartridge features a unique and advanced filtration system that is capable of removing a wide range of pollutants, such as chlorine, lead, and sediment. This technology is especially important in areas where water quality is a concern, as it can help to protect consumers from the harmful effects of contaminated water.The company's dedication to creating high-quality water purification solutions is evident in the development of this new filter cartridge. The product has undergone rigorous testing to ensure its effectiveness and reliability, and it has been designed to meet the highest standards of water filtration."We are thrilled to introduce our latest innovation in water purification technology," said [company spokesperson]. "At Filter Cartridge Company, we are committed to providing consumers with the best possible water filtration solutions, and this new filter cartridge is a reflection of that dedication. We believe that everyone deserves access to clean and healthy water, and we are proud to play a role in making that a reality."In addition to its advanced filtration capabilities, the new filter cartridge is also designed with convenience in mind. Its easy-to-install design makes it accessible to a wide range of consumers, and its long-lasting durability ensures that it will provide reliable water purification for an extended period of time.The company also offers a range of other water filtration products, including replacement filter cartridges for a variety of systems, as well as whole-house filtration systems and under-sink filters. This comprehensive selection of products allows consumers to find the perfect solution for their specific water purification needs.Filter Cartridge Company has built a strong reputation for providing high-quality water filtration solutions, and their commitment to innovation and excellence has set them apart in the industry. With the introduction of their latest filter cartridge, they are once again demonstrating their dedication to improving water quality for consumers everywhere.As concerns about water quality continue to grow, the demand for effective water purification solutions is increasing. Filter Cartridge Company's new filter cartridge is positioned to meet this demand by providing a reliable and efficient means of removing impurities from drinking water.The release of this new filter cartridge is a significant development for Filter Cartridge Company, as it represents their ongoing efforts to push the boundaries of water purification technology. As the company continues to innovate and expand its product line, consumers can expect to see even more advanced and effective solutions for water filtration in the future.Filter Cartridge Company remains at the forefront of the water filtration industry, and their latest product release is a testament to their ongoing commitment to providing consumers with the best possible water purification solutions. With their new filter cartridge, they are once again demonstrating their leadership in the field of water filtration, and consumers can trust that they are receiving the highest quality products for their water purification needs.