High-Quality 2205 Duplex Stainless Steel Mesh for Various Applications

By:Admin

The 2205 Duplex Stainless Steel Mesh is made from a combination of austenitic and ferritic stainless steels, offering a unique microstructure that provides excellent strength and corrosion resistance. This makes it suitable for a wide range of applications, including filtration, sieving, and screening in industries such as food processing, chemical processing, and marine engineering.

{} has a strong reputation for manufacturing high-quality stainless steel mesh products, and the introduction of 2205 Duplex Stainless Steel Mesh further solidifies its position as an industry leader. The company's state-of-the-art manufacturing facilities and advanced production techniques enable them to produce stainless steel mesh with superior mechanical properties and exceptional durability.

In addition to its superior strength and corrosion resistance, the 2205 Duplex Stainless Steel Mesh also offers excellent weldability and formability, making it easier to work with for fabricators and installers. The mesh is available in a variety of sizes and specifications to meet the specific requirements of different applications, providing customers with greater flexibility and options.

The launch of 2205 Duplex Stainless Steel Mesh represents {}'s commitment to innovation and excellence in the stainless steel mesh industry. The company continuously invests in research and development to create new and improved products that meet the evolving needs of its customers. By incorporating the latest materials and manufacturing technologies, {} strives to stay ahead of the competition and set new standards in the industry.

With its deep understanding of stainless steel materials and extensive experience in mesh manufacturing, {} is well-positioned to deliver the highest quality products to its customers. The company's dedication to quality and customer satisfaction has earned it a loyal customer base and a strong reputation in the industry. The introduction of 2205 Duplex Stainless Steel Mesh further demonstrates {}'s commitment to providing innovative solutions that meet the highest standards of performance and reliability.

As the demand for high-performance stainless steel mesh continues to grow, {} is poised to meet the needs of its customers with the introduction of 2205 Duplex Stainless Steel Mesh. The company's dedication to quality, innovation, and customer satisfaction sets it apart as a leading provider of stainless steel mesh products.

In conclusion, the introduction of 2205 Duplex Stainless Steel Mesh by {} represents a significant advancement in the stainless steel mesh industry. With its superior strength, corrosion resistance, and versatile properties, this new product is expected to meet the diverse needs of customers in various industries. Supported by {}'s expertise and commitment to excellence, 2205 Duplex Stainless Steel Mesh is set to become a preferred choice for businesses and professionals seeking high-quality stainless steel mesh solutions.

Company News & Blog

Versatile and Stylish Black Coated Wire Mesh: A Must-Have for Homes and Offices

Title: Innovative Black Coated Wire Mesh Revolutionizes the IndustryIntroduction:As the demand for reliable and durable wire mesh continues to rise across multiple sectors, the introduction of revolutionary black coated wire mesh by a prominent company promises to deliver exceptional performance and aesthetics. This innovative product boasts a range of features that make it a game-changer in the wire mesh industry. With its unique composition and cutting-edge technology, this mesh offers unparalleled strength, versatility, and longevity. In this article, we delve into the exceptional attributes of this black coated wire mesh and its potential applications across various industries.Paragraph 1:Black coated wire mesh, developed by the renowned manufacturer, is an innovative product designed to overcome the limitations associated with traditional wire meshes. Crafted from high-quality materials and coated with a durable black finish, this wire mesh offers not only superior functionality but also an impressive aesthetic appeal. The black color provides a modern and sleek appearance, making it an ideal choice for a range of applications.Paragraph 2:One of the key advantages of this black coated wire mesh lies in its exceptional strength and resilience. Manufactured using advanced techniques, this mesh can withstand heavy impact and high tension, making it suitable for demanding applications such as security fencing, animal enclosures, and industrial usage. The strength of this wire mesh ensures that it can effectively contain and protect without compromising on its structural integrity.Paragraph 3:Furthermore, the innovative composition of this black coated wire mesh exhibits outstanding resistance to corrosion, making it highly durable even in harsh environmental conditions. This unique feature allows the wire mesh to maintain its structural integrity for an extended period, reducing the need for frequent maintenance and replacement. Consequently, this black coated mesh offers long-term cost savings and increased operational efficiency, making it an economical choice for various industries.Paragraph 4:The versatility of this black coated wire mesh is another commendable aspect. Its applications extend beyond traditional uses, finding immense usability in architectural and interior design projects. From decorative wall panels to stylish room dividers, the sleek black finish adds a touch of elegance and modernity to any space. This opens up new possibilities for designers and architects to incorporate this black coated wire mesh in their creative endeavors.Paragraph 5:The implementation of this black coated wire mesh does not compromise on safety. With its tightly woven design and robust construction, it effectively prevents animals or objects from passing through while maintaining optimal visibility. This makes it an ideal choice for zoos, parks, and outdoor recreational areas, ensuring the safety of both animals and visitors.Paragraph 6:As sustainability and eco-friendliness increasingly become a priority, this black coated wire mesh aligns with these principles. Manufactured using environmentally friendly materials and employing responsible manufacturing processes, this wire mesh reduces its carbon footprint without compromising on quality or performance. This aspect makes it an attractive solution for eco-conscious projects and organizations.Conclusion:The introduction of this innovative black coated wire mesh has revolutionized the wire mesh industry. Its exceptional strength, durability, versatility, and aesthetic appeal have opened up new avenues for usage across various sectors. Whether it is for security, decorative, or architectural purposes, this black coated wire mesh offers a modern and reliable solution. With its efficient functionality, this wire mesh is set to transform industries and enhance safety and design options for years to come.

How to Choose the Best Mesh Stainer for Your Needs

Title: Innovative Mesh Strainer Revolutionizes Culinary ExperienceIntroduction:In today's rapidly evolving world, every industry is witnessing groundbreaking innovations, and the culinary industry is no exception. Introducing a revolutionary mesh strainer (brand name removed), a remarkable product that is set to redefine how we strain and sieve various cooking elements. This cutting-edge kitchen tool combines innovative design and impeccable functionality to deliver an unparalleled culinary experience. Developed by the esteemed company {}, this mesh strainer is poised to become an indispensable accessory in kitchens worldwide.1. Background:The concept behind this state-of-the-art mesh strainer stems from the need for a more efficient and user-friendly tool in the culinary realm. Traditional mesh strainers often fall short in terms of durability, precision, and ease of use. With years of research and development, the visionary minds at {} were able to identify these pain points and create the ultimate solution to address them.2. Superior Design and Construction:This mesh strainer redefines the standard with its unparalleled design and construction. Made from a high-quality, food-grade stainless steel material, it guarantees durability and longevity, ensuring it becomes a staple in every kitchen for years to come. The ergonomic handle provides a comfortable grip, minimizing strain during prolonged use.Moreover, the carefully engineered mesh design offers exceptional sieving precision. With strategically placed fine mesh wires, it effectively strains out even the smallest particles, ensuring a flawless end product. Whether it's draining pasta, rinsing vegetables, or sifting dry ingredients, this mesh strainer will effortlessly deliver immaculate results every time.3. Versatility at Its Finest:One of the key features of this mesh strainer is its versatility. With a range of diameters available, it caters to different cooking needs, from smaller portions to larger quantities. Its adaptability makes it suitable for straining liquids, separating pulp from juice, and even sifting powdered sugar over baked goods. The options are endless, making it an indispensable tool for both professional chefs and home cooks.4. Easy to Clean and Store:As cooking should be a delight from start to finish, this mesh strainer eases the burden of cleaning up afterwards. The seamless edges and non-stick surface simplify the cleaning process, ensuring no residue is left behind. Additionally, its compact design allows for easy storage, taking up minimal space in already overcrowded kitchen cabinets.5. Customer Satisfaction and Safety:{} places customer satisfaction and safety at the forefront of their priorities. This is reflected in this mesh strainer's commitment to meeting the highest industry standards. It is FDA-approved, BPA-free, and dishwasher-safe, ensuring peace of mind for consumers while preparing their meals. This dedication to customer safety further solidifies {}'s reputation as a leading innovator in the culinary industry.6. Availability and Future Prospects:The cutting-edge mesh strainer is now available for purchase online through multiple platforms, ensuring worldwide accessibility. Alongside its launch, {} has also promised continuous upgrades and enhancements based on customer feedback and technological advancements. This commitment to improvement further strengthens its position as a pioneer in kitchen tools and appliances.Conclusion:In an era where efficiency and convenience are paramount, the innovative mesh strainer (brand name removed) is poised to change the way we approach cooking and straining. With its impeccable design, outstanding functionality, versatility, and commitment to customer satisfaction, it is set to become a staple in kitchens worldwide. This groundbreaking product is a testament to {}'s dedication to revolutionizing the culinary experience and cementing its position as a leading company in the industry.

High-Quality Sintered Stainless Steel Mesh for Various Applications

Sintered Stainless Steel Mesh, a Revolutionary Product in the Filtration IndustryIn today's fast-paced world, innovation is key to success. One company that is leading the way in innovation is {}. With their latest product, Sintered Stainless Steel Mesh, they are revolutionizing the filtration industry.{} is a global leader in the manufacturing and distribution of filtration products. They have been in the industry for over 20 years, and they have a reputation for providing high-quality products and exceptional customer service. Their team of experts is dedicated to staying ahead of the curve and developing cutting-edge solutions for their clients’ needs.The Sintered Stainless Steel Mesh is the latest addition to their product line, and it is already making waves in the industry. This innovative product is designed to meet the increasing demand for high-performance filtration solutions in various applications, including automotive, aerospace, chemical processing, oil and gas, and food and beverage.The Sintered Stainless Steel Mesh is manufactured using a state-of-the-art sintering process, which involves compacting and forming stainless steel powder into a solid mass using heat and pressure. This results in a porous material with a high strength-to-weight ratio, excellent filtration properties, and resistance to corrosion and high temperatures.One of the key advantages of the Sintered Stainless Steel Mesh is its uniform pore structure, which allows for precise particle retention and efficient flow rates. This makes it ideal for applications where consistent and reliable filtration is crucial. Additionally, the material's durability and resistance to harsh environments make it a cost-effective solution for long-term use.The Sintered Stainless Steel Mesh is available in a wide range of pore sizes, thicknesses, and shapes to meet the specific requirements of different applications. This customizable feature sets it apart from traditional filtration media, allowing for a tailored solution that delivers optimal performance.Furthermore, the Sintered Stainless Steel Mesh is environmentally friendly, as it is made from recycled stainless steel and can be recycled at the end of its life cycle, reducing waste and promoting sustainability.The launch of the Sintered Stainless Steel Mesh marks a significant milestone for {}. Their commitment to advancing technology and meeting the evolving needs of their clients is evident in this groundbreaking product. They have already received positive feedback from early adopters, who have praised the Sintered Stainless Steel Mesh for its performance and durability.The innovative nature of the Sintered Stainless Steel Mesh aligns with {}'s mission to provide innovative solutions that improve efficiency, reliability, and sustainability. With their extensive expertise and vast resources, they are well-positioned to drive the adoption of this revolutionary product across various industries and applications.In conclusion, the introduction of the Sintered Stainless Steel Mesh by {} is a game-changer in the filtration industry. With its advanced manufacturing process, customizable features, and environmental benefits, it is set to redefine filtration standards and address the challenges of modern applications. As {} continues to expand its presence in the global market, the Sintered Stainless Steel Mesh will undoubtedly play a pivotal role in their ongoing success and contribute to the advancement of filtration technology.For more information about the Sintered Stainless Steel Mesh and other innovative products from {}, please visit their official website or contact their customer service team.

Durable and Heat-Resistant Wire Mesh for Industrial Use - A Closer Look

Nichrome Wire Mesh is a high-quality, versatile product that has a wide range of applications across various industries. This wire mesh is known for its excellent resistance to high temperatures, corrosion, and mechanical stress, making it a popular choice for many different purposes. From industrial filtration to heating elements, Nichrome Wire Mesh offers superior performance and reliability.The company behind this innovative product, a global leader in the manufacturing and supply of wire mesh products, has an extensive track record of providing high-quality materials to meet the needs of their diverse customer base. With state-of-the-art manufacturing facilities and a team of experienced professionals, they are committed to delivering top-notch products and exceptional service to their clients around the world.Nichrome Wire Mesh is a premium product that is manufactured using the finest quality materials and advanced production techniques. The company employs strict quality control measures to ensure that each piece of wire mesh meets the highest standards of performance and durability. As a result, their wire mesh products are trusted by customers in industries such as aerospace, automotive, petrochemical, and more, where reliable and efficient materials are crucial.One of the key features of Nichrome Wire Mesh is its exceptional resistance to high temperatures. This makes it an ideal choice for applications that involve exposure to extreme heat, such as industrial furnaces, ovens, and heating elements. The wire mesh can withstand elevated temperatures without losing its structural integrity, making it a dependable solution for demanding thermal environments.In addition to its heat resistance, Nichrome Wire Mesh also offers excellent corrosion resistance. This is particularly important for industries where exposure to chemicals or harsh environments is common. The wire mesh is designed to withstand corrosion and degradation, ensuring long-term performance and reliability in challenging conditions.Furthermore, Nichrome Wire Mesh exhibits outstanding mechanical strength, making it suitable for a wide range of industrial applications. Whether it's used for filtration, sieving, screening, or reinforcing, the wire mesh provides strong and durable support, enhancing the efficiency and longevity of various processes and equipment.The versatility of Nichrome Wire Mesh extends to its customization options. The company offers a range of mesh sizes, wire diameters, and configurations to meet the specific requirements of different applications. This flexibility, combined with the product's outstanding performance, makes it a preferred choice for businesses looking for tailor-made solutions to their unique challenges.As a leading supplier of wire mesh products, the company is dedicated to providing comprehensive support to its customers. From product selection to technical assistance, their team of experts is committed to delivering personalized service and reliable advice to help clients find the best wire mesh solution for their needs. Additionally, the company has a strong emphasis on sustainability and environmental responsibility, ensuring that their products are manufactured and delivered in an eco-friendly manner.In conclusion, Nichrome Wire Mesh is a superior product that offers exceptional heat resistance, corrosion resistance, and mechanical strength. With a commitment to quality, innovation, and customer satisfaction, the company behind this innovative product continues to set the industry standard for wire mesh solutions. Whether it's for industrial filtration, heating elements, or other critical applications, businesses can depend on Nichrome Wire Mesh to deliver outstanding performance and reliability.

Highly Efficient Sintered Candle Filter for Dispersion and Backwash Applications

and Dispersion and BackwashSintered Candle Filter: A Reliable Solution for Dispersion and BackwashThe process of filtration plays a vital role in many industries, especially where the quality of the product is critical. With the advancement in technology, various types of filters are introduced to meet the specific needs of different applications. Among them, sintered candle filter has gained much importance in recent years due to its high filtration efficiency and chemical resistance. This blog will discuss the significance of sintered candle filter, particularly for dispersion and backwash applications.What is a Sintered Candle Filter?A sintered candle filter is a type of ceramic filter that consists of a cylindrical shape with a porous structure. It is made of alumina, zirconia, or silicon carbide and is sintered at high temperatures to form a rigid and durable structure. The porous structure of the filter allows the fluid to pass through while retaining the particles and impurities. The filtration process occurs through surface filtration or depth filtration, depending on the pore structure of the filter.Significance of Sintered Candle Filter for DispersionDispersion is a critical process in many industries, including pharmaceutical, chemical, and food processing. It involves the mixing of two or more components to form a homogeneous solution. The quality and consistency of the final product depend on the proper mixing and dispersion of the components. Sintered candle filters are widely used for dispersion applications due to their high filtration efficiency and uniform pore size distribution. The uniform pore size distribution ensures the proper dispersion of the components by retaining the large particles and allowing the smaller particles to pass through. Moreover, the chemical resistance of the filter ensures the compatibility with a wide range of chemicals, enabling the filter to withstand aggressive chemical environments.Significance of Sintered Candle Filter for BackwashBackwash is a process used for cleaning the filter media to remove the impurities and particles accumulated during the filtration process. It involves reversing the flow of the fluid to dislodge the particles and flush them out of the filter. Sintered candle filters are widely used for backwash applications due to their rigid and durable structure and high resistance to thermal and chemical shock. The high filtration efficiency of the filter ensures the proper removal of the impurities during backwash, resulting in a clean and efficient filtration process.ConclusionSintered candle filters have gained much importance in recent years due to their high filtration efficiency, uniform pore size distribution, and chemical resistance. The significance of these filters for dispersion and backwash applications makes them a reliable solution for many industries. The proper selection of the filter material and pore size is crucial to ensure the optimal performance of the filter. Therefore, it is essential to consider the specific needs of the application before selecting the filter. So, the sintered candle filter is a great choice for industries looking for an efficient and reliable filtration solution for dispersion and backwash applications.

Durable and Versatile Coated Wire Mesh for Various Applications

Black Coated Wire Mesh: Providing Durability and Versatility for Various ApplicationsThe use of wire mesh has become a staple in various industries due to its durability, versatility, and cost-effective properties. One of the leading manufacturers in the industry, {Company Name}, has been at the forefront of producing high-quality wire mesh products, such as the popular Black Coated Wire Mesh.{Company Name} has a strong reputation for providing innovative solutions for a wide range of applications, including construction, agriculture, landscaping, and industrial environments. With a commitment to excellence and customer satisfaction, the company has continued to meet the ever-evolving demands of its clients by delivering top-notch products that meet industry standards and exceed expectations.The Black Coated Wire Mesh offered by {Company Name} is a testament to the company's dedication to quality and performance. With a durable black coating, this wire mesh is designed to withstand harsh environmental conditions, making it an ideal choice for outdoor applications. The black coating not only provides a sleek and modern look but also adds an extra layer of protection against rust and corrosion, ensuring long-term durability and reliability.One of the key features of the Black Coated Wire Mesh is its versatility. This product comes in a variety of mesh sizes, wire diameters, and roll lengths, allowing for customization to meet specific project requirements. Whether it's for fencing, animal enclosures, garden trellises, or decorative applications, the Black Coated Wire Mesh can be tailored to suit a wide range of needs, making it a popular choice for both residential and commercial use.In addition to its aesthetic appeal and versatility, the Black Coated Wire Mesh offers excellent functionality. The wire mesh is easy to install and can be cut to size, providing a practical solution for quick and hassle-free application. Its sturdy construction and high tensile strength make it suitable for demanding tasks, such as securing perimeters, creating partitions, and providing support for climbing plants. The Black Coated Wire Mesh is a reliable and cost-effective solution that offers outstanding performance for various projects.{Company Name}'s commitment to quality and innovation is evident in the development and production of the Black Coated Wire Mesh. The company utilizes state-of-the-art manufacturing processes and rigorous quality control measures to ensure that every roll of wire mesh meets the highest standards. From sourcing premium raw materials to employing skilled technicians, {Company Name} prioritizes excellence at every stage of production, resulting in a product that consistently delivers on its promise of durability and functionality.Furthermore, {Company Name} prides itself on its customer-centric approach. The company's dedicated team of professionals is knowledgeable, responsive, and committed to providing exceptional service to its customers. From product selection to technical support, {Company Name} is focused on building strong and lasting relationships with its clients, offering valuable assistance and expertise every step of the way.As the demand for reliable and versatile wire mesh solutions continues to grow, {Company Name} remains at the forefront of the industry, offering high-quality products like the Black Coated Wire Mesh. With a steadfast focus on quality, innovation, and customer satisfaction, the company continues to set the standard for excellence in the wire mesh market.In conclusion, the Black Coated Wire Mesh from {Company Name} is a top-tier solution for a wide range of applications, providing durability, versatility, and functionality. With its sleek black coating, customizable options, and superior performance, this wire mesh is an ideal choice for any project requiring a dependable and long-lasting solution. {Company Name} stands by its commitment to delivering excellence, setting itself apart as a trusted and reliable source for premium wire mesh products.

Molybdenum Wire Mesh: A Strong and Durable Material for Various Applications

Molybdenum Wire Mesh has been making waves in various industries due to its high tensile strength, corrosion resistance, and innovative applications. With the rising demand for reliable and durable materials, the company has emerged as a leading provider of molybdenum wire mesh products, serving a wide range of industries worldwide.The company, with over [X] years of experience in the industry, has established a solid reputation for delivering high-quality molybdenum wire mesh products that meet the most stringent industry standards. Their extensive range of products includes molybdenum wire cloth, molybdenum wire mesh, molybdenum woven wire mesh, and molybdenum sintered wire mesh, among others.One of the key factors that set the company apart from its competitors is its commitment to research and development. By investing in cutting-edge technology and a team of experienced professionals, they have been able to consistently innovate and improve their product offerings. This has allowed them to stay ahead of the curve and cater to the evolving needs of their clients across industries such as aerospace, automotive, chemical processing, and electronics.The molybdenum wire mesh offered by the company is known for its exceptional properties, making it suitable for various applications. Its high melting point, low coefficient of thermal expansion, and excellent electrical conductivity make it an ideal choice for use in high-temperature environments, thermal insulation, and electronic components.Furthermore, the corrosion resistance of molybdenum wire mesh makes it an excellent choice for applications in harsh chemical and marine environments. Its ability to withstand corrosion from acids, alkalis, and other harsh chemicals makes it a valuable material for filtration, separation, and purification processes.In addition to its physical properties, the company's molybdenum wire mesh products are also engineered to meet specific industry requirements. This includes customization of wire diameter, mesh count, and weave pattern to ensure that the mesh meets the exact specifications of the application.The company's commitment to quality and customer satisfaction has earned them a loyal customer base and a strong foothold in the global market. With a focus on continuous improvement and innovation, they are poised to further expand their reach and cater to new industries and applications.As part of their expansion plans, the company has also been actively engaging in partnerships and collaborations with industry leaders to explore new opportunities and enhance their product offerings. By leveraging their expertise and capabilities, they aim to further solidify their position as a trusted provider of molybdenum wire mesh products.Looking ahead, the company is optimistic about the prospects of molybdenum wire mesh in the global market. With the increasing demand for durable and reliable materials, especially in high-tech and industrial applications, they see a growing need for molybdenum wire mesh products. Through their unwavering commitment to quality, innovation, and customer satisfaction, they are well-positioned to capitalize on this growing demand and drive further growth and success in the years to come.

Durable High Nickel Alloy Wire Mesh for Industrial Applications

High Nickel Alloy Wire Mesh is a powerful and versatile material that has become an integral part of various industries due to its superior strength, corrosion resistance, and high temperature performance. This advanced material is widely used in chemical processing, aerospace, and automotive industries, as well as in the manufacturing of filters, screens, and sieves. One of the leading manufacturers of High Nickel Alloy Wire Mesh is {Company Name}, a company that has been at the forefront of innovation and quality in the wire mesh industry since its establishment. With a commitment to producing high-quality products and providing exceptional customer service, {Company Name} has earned a strong reputation as a trusted supplier of wire mesh products to a wide range of industries worldwide.{Company Name} offers a comprehensive range of High Nickel Alloy Wire Mesh products that are designed to meet the specific needs of its customers. These products are made from high-quality nickel-based alloys such as Inconel, Monel, and Hastelloy, which provide excellent resistance to corrosion, oxidation, and high temperatures. The company's High Nickel Alloy Wire Mesh is available in various forms, including woven wire mesh, welded wire mesh, and expanded metal mesh, and can be customized to meet the unique requirements of different applications.The versatility and superior performance of {Company Name}'s High Nickel Alloy Wire Mesh make it suitable for a wide range of applications. In the chemical processing industry, the material is used for filtration and separation purposes, due to its excellent resistance to corrosive chemicals and high temperatures. In the aerospace and automotive industries, High Nickel Alloy Wire Mesh is used in the manufacturing of engine components, exhaust systems, and other high-temperature applications, where its exceptional strength and heat resistance are essential.{Company Name} takes great pride in its ability to provide customized solutions to its customers. The company's team of experienced engineers and technicians work closely with each customer to understand their specific requirements and develop tailored solutions that meet or exceed their expectations. This personalized approach, combined with the company's commitment to quality and innovation, has earned {Company Name} a loyal customer base and a reputation for excellence in the wire mesh industry.In addition to its high-quality products, {Company Name} is also known for its exceptional customer service. The company's knowledgeable and responsive staff is dedicated to providing timely assistance and support to its customers, ensuring a smooth and seamless experience from the initial inquiry to the delivery of the finished product. Whether a customer requires technical guidance, product customization, or assistance with logistics, {Company Name} is committed to going above and beyond to meet their needs.With its extensive industry experience, commitment to quality, and dedication to customer satisfaction, {Company Name} has established itself as a global leader in the manufacturing and supply of High Nickel Alloy Wire Mesh. The company's products are highly regarded for their exceptional performance, durability, and reliability, making them the material of choice for a wide range of industrial applications.As {Company Name} continues to expand its product offerings and explore new opportunities for growth, it remains steadfast in its commitment to delivering superior quality products and unmatched customer service. With a focus on innovation and continuous improvement, {Company Name} is poised to remain at the forefront of the wire mesh industry and continue to exceed the expectations of its customers for years to come.

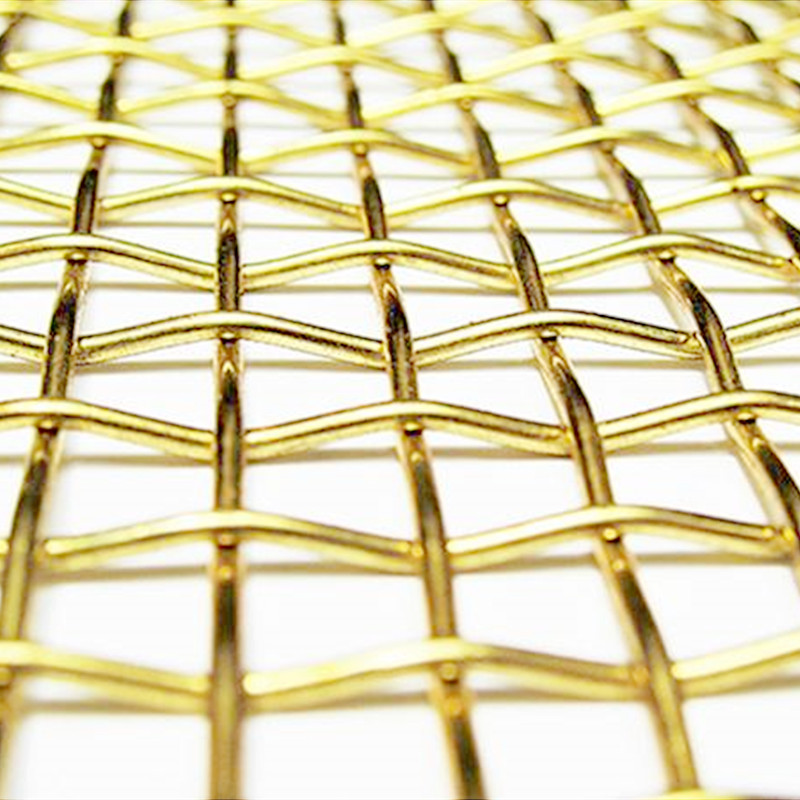

Brass Filter Screen Mesh with High Porosity and Smooth Surface for Copper Wire Mesh Screen

and Brass Copper Wire Mesh ScreenBrass Filter Screen Mesh and Brass Copper Wire Mesh Screen: What Are They and Where Are They Used?When it comes to industrial and commercial processes, the use of filters is integral in ensuring that the final product meets quality standards. Filters come in different materials and sizes depending on the application. However, one material that has stood the test of time is brass. Brass is an alloy of copper and zinc with distinct properties that make it preferred in different industries.One of the popular uses of brass is in the manufacture of filter screens. Brass filter screen mesh is produced by weaving or knitting brass wires of different thicknesses and porosity levels. The result is a durable and high-performance filter that can withstand harsh operating conditions.Typically, brass filter screen mesh is used in liquid filtration applications, such as water treatment and oil refining. The mesh’s porosity allows it to trap impurities while letting the filtered liquid through. Moreover, brass is resistant to corrosion, making it ideal for use in corrosive fluids.Another brass wire mesh common in industrial applications is the brass copper wire mesh screen. This type of mesh is produced by interweaving copper and brass wires to create a unique blend of mechanical and electrical properties. Brass copper wire mesh screen is highly conductive and has excellent electromagnetic shielding properties.Brass copper wire mesh screen is used in electronic devices, such as smartphones and computers, to shield against electromagnetic interference. Furthermore, it is used in filtration applications where high electrical conductivity is required, such as in the manufacture of batteries.In conclusion, brass filter screen mesh and brass copper wire mesh screen are an integral part of many industrial processes. Brass’s distinct properties make it an ideal material for different applications, including filtration and electromagnetic shielding. The next time you come across a brass filter or mesh screen, you now know what it is and where it is used.

Durable and Corrosion-Resistant Metal Mesh Used in Various Applications

Monel Mesh, a versatile and durable material, has been making waves in the industry for its wide range of applications and high-performance characteristics. The company behind this innovative product, {Company Name}, has been at the forefront of developing advanced materials and solutions for various industries.{Company Name} is a leading manufacturer and supplier of Monel Mesh, offering a wide range of specifications and customization options to meet the unique needs of their customers. With years of experience in the industry, the company has built a solid reputation for delivering high-quality products and exceptional customer service.Monel Mesh is a type of woven wire mesh that is made from a high-performance alloy known as Monel. This alloy is composed of approximately 65-70% nickel, 20-29% copper, and small amounts of iron, manganese, silicon, and carbon. The combination of these elements gives Monel Mesh its exceptional corrosion resistance, strength, and durability, making it suitable for a wide range of applications.One of the key advantages of Monel Mesh is its resistance to corrosion, especially in harsh environments such as marine or chemical processing plants. This makes it an ideal choice for applications where traditional materials may fail due to corrosion, such as filtration, separation, and screening processes.In addition to its corrosion resistance, Monel Mesh also offers excellent mechanical properties, including high tensile strength, toughness, and resistance to high temperatures. This makes it suitable for demanding applications such as aerospace, automotive, and industrial manufacturing.{Company Name} is committed to meeting the specific needs of their customers by offering custom fabrication services for Monel Mesh. This includes custom sizing, shaping, and finishing to ensure that the mesh meets the exact requirements of each application. With their state-of-the-art manufacturing facilities and skilled engineers, the company is able to deliver high-quality, precision-engineered Monel Mesh products to their customers.The versatility of Monel Mesh also extends to its wide range of applications, including filtration, separation, screening, and reinforcement in industries such as aerospace, oil and gas, marine, chemical processing, and automotive. Its combination of high-performance characteristics and customizability makes it a valuable material for a wide range of industries.As a leading supplier of Monel Mesh, {Company Name} has established a strong global presence, serving customers around the world with their high-quality products and reliable service. The company has built long-standing relationships with a diverse range of industries, earning a reputation for excellence and innovation in the field of advanced materials.With a commitment to quality, innovation, and customer satisfaction, {Company Name} continues to lead the way in the development and supply of Monel Mesh. Their dedication to meeting the unique needs of their customers and delivering outstanding products has positioned them as a trusted partner for businesses seeking high-performance materials for their applications.In conclusion, Monel Mesh, offered by {Company Name}, is a high-performance material that offers exceptional corrosion resistance, strength, and durability. With its wide range of applications and customizability, Monel Mesh has become a valuable solution for industries around the world. As a leading manufacturer and supplier of Monel Mesh, {Company Name} continues to set the standard for excellence and innovation in the field of advanced materials.