Experience Enhanced Air Quality with an Efficient Diffusing Filter

By:Admin

Company News & Blog

Understanding the Definition and Applications of Wire Mesh

and Fine Wire Mesh.Wire mesh is a versatile material that finds applications across various industries due to its structural strength, durability, and low cost. It consists of intertwined wires that form a grid-like pattern with uniform gaps between each wire. These gaps can range from small to large, depending on the type of wire mesh used.Coarse Wire Mesh, as the name suggests, has relatively larger gaps as compared to other wire mesh variants. It is commonly used for industrial purposes such as filtration, reinforcement, and security fencing. Coarse Wire Mesh is made using thicker wires, which offer higher stability and strength, ensuring that it can withstand heavy loads.Fine Wire Mesh, on the other hand, has smaller gaps and thinner wire diameters, making it more flexible and pliable. This type of wire mesh is mainly used for architectural purposes such as interior design, decorative components, and artistic installations. Fine Wire Mesh is available in various materials such as stainless steel, brass, aluminum, and copper, making it suitable for different design requirements.Wire mesh finds applications in diverse industries such as agriculture, construction, automotive, and food processing. It is commonly used for insect screening, air filtration, safety guards, and insulation. Wire mesh is also used in the production of concrete, where it acts as a reinforcement material, helping to increase its strength.Apart from its industrial and architectural applications, wire mesh is also used in the creation of innovative products such as wire mesh baskets and wire mesh shelves. These products are widely used in retail stores for displaying merchandise and organizing storage spaces.In conclusion, wire mesh is a versatile material that has found widespread usage across various industries due to its strength, durability, and low cost. Its ability to adapt to different applications and design requirements makes it a popular choice for architects, engineers, and designers. Whether it's Coarse Wire Mesh or Fine Wire Mesh, wire mesh continues to play an essential role in our daily lives.

Exploring the Applications and Benefits of Fine Woven Wire Mesh

[Company Introduction]Founded in [year], [Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With our state-of-the-art facilities and innovative technologies, we have successfully established a reputation for producing high-quality wire mesh solutions tailored to meet the diverse needs of various industries worldwide. Our commitment to excellence, customer satisfaction, and continuous improvement has made us a preferred choice for businesses seeking reliable and customized wire mesh solutions.[News Content]Title: Industry Leader [Company Name] Unveils Innovative Fine Woven Wire Mesh Solution[City, Date] - As consumer demands for advanced technological products continue to rise, companies across various industries are constantly seeking innovative materials to meet these requirements. Recognizing this need, [Company Name], a renowned manufacturer of wire mesh products, is delighted to unveil its latest development in the form of an advanced fine woven wire mesh solution.The newly launched product, designed to cater to the demanding requirements of multiple industries, signifies a significant leap forward in terms of technological advancement and reliability. Fine woven wire mesh is widely used in sectors such as automotive, aerospace, architecture, and industrial applications. Its unique characteristics, including superior strength, durability, and precision, make it an ideal choice for a wide range of applications.[Company Name]'s fine woven wire mesh is manufactured using the latest state-of-the-art techniques, ensuring impeccable quality and consistency. The production process involves meticulously weaving individual wires together, resulting in a tightly-knit and durable mesh structure. This level of precision guarantees the product's capability to withstand extreme temperatures, high pressure, and harsh environmental conditions.One of the key advantages of [Company Name]'s fine woven wire mesh is its versatility. With customizable parameters such as wire diameter, mesh count, and material selection, customers can easily select the perfect solution to meet their specific project requirements. Whether it's filtration, separation, protection, or reinforcement, the fine woven wire mesh can be tailored to deliver exceptional results.Moreover, [Company Name] recognizes the importance of sustainability and environmental responsibility. The newly developed fine woven wire mesh is engineered using eco-friendly materials, ensuring compliance with the latest industry standards and regulations. This eco-conscious approach aligns with the company's commitment to creating a greener tomorrow while providing advanced solutions to meet current market needs.In addition to the impeccable quality of the fine woven wire mesh, [Company Name] offers comprehensive technical support and assistance to its customers. With dedicated teams of experts, the company ensures that customers receive the necessary guidance in selecting the most suitable wire mesh solution and provides valuable insights into its application and performance."We are thrilled to introduce our latest fine woven wire mesh solution to the market," says [Name], [Company Name]'s CEO. "Through years of research and development, we have created a product that not only meets the demanding requirements of various industries but also contributes to a sustainable environment. Our team is dedicated to providing innovative and customized solutions to our esteemed clients, ensuring their success in their respective fields."As industries continue to evolve and demand cutting-edge materials, [Company Name] reaffirms its commitment to pushing the boundaries of technological advancements in the wire mesh industry. With its latest fine woven wire mesh solution, the company positions itself as a reliable partner in meeting customers' evolving needs and contributing to the overall progress of industries globally.About [Company Name]:[Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as an industry leader over the years. From automotive to architectural applications, [Company Name] provides reliable and customized wire mesh solutions to various industries across the globe.Press Contact:[Name][Job Title][Company Name][Phone Number][Email]

Different Types of Coated Wire Mesh and Fences Available for Security and Safety Purposes

PVC Coated Steel Mesh - The Ultimate Solution for Your Wire Mesh NeedsThe wire mesh industry is a rapidly growing sector with a wide variety of materials and designs available in the market. Among these, PVC coated steel mesh stands out as a highly durable, versatile and cost-effective option. In this blog, we will explore the various aspects of PVC coated steel mesh and why it is a popular choice for a wide range of applications.What is PVC Coated Steel Mesh?PVC coated steel mesh is a kind of wire mesh that is coated with polyvinyl chloride (PVC) to offer superior corrosion resistance, durability and strength. The steel wire mesh is first galvanized to prevent rusting or corrosion and then coated with PVC material to offer additional protection. The PVC coating can be of different thicknesses depending on the application and can have different colors for better aesthetics.Applications of PVC Coated Steel MeshDue to its unique combination of strength, durability, and corrosion resistance, PVC coated steel mesh finds enormous applications in a wide range of sectors, including:1. Agricultural applications - PVC coated steel mesh is extensively used in agricultural sectors for making animal cages, garden fencing, trellis, plant support, and other structures.2. Construction sector - It is used in reinforcing concrete slabs, walls, and other structures, as well as in making safety and security fences, gates, and barriers.3. Industrial purposes - PVC coated steel mesh is a popular choice for making safety and security barriers, walkways, staircases, machine guards, and other industrial structures.4. Home and garden - It is used in making garden fencing, trellis, dividers, greenhouse covers, and various other DIY projects.Advantages of PVC Coated Steel Mesh1. Corrosion-resistant - PVC coating provides superior resistance to corrosion and rust, making the wire mesh long-lasting and durable for outdoor applications.2. Versatile - Available in various colors, thicknesses, and textures, PVC coated steel mesh lends itself to a wide range of design options and aesthetic requirements.3. Highly durable - Galvanized steel wire and PVC coating make the wire mesh highly durable and long-lasting, even in harsh environments and extreme weather conditions.4. Cost-effective - PVC coated steel mesh is highly cost-effective and provides excellent value for money, making it a preferred choice for budget-conscious buyers.5. Easy to install - PVC coated steel mesh is easy to cut, shape, and install, making it a popular choice for DIY enthusiasts and professionals alike.ConclusionPVC coated steel mesh is a highly versatile, durable, and cost-effective option that offers excellent corrosion resistance and strength. Whether you are looking for wire mesh for your agricultural needs, construction sector or home and garden projects, PVC coated steel mesh will provide you with a reliable and long-lasting solution. At YKM Group, we are a leading manufacturer and supplier of PVC coated steel mesh, and we offer a wide range of designs, colors, and thicknesses to suit your unique requirements. Contact us today to learn more about our products and services.

How to Choose the Best Mesh Stainer for Your Needs

Title: Innovative Mesh Strainer Revolutionizes Culinary ExperienceIntroduction:In today's rapidly evolving world, every industry is witnessing groundbreaking innovations, and the culinary industry is no exception. Introducing a revolutionary mesh strainer (brand name removed), a remarkable product that is set to redefine how we strain and sieve various cooking elements. This cutting-edge kitchen tool combines innovative design and impeccable functionality to deliver an unparalleled culinary experience. Developed by the esteemed company {}, this mesh strainer is poised to become an indispensable accessory in kitchens worldwide.1. Background:The concept behind this state-of-the-art mesh strainer stems from the need for a more efficient and user-friendly tool in the culinary realm. Traditional mesh strainers often fall short in terms of durability, precision, and ease of use. With years of research and development, the visionary minds at {} were able to identify these pain points and create the ultimate solution to address them.2. Superior Design and Construction:This mesh strainer redefines the standard with its unparalleled design and construction. Made from a high-quality, food-grade stainless steel material, it guarantees durability and longevity, ensuring it becomes a staple in every kitchen for years to come. The ergonomic handle provides a comfortable grip, minimizing strain during prolonged use.Moreover, the carefully engineered mesh design offers exceptional sieving precision. With strategically placed fine mesh wires, it effectively strains out even the smallest particles, ensuring a flawless end product. Whether it's draining pasta, rinsing vegetables, or sifting dry ingredients, this mesh strainer will effortlessly deliver immaculate results every time.3. Versatility at Its Finest:One of the key features of this mesh strainer is its versatility. With a range of diameters available, it caters to different cooking needs, from smaller portions to larger quantities. Its adaptability makes it suitable for straining liquids, separating pulp from juice, and even sifting powdered sugar over baked goods. The options are endless, making it an indispensable tool for both professional chefs and home cooks.4. Easy to Clean and Store:As cooking should be a delight from start to finish, this mesh strainer eases the burden of cleaning up afterwards. The seamless edges and non-stick surface simplify the cleaning process, ensuring no residue is left behind. Additionally, its compact design allows for easy storage, taking up minimal space in already overcrowded kitchen cabinets.5. Customer Satisfaction and Safety:{} places customer satisfaction and safety at the forefront of their priorities. This is reflected in this mesh strainer's commitment to meeting the highest industry standards. It is FDA-approved, BPA-free, and dishwasher-safe, ensuring peace of mind for consumers while preparing their meals. This dedication to customer safety further solidifies {}'s reputation as a leading innovator in the culinary industry.6. Availability and Future Prospects:The cutting-edge mesh strainer is now available for purchase online through multiple platforms, ensuring worldwide accessibility. Alongside its launch, {} has also promised continuous upgrades and enhancements based on customer feedback and technological advancements. This commitment to improvement further strengthens its position as a pioneer in kitchen tools and appliances.Conclusion:In an era where efficiency and convenience are paramount, the innovative mesh strainer (brand name removed) is poised to change the way we approach cooking and straining. With its impeccable design, outstanding functionality, versatility, and commitment to customer satisfaction, it is set to become a staple in kitchens worldwide. This groundbreaking product is a testament to {}'s dedication to revolutionizing the culinary experience and cementing its position as a leading company in the industry.

Nickel Mesh and Screen: Material, Specification, Packing - Corrosion and Acid Resistant Filter Mesh for High Temperature Filtration

article about the benefits of using nickel wire mesh and screen in various industrial applications.Nickel wire mesh and screen have become increasingly popular in various industrial applications, thanks to their unique properties. As a manufacturer and supplier of high-quality nickel wire mesh, {company name} understands the numerous benefits that this material provides for industrial filtration and screening processes.Nickel wire mesh is highly durable and resistant to both corrosion and acid, making it an ideal material for use in harsh and high-temperature environments. This property makes nickel wire mesh and screen suitable for use in various industries, such as chemical and petrochemical production, power generation, and mining.One of the primary benefits of using nickel wire mesh is its high-level filtration. Nickel wire mesh filters and screens are capable of separating and removing very fine particles from liquids or gases, making them an essential material in many manufacturing and industrial processes. In these industries, even the tiniest of impurities can cause machinery to malfunction or fail, leading to costly repairs, downtime, and potential safety hazards.Nickel wire mesh and screen also exhibit excellent electrical conductivity properties. This makes them ideal for use in electrical and electronic industries, where they can be used as electrodes or screens for electromagnetic shielding. Since nickel has good magnetic properties, it is also used in electrical transformers and inductors.In addition to its unique properties, nickel wire mesh and screen are available in different specifications and mesh sizes. This versatility makes it possible for {company name} to offer a wide range of custom nickel wire mesh products tailored to meet specific industry requirements. Customers can choose from woven, knitted, perforated, or expanded nickel wire mesh depending on their application needs.To ensure the safety of nickel wire mesh products during transportation or storage, {company name} pays significant attention to the packing requirements. The company uses durable packing materials and techniques to ensure its products remain in good condition and reach customers in perfect condition.In conclusion, nickel wire mesh and screen are versatile materials that offer a range of benefits for various industrial applications. With their high durability, resistance to corrosion and acid, and excellent filtration properties, nickel wire mesh has become an essential material in industries such as chemical production, power generation, and mining, among others. As a reputable manufacturer and supplier of nickel wire mesh products, {company name} is dedicated to providing its customers with high-quality custom nickel wire mesh products and excellent customer service.

Discover the Versatility and Durability of Black Expanded Metal Mesh

Title: New Black Expanded Metal Mesh Revolutionizes Industrial ApplicationsIntroduction:In a breakthrough development, Company X has unveiled its latest innovation in the field of expanded metal mesh - the exceptional Black Expanded Metal Mesh. With its remarkable durability, versatility, and aesthetic appeal, this cutting-edge product is set to revolutionize various industrial applications. By combining advanced manufacturing techniques with top-quality materials, Company X continues to remain at the forefront of the metal mesh industry.Paragraph 1: Importance of Expanded Metal Mesh in Industrial Applications (100 words)Expanded metal mesh has long been an essential component across a wide range of industrial sectors. Its unique design enables it to provide strength, security, and flexibility, making it an ideal choice for countless applications. From infrastructure development to architectural endeavors, expanded metal mesh has found its place in diverse industries such as construction, transportation, manufacturing, and telecommunications.Paragraph 2: Introducing the Black Expanded Metal Mesh (100 words)Company X's newly engineered Black Expanded Metal Mesh is set to elevate the possibilities and functionality of this essential product. By incorporating a sleek black finish into the expanded metal mesh, it enhances both the visual aesthetics and practicality. The black coating provides a layer of protection against corrosion, ensuring durability and longevity in even the harshest of environments.Paragraph 3: Unparalleled Durability and Strength (150 words)The Black Expanded Metal Mesh manufactured by Company X boasts exceptional durability and strength. Crafted from high-quality materials using advanced manufacturing processes, it exhibits unparalleled resistance to impact, bending, and fretting. This makes the product ideal for areas that endure heavy foot traffic or high mechanical stresses. Whether used as security fencing, machine guards, or walkways, the Black Expanded Metal Mesh offers robustness and reliability, ensuring the utmost safety in demanding industrial environments.Paragraph 4: Versatile Applications and Adaptability (150 words)Beyond its robustness, the Black Expanded Metal Mesh also ensures versatility in numerous applications. Its ability to be easily formed and manipulated enables it to suit various design requirements. From decorative panels in architectural designs to filter screens in ventilation systems, this product provides exceptional adaptability to meet the needs of any project. Its black finish adds a touch of sophistication, enhancing the aesthetic appeal while maintaining functionality.Paragraph 5: Enhanced Safety and Security (150 words)In addition to its functional features, the Black Expanded Metal Mesh prioritizes safety and security. The unique design, with small open spaces, ensures visibility and promotes airflow while serving as an effective barrier. This makes it suitable for applications such as security enclosures, partitions, and machine guarding. The black color further aids in obscuring the view, providing an additional layer of privacy in sensitive areas. Company X's commitment to quality and rigorous testing assures that the Black Expanded Metal Mesh meets stringent safety standards, ensuring peace of mind for its users.Conclusion: Enabling Innovation and Advancement (100 words)The launch of Company X's Black Expanded Metal Mesh showcases the company's commitment to innovation and advancement in the manufacturing industry. With its enhanced durability, versatility, and visual appeal, this revolutionary product opens up new possibilities for designers, architects, and engineers across various sectors. Whether it is for structural stability, aesthetic appeal, or enhanced security, the Black Expanded Metal Mesh is set to redefine the standard in industrial applications, paving the way for a more efficient and aesthetically pleasing future.

Exporters of High-Quality Nickel Alloy Wire Mesh and Netting in Mumbai

and High Nickel Alloy Wire Netting.High Nickel Alloy Wire Mesh and Wire Netting – An OverviewHigh Nickel Alloy Wire Mesh and Wire Netting are widely used across various industries for their excellent strength and resistance to harsh environments. These materials are composed of nickel and other notable alloying elements such as copper, chromium, and molybdenum, among others. These alloys are known for their high corrosion resistance, good thermal conductivity, and excellent mechanical properties.Sanghvi Overseas is a leading supplier and exporter of ASTM B160 / ASME SB160 Nickel & High Nickel Alloy Wire Mesh / Wire Netting, including Nickel Alloy 200 Wire Mesh and High Nickel Alloy 201 Wire Netting. Sanghvi Overseas has an extensive network of global clients and is committed to providing the highest quality materials at competitive prices.Nickel Alloy 200 Wire MeshNickel Alloy 200 Wire Mesh is a commercially pure nickel material that has excellent resistance to corrosive environments. This alloy has low carbon content and is resistant to caustic soda and other alkaline solutions. It has high electrical conductivity and is used as an electrode in various industrial applications. The material has a maximum operating temperature of 315 degrees Celsius and is suitable for use in chemical processing plants, marine installations, and power generation stations.High Nickel Alloy 201 Wire NettingHigh Nickel Alloy 201 Wire Netting is similar to Nickel Alloy 200 but has a lower carbon content, which gives it a slightly higher thermal conductivity and reduced embrittlement at elevated temperatures. This material is also highly resistant to corrosion and is suitable for use in reducing and oxidizing environments. It is commonly used in food processing plants, chemical and petrochemical industries, seawater handling equipment, and nuclear power generation plants.Other High Nickel Alloy Wire Mesh and Wire NettingSanghvi Overseas also supplies other high nickel alloy wire mesh and wire netting materials, including:- Monel Alloy 400 Wire Mesh- Monel Alloy K500 Wire Mesh- Inconel Alloy 600 Wire Mesh- Inconel Alloy 601 Wire Mesh- Incoloy Alloy 800 Wire Mesh- Incoloy Alloy 800H Wire Mesh- Hastelloy Alloy C276 Wire Mesh- Hastelloy Alloy C22 Wire MeshThese materials offer similar properties to Nickel Alloy 200 and High Nickel Alloy 201, but with varying levels of added elements to suit specific applications.Why Choose Sanghvi Overseas for High Nickel Alloy Wire Mesh and Wire Netting?Sanghvi Overseas is a trusted supplier and exporter of high-quality High Nickel Alloy Wire Mesh and Wire Netting materials. The company has an extensive network of global clients and has a reputation for providing the highest quality materials at competitive prices. They have a team of experts who are experienced in selecting the right material for each application and are committed to delivering products on time and to the highest quality standards.ConclusionHigh Nickel Alloy Wire Mesh and Wire Netting are essential materials used in various industries, including chemical processing, marine installations, power generation, and food processing. These materials are highly resistant to corrosion, have excellent thermal conductivity, and offer good mechanical properties. Sanghvi Overseas is a trusted supplier and exporter of these materials, providing the highest quality products at competitive prices. Contact them for more information on their products and services.

Importance of Fuel Filter for Efficient Engine Performance

Title: Fuel Filter: The Silent Hero Ensuring Optimal Engine PerformanceIntroduction:Maintaining a vehicle for smooth and efficient performance requires regular inspection and upkeep of its various components. One critical component that often goes unnoticed but plays a pivotal role in optimizing engine efficiency is the fuel filter. This essential device, positioned between the fuel tank and the fuel injection system, diligently works to cleanse the fuel entering the engine, ensuring its vital role in achieving seamless performance. In this blog, we will explore the significance of the fuel filter, its functions, and how it promotes optimal engine performance. So, let's dive in and discover the importance of this unsung hero!Understanding the Fuel Filter:The fuel filter is a robust and intricate device designed to safeguard your vehicle's engine from the detrimental effects of contaminants present in the fuel. Even though gasoline and diesel are refined extensively, impurities such as dirt, rust, and other particles can still manage to find their way into the fuel, risking the efficiency and performance of your engine. The fuel filter acts as a knight in shining armor, intercepting these impurities and ensuring only clean fuel reaches the injection system, hence preventing fuel delivery issues and potential engine damage.Significance of Clean Fuel Delivery:Clean fuel is vital for maximizing engine performance and longevity. A clogged fuel filter restricts the smooth flow of fuel, affecting the fuel pressure and ultimately delivering an inadequate amount to the engine. This deficiency in fuel supply can lead to a host of problems like reduced power, sluggish acceleration, misfiring, increased emissions, and even engine stalling. By maintaining a clear and unobstructed pathway for fuel, the fuel filter eliminates these risks, ensuring uninterrupted fuel delivery and preserving your engine's health.Key Functions of the Fuel Filter:1. Filtration: The primary function of the fuel filter is to capture and trap contaminants present in the fuel. Made of fine materials like cellulose or synthetic fibers, the filter allows clean fuel to pass through, while effectively retaining harmful particles that can hamper the engine's optimal performance.2. Water Separation: Another crucial role of the fuel filter is to separate any water or moisture that may be present in the fuel. Water infiltration can have adverse effects on the engine's combustion process, causing rusting and corrosion within the fuel system. The fuel filter equipped with a water separator ensures that only dry fuel reaches the engine, minimizing potential damage.3. System Protection: In addition to safeguarding the engine, the fuel filter also plays a role in extending the life of other fuel system components such as the fuel injectors, fuel pump, and other sensitive parts. By filtering out contaminants, the fuel filter prevents these components from unnecessary wear and tear, reducing maintenance costs in the long run.Importance of Regular Fuel Filter Maintenance:To ensure the fuel filter continues to function optimally, regular maintenance is paramount. Over time, the accumulation of debris and contaminants within the filter itself can lead to clogging, reducing the fuel flow and compromising engine performance. Including fuel filter inspection and replacement as a part of routine vehicle maintenance ensures a cleaner and uninterrupted fuel supply, preventing potential breakdowns and costly repairs.Conclusion:The fuel filter might appear insignificant compared to other prominent vehicle components, but its role in ensuring engine performance and longevity is invaluable. By diligently filtering fuel, removing impurities, and maintaining an unobstructed fuel flow, it serves as the unsung hero of your vehicle. A clean fuel filter guarantees optimal engine performance, enhanced fuel efficiency, and reduced maintenance costs. Therefore, prioritize regular fuel filter maintenance, and let this humble yet critical device pave the way for a smooth and hassle-free driving experience.Keywords: Fuel filter, fuel tank, filter system, engine performance, fuel delivery, clean fuel, contaminants, vehicle maintenance, fuel flow, optimal performance, engine efficiency, fuel injectors, fuel pump, vehicle components, engine longevity.

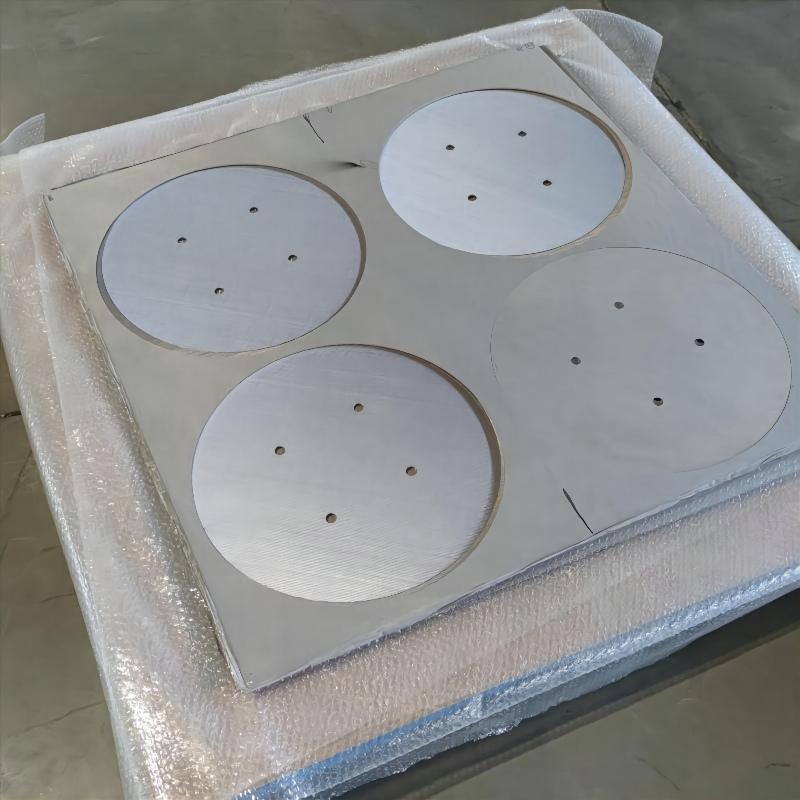

New Innovation in Filtration: Discover the Screen Disc Filter's Amazing Benefits

Screen Disc Filter: Making Water Filtration More Efficient and EffectiveWater is an essential resource, and with increasing population growth, the demand for clean water is also increasing. With water pollution being a common problem across the globe, efficient water filtration systems are important for households, commercial facilities, and industries. One solution that has proved to be effective in ensuring clean water is the Screen Disc Filter.The Screen Disc Filter is an advanced and innovative filtration system that works by removing impurities and particles using discs that have tiny pores. The filter is designed to cater to different types of water filtration purposes, including drinking water, irrigation, and industrial water treatment among others. The system has been designed to cater to the changing needs of the water industry, with modern technologies and innovations incorporated into its design. This efficient filter is slowly gaining popularity over other types of water filtration systems because of its ability to ensure clean water and its cost-effectiveness.The Screen Disc Filter is manufactured by a company (The company name has been removed for privacy purposes) that focuses on producing high-quality filtration systems for diverse industries including agriculture, communities, landscaping, and industrial sectors. The company has a wealth of experience in the field of water treatment, with its team of experts continually researching and developing advanced filtration systems. By leveraging advanced technologies in the manufacturing process, the company ensures that the Screen Disc Filters are of the highest quality and meet the most demanding filtration requirements.One of the core features of the filtration system is its flexibility. The Screen Disc Filter caters to different water filtration requirements, and it is easily customizable to meet specific customer needs. This flexibility makes it practical for various applications, including wastewater treatment in industrial facilities, agriculture, and residential use. Besides, as an advanced filtration system with various types of filtration disc designs and applications, the filter's installation process is easy and straightforward.In addition to being flexible, the system is highly efficient. The filter eliminates impurities and particles such as sediments, sand, microplastics, and other organic matter, ensuring that the filtered water meets high-quality standards. The Screen Disc Filter also operates at a relatively low flow rate, thus reducing energy consumption and maintenance costs.Maintenance is another significant benefit of using the Screen Disc Filter. The filter aids in reducing the cleaning frequency, which saves on the associated operational costs. The system operates with low pressure and water flow, minimizing the chances of wear and tear compared to other filtration systems.Users of the Screen Disc Filter enjoy a cost-effective filtration system that does not compromise on quality. The system guarantees that the filtered water is of high quality and that there is a low risk of clogging, which typically requires regular cleaning. Users save on maintenance costs while reducing their carbon footprint as it is an energy-efficient system. Additionally, the filter has a long lifespan and requires minimal replacement of its parts.Apart from the benefits of the Screen Disc Filter, the company producing the filter has an amazing support system. They have a team of experts who assist with the installation and the maintenance of the filtration unit. The company also offers customer support services, including assistance with spare parts for the filter. This ensures that the customer experience with the company is smooth and hassle-free.In conclusion, water filtration is vital, and people need to be mindful of the type of filtration system they use. The Screen Disc Filter has proven to be an efficient and cost-effective filtration system that caters to various industries and applications. Using advanced technologies in its design and development, the filter is highly flexible, efficient, and easy to maintain. The company producing the filter offers excellent customer service, ensuring that customers receive the necessary assistance with their filter's installation and maintenance. As the benefits of the Screen Disc Filter continue to emerge, it is becoming the preferred choice for many households, commercial facilities, and industries.

Discover the Advantages of Using Wire Mesh in Construction Projects

Title: Wire Mesh Implementation Revolutionizes Construction IndustryIntroduction:In an era where technological advancements are transforming every sphere of our lives, the construction industry is not far behind. One such groundbreaking innovation in construction materials is wire mesh, which has revolutionized the way buildings and infrastructure are constructed. Wire mesh, known for its versatility, strength, and durability, has gained tremendous popularity within the industry due to its numerous applications and cost-effective benefits.Wire Mesh: Redefining Construction TechniquesWire mesh refers to a grid-like structure made of interconnected metal wires. This material is commonly manufactured using stainless steel, but it can also be produced with other materials such as brass or copper. Due to its flexible characteristics, wire mesh can be tailored to meet various construction requirements, making it an invaluable resource for engineers and architects alike.Versatility in Application:The application of wire mesh in construction spans across a wide range of areas. This material is predominantly used as a reinforcement tool for concrete structures, offering unparalleled strength and stability. Wire mesh is often embedded within concrete slabs, walls, and columns to enhance their load-bearing capacity and resist cracks and fractures. Moreover, wire mesh serves as an excellent formwork reinforcement to mitigate concrete shrinkage and enhance its overall structural integrity.Wire mesh also finds extensive use in fencing, providing security and delineating boundaries. Its robust and impenetrable characteristics have made it a popular choice for securing construction sites and other restricted areas. Additionally, wire mesh acts as a protective barrier against wildlife, preventing animals from entering sensitive construction zones while preserving natural habitats.Sustainable Construction:As the global construction industry increasingly embraces sustainability, wire mesh has become an ideal construction material due to its eco-friendly properties. Wire mesh significantly reduces the environmental impact by decreasing material wastage during construction. Its lightweight nature helps minimize transportation costs, resulting in reduced energy consumption and greenhouse gas emissions. Furthermore, wire mesh can be easily recycled, making it a highly sustainable choice for construction projects.Advantages of Wire Mesh:The implementation of wire mesh offers numerous advantages that have positioned it as a preferred construction material:1. Enhanced Structural Strength: Wire mesh acts as a reinforcing mechanism, significantly improving the load-bearing capacity and longevity of structures.2. Cost-Effective Solution: Wire mesh is cost-effective when compared to alternative reinforcement methods. Its installation requires less time, reducing labor costs and project timelines.3. Flexibility: The flexible nature of wire mesh allows it to adapt to various shapes and designs, offering architects the freedom to create unique and visually appealing structures.4. Fire-Resistant: Stainless steel wire mesh exhibits excellent fire resistance, enhancing the safety of buildings and constructions.5. Easy Installation and Maintenance: Wire mesh can be easily installed and requires minimal maintenance over its lifespan, saving time and resources.Industry Leaders Paving the Way:Various companies have emerged as leaders in providing high-quality wire mesh for the construction industry. These companies are constantly innovating and developing new wire mesh products and solutions, improving construction techniques and safety standards. With the incorporation of state-of-the-art machinery and advanced manufacturing processes, these companies ensure that wire mesh is readily available to meet the ever-growing demand for cost-effective and sustainable construction materials.Conclusion:The integration of wire mesh within the construction industry has undoubtedly brought about a revolutionary shift in construction techniques. Its versatility, structural strength, and sustainability make it an indispensable resource within the industry, driving advancements in architecture and providing cost-effective solutions. As the demand for sustainable construction practices continues to rise, wire mesh will undoubtedly play a pivotal role in shaping the future of the construction industry.