Effective Industrial Gas Filters for Clean and Safe Work Environments

By:Admin

Industrial Gas Filter, a leading provider of filtration solutions for industrial applications, has announced the launch of its latest innovative filtering technology. The new product is designed to provide enhanced filtration capabilities for a wide range of industrial gases, ensuring cleaner and safer working environments for businesses in various industries.

With a commitment to delivering high-quality filtration solutions that meet the evolving needs of its customers, Industrial Gas Filter has invested significant resources in researching and developing its latest filtering technology. The result is a cutting-edge filtration system that offers superior performance and reliability, setting a new standard for industrial gas filtration.

The new filtering technology features advanced materials and design elements that enable it to effectively remove a wide range of impurities and contaminants from industrial gases. This includes particulate matter, moisture, oil, and other potentially harmful substances that can compromise the quality and safety of industrial gas streams. By implementing the new filtration system, businesses can minimize the risk of equipment damage, process inefficiencies, and worker exposure to hazardous substances, ultimately improving operational performance and safety.

One of the key advantages of Industrial Gas Filter's new technology is its versatility and adaptability to different industrial applications. Whether used in manufacturing, petrochemical, pharmaceutical, food and beverage, or other industrial settings, the filtering technology can be customized to meet specific gas filtration requirements. This flexibility makes it an ideal solution for businesses with diverse filtration needs, allowing them to benefit from a single, comprehensive filtration system for multiple applications.

In addition to its advanced filtration capabilities, the new technology also boasts enhanced efficiency and durability. With optimized design features and materials, the filtration system offers extended service life, reducing maintenance requirements and associated costs for businesses. Furthermore, the system's efficiency in removing impurities from industrial gases contributes to improved operational performance, energy savings, and reduced environmental impact, aligning with the growing emphasis on sustainability in industrial practices.

Industrial Gas Filter has a long-standing reputation for delivering reliable filtration solutions and exceptional customer support. With a team of experienced engineers and filtration experts, the company is well-equipped to provide comprehensive technical assistance, product customization, and ongoing maintenance services to ensure the optimal performance of its filtration systems. The launch of the new technology further demonstrates Industrial Gas Filter's commitment to continuous innovation and its dedication to meeting the evolving needs of its customers.

"We are thrilled to introduce our latest advanced filtering technology to the market," said the spokesperson for Industrial Gas Filter. "With this innovation, we are able to offer our customers a superior solution for ensuring the cleanliness and safety of their industrial gas streams. We believe that this new technology will make a significant impact in enhancing the operational efficiency and safety of various industries, and we look forward to supporting our customers in implementing this cutting-edge filtration system."

As industrial businesses continue to prioritize the quality and safety of their operations, the demand for advanced filtration solutions remains strong. Industrial Gas Filter's new technology is well-positioned to address this demand, providing businesses with a reliable and effective means of achieving optimal gas filtration performance.

With its commitment to innovation, quality, and customer satisfaction, Industrial Gas Filter is poised to make a significant impact in the industrial filtration market with its latest advanced filtering technology. The company's dedication to continuous improvement and its ability to deliver tailored filtration solutions affirm its position as a trusted partner for businesses seeking high-performance filtration solutions for industrial gases.

Company News & Blog

Enhance Your Windows with Metal Mesh for Added Security and Style

Metal Mesh Set to Revolutionize Window SecurityNew technology has been developed to help homeowners and businesses alike enhance their security in a more discreet and innovative way. The new metal mesh solution is specially designed to offer a more robust window protection system that provides optimal protection against intruders from entering your home or premises.The company has invested heavily in researching and developing this metal mesh solution, which is guaranteed to take the industry by storm. The metal mesh solution is aimed at businesses and homeowners who prioritize their security but don't want to negatively impact on the aesthetic of their property.The current options in the market are limiting when it comes to providing both an aesthetically pleasing and highly functional protection system. The metal mesh solution promises to provide both, making it easier for individuals and companies to have a higher level of security without sacrificing the beauty of their property.The Metal Mesh for Windows is a product that is designed to revolutionize the industry. The patented technology is different from any other product in the market, and this unique selling point has allowed the company to differentiate itself from the competitors. The metal mesh is manufactured with high-quality materials, providing a superior level of strength and durability, ensuring they can withstand even the toughest weather conditions."The product solves a longstanding problem in the market. It has been developed to offer homeowners and businesses a viable solution that provides an immediate response to their security concerns. The innovation offers a level of security not previously practiced, making it a game-changer in the industry," said the company’s CEO.The Mesh product has been designed with a multiple-layered construction, providing additional strength and support to the system. The company's development team has engineered the metal mesh to resist cutting, making it impossible for intruders to gain unauthorized access to the property."Security is a crucial aspect of any home or business, and we are proud to be at the forefront of a new era where security systems are not only functional but beautiful. Our aim is to provide our clients with a solution that meets both their security requirements and aesthetic needs," he added.The product can be customized to a range of sizes, making it a versatile solution that can be tailored to meet client needs. The mesh comes in different colors, allowing us to choose a color that complements their property or blends in with the existing décor.The metal mesh solution is not limited to residential or commercial properties but can work for a variety of applications. It is ideal for properties that are prone to break-ins such as storefronts, museums, and other buildings with artifacts and valuable items. The security solution allows for increased visibility from inside the property while also providing 24/7 protection and peace of mind for the occupants.Installing the metal mesh solution is easy and requires minimal disruption. The product can be installed using standard fixing, ensuring a quick and easy installation process.The security mesh provides added benefits beyond security. It is an excellent solution for reducing the noise levels, preventing debris from entering the property, and even reducing the temperature within the building.In conclusion, the Metal Mesh for Windows is a game-changer in the window security industry. Its patented technology, combined with its flexibility and aesthetic appeal, provides both homes and businesses with excellent security, while also maintaining the beauty of the property. The innovative design is set to take the industry by storm, and clients will be eager to enjoy a new level of security like never before.

Production Line for Expanded Metal Mesh Architrave Beads for Expansion Joints

Expansion Joint Beads – The Backbone of a Strong ConstructionOne of the most important aspects of any construction project is ensuring its durability and longevity. An expansive joint is one of the solutions to the problem of cracks and movement in a building or structure over time. The perfect partner in achieving this is an expansion joint bead.Expansion joint beads, also known as casing beads, are a fundamental component that is used in building and construction projects that require joints. These are thin, durable metal strips that are designed to cover and seal the gaps created between different areas of a structure, such as floors, walls, and ceilings.Casing beads are most commonly used in the construction industry for exterior wall finishes, helping to create a smooth and protective finish around the windows and doors. These beads are also instrumental in reinforcing the integrity of the structure by creating a barrier between the wall surfaces and the window or door frames.Anber expanded metal mesh machine architrave beads production line is a prime example of a top-of-the-line manufacturing process that produces superior quality expansion joint beads. These beads are made from high-quality, corrosion-resistant raw materials and are manufactured through a meticulous, highly advanced production process. In this way, users of Anber Expanded Mesh Casing Bead can be assured of their quality and longevity.There are various types of casings available, such as PVC or plastic beads, but nothing compares to the strength and durability of metal casing beads. Metal joint expansion beads are generally more long-lasting and reliable and guarantee that the structure will remain stable for many years to come.Expanded Architrave Bead Machine offers an assortment of customization options that cater to different demands in constructing buildings. From standard sizes to varying lengths and widths, designs, and colors, it is an adaptable material that can provide an excellent aesthetic and practical finish to the surfaces.The benefits of using expansion joint beads are numerous. Here are some of the most notable:1. Durability: Metal casing beads, particularly those made of galvanized steel, are extremely durable and offer excellent resistance to rust and weather conditions.2. Strength: Casing beads serve as an additional support to the structure and provide extra durability.3. Easy to install: Joint expansion beads are straightforward to install and require no specialized tools or equipment.4. Cost-effective: Metal joint expansion beads offer better value for money than other types of casings due to their longevity and durability.5. Aesthetic finish: With the various options available, casing beads can add an elegant and professional finish to any construction project.In conclusion, it is essential to choose the right materials and ensure proper installation when working on any construction project. Expansion joint beads are an indispensable component in creating a strong and long-lasting structure. With a reliable and reputed supplier like Anber Expanded Mesh Casing Bead, construction professionals and DIY enthusiasts can achieve their desired results with ease and confidence.

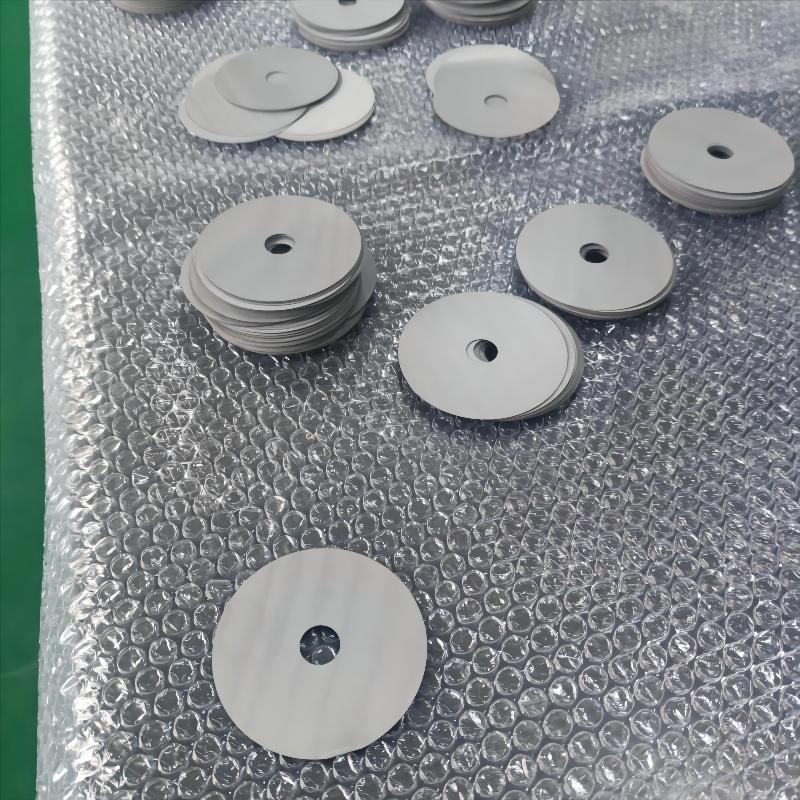

3 Vital Things to Know About Sintered Powder Filters

Sintered Powder Filter Revolutionizes Filtration Technology: A Breakthrough by an Innovative Company[Company Name], a renowned player in the field of filtration technology, has introduced a revolutionary product in the market – the Sintered Powder Filter. This groundbreaking invention promises to redefine the way we approach filtration, offering a highly efficient and reliable solution to a wide range of industries.As we know, filtration is a critical process in various sectors, including pharmaceuticals, chemicals, food and beverage, oil and gas, automotive, and many others. Traditionally, filters have been made using materials like fabric, paper, metal mesh, or ceramics. While these conventional filters have served their purpose, they often come with limitations such as low durability, limited pore size options, or poor overall performance.Addressing these challenges head-on, [Company Name] has leveraged its expertise and innovative mindset to develop the Sintered Powder Filter. This filter is a result of the company's commitment to providing cutting-edge solutions that meet the evolving needs of industries worldwide.So, what makes the Sintered Powder Filter different and superior to its counterparts? The answer lies in its unique construction and advanced features. The filter is manufactured by compacting metal powders, followed by high-temperature sintering. This process creates a highly porous structure with precise particle size distribution and uniform pore sizes.This uniformity in pore sizes is one of the key advantages of the Sintered Powder Filter. It ensures consistent and reliable filtration, removing impurities with exceptional efficiency. The filter can effectively eliminate particles as small as submicron levels, providing a level of filtration precision that surpasses traditional filters.Additionally, the Sintered Powder Filter's structure offers high strength, resulting in superior durability and resistance to harsh operating conditions. It can withstand high temperatures, corrosive chemicals, and high-pressure environments, making it ideal for applications in extreme conditions. This robustness translates into extended filter life and reduced maintenance costs.Moreover, the Sintered Powder Filter's versatility is worth mentioning. Its pore size can be tailored according to specific requirements, making it adaptable to various industries and filtration needs. Whether it is for clarifying liquids, capturing fine particles, or separating solids and gases, this filter can be customized to deliver optimal results.Furthermore, the Sintered Powder Filter offers the advantage of backwashing, a feature absent in conventional filters. This capability allows for easy cleaning and regeneration of the filter, bringing it back to its original performance without the need for replacement. This significantly reduces operational costs and ensures long-term usability, making it an economical choice for industries.[Company Name] takes pride in its commitment to sustainability and recognizes the importance of minimizing its environmental impact. The Sintered Powder Filter aligns perfectly with this ethos, as it is a reusable, eco-friendly solution compared to disposable filters. Its long lifespan, combined with the ability to be cleaned and reused, contributes to a more sustainable approach to filtration.As [Company Name] introduces the Sintered Powder Filter to the market, industries worldwide are eagerly embracing this innovative solution. Early adopters have already reported significant improvements in filtration efficiency, reduced downtime for maintenance, and enhanced product quality.The Sintered Powder Filter represents a game-changer in the field of filtration technology. Its unparalleled filtration precision, durability, versatility, and sustainability make it an attractive choice for businesses across various sectors. As [Company Name] continues to innovate and invest in research and development, we can expect further advancements in filtration technology and more groundbreaking solutions to meet the evolving needs of industries worldwide.

Durable and Reliable Metal Porous Sintered Filter for Industrial Use

Metal Porous Sintered Filter Enhances Filtration Efficiency for Various IndustriesIn today's rapidly evolving industrial landscape, the importance of efficient filtration solutions cannot be overstated. Whether it's in the automotive, aerospace, chemical, or petrochemical industries, the need for precise and reliable filtration systems is paramount. This is where the Metal Porous Sintered Filter, produced by a leading filtration technology company, comes into play. This innovative product has proven to be a game-changer for industries looking to enhance their filtration processes and ensure optimal performance.The Metal Porous Sintered Filter is a cutting-edge filtration solution that offers a combination of high efficiency, durability, and versatility. Its unique design and advanced materials make it an ideal choice for a wide range of applications. From removing impurities in liquids and gases to capturing particles of varying sizes, this filter excels in delivering superior performance across different industrial settings.The secret behind the success of the Metal Porous Sintered Filter lies in its construction. The filter is made from high-quality metal powders that are sintered together to create a porous structure with precise and uniform pore sizes. This sophisticated manufacturing process results in a filter that is capable of achieving exceptional levels of particle retention while maintaining high flow rates. Additionally, the filter's robust construction allows it to withstand extreme temperatures and corrosive environments, making it a reliable and long-lasting solution for demanding industrial applications.One of the key advantages of the Metal Porous Sintered Filter is its adaptability to diverse filtration requirements. With the ability to customize pore sizes, thickness, and overall dimensions, the filter can be tailored to meet specific filtration needs, ensuring optimal performance in different operating conditions. This flexibility makes it an ideal choice for industries that demand precision and reliability in their filtration processes.Furthermore, the Metal Porous Sintered Filter is designed to be easily integrated into existing filtration systems, allowing for seamless upgrades without the need for extensive retooling or modifications. This feature not only enhances the filter's convenience but also makes it a cost-effective solution for businesses looking to improve their filtration efficiency.The company behind the Metal Porous Sintered Filter has established itself as a leader in the field of filtration technology. With a strong focus on research and development, the company has continuously pushed the boundaries of filtration innovation, bringing to market products that set new standards for performance and reliability.With a team of highly skilled engineers and experts, the company is committed to providing comprehensive filtration solutions that address the evolving needs of modern industries. Moreover, the company's dedication to quality and customer satisfaction has earned it a reputation for excellence, with a growing list of clients who rely on its products to ensure the smooth operation of their processes.In addition to the Metal Porous Sintered Filter, the company offers a comprehensive range of filtration products and services, including custom filtration solutions, technical support, and maintenance services. This holistic approach allows the company to cater to the unique requirements of each customer, providing them with tailored solutions that deliver maximum value and performance.Looking ahead, the company remains focused on driving innovation in filtration technology, with a commitment to staying ahead of industry trends and continually raising the bar for filtration efficiency. By leveraging its expertise and resources, the company aims to further expand its product portfolio and enhance its capabilities, ensuring that it continues to be at the forefront of filtration innovation.In conclusion, the Metal Porous Sintered Filter represents a significant advancement in filtration technology, offering unparalleled efficiency, durability, and versatility for a wide range of industrial applications. Backed by a company with a proven track record of excellence and a commitment to innovation, this filter is poised to play a pivotal role in shaping the future of filtration. As industries continue to evolve and demand higher standards for filtration performance, the Metal Porous Sintered Filter stands ready to meet and exceed these expectations, providing businesses with a reliable and effective solution for their filtration needs.

Top Sintered Mesh Filter Disc: Enhance Filtration Efficiency with Advanced Technology

Title: Leading Manufacturer Unveils Cutting-Edge Sintered Mesh Filter Disc, Revolutionizing Filtration SystemsIntroduction:In the rapidly evolving world of filtration technology, renowned industry leader, Manufacturing Co., is making waves with its latest breakthrough - the groundbreaking Sintered Mesh Filter Disc. With an unwavering commitment to innovation and excellence, the company has once again raised the bar by revolutionizing filtration systems across various industries.Body:1. Unveiling the Sintered Mesh Filter Disc:Manufacturing Co. proudly presents the highly-anticipated Sintered Mesh Filter Disc, a cutting-edge product set to transform the way particles are filtered across numerous applications. This advanced filter disc combines superior materials, precision manufacturing, and innovative design to deliver unmatched performance, improved efficiency, and prolonged service life.2. Unparalleled Filtration Efficiency:The Sintered Mesh Filter Disc boasts an exceptionally high level of filtration efficiency, enabling it to remove even the tiniest particles with remarkable accuracy. The tightly-knit mesh structure ensures an optimal flow rate, allowing for efficient filtration while maintaining minimal pressure drop. This remarkable feature makes it an ideal choice for industries such as pharmaceuticals, petrochemicals, food and beverage, and wastewater treatment.3. Enhanced Durability and Longevity:Manufacturing Co.'s Sintered Mesh Filter Disc is built to withstand harsh conditions and extreme temperatures, making it a highly durable and reliable filtration solution. The carefully selected sintered mesh materials enable the disc to resist corrosion and oxidation, ensuring a prolonged service life compared to traditional filters. This longevity translates into significant cost savings for industries that heavily rely on filtration systems.4. Versatile Applications:The versatility of the Sintered Mesh Filter Disc is a standout feature, as it can be seamlessly integrated into various applications across diverse industries. Its exceptional filtration efficiency, coupled with the ability to withstand high pressure and temperature, makes it an excellent choice for applications such as gas and liquid separation, catalyst recovery, polymer filtration, and more. The adaptability and wide range of applications make this filter disc a truly indispensable component in numerous industrial processes.5. Quality Manufacturing Process:Manufacturing Co. employs state-of-the-art manufacturing techniques to ensure the highest level of quality and precision during the production of the Sintered Mesh Filter Disc. Relying on advanced sintering technology, the company achieves a perfectly uniform and robust mesh structure, resulting in consistent performance and exceptional product reliability. Additionally, a stringent quality control process is implemented at every stage to guarantee that each filter disc meets or exceeds industry standards.6. Commitment to Sustainability:As a responsible manufacturer, Manufacturing Co. prioritizes sustainability in every aspect of its operations. The Sintered Mesh Filter Disc reflects this commitment, as it is designed for ease of maintenance and cleaning, effectively reducing waste and minimizing the need for frequent replacements. With its exceptional durability and longevity, the filter disc plays a pivotal role in promoting eco-friendly practices within the industry.Conclusion:Manufacturing Co's introduction of the state-of-the-art Sintered Mesh Filter Disc marks a significant milestone in the evolution of filtration technology. Combining exceptional filtration efficiency, enhanced durability, and unmatched versatility, this groundbreaking product is set to revolutionize filtration systems across a wide range of industries. With a steadfast commitment to innovation and sustainability, Manufacturing Co. continues to be at the forefront of delivering cutting-edge solutions that address the evolving needs of global industries.

Top Quality Stainless Steel Wire Mesh for Your Industrial Needs

Stainless Steel Wire Mesh: A Versatile and Durable Choice for Multiple ApplicationsStainless steel wire mesh is an extremely versatile material that can be used in a variety of industrial and commercial applications. This material is known for its strength, durability and resistance to corrosion and rust, making it ideal for use in harsh environments.One of the most common types of stainless steel wire mesh is the square welded wire mesh, which is made up of a series of square-shaped wires that are welded together at their intersection points. This creates a strong and durable mesh that is ideal for use in fencing, partitions, window guards, and other applications where security and durability are important.Another type of stainless steel wire mesh is the hexagonal wire mesh, which is made up of a series of interconnected hexagons. This type of mesh is commonly used in agricultural and horticultural applications, such as bird cages, rabbit hutches, and plant supports.Additionally, stainless steel wire mesh is also available in spring steel wire mesh. This type of mesh is made up of a series of tightly coiled springs that are interconnected to create a strong and flexible mesh. This type of mesh is ideal for use in applications that require flexibility and deformation resistance.The Benefits of Stainless Steel Wire MeshStainless steel wire mesh offers a number of advantages over other materials, including:1. High strength and durability: Stainless steel wire mesh is extremely durable and can withstand heavy loads without breaking or bending. It is also resistant to corrosion and rust, making it ideal for use in harsh environments, both indoors and outdoors.2. Wide range of applications: Stainless steel wire mesh can be used in a variety of applications, including fencing, window guards, partitions, bird cages, rabbit hutches, and plant supports.3. Easy to install: Stainless steel wire mesh is easy to install and can be cut to fit any size or shape. It also requires minimal maintenance, making it a cost-effective and long-lasting solution.4. Hygienic: Stainless steel wire mesh is easy to clean and maintain, making it an ideal choice for applications where hygiene is important, such as in food processing and healthcare facilities.5. Appearance: Stainless steel wire mesh is available in a variety of different finishes, including brushed, polished, and powder-coated, making it easy to match the mesh with the aesthetics of the surrounding environment.ConclusionStainless steel wire mesh is a versatile and durable material that is ideal for use in a wide range of industrial and commercial applications. With its high strength, durability, resistance to corrosion and rust, and wide range of applications, stainless steel wire mesh has become a popular choice among architects, designers, and engineers around the world.Moreover, if you need flexibility and deformation resistance, then spring steel wire mesh is also an ideal option for you. With its tight coiled springs interconnected to create a strong but flexible mesh, it can be used in various applications as well.So, if you are looking for a material that is strong, durable, and long-lasting, then stainless steel wire mesh is the perfect choice for your project.

Affordable and Durable Lightweight Steel Mesh for Construction Projects

Innovative Lightweight Steel Mesh Revolutionizes Construction IndustryThe construction industry is constantly evolving with new technologies and materials that aim to improve efficiency and durability. Recently, a groundbreaking lightweight steel mesh has been introduced by a leading steel manufacturer, {Company Name}. This innovative product is set to revolutionize the construction industry and offer a wide range of benefits for various applications.{Company Name} has been a prominent player in the steel manufacturing industry for over two decades. With a strong emphasis on research and development, the company has continuously strived to introduce new and improved products that meet the evolving needs of the construction sector. The introduction of the lightweight steel mesh is a testament to their commitment to innovation and excellence.The lightweight steel mesh, which is made from high-quality steel, offers a multitude of advantages over traditional materials. Its superior strength-to-weight ratio makes it an ideal choice for various construction applications. The use of this innovative material can significantly reduce the overall weight of structures, thereby minimizing the load on supporting elements and reducing the overall construction costs.In addition to its lightweight properties, the steel mesh also boasts exceptional durability and resistance to corrosion. This ensures that structures built using this material will have a longer lifespan and require minimal maintenance, resulting in long-term cost savings for property owners and developers. Furthermore, the lightweight steel mesh is also highly versatile and can be tailored to suit specific project requirements, making it an ideal choice for a wide range of applications.One of the key advantages of the lightweight steel mesh is its environmental sustainability. With a growing focus on eco-friendly construction practices, this innovative material aligns with the industry's push towards more sustainable building solutions. Its lightweight nature reduces the overall environmental impact of construction projects, while its durability ensures that structures built using this material will have a reduced carbon footprint over their lifecycle.The introduction of the lightweight steel mesh has garnered significant attention within the construction industry, with developers and contractors expressing keen interest in adopting this innovative material for their upcoming projects. Its potential to enhance structural integrity, reduce construction costs, and contribute to sustainable building practices has positioned it as a game-changer in the industry.{Company Name} is committed to supporting its clients in integrating this revolutionary material into their projects. The company provides comprehensive technical support and consultation services to ensure that the lightweight steel mesh is seamlessly incorporated into construction plans, enabling clients to fully capitalize on the benefits it offers.The lightweight steel mesh has been met with enthusiasm from industry professionals, with many recognizing its potential to streamline construction processes and deliver superior results. As the demand for innovative and sustainable building materials continues to grow, the introduction of the lightweight steel mesh has positioned {Company Name} as a trailblazer in the construction sector.With its superior strength and durability, as well as its sustainable and cost-effective properties, the lightweight steel mesh is poised to redefine construction standards and set new benchmarks for excellence in the industry. As the uptake of this innovative material gains momentum, it is expected to become a staple in construction projects, offering a compelling solution for developers, contractors, and property owners alike.

Durable and Versatile Metal Mesh for Various Applications

Stainless Steel Metal Mesh Revolutionizes Industrial Applications Stainless steel metal mesh has become an indispensable material in various industries due to its durability, strength, and versatility. With the escalating demand for high-quality metal mesh, more and more companies are venturing into the production of this essential material. One such company, which has made a significant impact in this industry, is the {remove brand name}.{Remove brand name} is a leading manufacturer of stainless steel metal mesh, and they have been at the forefront of innovation in the field. The company's commitment to producing top-quality metal mesh has resulted in them becoming a go-to supplier for a wide range of industries, including construction, automotive, aerospace, and more.The key to the success of {remove brand name} lies in their dedication to quality and their relentless pursuit of excellence. The company has invested heavily in state-of-the-art manufacturing facilities and has employed a team of highly skilled engineers and technicians to ensure that their metal mesh products meet the highest standards.One of the key advantages of stainless steel metal mesh is its resistance to corrosion, making it ideal for use in harsh and demanding environments. {Remove brand name} has capitalized on this attribute and has developed a range of metal mesh products that are specifically designed to withstand the rigors of industrial applications. From filtration and sieving to screening and protection, their metal mesh products have proven to be highly effective in a myriad of applications.In addition to their standard range of metal mesh products, {remove brand name} also offers custom manufacturing services, allowing their customers to tailor the specifications of the metal mesh to meet their specific needs. This level of flexibility has made {remove brand name} a preferred supplier for many companies who require bespoke metal mesh solutions for their projects.Furthermore, the company's commitment to sustainability is evident in their manufacturing processes. They have implemented eco-friendly practices and have adopted the use of recycled materials wherever possible, reducing the environmental impact of their operations.One of the most notable achievements of {remove brand name} is their development of a pioneering stainless steel metal mesh that incorporates advanced technologies to enhance its performance. This innovative product has been met with great enthusiasm from the industry, as it promises to push the boundaries of what stainless steel metal mesh can achieve.The advanced metal mesh developed by {remove brand name} boasts improved strength, durability, and flexibility, making it an ideal choice for even the most demanding applications. Its enhanced properties provide a significant advantage to companies looking for reliable and long-lasting metal mesh solutions.Furthermore, the innovative metal mesh from {remove brand name} has been instrumental in driving advancements in a wide range of industries. Its use in the construction sector has resulted in the creation of safer and more resilient structures, while in the automotive industry, it has contributed to the development of more efficient and lightweight vehicles. Additionally, in the aerospace industry, the advanced metal mesh has been employed in the manufacturing of aircraft components, where its superior properties have proven to be invaluable.Looking ahead, {remove brand name} remains committed to pushing the boundaries of innovation in the metal mesh industry. With a relentless focus on quality, sustainability, and technological advancement, the company is poised to continue leading the way in providing high-performance stainless steel metal mesh solutions to meet the evolving needs of industries around the globe.In conclusion, stainless steel metal mesh has emerged as a crucial material for a wide array of industrial applications, and companies like {remove brand name} have played a pivotal role in its proliferation. With a strong commitment to quality, innovation, and sustainability, {remove brand name} has established itself as a trusted partner for companies seeking reliable and high-performance metal mesh solutions. As the demand for stainless steel metal mesh continues to grow, {remove brand name} is well-positioned to drive further advancements in this essential industry.

Efficient Disc Filters: Enhancing Screening Performance for Diverse Applications

Title: Revolutionizing Filtration Technology: Screen Disc Filter Sets New Standards in Sustainable Water Management Introduction:Water scarcity is a global concern, with many regions facing severe challenges in accessing safe and clean water for daily use. As a result, it becomes crucial to develop innovative filtration technologies that not only ensure higher filtration efficiency but also promote sustainability. In this quest, a company has pioneered the design and production of the revolutionary Screen Disc Filter – an advanced filtration system that aims to revolutionize water management practices.Company Background:[Company Name], an industry leader in water filtration solutions, has been at the forefront of developing cutting-edge technologies to address the world's increasing water scarcity issues. With a strong focus on sustainability and environmental stewardship, the company has consistently driven ground-breaking advancements in filtration systems.Screen Disc Filter Overview:The Screen Disc Filter, developed by [Company Name], is a state-of-the-art filtration system designed to remove impurities and contaminants, guaranteeing the delivery of water that meets the highest quality standards. Its unique feature is the implementation of an innovative, self-cleaning mechanism that minimizes maintenance requirements, increases filtration efficiency, and prolongs the lifespan of the filter.Filtration Process:The Screen Disc Filter employs a multi-stage filtration process that ensures exceptional water purification. The system consists of a series of stacked discs, each containing micron-sized screens. Water flows through these screens, trapping suspended particles such as sediments, debris, and microorganisms. The precisely engineered design of the discs ensures optimum water flow, preventing clogging and maintaining consistent filtration performance.Self-Cleaning Mechanism:One of the standout features of the Screen Disc Filter is its efficient self-cleaning mechanism. The system employs a combination of high-pressure backwashing and suction cleaning to dislodge trapped particles from the screens. This unique automated process significantly reduces downtime, as the filter can continue operating while cleaning cycles occur. This not only minimizes maintenance costs but also enhances the overall efficiency and reliability of the filtration system.Key Features and Benefits:1. High Filtration Efficiency: The Screen Disc Filter offers unmatched filtration efficiency, capable of removing particles as small as a few microns. This ensures the delivery of clean, clear water for various applications, including industrial processes, agriculture, and municipal water supply.2. Reduced Maintenance: The self-cleaning mechanism eliminates the need for frequent manual cleaning, reducing maintenance efforts and costs. This makes the Screen Disc Filter a cost-effective solution for long-term sustainable water management.3. Enhanced Durability: The robust construction of the Screen Disc Filter ensures its durability and longevity, even under demanding operating conditions. Its corrosion-resistant materials and advanced engineering minimize wear and tear, guaranteeing reliable filtration performance over its extended lifespan.4. Environmental Sustainability: By efficiently removing impurities without excessive backwashing or chemical treatment, the Screen Disc Filter helps conserve water resources and reduces the environmental impact associated with traditional filtration methods.Conclusion:In a world grappling with water scarcity, the Screen Disc Filter represents a game-changing advancement in water filtration technology. With its exceptional efficiency, low maintenance requirements, and sustainability-focused design, this innovative filter provides a reliable solution for water management across various sectors. [Company Name] continues to demonstrate its commitment to developing revolutionary products that address global challenges, ensuring a sustainable and brighter future for water access worldwide.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.