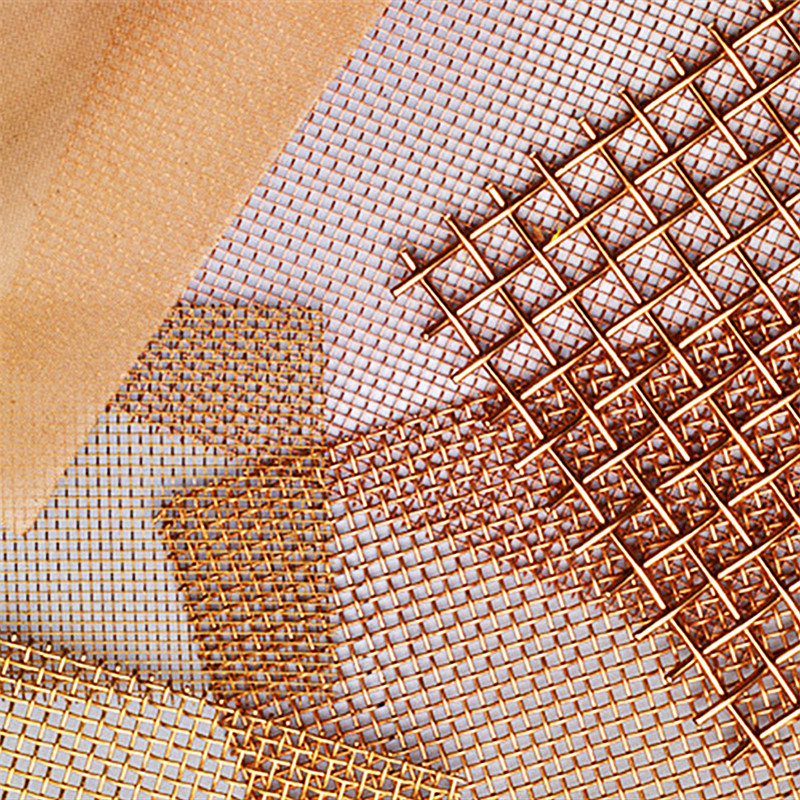

Durable and Corrosion-Resistant Metal Mesh Used in Various Applications

By:Admin

{Company Name} is a leading manufacturer and supplier of Monel Mesh, offering a wide range of specifications and customization options to meet the unique needs of their customers. With years of experience in the industry, the company has built a solid reputation for delivering high-quality products and exceptional customer service.

Monel Mesh is a type of woven wire mesh that is made from a high-performance alloy known as Monel. This alloy is composed of approximately 65-70% nickel, 20-29% copper, and small amounts of iron, manganese, silicon, and carbon. The combination of these elements gives Monel Mesh its exceptional corrosion resistance, strength, and durability, making it suitable for a wide range of applications.

One of the key advantages of Monel Mesh is its resistance to corrosion, especially in harsh environments such as marine or chemical processing plants. This makes it an ideal choice for applications where traditional materials may fail due to corrosion, such as filtration, separation, and screening processes.

In addition to its corrosion resistance, Monel Mesh also offers excellent mechanical properties, including high tensile strength, toughness, and resistance to high temperatures. This makes it suitable for demanding applications such as aerospace, automotive, and industrial manufacturing.

{Company Name} is committed to meeting the specific needs of their customers by offering custom fabrication services for Monel Mesh. This includes custom sizing, shaping, and finishing to ensure that the mesh meets the exact requirements of each application. With their state-of-the-art manufacturing facilities and skilled engineers, the company is able to deliver high-quality, precision-engineered Monel Mesh products to their customers.

The versatility of Monel Mesh also extends to its wide range of applications, including filtration, separation, screening, and reinforcement in industries such as aerospace, oil and gas, marine, chemical processing, and automotive. Its combination of high-performance characteristics and customizability makes it a valuable material for a wide range of industries.

As a leading supplier of Monel Mesh, {Company Name} has established a strong global presence, serving customers around the world with their high-quality products and reliable service. The company has built long-standing relationships with a diverse range of industries, earning a reputation for excellence and innovation in the field of advanced materials.

With a commitment to quality, innovation, and customer satisfaction, {Company Name} continues to lead the way in the development and supply of Monel Mesh. Their dedication to meeting the unique needs of their customers and delivering outstanding products has positioned them as a trusted partner for businesses seeking high-performance materials for their applications.

In conclusion, Monel Mesh, offered by {Company Name}, is a high-performance material that offers exceptional corrosion resistance, strength, and durability. With its wide range of applications and customizability, Monel Mesh has become a valuable solution for industries around the world. As a leading manufacturer and supplier of Monel Mesh, {Company Name} continues to set the standard for excellence and innovation in the field of advanced materials.

Company News & Blog

Exploring the Applications and Benefits of Fine Woven Wire Mesh

[Company Introduction]Founded in [year], [Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With our state-of-the-art facilities and innovative technologies, we have successfully established a reputation for producing high-quality wire mesh solutions tailored to meet the diverse needs of various industries worldwide. Our commitment to excellence, customer satisfaction, and continuous improvement has made us a preferred choice for businesses seeking reliable and customized wire mesh solutions.[News Content]Title: Industry Leader [Company Name] Unveils Innovative Fine Woven Wire Mesh Solution[City, Date] - As consumer demands for advanced technological products continue to rise, companies across various industries are constantly seeking innovative materials to meet these requirements. Recognizing this need, [Company Name], a renowned manufacturer of wire mesh products, is delighted to unveil its latest development in the form of an advanced fine woven wire mesh solution.The newly launched product, designed to cater to the demanding requirements of multiple industries, signifies a significant leap forward in terms of technological advancement and reliability. Fine woven wire mesh is widely used in sectors such as automotive, aerospace, architecture, and industrial applications. Its unique characteristics, including superior strength, durability, and precision, make it an ideal choice for a wide range of applications.[Company Name]'s fine woven wire mesh is manufactured using the latest state-of-the-art techniques, ensuring impeccable quality and consistency. The production process involves meticulously weaving individual wires together, resulting in a tightly-knit and durable mesh structure. This level of precision guarantees the product's capability to withstand extreme temperatures, high pressure, and harsh environmental conditions.One of the key advantages of [Company Name]'s fine woven wire mesh is its versatility. With customizable parameters such as wire diameter, mesh count, and material selection, customers can easily select the perfect solution to meet their specific project requirements. Whether it's filtration, separation, protection, or reinforcement, the fine woven wire mesh can be tailored to deliver exceptional results.Moreover, [Company Name] recognizes the importance of sustainability and environmental responsibility. The newly developed fine woven wire mesh is engineered using eco-friendly materials, ensuring compliance with the latest industry standards and regulations. This eco-conscious approach aligns with the company's commitment to creating a greener tomorrow while providing advanced solutions to meet current market needs.In addition to the impeccable quality of the fine woven wire mesh, [Company Name] offers comprehensive technical support and assistance to its customers. With dedicated teams of experts, the company ensures that customers receive the necessary guidance in selecting the most suitable wire mesh solution and provides valuable insights into its application and performance."We are thrilled to introduce our latest fine woven wire mesh solution to the market," says [Name], [Company Name]'s CEO. "Through years of research and development, we have created a product that not only meets the demanding requirements of various industries but also contributes to a sustainable environment. Our team is dedicated to providing innovative and customized solutions to our esteemed clients, ensuring their success in their respective fields."As industries continue to evolve and demand cutting-edge materials, [Company Name] reaffirms its commitment to pushing the boundaries of technological advancements in the wire mesh industry. With its latest fine woven wire mesh solution, the company positions itself as a reliable partner in meeting customers' evolving needs and contributing to the overall progress of industries globally.About [Company Name]:[Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as an industry leader over the years. From automotive to architectural applications, [Company Name] provides reliable and customized wire mesh solutions to various industries across the globe.Press Contact:[Name][Job Title][Company Name][Phone Number][Email]

Metal Wire Mesh Production: Industrial and Conveyor Belt Mesh from Special Weaving Machines

: A Strong and Versatile Material for Diverse Applications Industrial metal mesh, also known as wire mesh or wire cloth, is a versatile material that is widely used in various industries, including construction, mining, oil and gas, agriculture, automotive, and many others. It is made by weaving or welding metal wires together to create a grid-like pattern that can be customized to meet specific requirements. In this blog, we will explore the benefits and applications of industrial metal mesh and why it is a popular choice for many industrial applications.Benefits of Industrial Metal MeshIndustrial metal mesh offers several advantages that make it a sought-after material for a wide range of applications. Some of the key benefits of industrial metal mesh include:1. Strength and Durability: Industrial metal mesh is known for its strength and durability, making it ideal for use in heavy-duty applications that require a robust material.2. Versatility: Industrial metal mesh is available in a range of materials, such as stainless steel, galvanized steel, brass, and copper, as well as different wire sizes, weaves, and coatings. This versatility allows it to be used in numerous applications, from filtration to decoration.3. Easy to Customize: Industrial metal mesh can be easily customized based on specific requirements, such as size, shape, and opening, to ensure it meets the exact specifications needed to get the job done.4. Cost-Effective: Industrial metal mesh is a cost-effective solution compared to other materials, such as solid metal, and can help companies save money on manufacturing and maintenance costs.Applications of Industrial Metal MeshIndustrial metal mesh is used in a wide range of applications across various industries, such as:1. Filtration: Industrial metal mesh is used in filtration systems to remove unwanted particles from liquids and gases. It is commonly used in industries such as chemical processing, food and beverage, and pharmaceuticals.2. Separation: Industrial metal mesh is used for separating and grading materials. For example, it is used in mining and construction industries to separate rocks and gravel.3. Security: Industrial metal mesh is used as a security barrier, such as window screens, fencing, and cages, in prisons, airports, and other high-security areas.4. Conveyor Belts: Industrial metal mesh is used as a conveyor belt material in the food and beverage industry, where hygiene is critical, as it is easy to clean and doesn't harbor bacteria.5. Decoration: Industrial metal mesh is also used as a decorative material in architecture and interior design. It can be used as cladding, facades, and partitions to add visual interest to a space.ConclusionIndustrial metal mesh is a versatile material that offers a range of benefits and can be used in various applications. Its strength, durability, versatility, easy customization, and cost-effectiveness make it an attractive choice for many industrial applications. Whether you are looking for a filtration system, separation solution, security barrier, conveyor belt material, or decorative element, industrial metal mesh can meet your needs. If you need help selecting the right industrial metal mesh for your application, contact a reputable manufacturer or supplier for expert advice.

The Latest Advancements in Sintered Metal Candle Filter Technology Revealed

Sintered Metal Filter: The New Standard for Candle FiltrationCandle filtration is a popular and effective method of filtering liquids. In recent times, the use of sintered metal candle filters has revolutionized the filtration industry by setting a new standard of efficiency and effectiveness. Sintered metal candle filters are made from fine metal powders that are formed into a filter element under high temperature and pressure conditions. These filters are used in various industries including petrochemical refineries, oil and gas production, food and beverage processing, and pharmaceutical manufacturing.Sintered metal candle filters are designed to remove impurities from liquids by trapping them in the pores of the filter element. These filters have a high dirt-holding capacity and offer excellent purification efficiency. They can filter out particles as small as 0.5 microns. Additionally, sintered metal candle filters operate at low pressure drop, which means that they save energy and reduce operating costs.One company that has been at the forefront of producing sintered metal candle filters is {company name}. They have been supplying sintered metal filters to various industries for more than a decade. Their filters are known for their high quality, durability, and reliability. The company has invested heavily in research and development to improve the performance of their filters, and as a result, their products are highly sought after in the market.In addition to producing sintered metal candle filters, {company name} also provides filter cleaning and reconditioning services. This is important because filters that are not cleaned and maintained properly can become clogged with dirt and other impurities. This can lead to reduced filter efficiency or even filter failure. {Company name}’s cleaning and reconditioning services help to prolong the lifespan of the filter element and ensure that it operates at optimal efficiency.Sintered metal candle filters from {company name} have been used in various applications across different industries. For example, they have been used in the petrochemical industry to remove impurities from the oil before it is processed further. They have also been used in the food and beverage industry to remove solids, bacteria, and other contaminants from liquids such as juice, beer, and wine. In the pharmaceutical industry, sintered metal candle filters have been used to remove impurities from drugs, vaccines, and other medical products.One of the benefits of using sintered metal candle filters from {company name} is that they are customizable. The company can produce filters of different sizes, shapes, and specifications to meet the specific needs of different customers. This ensures that their filters can be used in a wide range of applications.Sintered metal candle filters from {company name} have been well received by their customers. One of their clients, a large oil and gas company, reported that the filters improved their production efficiency by reducing the downtime caused by frequent filter changes. Another customer, a pharmaceutical manufacturing company, reported that {company name}’s filters helped them to meet the regulatory requirements for purity and quality of their products.In conclusion, sintered metal candle filters have set a new standard for filtration efficiency and effectiveness. Companies such as {company name} have been instrumental in producing high-quality sintered metal candle filters that are used in various industries. The durability, reliability, and customizability of their filters have made them a popular choice for many customers. With their commitment to research and development, {company name} is poised to continue supplying the market with innovative sintered metal candle filters that meet the evolving needs of different industries.

Silver Coated Aluminum Powder - High Quality & Purity - 25g, -200 Mesh, 99.9%

Aluminum is one of the most versatile metals that has continued to revolutionize modern industries, from transportation to construction and even aerospace. The use of aluminum in various industries has become increasingly popular over recent decades, thanks to its unique properties, such as its durability, strength, and lightweight nature.Leading in the production of aluminum products is Alfa Aesar, a leading manufacturer of research chemicals and materials. Alfa Aesar has been in the industry for over 50 years, providing high-quality aluminum products that meet the needs and requirements of different industries.One of their most popular aluminum products is their silver-coated aluminum powder, typically -200 mesh and 99.9% pure (metals basis), and contains 19-21% wt of silver (Ag). This product is perfect for industries that require an aluminum product with high electrical conductivity, including the electrical and electronics industry, aerospace, and defense industry.Aluminum products typically possess a good electrical conductivity level; however, by adding a thin layer of silver, the electrical conductivity is improved further. This makes silver-coated aluminum an excellent material for producing electrical contacts and conductors.Additionally, the coating of silver provides a high level of corrosion resistance, improving the durability and longevity of products made with this silver-coated aluminum powder. This property is vital, particularly for products used in the construction industry, where exposure to harsh weather conditions is expected.The use of Alfa Aesar's silver-coated aluminum powder is not limited to the electrical and electronics industry, aerospace, and defense industry; it is also applicable in the production of automotive parts, additive manufacturing processes, and coatings. This further emphasizes the versatility of aluminum products and Alfa Aesar's dedication to providing high-quality materials that meet the various needs of modern industries.Alfa Aesar's manufacturing processes are environmentally friendly and comply with industry standards. The company has a long-standing passion for innovation, and their team of experienced engineers and scientists continually work towards developing high-performance products that meet global customer demands.The company's customer service team is knowledgeable and always ready to provide needed technical support to ensure that customers get the best aluminum products that align with their business needs. Customers can also access educational and technical resources made available on their website to improve their understanding of the products.Alfa Aesar's dedication to producing high-quality, reliable aluminum products has earned them international recognition and numerous awards, making them a leader in the industry. Their commitment to research and development, coupled with their adherence to industry standards, ensures that the company continues to provide top-quality products and services to their customers globally.In conclusion, aluminum products are increasingly becoming popular in various industries, and Alfa Aesar's silver-coated aluminum powder is one of the most sought-after products. Its unique properties make it an excellent material for producing electrical contacts and conductors, automotive parts, additive manufacturing processes, and coatings. Alfa Aesar's commitment to innovation, high-quality production, and excellent customer service has placed them among the top manufacturers of aluminum products globally.

Discover the Versatility and Durability of Wire Mesh Products

Title: Innovations in Wire Mesh Technology Revolutionize Various IndustriesIntroduction:Wire mesh is a versatile material that has found applications in numerous industries such as construction, agriculture, filtration, and automotive. In recent years, Cooper Wire Mesh, a leading manufacturer in the wire mesh industry, has emerged as a pioneer in developing innovative wire mesh solutions that cater to the ever-evolving needs of these industries.1. Application in the Construction Industry:Cooper Wire Mesh has revolutionized the construction industry with its cutting-edge wire mesh products. Their high-quality and durable wire mesh materials have become an integral component in reinforced concrete structures. By enhancing the strength and stability of the construction materials, Cooper Wire Mesh ensures the safety and longevity of buildings, bridges, and other infrastructure projects.Furthermore, their wire mesh solutions also offer effective solutions for designing and constructing spectacular architectural facades. The versatility of Cooper Wire Mesh enables architects to create unique, visually appealing designs while still maintaining structural integrity.2. Advancements in Agricultural Applications:In the agricultural sector, Cooper Wire Mesh has introduced several innovative solutions to address the challenges faced by farmers globally. Their wire mesh fencing and netting products provide effective protection against pests, predators, and environmental factors that can harm crops. These solutions have proven crucial in ensuring increased crop yield and reducing crop loss due to unwanted intrusions.Additionally, Cooper Wire Mesh has developed state-of-the-art mesh systems for enclosing livestock and creating animal enclosures. These mesh solutions offer both strength and flexibility, ensuring the safety and well-being of livestock while allowing for easy maintenance and cost-effective installation.3. Filtration Solutions for Enhanced Industrial Performance:Cooper Wire Mesh has also been at the forefront of developing advanced filtration solutions for various industrial applications. Their wire mesh filters and screens are designed to meet specific requirements, ensuring superior performance and durability.These filtration products find extensive use in oil and gas, chemical processing, and pharmaceutical industries, where the removal of impurities and contaminants from liquids and gases is crucial. Cooper Wire Mesh's technological advancements has led to the development of mesh materials with precise pore sizes and enhanced filtration efficiency, leading to improved product quality and reduced maintenance costs.4. Revolutionizing the Automotive Industry:With increasing emphasis on high-performance and lightweight vehicles, Cooper Wire Mesh has made significant contributions to the automotive industry. Their wire mesh materials are used as reinforcing elements in the production of automobile parts, providing better structural integrity and crash-resistance. Additionally, Cooper Wire Mesh's mesh grilles and protective mesh solutions have gained popularity in the automotive sector for their aesthetic appeal and protection against debris.Conclusion:The innovative wire mesh solutions created by Cooper Wire Mesh have undoubtedly transformed a wide range of industries, from construction and agriculture to filtration and automotive sectors. By constantly pushing boundaries and developing cutting-edge technologies, Cooper Wire Mesh has become the go-to supplier for wire mesh solutions worldwide. With their dedication to quality, reliability, and customer-centric approach, Cooper Wire Mesh is sure to continue revolutionizing the industries they serve.

Efficient Disc Filters: Enhancing Screening Performance for Diverse Applications

Title: Revolutionizing Filtration Technology: Screen Disc Filter Sets New Standards in Sustainable Water Management Introduction:Water scarcity is a global concern, with many regions facing severe challenges in accessing safe and clean water for daily use. As a result, it becomes crucial to develop innovative filtration technologies that not only ensure higher filtration efficiency but also promote sustainability. In this quest, a company has pioneered the design and production of the revolutionary Screen Disc Filter – an advanced filtration system that aims to revolutionize water management practices.Company Background:[Company Name], an industry leader in water filtration solutions, has been at the forefront of developing cutting-edge technologies to address the world's increasing water scarcity issues. With a strong focus on sustainability and environmental stewardship, the company has consistently driven ground-breaking advancements in filtration systems.Screen Disc Filter Overview:The Screen Disc Filter, developed by [Company Name], is a state-of-the-art filtration system designed to remove impurities and contaminants, guaranteeing the delivery of water that meets the highest quality standards. Its unique feature is the implementation of an innovative, self-cleaning mechanism that minimizes maintenance requirements, increases filtration efficiency, and prolongs the lifespan of the filter.Filtration Process:The Screen Disc Filter employs a multi-stage filtration process that ensures exceptional water purification. The system consists of a series of stacked discs, each containing micron-sized screens. Water flows through these screens, trapping suspended particles such as sediments, debris, and microorganisms. The precisely engineered design of the discs ensures optimum water flow, preventing clogging and maintaining consistent filtration performance.Self-Cleaning Mechanism:One of the standout features of the Screen Disc Filter is its efficient self-cleaning mechanism. The system employs a combination of high-pressure backwashing and suction cleaning to dislodge trapped particles from the screens. This unique automated process significantly reduces downtime, as the filter can continue operating while cleaning cycles occur. This not only minimizes maintenance costs but also enhances the overall efficiency and reliability of the filtration system.Key Features and Benefits:1. High Filtration Efficiency: The Screen Disc Filter offers unmatched filtration efficiency, capable of removing particles as small as a few microns. This ensures the delivery of clean, clear water for various applications, including industrial processes, agriculture, and municipal water supply.2. Reduced Maintenance: The self-cleaning mechanism eliminates the need for frequent manual cleaning, reducing maintenance efforts and costs. This makes the Screen Disc Filter a cost-effective solution for long-term sustainable water management.3. Enhanced Durability: The robust construction of the Screen Disc Filter ensures its durability and longevity, even under demanding operating conditions. Its corrosion-resistant materials and advanced engineering minimize wear and tear, guaranteeing reliable filtration performance over its extended lifespan.4. Environmental Sustainability: By efficiently removing impurities without excessive backwashing or chemical treatment, the Screen Disc Filter helps conserve water resources and reduces the environmental impact associated with traditional filtration methods.Conclusion:In a world grappling with water scarcity, the Screen Disc Filter represents a game-changing advancement in water filtration technology. With its exceptional efficiency, low maintenance requirements, and sustainability-focused design, this innovative filter provides a reliable solution for water management across various sectors. [Company Name] continues to demonstrate its commitment to developing revolutionary products that address global challenges, ensuring a sustainable and brighter future for water access worldwide.

Get Tantalum Aluminide at Competitive Prices and Fast Delivery Times

Introduction:Tantalum Aluminide is a popular material in the manufacturing industry due to its unique chemical and physical properties. It is a corrosion-resistant metal that is commonly used in a wide range of applications, including aerospace, chemical processing, and medical implants. In this blog, we will discuss the properties, applications, and benefits of Tantalum Aluminide in detail. We will also take a brief look at Tantalum Wire Mesh, another popular material used in various industrial applications.Properties of Tantalum Aluminide:Tantalum Aluminide is a silvery grey, ductile, and metallic alloy composed of tantalum and aluminum. The combination of tantalum and aluminum provides excellent mechanical strength, high-temperature stability, and corrosion resistance. Tantalum Aluminide has a low density of 8.4 g/cm³, making it a suitable material for lightweight applications. It has a melting point of 2250 °C and a Young’s modulus of around 330 GPa. Additionally, Tantalum Aluminide has a low coefficient of thermal expansion, which makes it an ideal material for high-temperature environments.Applications of Tantalum Aluminide:Tantalum Aluminide has numerous applications due to its unique properties. It is commonly used in aerospace components such as turbine blades, heat shields, and exhaust nozzles. It is also used in chemical processing as a catalyst support or coating. In the medical industry, Tantalum Aluminide is used in implants and prosthetic devices due to its biocompatibility and corrosion resistance. Moreover, Tantalum Aluminide is used as a protective coating in nuclear power plants and other high-temperature environments.Benefits of Tantalum Aluminide:Tantalum Aluminide has numerous benefits that make it popular in the manufacturing industry. Some of the benefits of using Tantalum Aluminide include:1. Corrosion Resistance: Tantalum Aluminide is highly resistant to corrosion and can withstand harsh chemical environments. This property makes it ideal for use in chemical processing and medical implants.2. High-Temperature Stability: Tantalum Aluminide can withstand high temperatures without losing its strength or ductility. This property makes it an excellent material for use in aerospace and nuclear power plants.3. Lightweight: Tantalum Aluminide has a low density, making it lightweight and a suitable material for applications where weight is a concern.4. Biocompatibility: Tantalum Aluminide is biocompatible and can be used in medical implants and prosthetic devices without causing any adverse reactions.Tantalum Wire Mesh:Tantalum wire mesh is another popular material used in the manufacturing industry that is made up of pure tantalum wire. Tantalum wire mesh has many unique properties that make it ideal for various applications. Some of the properties of Tantalum wire mesh include:1. Excellent Corrosion Resistance: Tantalum wire mesh is highly resistant to corrosion and can withstand harsh chemical environments.2. High-Temperature Stability: Tantalum wire mesh can withstand high temperatures without losing its strength or ductility.3. Lightweight: Tantalum wire mesh has a very low density, making it ideal for lightweight applications.4. Good Electrical Conductivity: Tantalum wire mesh has a high electrical conductivity, making it suitable for electrical and electronic applications.Conclusion:In conclusion, Tantalum Aluminide and Tantalum wire mesh are two popular materials used in the manufacturing industry. Both materials possess unique properties that make them ideal for various applications. Tantalum Aluminide is commonly used in aerospace, chemical processing, and medical implants, while Tantalum wire mesh is used in electrical and electronic applications. The benefits of using Tantalum Aluminide and Tantalum wire mesh include high-temperature stability, corrosion resistance, and lightweight. SAM is a leading supplier of Tantalum Aluminide, including Tantalum wire mesh, with competitive pricing and excellent lead times.

Find a Diverse Range of Wire Mesh Materials from Retailer and Wholesalers

Title: Expansive Range of Wire Mesh Materials Offered by Leading Wholesalers and RetailersSubtitle: Metal Wire Netting Positioned as a Leading Supplier for Wire Mesh Needs[City, Date] - Wire mesh has become an indispensable component across various industries due to its versatility and wide-ranging applications. Recognizing the surging demand for high-quality wire mesh solutions, prominent wholesalers and retailers have emerged in the market, offering a diverse selection of materials. Metal Wire Netting, a key player in this industry, has gained a remarkable reputation for providing a comprehensive range of wire mesh and associated products.As wire mesh continues to find application in construction, agriculture, manufacturing, and domestic sectors, the availability of a wide array of materials has become essential for meeting the varied demands of these industries. In response to this growing need, Metal Wire Netting has curated a vast selection of wire mesh materials, catering to the requirements of diverse clientele, including retailers, wholesalers, and end-users.One of the prime materials offered by Metal Wire Netting is galvanized wire mesh. Renowned for its exceptional durability and resistance to rust and corrosion, galvanized wire mesh is extensively used in multiple industrial applications. The company's high-quality galvanized wire mesh ensures reliable performance and longevity, making it a popular choice among customers.Another essential product available from Metal Wire Netting is barbed wire mesh. Specially designed to enhance security measures, barbed wire mesh finds utility in diverse sectors such as agriculture, perimeter fencing, and secured facilities. Metal Wire Netting's barbed wire mesh provides strong barriers and acts as an effective deterrent against unauthorized access, ensuring safety and peace of mind for customers.Hexagonal wire netting is yet another prominent offering from Metal Wire Netting. This type of wire mesh is widely used in the agriculture sector, providing a secure boundary for livestock enclosures, chicken coops, and garden fences. With its flexible and lightweight nature, hexagonal wire netting allows for easy installation and maneuverability.Expanding its product range, Metal Wire Netting also offers expanded metal mesh, which finds application in architectural projects, security installations, and filtration systems. This versatile material is known for its high strength-to-weight ratio, allowing for a cost-effective and durable solution for various industrial requirements.Additionally, the company provides perforated metals, a practical option for applications demanding enhanced ventilation, sound-proofing, and aesthetics. The versatility of perforated metals makes them ideal for architectural facades, interior designs, and industrial machinery.Metal Wire Netting's commitment to quality, superior customer service, and competitive pricing has enabled the company to establish itself as a trusted supplier in the wire mesh industry. With an extensive and diverse range of wire mesh materials on offer, the company ensures that customers can find the perfect solution for their unique requirements.Establishing strong relationships with both wholesalers and retailers, Metal Wire Netting acts as a reliable partner for businesses of all sizes. The company provides customized solutions, including bulk orders, tailored packaging, and timely deliveries, ensuring optimal satisfaction for its clientele.In conclusion, the demand for wire mesh materials continues to rise across various industries, necessitating the need for reputable wholesalers and retailers. Metal Wire Netting stands out as a key player in this industry, offering an extensive selection of materials, including galvanized wire mesh, barbed wire mesh, hexagonal wire netting, expanded metal, perforated metals, and more. Their dedication to quality and exceptional customer service has positioned them as a trusted supplier for wire mesh needs, catering to the diverse requirements of wholesalers, retailers, and end-users alike.Press Contact:[Contact Name][Company Name][Address][Phone][Email]

Pleated Mesh Filter Element - Find Your Ideal Product at WireMesh.Net

Elements, Wire Mesh Products, Technical Data, Innovation, Fast Delivery.Wire Mesh Products for Various IndustriesWire mesh products are an essential component of many industries, providing filtration, separation, and support of materials in various applications. From the food and beverage industry, where wire mesh screens are used to filter out impurities, to the pharmaceutical industry, where they are used to separate particles of different sizes, wire mesh products play a vital role in many manufacturing processes.At (brand name), we offer a comprehensive range of wire mesh products, including pleated wire mesh filter elements, which have become increasingly popular due to their high filtration efficiency and easy maintenance. Our pleated wire mesh filter elements are designed to capture particles down to sub-micron levels, making them suitable for a wide range of applications.Pleated Wire Mesh Filter Elements: A Superior Filtration SolutionPleated wire mesh filter elements have several advantages over the traditional flat mesh filter elements. The pleated design of these filter elements provides a larger filtration surface area, which increases the dirt-holding capacity and extends the service life of the filter.The pleated design also reduces pressure drop, which means less energy is needed to maintain the required flow rate. This results in cost savings and reduced carbon footprint. Moreover, the pleated design allows for effortless cleaning, making these filter elements more sustainable and cost-effective in the long run.At (brand name), our pleated wire mesh filter elements are available in various materials such as stainless steel, brass, and copper, depending on the application. Our technical data sheets provide detailed information on the filtration efficiency, pressure drop, and dirt-holding capacity of each filter element, helping you select the right filter element for your specific application.Innovation and Fast Delivery of Wire Mesh ProductsAt (brand name), we understand the importance of innovation and staying up-to-date with the latest industry trends. We continuously invest in research and development to develop new and improved wire mesh products that meet the evolving needs of our customers.We also understand the importance of fast delivery in today's fast-paced business environment. Our extensive inventory and well-established logistics network allow us to offer fast and efficient delivery of wire mesh products to our customers worldwide.ConclusionWire mesh products are an integral part of many industries and applications. Pleated wire mesh filter elements offer superior filtration efficiency, easy maintenance, and cost-effectiveness, making them an ideal choice for a wide range of applications.At (brand name), we offer a comprehensive range of wire mesh products, including pleated wire mesh filter elements, backed by technical data, innovation, and fast delivery to meet the demanding needs of our customers. Contact us today to find out how we can help you with your wire mesh requirements.

High-Quality Sintered Brass Filter for Various Applications

Sintered Brass Filter: A Breakthrough in Filtration TechnologyThe filtration industry is constantly evolving, with companies developing innovative products to meet the ever-growing demand for improved filtration solutions. One such breakthrough in filtration technology is the Sintered Brass Filter, a revolutionary product that offers enhanced performance and durability. Sintered Brass Filter, produced by a leading manufacturer in the filtration industry, is a game-changer in the field of liquid and gas filtration. The filter is made from high-quality brass material that has been sintered to create a porous structure, allowing for the efficient and precise filtration of particles and impurities from a wide range of liquids and gases. The unique manufacturing process of the Sintered Brass Filter results in a rigid and durable structure that can withstand high temperatures and pressures, making it ideal for use in demanding industrial applications.The benefits of the Sintered Brass Filter are numerous. Its high filtration efficiency ensures that even the smallest particles are effectively captured, providing a clean and pure output. This makes it a valuable asset in industries such as petrochemical, pharmaceutical, food and beverage, and automotive, where the quality of the final product is of utmost importance. Additionally, the durability of the Sintered Brass Filter means that it has a long service life, reducing maintenance and replacement costs for end-users.Moreover, the versatile nature of the Sintered Brass Filter makes it suitable for a wide range of applications. Whether it is used for filtering corrosive chemicals, separating solids from liquids, or purifying gases, the filter can be customized to meet specific requirements, thanks to its exceptional design flexibility. This adaptability is a testament to the innovative engineering and manufacturing capabilities of the company behind the Sintered Brass Filter.Speaking of the company, {} is a renowned leader in the filtration industry, with a rich history of providing cutting-edge filtration solutions to its customers worldwide. With a strong focus on research and development, the company has consistently delivered top-quality products that meet the diverse needs of various industries. The Sintered Brass Filter is a testament to the company's commitment to innovation and excellence, as it showcases their ability to push the boundaries of filtration technology.Furthermore, {} is dedicated to providing comprehensive support to its customers, offering technical expertise and personalized solutions to ensure that their filtration challenges are effectively addressed. Their strong emphasis on customer satisfaction has cemented their reputation as a trusted partner in the filtration industry, with a track record of delivering value and reliability.As the demand for advanced filtration solutions continues to grow, the introduction of the Sintered Brass Filter is poised to make a significant impact in the industry. Its combination of high performance, durability, and versatility sets a new standard for filtration technology, providing a competitive edge to businesses across various sectors. With {} at the forefront of this innovation, the future of filtration looks promising, with the Sintered Brass Filter leading the way towards cleaner, safer, and more efficient processes.In conclusion, the Sintered Brass Filter represents a milestone in filtration technology, offering a superior solution for the purification of liquids and gases. Its innovative design, coupled with the expertise of {}, is set to redefine the standards of filtration performance and reliability. As industries strive for higher efficiency and quality in their processes, the Sintered Brass Filter stands ready to meet their needs, setting a new benchmark for filtration excellence.