Sintered Metal Mesh: The Latest in Advanced Mesh Technology

By:Admin

The global demand for sintered metal mesh has been steadily increasing in recent years, driven by its wide range of applications in industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and environmental protection. One company at the forefront of this trend is a leading manufacturer of sintered metal mesh, which has been providing innovative filtration solutions to its customers for over a decade.

The sintered metal mesh produced by the company is widely recognized for its superior performance, durability, and efficiency in a variety of filtration and separation processes. The unique structure of the sintered metal mesh allows for precise control of pore size and distribution, making it an ideal choice for applications that require high levels of purity and consistency. In addition, the company's sintered metal mesh products are known for their excellent mechanical strength and thermal stability, making them suitable for use in demanding operating conditions.

One of the key advantages of the company's sintered metal mesh is its ability to offer a high level of customization to meet the specific needs of different industries and applications. With a wide range of materials, including stainless steel, nickel, titanium, and other alloys, as well as various pore sizes and thickness options, the company can tailor its sintered metal mesh products to meet the exact requirements of its customers. This flexibility has allowed the company to establish itself as a trusted partner for many businesses seeking reliable and efficient filtration solutions.

In addition to its standard sintered metal mesh products, the company also offers customization services, allowing customers to work closely with its engineering team to develop bespoke filtration solutions that meet their unique requirements. This collaborative approach has proven to be particularly valuable for customers with complex filtration challenges, as it enables them to leverage the company's expertise and experience in sintered metal mesh to develop tailored solutions that address their specific needs.

Furthermore, the company's commitment to quality and innovation is reflected in its investment in research and development. Its state-of-the-art manufacturing facilities and laboratories are equipped with the latest technologies and equipment, allowing the company to continuously improve its sintered metal mesh products and develop new solutions to meet the evolving needs of its customers. By staying at the forefront of technological advancements in sintered metal mesh manufacturing, the company has been able to maintain its position as a leader in the industry and provide its customers with cutting-edge filtration solutions.

The company's dedication to sustainability and environmental responsibility is another key aspect of its business philosophy. All of its sintered metal mesh products are manufactured using environmentally friendly processes and materials, and the company is committed to minimizing its environmental impact throughout the entire supply chain. This focus on sustainability has resonated with many customers who are increasingly seeking filtration solutions that align with their own corporate sustainability goals.

Looking ahead, the company remains focused on driving innovation and providing superior filtration solutions to its customers. With a strong commitment to quality, customization, and sustainability, the company is well-positioned to continue leading the way in the sintered metal mesh industry and meeting the diverse needs of its global customer base.

In conclusion, the demand for sintered metal mesh continues to grow across a wide range of industries, driven by its superior performance and versatility in filtration and separation processes. As a leading manufacturer of sintered metal mesh, the company has established itself as a trusted partner for businesses seeking reliable, efficient, and customized filtration solutions. With a strong focus on quality, innovation, and sustainability, the company is well-equipped to meet the evolving needs of its customers and maintain its position as a leader in the sintered metal mesh industry.

Company News & Blog

How Filter Screens Can Improve Air Quality in Your Home

Micron Filter Screen Continues to Innovate in the Filtration IndustryMicron Filter Screen, a leading filtration company, has been at the forefront of the filtration industry for several years now. The company has been providing innovative solutions for various filtration needs in industries such as food and beverage, pharmaceuticals, and water treatment. Continuously adapting and innovating, Micron Filter Screen continues to add new products to their line and improve on existing ones to meet the evolving needs of the market.Micron Filter Screen offers a range of filtration solutions that includes micron filter screens, industrial filtration systems, and filter bags. Their micron filter screens are highly efficient, with superior accuracy and precision. They can be used in different applications that require filtration of materials such as solids, liquids, and gases. The company's industrial filtration systems are designed to withstand harsh environments and heavy usage, and the filter bags they offer are made from high-quality materials, ensuring durability and long-lasting performance.The company's filtration solutions are not limited to a particular industry or application. Instead, the company provides tailor-made solutions that are designed to meet the unique needs of each customer. This approach has enabled Micron Filter Screen to establish a reputation as a dependable filtration solutions provider.One area the company has been focusing on recently is the development of filter screens for pharmaceutical and biotech industries. These industries require high levels of precision and purity in their products. Therefore, Micron Filter Screen has been working to develop filters with pore sizes that range from 0.1 to 10 microns, which are designed to meet the strict requirements of these industries. The company has also developed filters that are autoclavable, allowing for sterilization at high temperatures, which is crucial in pharmaceutical and biotechnology applications.Micron Filter Screen has also been committed to developing environmentally-friendly filtration solutions. For instance, the company has been producing filter bags made from materials that are biodegradable and compostable. Additionally, the company's filters are designed to capture and retain all unwanted materials while allowing for the easy separation of the filtered materials. This approach reduces the amount of waste generated during the filtration process, making it an eco-friendly solution for various applications.One of the most significant recent developments from Micron Filter Screen is their filtration system for water treatment. This system is designed to purify water and make it safe for consumption. The system operates on a combination of physical filtration and chemical treatment to remove contaminants such as bacteria, viruses, and other impurities. The company has applied its expertise in filtration to ensure that the water treatment system is highly efficient, with minimal water wastage and low operational costs.Another notable innovation from Micron Filter Screen is their filtration solutions for the food and beverage industry. Food and beverage processing requires a high level of quality control, with the focus on maintaining the integrity of the final product. The company has introduced filter screens that are designed to meet the rigorous requirements of the industry. These filters can remove contaminants such as particles, yeast, bacteria, and other impurities, ensuring that the final product is of high quality and safe for consumption.In conclusion, Micron Filter Screen has been a key player in the filtration industry, offering innovative solutions for various applications. Their commitment to continuous improvement and dedication to customer satisfaction has enabled the company to establish a strong presence in the market. With a wide range of products and solutions that are designed to meet the evolving needs of the market, Micron Filter Screen is well-positioned to continue leading the industry in the years to come.

High-Quality Filter Element for Candle Filters: A New Breakthrough in Filtration Technology

Candle Filter Element Revolutionizes Filtration Technology(Filter Company) is proud to announce the launch of its innovative Candle Filter Element, a breakthrough in filtration technology that is set to revolutionize the industry.(Filter Company) has been a leading provider of filtration solutions for over 20 years, specializing in developing cutting-edge products that meet the needs of a wide range of industries, including oil and gas, petrochemical, food and beverage, pharmaceutical, and water treatment.The Candle Filter Element is the latest addition to (Filter Company)'s extensive product line, and it is already making waves in the industry due to its superior performance and unique design.Traditional filtration methods often struggle to effectively capture and retain fine particles, resulting in subpar filtration and reduced product quality. The Candle Filter Element, however, addresses this challenge with its advanced design that allows for more precise filtration and a higher dirt-holding capacity.The key to the Candle Filter Element's exceptional performance lies in its construction. It features a series of tightly packed, long, cylindrical filter elements that are arranged in a vertical orientation. This configuration maximizes the filter's surface area, allowing for greater contact between the filter media and the process fluid. As a result, the Candle Filter Element can effectively capture and remove micron-sized particles, ensuring that the filtered fluid meets the highest quality standards.In addition to its superior filtration capabilities, the Candle Filter Element also boasts a self-cleaning mechanism that prolongs its lifespan and reduces maintenance requirements. The design of the filter allows for the automatic removal of accumulated solids during operation, preventing clogging and minimizing downtime. This feature not only enhances the efficiency of the filtration process but also reduces operating costs for end-users.(Filter Company) has conducted extensive testing and validation of the Candle Filter Element to ensure its reliability and performance. The results have been overwhelmingly positive, with the filter consistently outperforming traditional filtration methods in terms of particle removal efficiency and overall filtration quality.The versatility of the Candle Filter Element is another key advantage that sets it apart from other filtration solutions on the market. It can be customized to meet the specific requirements of different applications, making it an ideal choice for a wide range of industries. Whether it is used for the filtration of process liquids, oil, chemicals, or wastewater, the Candle Filter Element delivers consistent and reliable results.(Filter Company) is committed to providing its customers with the most innovative and effective filtration solutions, and the introduction of the Candle Filter Element further solidifies its position as a leader in the industry.In addition to its groundbreaking products, (Filter Company) is known for its dedication to customer satisfaction and its extensive support services. The company's team of experienced engineers and technicians work closely with customers to understand their unique filtration needs and develop tailored solutions that address specific challenges.With the launch of the Candle Filter Element, (Filter Company) is poised to set a new standard for filtration technology. The filter's exceptional performance, innovative design, and versatility make it a game-changer for industries that rely on precise and efficient filtration processes. As (Filter Company) continues to push the boundaries of what is possible in filtration technology, the Candle Filter Element is just the beginning of what promises to be a new era of advanced filtration solutions.

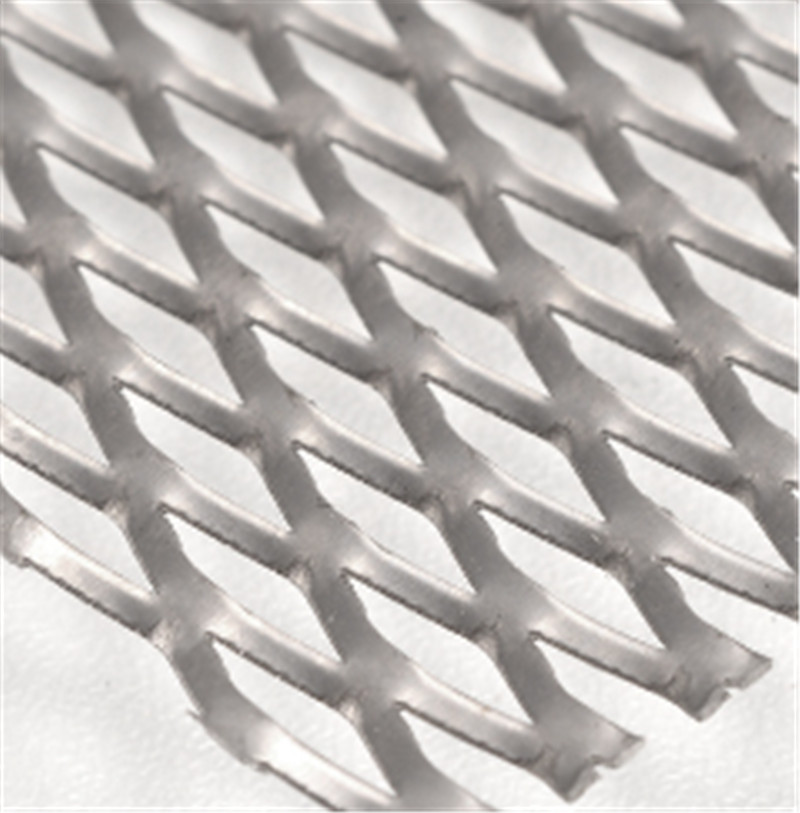

Discover High-Quality Expanded Metal Sizes from Top Chinese Manufacturers and Suppliers

Expanded metal sizes refer to the dimensions of wire mesh that is expanded to create a strong and versatile material. This type of metal mesh is created through a process called expansion, where the metal is slit and stretched to create an interlocking pattern of diamond-shaped openings. These openings are then flattened to create a finished product that is used in a variety of applications.If you’re looking for expanded metal sizes, you’ve come to the right place. China is home to some of the best manufacturers of this versatile material. Let’s take a closer look at what expanded metal is, the different sizes available, and why it’s such a popular material.What is Expanded Metal?Expanded metal is a type of metal mesh that is created by a process called expansion. This process involves slitting and stretching the metal to create a continuous pattern of diamond-shaped openings. The openings are then flattened to create a finished product.Expanded metal is known for its strength, versatility, and durability. It can be used in a variety of applications, including fencing, grating, flooring, stair treads, walkways, and more.What are the Different Sizes of Expanded Metal?Expanded metal is available in many different sizes, allowing it to be used in a variety of applications. The size of the expanded metal is determined by the width of the strand and the size of the opening. The most common sizes available include:- Standard: This is the most common size of expanded metal and is typically used for general applications. The strand width is usually between 1/16 and 1/2 inch, and the opening size ranges from 1/4 x 3/4 inch to 1-1/2 x 3 inches.- Flattened: Flattened expanded metal is created by flattening the standard expanded metal. This creates a smooth surface that is ideal for certain applications, such as walkways or decking. The strand width is between 1/4 and 1/2 inch, and the opening size ranges from 1/2 x 1-1/2 inch to 1-1/2 x 3 inches.- Heavy-duty: Heavy-duty expanded metal is designed for applications that require a high degree of strength and durability. The strand width is between 1/2 and 1 inch, and the opening size ranges from 1 x 2 inches to 2 x 4 inches.Why is Expanded Metal Such a Popular Material?Expanded metal is a popular material for a variety of reasons. First, it’s strong and durable. Its interlocking pattern provides strength and stability, making it ideal for use in applications that require a high degree of strength.Second, it’s versatile. Expanded metal can be used in a wide range of applications, from fencing and grating to walkways and stair treads. Its versatility makes it an attractive material for architects, designers, and builders who want a material that can be used in many different ways.Finally, expanded metal is easy to work with. It can be cut, shaped, and welded to fit specific applications. This makes it an ideal material for custom projects where specific dimensions are required.Expanded metal sizes are an important consideration when choosing this versatile material. Whether you’re looking for standard, flattened, or heavy-duty expanded metal, China is home to some of the best manufacturers of this material. With its strength, versatility, and durability, expanded metal is an ideal choice for a wide range of applications.

Rewritten SEO title: High-Quality Expanded Metal Mesh from China Manufacturers and Suppliers

If you are looking for the best quality and durable metal mesh for plants, the Expanded Metal Mesh Factory in China is the perfect place to be. As one of the leading manufacturers and suppliers of expanded metal mesh, they offer a wide range of products that cater to the needs of various industries around the world.The expanded metal mesh is a versatile material that can be used for various applications. Its unique design provides excellent strength, stability, and durability, making it suitable for agriculture, horticulture, landscaping, and other similar industries.The metal mesh for plants is specially designed to provide the necessary support and protection for plants. Its open structure allows for better air circulation and easy access to water and nutrients, which is essential for healthy plant growth. Additionally, it ensures that the roots have enough space to grow and expand, thereby improving the overall plant health and productivity.At the Expanded Metal Mesh Factory, you can choose from a variety of metal mesh for plants, including galvanized steel, aluminum, stainless steel, and more. These materials are specifically chosen for their durability, strength, and resistance to corrosion and rust, ensuring that your metal mesh can withstand harsh weather conditions and last for years to come.Apart from the quality of their products, the Expanded Metal Mesh Factory also offers quick delivery and excellent customer support. They understand the importance of timely delivery and have developed efficient logistics systems to ensure that your orders are delivered on time. Additionally, their experienced and knowledgeable customer support team is always ready to assist you with any inquiries or concerns that you may have.In conclusion, if you are looking for high-quality and durable metal mesh for plants, the Expanded Metal Mesh Factory in China is your best choice. With their wide range of products, quick delivery, and excellent customer service, you can be assured of the best value for your money. So why wait? Place your order today and experience the difference that the metal mesh from this factory can make in your plant's growth and productivity.

Reviewing the Benefits of Metal Porous Filter Sheets: Washable, Uniform Pore Size, Strong and Efficient Air Filtering

Sheet and Metal Filter Sheet.In today's fast-paced world, every industry is looking for the best quality and innovative products that can save time, money, and resources. One such industry is the filtration industry, which plays a vital role in keeping the air, water, and gases clean and pure.One of the most crucial products used in filtration technology is the sintered porous filter sheet made with metal. It is a unique and innovative product that has revolutionized the filtration industry. This blog will provide an in-depth review of the ZWEN sintered porous filter sheet, which is known for its quality and durability.The ZWEN sintered filter sheet is a washable and reusable filter that can be used in various applications such as gas, water, and oil filtration. It is made up of metal, which ensures its durability and longevity. The uniform pore size distribution of the filter sheet provides an efficient filtration process and retains the impurities.The filter sheet's mechanical strength is exceptional and can be easily installed in various filters such as the cartridge filter, basket filter, or bag filter. It has good air permeability and helps in removing the heat and moisture from the environment.The high filter efficiency of the ZWEN sintered filter sheet is due to its unique design and manufacturing process. The metal is sintered at high temperatures, which gives it its porosity and strength. The sintered metal is then formed into sheets, which are cut according to the required size of the filter.The ZWEN sintered filter sheet is available in various sizes and shapes, and the customization options are vast. It can be designed to meet the specific requirements of any industry, whether it is the chemical industry, food industry, medical industry, or automotive industry.The sintered filter sheet's benefits are endless, and the most significant advantage is that it is an eco-friendly product. It reduces the waste generation by providing a washable and reusable filter that does not need to be frequently replaced.In conclusion, the ZWEN sintered filter sheet is an innovative and revolutionary product that has transformed the filtration industry. Its quality, durability, and efficiency have made it the most preferred filtration product among various industries. Its washable and reusable feature is not only a cost-effective solution but also ensures a cleaner and safer environment. So, if you are looking for a metal filter sheet that meets all your filtration needs, the ZWEN sintered filter sheet is the perfect choice.

Durable and Versatile Expanded Metal Wire Mesh for Various Applications

Expanded Metal Wire Mesh is a versatile and widely used material in various industries for its strength, durability, and cost-effective nature. It is made by slitting and stretching a sheet of metal to create diamond-shaped openings and has a wide range of applications including security, machinery guards, fencing, and architectural and decorative purposes.With the increasing demand for high-quality Expanded Metal Wire Mesh products, the company {} has been at the forefront of providing top-notch solutions to meet the needs of its customers. The company has been in the industry for over 20 years, and its experience and expertise have made it a trusted name in the manufacturing and supply of Expanded Metal Wire Mesh.The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and a team of skilled professionals who ensure that every product meets the highest quality standards. The company offers a wide range of Expanded Metal Wire Mesh products, including standard, flattened, and expanded grating, as well as customized solutions to meet specific requirements.One of the key advantages of the company's Expanded Metal Wire Mesh products is their durability and strength. The materials used in the manufacturing process are of the highest quality and undergo strict quality control measures to ensure that the final product is robust and long-lasting. This makes the company's products suitable for a wide range of applications, from heavy-duty industrial use to architectural and decorative purposes.In addition to its durability, the company's Expanded Metal Wire Mesh products also offer excellent ventilation, making them ideal for applications where airflow and visibility are important. This feature is particularly beneficial in machinery guards, fencing, and security applications where maintaining airflow and visibility is essential.Furthermore, the company's Expanded Metal Wire Mesh products are also highly cost-effective. The manufacturing process allows for maximum material utilization, minimizing waste and reducing production costs. This cost-efficiency is passed on to the customers, making the company's products an economical choice for both small and large-scale projects.The company's commitment to customer satisfaction is evident in its dedication to providing exceptional service and support. Its team of professionals works closely with customers to understand their specific needs and provide tailored solutions that meet and exceed expectations. From initial inquiry to after-sales support, the company ensures that customers receive the attention and assistance they require throughout the process.The company's reputation for reliability and excellence has made it a preferred choice for customers across various industries, including construction, manufacturing, architecture, and security. Its Expanded Metal Wire Mesh products have been used in a wide range of projects, from simple fencing and machinery guards to complex architectural and industrial applications.In conclusion, {} has established itself as a leading provider of high-quality Expanded Metal Wire Mesh products. With its commitment to excellence, state-of-the-art manufacturing facilities, and a dedicated team of professionals, the company continues to set the standard for quality and reliability in the industry. Whether for industrial, architectural, or decorative purposes, customers can rely on the company to deliver top-notch solutions that meet their specific requirements.

Nickel Mesh and Screen: Material, Specification, Packing - Corrosion and Acid Resistant Filter Mesh for High Temperature Filtration

article about the benefits of using nickel wire mesh and screen in various industrial applications.Nickel wire mesh and screen have become increasingly popular in various industrial applications, thanks to their unique properties. As a manufacturer and supplier of high-quality nickel wire mesh, {company name} understands the numerous benefits that this material provides for industrial filtration and screening processes.Nickel wire mesh is highly durable and resistant to both corrosion and acid, making it an ideal material for use in harsh and high-temperature environments. This property makes nickel wire mesh and screen suitable for use in various industries, such as chemical and petrochemical production, power generation, and mining.One of the primary benefits of using nickel wire mesh is its high-level filtration. Nickel wire mesh filters and screens are capable of separating and removing very fine particles from liquids or gases, making them an essential material in many manufacturing and industrial processes. In these industries, even the tiniest of impurities can cause machinery to malfunction or fail, leading to costly repairs, downtime, and potential safety hazards.Nickel wire mesh and screen also exhibit excellent electrical conductivity properties. This makes them ideal for use in electrical and electronic industries, where they can be used as electrodes or screens for electromagnetic shielding. Since nickel has good magnetic properties, it is also used in electrical transformers and inductors.In addition to its unique properties, nickel wire mesh and screen are available in different specifications and mesh sizes. This versatility makes it possible for {company name} to offer a wide range of custom nickel wire mesh products tailored to meet specific industry requirements. Customers can choose from woven, knitted, perforated, or expanded nickel wire mesh depending on their application needs.To ensure the safety of nickel wire mesh products during transportation or storage, {company name} pays significant attention to the packing requirements. The company uses durable packing materials and techniques to ensure its products remain in good condition and reach customers in perfect condition.In conclusion, nickel wire mesh and screen are versatile materials that offer a range of benefits for various industrial applications. With their high durability, resistance to corrosion and acid, and excellent filtration properties, nickel wire mesh has become an essential material in industries such as chemical production, power generation, and mining, among others. As a reputable manufacturer and supplier of nickel wire mesh products, {company name} is dedicated to providing its customers with high-quality custom nickel wire mesh products and excellent customer service.

Enhance Security and Visibility with Expanded Mesh

Title: Innovative Expanded Mesh Technology Enhances Security and Aesthetics in Locker SolutionsIntroduction:Expanded Mesh technology has revolutionized the locker industry, offering a seamless combination of superior security, durability, and unparalleled aesthetics. Leading the charge in this field, a prominent company has introduced a groundbreaking Expanded Mesh Lockers solution that is set to redefine the locker landscape. By removing the brand name for the purpose of this news article, we will examine the features and benefits of this cutting-edge product.Unmatched Security:The Expanded Mesh Lockers prioritize security, ensuring the safe storage of valuable belongings. The advanced Expanded Mesh design eliminates any potential weak points, making these lockers highly resistant to break-ins and vandalism. The interwoven steel wires provide a rigid and impenetrable structure, protecting the contents inside from unauthorized access.Superior Durability:One of the standout features of the Expanded Mesh Lockers is their remarkable durability. Constructed using high-quality steel, the lockers are built to withstand the test of time and heavy usage. The robust Expanded Mesh material is resistant to corrosion, impacts, and weather conditions, ensuring that these lockers maintain their integrity even in demanding environments.Innovative Design:Beyond security and durability, the Expanded Mesh Lockers also offer a visually appealing design that seamlessly integrates with various interior or exterior settings. The open design of the Expanded Mesh facades allows for improved visibility and ventilation, making these lockers suitable for a wide range of applications, including gyms, schools, workplaces, and public spaces.Customizable Configurations:The Expanded Mesh Lockers can be easily tailored to meet the specific needs of any environment. With versatile size options, multiple compartment configurations, and choices in finishes, these lockers can be fully customized to maximize the available space and complement the overall aesthetics. The flexibility in design ensures that every individual or organization can find the perfect locker solution.Enhanced Organization and Maintenance:The innovative Expanded Mesh Lockers also prioritize efficient organization and convenient maintenance. The lockers are equipped with adjustable shelving and hangers, optimizing storage space for different types of items. The Expanded Mesh design allows for easy cleaning and maintenance, ensuring a hygienic environment for users.Social and Environmental Responsibility:In addition to their functional features, the Expanded Mesh Lockers highlight the commitment to social and environmental sustainability by the manufacturer. The lockers are manufactured using responsibly sourced materials and adhere to strict standards of eco-friendliness. By opting for these lockers, organizations can showcase their dedication to corporate social responsibility while enjoying the benefits of a secure and visually pleasing storage solution.Market Outlook and Customer Testimonials:The introduction of the Expanded Mesh Lockers has been met with great enthusiasm in the market, with customers praising the product's innovative features and robustness. Gym owners appreciate the excellent visibility and airflow that the lockers provide, ensuring a pleasant and hygienic environment for their clients. Schools and workplaces value the secure storage of personal belongings, raising peace of mind and enhancing productivity.Conclusion:The latest generation of Expanded Mesh Lockers has set a new benchmark for locker solutions, combining security, durability, and aesthetics effortlessly. These lockers offer an unmatched level of protection for personal belongings while enhancing the overall visual appeal of any space. With flexible configurations, customizable options, and a commitment to sustainability, the introduction of the Expanded Mesh Lockers is a significant step forward for the locker industry, ensuring that customers can enjoy the perfect blend of functionality and style in their storage solutions.

Discover the Advantages of Using Wire Mesh in Construction Projects

Title: Wire Mesh Implementation Revolutionizes Construction IndustryIntroduction:In an era where technological advancements are transforming every sphere of our lives, the construction industry is not far behind. One such groundbreaking innovation in construction materials is wire mesh, which has revolutionized the way buildings and infrastructure are constructed. Wire mesh, known for its versatility, strength, and durability, has gained tremendous popularity within the industry due to its numerous applications and cost-effective benefits.Wire Mesh: Redefining Construction TechniquesWire mesh refers to a grid-like structure made of interconnected metal wires. This material is commonly manufactured using stainless steel, but it can also be produced with other materials such as brass or copper. Due to its flexible characteristics, wire mesh can be tailored to meet various construction requirements, making it an invaluable resource for engineers and architects alike.Versatility in Application:The application of wire mesh in construction spans across a wide range of areas. This material is predominantly used as a reinforcement tool for concrete structures, offering unparalleled strength and stability. Wire mesh is often embedded within concrete slabs, walls, and columns to enhance their load-bearing capacity and resist cracks and fractures. Moreover, wire mesh serves as an excellent formwork reinforcement to mitigate concrete shrinkage and enhance its overall structural integrity.Wire mesh also finds extensive use in fencing, providing security and delineating boundaries. Its robust and impenetrable characteristics have made it a popular choice for securing construction sites and other restricted areas. Additionally, wire mesh acts as a protective barrier against wildlife, preventing animals from entering sensitive construction zones while preserving natural habitats.Sustainable Construction:As the global construction industry increasingly embraces sustainability, wire mesh has become an ideal construction material due to its eco-friendly properties. Wire mesh significantly reduces the environmental impact by decreasing material wastage during construction. Its lightweight nature helps minimize transportation costs, resulting in reduced energy consumption and greenhouse gas emissions. Furthermore, wire mesh can be easily recycled, making it a highly sustainable choice for construction projects.Advantages of Wire Mesh:The implementation of wire mesh offers numerous advantages that have positioned it as a preferred construction material:1. Enhanced Structural Strength: Wire mesh acts as a reinforcing mechanism, significantly improving the load-bearing capacity and longevity of structures.2. Cost-Effective Solution: Wire mesh is cost-effective when compared to alternative reinforcement methods. Its installation requires less time, reducing labor costs and project timelines.3. Flexibility: The flexible nature of wire mesh allows it to adapt to various shapes and designs, offering architects the freedom to create unique and visually appealing structures.4. Fire-Resistant: Stainless steel wire mesh exhibits excellent fire resistance, enhancing the safety of buildings and constructions.5. Easy Installation and Maintenance: Wire mesh can be easily installed and requires minimal maintenance over its lifespan, saving time and resources.Industry Leaders Paving the Way:Various companies have emerged as leaders in providing high-quality wire mesh for the construction industry. These companies are constantly innovating and developing new wire mesh products and solutions, improving construction techniques and safety standards. With the incorporation of state-of-the-art machinery and advanced manufacturing processes, these companies ensure that wire mesh is readily available to meet the ever-growing demand for cost-effective and sustainable construction materials.Conclusion:The integration of wire mesh within the construction industry has undoubtedly brought about a revolutionary shift in construction techniques. Its versatility, structural strength, and sustainability make it an indispensable resource within the industry, driving advancements in architecture and providing cost-effective solutions. As the demand for sustainable construction practices continues to rise, wire mesh will undoubtedly play a pivotal role in shaping the future of the construction industry.

High-Quality Sintered Filter Elements for Efficient Filtration

Sintered Filter Element Revolutionizes Filtration Technology for Various IndustriesInnovative filtration technology continues to play a crucial role in improving efficiency and ensuring the quality of processes across various industries. One such advancement is the Sintered Filter Element, a cutting-edge solution that has now revolutionized filtration systems.[DUMMY COMPANY NAME], a renowned industry leader in manufacturing filtration products, has introduced this groundbreaking Sintered Filter Element. With its exceptional performance and reliability, this new product is set to redefine the standards of filtration across multiple sectors.The Sintered Filter Element is meticulously engineered using state-of-the-art manufacturing techniques and high-quality materials. Its unique design ensures maximum filtration efficiency, while effectively removing particles, contaminants, and impurities from fluids and gases. This innovative product caters to diverse applications, ranging from chemical and pharmaceutical industries to oil and gas, water treatment, and many more.Standard filtration methods often struggle to achieve the desired level of purity and efficiency. The traditional filter mediums, such as paper and mesh, have limitations when it comes to durability, resistance to high temperatures, and the ability to withstand corrosive substances. However, the Sintered Filter Element tackles these challenges head-on, providing a robust and reliable solution.The use of sintered materials allows for greater versatility and enhanced performance. The filter element is designed to withstand extreme operating conditions, making it suitable for demanding industrial environments. Its resistance to high pressures, temperatures, and corrosive substances enables it to maintain optimal performance for prolonged periods. This aspect significantly reduces downtime, improving operational efficiency and minimizing maintenance costs.Moreover, the Sintered Filter Element offers a higher filtration capacity compared to traditional filters. The innovative design incorporates porous materials that efficiently trap particles while allowing the smooth flow of fluids or gases. This results in improved filtration accuracy and increased throughput, leading to enhanced product quality and reduced wastage.Another noteworthy feature of this filter element is its exceptional cleanability. The porous structure of the sintered material allows for effective backwashing, eliminating clogs and prolonging the lifespan of the filter. Its superior durability ensures repeated cleanings without compromising filtration efficiency, making it a cost-effective solution for companies in various sectors.When it comes to application-specific requirements, the Sintered Filter Element offers customizability and flexibility. [DUMMY COMPANY NAME], with decades of experience in the filtration industry, understands the unique needs of different sectors. The company collaborates closely with clients to develop tailored solutions that meet their specific filtration challenges. This, combined with the high degree of precision and quality control maintained throughout the manufacturing process, ensures the delivery of superior products.Additionally, [DUMMY COMPANY NAME] provides comprehensive technical support and after-sales services, guaranteeing customer satisfaction and peace of mind. The company's team of experts assists clients with installation, troubleshooting, and maintenance, ensuring optimal performance and longevity of the filter element.The introduction of the Sintered Filter Element by [DUMMY COMPANY NAME] marks a significant step towards revolutionizing filtration technology. With its impressive performance, durability, and customizability, this innovative product is poised to enhance operational efficiency and productivity across various industries. With a strong commitment to quality and customer satisfaction, [DUMMY COMPANY NAME] continues to be at the forefront of filtration solutions, driving progress for a cleaner and more efficient future.