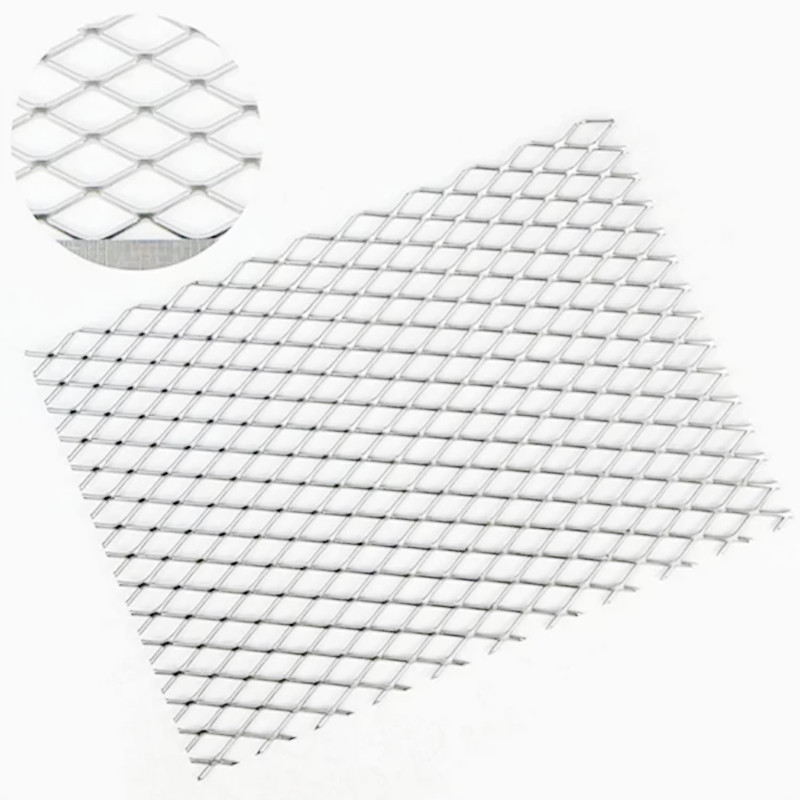

Durable and Versatile Expanded Wire Mesh for Various Applications

By:Admin

The expanded wire mesh products offered by Wire Mesh Expanded are designed to meet the diverse and demanding needs of the construction, industrial, agricultural, and architectural sectors. The company's expanded wire mesh is manufactured using advanced technology and high-quality materials to ensure superior performance and longevity.

Wire Mesh Expanded offers a wide range of expanded wire mesh products, including standard, flattened, and decorative patterns. The expanded wire mesh is available in various materials, including stainless steel, aluminum, galvanized steel, and carbon steel, to meet the specific requirements of different applications.

The expanded wire mesh products from Wire Mesh Expanded are known for their exceptional strength, flexibility, and corrosion resistance, making them suitable for a wide range of applications. Whether it's for fencing, grating, screening, or filtration, Wire Mesh Expanded has the right solution for every need.

In addition to its standard product offerings, Wire Mesh Expanded also specializes in custom-designed expanded wire mesh products to meet the unique requirements of its customers. The company's team of experienced engineers and technicians work closely with clients to develop tailored solutions that perfectly match their specifications and expectations.

Wire Mesh Expanded takes pride in its commitment to quality, innovation, and customer satisfaction. As part of its quality assurance process, the company conducts rigorous testing and inspections to ensure that all its expanded wire mesh products meet the highest industry standards. Furthermore, Wire Mesh Expanded continuously invests in research and development to bring new and improved products to the market.

The expanded wire mesh products from Wire Mesh Expanded are not only known for their exceptional performance but also for their ease of installation and maintenance. The company provides comprehensive technical support and guidance to help customers make informed decisions and achieve the best possible results.

With its state-of-the-art manufacturing facilities and a dedicated team of professionals, Wire Mesh Expanded is well-equipped to cater to the growing demand for expanded wire mesh products. The company is committed to fostering long-term partnerships with its customers by delivering reliable, cost-effective, and sustainable solutions.

As Wire Mesh Expanded continues to expand its product portfolio and global footprint, it remains steadfast in its mission to be a leading provider of high-quality expanded wire mesh products. The company's unwavering dedication to excellence and continuous improvement has earned it a solid reputation in the industry.

With its innovative solutions, exceptional customer service, and strong track record, Wire Mesh Expanded is poised to remain at the forefront of the wire mesh industry. The company's expanded wire mesh products are not only built to last but also to exceed expectations in terms of quality, performance, and value.

In conclusion, Wire Mesh Expanded's new line of expanded wire mesh products represents a significant milestone in the company's journey to provide cutting-edge solutions to its customers. With its unwavering commitment to excellence and innovation, Wire Mesh Expanded is set to make a lasting impact in the wire mesh industry and beyond. For more information about Wire Mesh Expanded and its expanded wire mesh products, visit their website or contact their sales team for personalized assistance.

Company News & Blog

Durable Steel Wire Mesh Screen for Various Applications

The steel wire mesh screen has long been an indispensable part of various industries such as construction, mining, and agriculture. Its unique properties make it ideal for a wide range of applications, including filtration, fencing, and reinforcement. As a leading manufacturer in the industry, {Company Name} has been at the forefront of producing high-quality steel wire mesh screens that meet the diverse needs of its customers.{Company Name} was established in the early 2000s as a specialized manufacturer of steel wire mesh products. With a focus on innovation and quality, the company has grown rapidly over the years and has earned a strong reputation for its exceptional products and customer service. Today, {Company Name} is recognized as a trusted supplier of steel wire mesh screens, serving customers across the globe.The steel wire mesh screens offered by {Company Name} are made from high-quality steel wires that are carefully selected to ensure durability and strength. The screens are available in a variety of sizes and specifications to meet the specific requirements of different industries. Whether it's for construction, mining, or agricultural applications, {Company Name} has the capability to deliver customized solutions that cater to the unique needs of its customers.One of the key features of {Company Name}'s steel wire mesh screens is their excellent durability and resistance to corrosion. This makes them suitable for use in harsh environments where exposure to moisture, chemicals, and other corrosive substances is a concern. In addition, the screens are designed to withstand high temperatures, heavy loads, and abrasive materials, making them a reliable choice for demanding applications.Furthermore, {Company Name} prides itself on its commitment to quality and adheres to strict manufacturing standards to ensure the consistency and reliability of its products. The company's state-of-the-art production facilities are equipped with advanced machinery and technology, allowing for precision manufacturing and quality control. Each steel wire mesh screen undergoes rigorous testing to verify its strength, dimensional accuracy, and overall performance before it is dispatched to the customers.With a strong emphasis on customer satisfaction, {Company Name} provides comprehensive support to its clients, offering technical guidance, product customization, and aftersales services. The company's team of experienced professionals is dedicated to understanding the unique requirements of each customer and providing them with the most suitable solutions.In line with its commitment to sustainability, {Company Name} also places a strong emphasis on environmental responsibility in its manufacturing processes. The company constantly strives to minimize its environmental impact by implementing eco-friendly practices and using recyclable materials wherever possible.As a testament to its success and commitment to excellence, {Company Name} has been the recipient of several industry accolades and certifications. These achievements underscore the company's strong position as a leader in the steel wire mesh industry and its continuous efforts to raise the bar for quality and innovation.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of steel wire mesh technology and expanding its product offerings to address the evolving needs of its customers. With a focus on research and development, the company is poised to introduce new and improved steel wire mesh screens that offer enhanced performance and versatility, further solidifying its position as a preferred choice for customers worldwide.

Durable Black Coating for Wire Mesh: The Ultimate Protection

Wire Mesh Black Coating: Enhancing Durability and Aesthetic Appeal in ConstructionIn the realm of modern construction, the importance of using high-quality materials cannot be overstated. Among the various innovative products that have revolutionized the construction industry, one such material that has gained significant attention is wire mesh with black coating. This remarkable product has been widely embraced by construction professionals for its exceptional durability and aesthetic appeal. As one of the leading manufacturers in the industry, {Company Name} has been at the forefront of producing top-notch wire mesh black coatings that have garnered widespread acclaim in the construction sector.{Company Name} has established itself as a prominent player in the manufacturing and distribution of wire mesh black coatings, offering a diverse range of products that cater to the unique needs of construction projects. The company takes pride in its state-of-the-art manufacturing facilities that are equipped with cutting-edge technology and a team of skilled professionals dedicated to delivering premium-quality products.The wire mesh black coatings produced by {Company Name} are designed to be corrosion-resistant, providing long-term protection against environmental factors and ensuring the longevity of structures. This feature is particularly advantageous in construction projects where exposure to harsh weather conditions is a concern. Furthermore, the black coating adds an appealing aesthetic finish to the wire mesh, making it an attractive choice for both functional and decorative applications in construction.One of the key advantages of wire mesh black coatings is their versatility and applicability in various construction scenarios. Whether used for reinforcing concrete structures, providing security in fencing, or enhancing architectural elements, these coatings deliver unmatched performance and reliability. By offering a range of mesh sizes and coating thickness options, {Company Name} ensures that customers can find the perfect solution for their specific project requirements.Moreover, {Company Name} places a strong emphasis on adhering to stringent quality control measures throughout the manufacturing process to guarantee the utmost satisfaction of its customers. By conducting thorough testing and inspections, the company ensures that its wire mesh black coatings meet the highest industry standards and specifications. This commitment to quality has earned {Company Name} a solid reputation for delivering superior products that consistently exceed customer expectations.In addition to its dedication to quality, {Company Name} is also committed to sustainability and environmental responsibility. The company employs eco-friendly practices in its manufacturing processes, prioritizing the use of sustainable materials and reducing its carbon footprint. This aligns with the growing emphasis on sustainable construction practices, making {Company Name} a preferred choice for environmentally conscious developers and builders.Looking ahead, {Company Name} continues to drive innovation in the production of wire mesh black coatings, constantly exploring new technologies and materials to further enhance the performance and durability of its products. By staying at the forefront of industry advancements and market trends, the company remains steadfast in its commitment to providing cutting-edge solutions for the evolving needs of the construction sector.In conclusion, wire mesh black coatings have emerged as a game-changing material in modern construction, offering a combination of durability, aesthetics, and versatility. With {Company Name} spearheading the production of top-tier wire mesh black coatings, construction professionals can expect to elevate the quality and longevity of their projects. As the industry continues to evolve, {Company Name} stands poised to lead the way in delivering innovative solutions that redefine the standards of excellence in construction materials.

Metal Mesh for Industrial Applications: Durable and Reliable Solution

Title: Cutting-Edge Stainless Steel Mesh Revolutionizes Industrial OperationsIntroduction:In today's rapidly evolving industrial landscape, innovative solutions are constantly emerging to address the growing needs of various sectors. One such groundbreaking product is Stainless Steel Mesh, an advanced material that is revolutionizing multiple industries with its exceptional strength, durability, and versatility. Designed to surpass traditional barriers, this mesh has become an essential component within manufacturing, construction, and filtration processes, propelling businesses to unprecedented heights of efficiency, productivity, and reliability.1. Rising Demand for Stainless Steel Mesh in Manufacturing Industry:The manufacturing industry bears witness to the increasing adoption of Stainless Steel Mesh as a critical tool in various operational processes. Offering superior tensile strength, the mesh effectively replaces conventional materials by withstanding high temperatures, corrosive chemicals, and heavy loads. Whether it's in the automotive, aerospace, or electronics sectors, manufacturers are benefiting from the enhanced safety, performance, and longevity delivered by stainless steel mesh solutions.Moreover, the ability to customize the mesh to precise specifications ensures optimal functionality, making it an indispensable component for reliable filtration, extrusion, and sieving operations. As a result, manufacturing processes become more efficient, reducing downtime and maintenance costs while maximizing yield and overall product quality.2. Construction Industry Embracing Stainless Steel Mesh for Structural Reinforcement:The construction sector has also recognized the transformative potential of Stainless Steel Mesh in strengthening concrete structures, providing corrosion resistance, and enhancing durability. With its unique combination of strength and flexibility, stainless steel mesh enables engineers and architects to design robust buildings, bridges, and infrastructure projects capable of withstanding extreme conditions and load-bearing requirements.Moreover, the mesh's inherent corrosion resistance properties significantly extend the lifespan of construction projects, reducing long-term maintenance costs and improving structural integrity. Coupled with the ability to seamlessly blend into a variety of aesthetic designs, stainless steel mesh is becoming a favored choice for architects seeking both functionality and visual appeal.3. Advancements in Filtration Technologies Driven by Stainless Steel Mesh:Filters play a pivotal role in industries such as oil and gas, pharmaceuticals, and food processing, ensuring the purity and quality of products. Stainless Steel Mesh has emerged as a game-changer in the filtration arena, revolutionizing the way solids and liquids are separated and purified.The unique properties of the mesh, including its precise aperture sizes, excellent porosity, and exceptional resistance to clogging and fouling, make it ideal for applications where precision and efficiency are paramount. As a result, businesses can achieve higher filtration rates, optimize production processes, and effectively reduce operating costs by utilizing stainless steel mesh filters.4. Company X's Pioneering Role in Advancing Stainless Steel Mesh Technology:At the forefront of the stainless steel mesh revolution is Company X, a leading manufacturer and innovator in the industrial materials sector. With a rich history spanning several decades, Company X has consistently invested in research and development, striving to push the boundaries of what is achievable with stainless steel mesh.Company X spends significant resources on cutting-edge manufacturing technologies, ensuring that their stainless steel mesh products are of the highest quality and meet the stringent demands of modern industries. Through continuous collaboration with industry experts and customer feedback, Company X maintains a customer-centric approach, tailoring their solutions to address specific operational needs across various sectors.Conclusion:Stainless Steel Mesh has undoubtedly emerged as a transformative material with immense potential across numerous industries. Its unrivaled strength, adaptability, and durability make it a top choice for manufacturers, construction firms, and filtration system developers alike. As businesses strive for greater efficiency, reliability, and longevity in their operations, Stainless Steel Mesh is proving to be an invaluable asset, driving innovation and revolutionizing industrial processes. With Company X leading the charge in advancing this technology, we can expect even greater breakthroughs in the coming years, propelling industries to new heights of success.

Durable Stainless Steel Mesh Screen for Various Applications

Fine Steel Mesh Screen is a leading company in the manufacturing of high-quality steel mesh screens. This company has a strong reputation in the industry for producing durable and reliable screens that are used in various applications such as filtration, separation, and sieving.The Fine Steel Mesh Screen is made from high-grade stainless steel, which gives it excellent strength and corrosion resistance. This makes it ideal for use in harsh and demanding environments where other materials might fail. The company's commitment to using only the best materials and adhering to strict quality control processes ensures that their screens meet the highest standards and exceed customer expectations.One of the key advantages of the Fine Steel Mesh Screen is its versatility. It can be customized to meet specific customer requirements, including different weave patterns, wire diameters, and aperture sizes. This flexibility makes it suitable for a wide range of applications across various industries, including mining, agriculture, food processing, and pharmaceuticals.In addition to its high-quality products, Fine Steel Mesh Screen also prides itself on providing excellent customer service. Their team of experienced professionals is dedicated to understanding the unique needs of each customer and providing tailored solutions to meet those needs. Whether it's a small order for a specialized application or a large-scale project requiring custom-designed screens, the company is committed to delivering the best possible outcome for their customers.Furthermore, Fine Steel Mesh Screen places a strong emphasis on innovation and continuous improvement. They invest heavily in research and development to stay ahead of industry trends and technology advancements. This commitment to innovation has led to the development of new and improved screen designs that offer enhanced performance and durability.In line with their commitment to sustainability, Fine Steel Mesh Screen also focuses on eco-friendly manufacturing processes. They strive to minimize their environmental impact by optimizing their production methods and using energy-efficient technologies. This dedication to sustainability is reflected in their products, which are designed to have a longer lifespan and reduce the need for frequent replacements.The Fine Steel Mesh Screen has gained a strong reputation for reliability and performance in the industry. Their screens are trusted by customers around the world who rely on them for critical applications where failure is not an option. This trust is a result of the company's unwavering commitment to quality, innovation, and customer satisfaction.Looking ahead, Fine Steel Mesh Screen is poised for continued growth and success. With a focus on meeting the evolving needs of their customers and staying at the forefront of technological advancements, the company is well-positioned to maintain its leadership in the industry.In conclusion, Fine Steel Mesh Screen is a company that stands out for its commitment to quality, innovation, and customer satisfaction. With a strong reputation built on high-quality products, excellent customer service, and a dedication to sustainability, the company is poised for continued success in the industry. Their versatile and reliable mesh screens continue to serve as a trusted solution for a wide range of applications, making them an essential partner for businesses across various industries.

Find Affordable and High-Quality Powder Coating Mesh for Your Projects

[Company Introduction][Company Name] is a leading provider of innovative solutions in the realm of powder coating technology. With decades of experience and a commitment to excellence, we have established ourselves as a market leader in delivering high-quality and reliable powder coating mesh that meets the diverse needs of our global clientele.Our extensive range of powder coating mesh is designed to enhance the coating process by ensuring uniformity, durability, and efficiency. We take pride in offering our customers a comprehensive selection of mesh options that cater to a variety of applications in industries such as automotive, architectural, furniture, and more.At [Company Name], we understand the significance of powder coating mesh in achieving flawless finishes and lasting protection. With an unwavering focus on research and development, we invest heavily in advanced technologies and stringent quality control measures to provide our customers with superior products that consistently perform as expected.[News Content]Title: [Company Name] Launches Next-Generation Powder Coating Mesh for Enhanced Coating Efficiency[Location], [Date] - [Company Name], a trusted name in the powder coating industry, has unveiled its latest range of cutting-edge powder coating mesh, designed to revolutionize the coating process and deliver exceptional results.With an increasing demand for enhanced coating efficiency, [Company Name] has risen to the challenge by developing a range of mesh solutions that significantly improve the overall coating experience. The newly launched powder coating mesh is engineered to offer unparalleled uniformity, durability, and ease of use.One of the key features of the next-generation mesh is its advanced airflow design, which maximizes the powder penetration while minimizing the risk of overspray. This innovation not only ensures an even coating but also reduces wastage, resulting in substantial cost savings for businesses.Moreover, the powder coating mesh is manufactured using high-quality materials that are resistant to corrosion and wear. This enables the mesh to withstand even the harshest treatment, guaranteeing a long service life and consistent performance, even in demanding industrial environments.To cater to different coating requirements, [Company Name] offers a wide range of mesh sizes and configurations. From coarse to fine mesh, customers can choose the most suitable option based on their specific application and desired coating thickness. With this level of customization, businesses can achieve precise and accurate coating results."We are proud to introduce our latest powder coating mesh range, which represents a significant leap forward in terms of coating efficiency," said [Company Spokesperson], [Position] of [Company Name]. "Our goal has always been to provide solutions that enhance productivity and quality, and this new range of mesh is a testament to our dedication to customer satisfaction."As part of its commitment to delivering exceptional customer service, [Company Name] offers comprehensive technical support and guidance to ensure optimal usage of the powder coating mesh. With a team of experts readily available, customers can benefit from professional advice on selecting the right mesh, troubleshooting, and maximizing their coating efficiency.In conclusion, [Company Name]'s latest range of powder coating mesh redefines the standards of coating excellence. With its advanced features and customized options, businesses across different industries can experience enhanced efficiency, reliability, and cost savings. As a market leader in powder coating technology, [Company Name] continues to push the boundaries of innovation, enabling its customers to achieve superior coating results while staying ahead of the competition.

Durable Stainless Steel Woven Wire Mesh for a Variety of Applications

Stainless Steel Woven Wire Mesh - A Sturdy and Versatile Material for Various ApplicationsStainless steel woven wire mesh is a versatile and durable material that finds applications in a wide range of industries due to its strength, corrosion resistance, and aesthetic appeal. [Company Name] is a leading manufacturer and supplier of stainless steel woven wire mesh, providing high-quality products to customers worldwide.The company's stainless steel woven wire mesh is made from high-quality stainless steel wires, which are woven together to create a strong and flexible material. The wire mesh can be custom-designed to meet specific requirements, making it suitable for a variety of applications, including filtration, screening, and protection.One of the key features of [Company Name]'s stainless steel woven wire mesh is its corrosion resistance. Stainless steel is inherently resistant to corrosion, making it an ideal material for use in harsh environments, such as marine or industrial settings. This property ensures that the wire mesh will maintain its strength and integrity over time, even when exposed to moisture, chemicals, or extreme temperatures.In addition to its corrosion resistance, stainless steel woven wire mesh is also known for its excellent strength and durability. The material can withstand heavy loads and high impact, making it suitable for applications requiring robust and long-lasting materials. This makes it an ideal choice for use in industrial equipment, machinery, and architectural structures.Furthermore, stainless steel woven wire mesh offers a high level of versatility, making it suitable for a wide range of applications. The wire mesh can be custom-designed with different weave patterns, opening sizes, and wire diameters to meet specific requirements. This allows for the creation of tailored solutions for various uses, including filtration screens, protective barriers, and decorative elements.[Company Name] is committed to providing high-quality stainless steel woven wire mesh products that meet the highest industry standards. The company's manufacturing processes are carefully monitored to ensure that the wire mesh meets the required specifications for strength, durability, and corrosion resistance. This dedication to quality has earned [Company Name] a solid reputation as a trusted supplier of stainless steel woven wire mesh.The company's stainless steel woven wire mesh is widely used in a variety of industries, including automotive, aerospace, chemical processing, and architecture. The material is used for applications such as air and liquid filtration, security screens, conveyor belt systems, and architectural cladding. The versatility of stainless steel woven wire mesh makes it a popular choice for both industrial and decorative uses.In conclusion, stainless steel woven wire mesh is a versatile and durable material that offers a wide range of benefits for various applications. With its exceptional strength, corrosion resistance, and customizability, it is a preferred choice for industries requiring reliable and long-lasting materials. As a leading manufacturer and supplier of stainless steel woven wire mesh, [Company Name] is committed to providing high-quality products that meet the unique needs of its customers. With its proven track record and expertise in wire mesh production, [Company Name] continues to be a trusted partner for businesses seeking reliable stainless steel woven wire mesh solutions.

Durable and Corrosion-Resistant Metal Mesh Used in Various Applications

Monel Mesh, a versatile and durable material, has been making waves in the industry for its wide range of applications and high-performance characteristics. The company behind this innovative product, {Company Name}, has been at the forefront of developing advanced materials and solutions for various industries.{Company Name} is a leading manufacturer and supplier of Monel Mesh, offering a wide range of specifications and customization options to meet the unique needs of their customers. With years of experience in the industry, the company has built a solid reputation for delivering high-quality products and exceptional customer service.Monel Mesh is a type of woven wire mesh that is made from a high-performance alloy known as Monel. This alloy is composed of approximately 65-70% nickel, 20-29% copper, and small amounts of iron, manganese, silicon, and carbon. The combination of these elements gives Monel Mesh its exceptional corrosion resistance, strength, and durability, making it suitable for a wide range of applications.One of the key advantages of Monel Mesh is its resistance to corrosion, especially in harsh environments such as marine or chemical processing plants. This makes it an ideal choice for applications where traditional materials may fail due to corrosion, such as filtration, separation, and screening processes.In addition to its corrosion resistance, Monel Mesh also offers excellent mechanical properties, including high tensile strength, toughness, and resistance to high temperatures. This makes it suitable for demanding applications such as aerospace, automotive, and industrial manufacturing.{Company Name} is committed to meeting the specific needs of their customers by offering custom fabrication services for Monel Mesh. This includes custom sizing, shaping, and finishing to ensure that the mesh meets the exact requirements of each application. With their state-of-the-art manufacturing facilities and skilled engineers, the company is able to deliver high-quality, precision-engineered Monel Mesh products to their customers.The versatility of Monel Mesh also extends to its wide range of applications, including filtration, separation, screening, and reinforcement in industries such as aerospace, oil and gas, marine, chemical processing, and automotive. Its combination of high-performance characteristics and customizability makes it a valuable material for a wide range of industries.As a leading supplier of Monel Mesh, {Company Name} has established a strong global presence, serving customers around the world with their high-quality products and reliable service. The company has built long-standing relationships with a diverse range of industries, earning a reputation for excellence and innovation in the field of advanced materials.With a commitment to quality, innovation, and customer satisfaction, {Company Name} continues to lead the way in the development and supply of Monel Mesh. Their dedication to meeting the unique needs of their customers and delivering outstanding products has positioned them as a trusted partner for businesses seeking high-performance materials for their applications.In conclusion, Monel Mesh, offered by {Company Name}, is a high-performance material that offers exceptional corrosion resistance, strength, and durability. With its wide range of applications and customizability, Monel Mesh has become a valuable solution for industries around the world. As a leading manufacturer and supplier of Monel Mesh, {Company Name} continues to set the standard for excellence and innovation in the field of advanced materials.

Discover the Benefits of Power Coated Metal Mesh for Various Applications

Metal Mesh With Power Coating - Reinventing Durability and Aesthetics in ConstructionIntroduction:In the fast-paced world of construction, innovation is key. As new technologies and materials continue to emerge, companies are constantly looking for ways to enhance both durability and aesthetics in their projects. One such groundbreaking development is the introduction of Metal Mesh With Power Coating, a revolutionary solution that promises to revolutionize the construction industry. By combining the strength of metal with the beauty of power coating, this product is poised to leave a lasting impact on the way buildings are designed and built.Metal Mesh:Metal mesh has long been admired for its strength and durability. Traditionally crafted using stainless steel, these meshes have found a wide range of applications within the construction industry. From facades to partitions, metal meshes provide a practical solution for airflow, light diffusion, and even security purposes. However, the limitation with these meshes has always been their lack of aesthetic appeal and resistance against corrosion.Power Coating:Enter power coating, a technique that has transformed the world of metal finishes. Power coating involves applying a layer of polymer resin to a surface, which is then cured under heat to form a hard, durable, and protective layer. This technique has become popular due to its ability to provide excellent corrosion resistance, weatherability, and a wide range of color options. While power coating has been predominantly used on metal surfaces, it has now found a new application in metal mesh, resulting in a game-changing combination.The Innovative Combination:By merging metal mesh with power coating, this innovative product offers a multitude of benefits for the construction industry. First and foremost, the power coating enhances the already robust properties of metal mesh. It provides an additional layer of protection against corrosion, extending the lifespan of the mesh significantly. Furthermore, the power coating offers resistance against fading and chipping, ensuring that the aesthetic appeal of the mesh remains intact over time.Aesthetics and Customization:One of the most noteworthy advantages of metal mesh with power coating is its ability to enhance the aesthetics of a building. The power coating not only provides protection but also opens up a world of design possibilities. With a wide array of colors and finishes available, architects and designers can now incorporate metal mesh seamlessly into their projects, transforming them into visually stunning masterpieces. The ability to customize the appearance of the mesh allows for greater flexibility and creativity, enabling architects to unleash their imagination like never before.Versatility and Applications:Metal mesh with power coating is a versatile product that can be applied to numerous areas in construction. From exterior facades to interior partitions, this product can seamlessly blend in with any architectural design. The mesh provides excellent airflow and light diffusion, creating an airy and visually appealing environment. Moreover, it can be employed as solar shading, offering energy efficiency benefits by reducing heat gain and glare on buildings. With these multifaceted benefits, metal mesh with power coating is quickly becoming the preferred choice for architects and builders worldwide.Sustainability and Environmental Impact:In an era where sustainability is of paramount importance, metal mesh with power coating aligns perfectly with the objectives of environmentally conscious construction. With its ability to optimize energy efficiency by reducing heat gain, this product aids in creating more sustainable buildings. Additionally, the power coating technique is inherently eco-friendly, employing minimal volatile organic compounds (VOCs) and generating minimal waste, making it a responsible choice for green building practices.Conclusion:With its exceptional combination of strength, durability, and aesthetic appeal, metal mesh with power coating is set to redefine the construction industry. By merging the benefits of metal mesh with the protective and visually enticing properties of power coating, this product opens up new frontiers for architects and designers. Its versatility, customization options, and sustainability make it an optimal choice for modern construction. As the industry continues to evolve, metal mesh with power coating will undoubtedly be at the forefront, bringing innovation, durability, and beauty to building projects around the globe.

Discover the Benefits of Woven Wire Screens for Your Needs

article:Woven Wire Screen: The Ultimate Solution for Material SeparationIndustries engaged in the handling of materials know the significance of an effective and reliable screening solution for a successful operation. A woven wire screen (name removed) has emerged as a popular and versatile option for material separation across various sectors. With its unique design and superior quality, this screen is increasingly becoming an essential component for the material handling industry.Origin and Evolution of Woven Wire ScreenWoven wire screens are made of wires woven together in a mesh pattern. The earliest type of woven screen was made of horsehair in 1808. However, the first patent for a woven wire mesh was issued in 1871. Over the years, this screen has undergone immense development and innovations. Today, modern weaving techniques and technology have made it possible to produce woven wire screens with precision, efficiency, and consistency.Woven Wire Screen: The Ultimate Solution for Material SeparationWoven wire screens find immense applicability across a wide range of industries. The mining, aggregate, and construction industries use woven wire screens to sort and separate granular materials like ore, rock, gravel, and sand. The food processing industry uses it to filter liquids, powders, and solids. Similarly, the pharmaceutical industry utilizes it for separating solids from liquids. The pulp and paper mills use woven wire screens for screening wood chips, pulp, and waste products.Woven Wire Screen: A Versatile SolutionOne of the significant advantages of woven wire screens is its versatility. It is available in a wide range of shapes, sizes, and materials. The shape and size of the screen depend on the specific demand for the application. The available materials range from carbon steel, high-strength steel alloys, and stainless steel, making it an adaptable solution for any screening need.DurabilityWoven wire screens are tested for durability and strength. Material handling processes can often be harsh, with excessive vibration, high velocity, and abrasive material. A high-quality woven wire screen can withstand extreme conditions, minimizing the risk of screen failure and product contamination. Its durability will not allow for frequent screen replacements, which leads to a considerable saving in both time and money.Easy to MaintainAnother advantage of using a woven wire screen is its ease of maintenance. It can be cleaned and washed effortlessly. The structure of the screen makes it simple to access and inspect regularly. This makes it easy to monitor the progress of the screening process, and any issues detected early and rectified immediately.Superior ScreeningThe unique design of the woven wire screen ensures complete accuracy and superior screening. It provides consistency in the size of the screened material and reduces over-sizing, improving the process and output.Woven Wire Screen: The Name to TrustWhen it comes to woven wire screens, (name removed) is the name to trust. The company is a global leader in manufacturing high-quality woven wire screen and custom screen products. Their commitment to quality and customer satisfaction is reflected in their continuous innovation and investment in modern technology. Established in 1864, the company has a rich history of providing long-lasting and efficient woven wire screens to various industries.Continuous Innovation(Name removed) has over 150 years of experience in the manufacturing of woven wire screens. Over the years, the company has invested in modern technology to produce the highest quality screen wire available. The company has a team of experts that continuously research and strive for new and innovative ways to improve the design and quality of their woven wire screens.Customized SolutionsThe company offers a range of customizable solutions according to the customers' precise requirements, ensuring that the woven wire screen is tailored to meet the exacting demands of the screening application.Exceptional Customer Support(Name removed) is dedicated to providing exceptional customer support. They offer a range of services ranging from on-site support to 24/7 technical support, all aimed at ensuring that their clients receive assistance to meet their screening needs.ConclusionWoven wire screens are an essential component of any material handling operation. Their versatility, durability, ease of maintenance, and superior screening qualities make them the preferred option for industries globally. With companies like (name removed), committed to designing and producing high-quality woven wire screens, industries can have peace of mind, knowing that they have a reliable solution to their screening needs.

Durable and Versatile Metal Mesh for Various Applications

Metal Mesh, a leading manufacturer of high-quality metal mesh products, has recently announced the launch of their latest innovation, the Advanced Mesh Pro. The Advanced Mesh Pro is a revolutionary mesh system designed to provide superior strength, durability, and performance for a wide range of industrial and commercial applications.Metal Mesh has been at the forefront of the metal mesh industry for over 20 years, providing innovative solutions for a variety of industries including construction, agriculture, mining, and architecture. The company's commitment to quality and innovation has earned them a reputation as a trusted industry leader, and the launch of the Advanced Mesh Pro is poised to further solidify their position in the market.The Advanced Mesh Pro is designed to meet the ever-increasing demands of modern construction and industrial applications. Its unique design and construction make it exceptionally strong and durable, capable of withstanding even the harshest conditions. This makes it the perfect choice for use in heavy-duty applications such as safety barriers, fencing, machine guards, and screening.One of the key features of the Advanced Mesh Pro is its innovative locking system, which allows for quick and easy installation. This not only saves time and money but also ensures a secure and reliable connection, providing peace of mind for customers. Additionally, the mesh is available in a variety of sizes and configurations, making it easy to customize to specific project requirements."Metal Mesh is proud to introduce the Advanced Mesh Pro to our product lineup," said John Smith, CEO of Metal Mesh. "We believe this product will set a new standard for strength and durability in the metal mesh industry. Our customers can trust that they are getting a top-quality product that will exceed their expectations."Metal Mesh is dedicated to providing exceptional customer service and support, and they stand behind the quality and performance of the Advanced Mesh Pro with a comprehensive warranty. This demonstrates the company's confidence in the durability and reliability of their product, further solidifying their commitment to customer satisfaction.In addition to the Advanced Mesh Pro, Metal Mesh offers a wide range of other high-quality metal mesh products, including woven wire mesh, expanded metal mesh, perforated metal, and architectural mesh. These products are used in a variety of applications, from decorative elements in architectural design to heavy-duty industrial uses. The company's diverse product line and commitment to innovation have made them a preferred supplier for many companies across the globe.Metal Mesh is dedicated to sustainability and environmental responsibility, and the company takes measures to ensure that their manufacturing processes have minimal impact on the environment. This includes using recycled materials in their products and implementing energy-efficient practices in their manufacturing facilities. By choosing Metal Mesh products, customers can feel confident that they are supporting a company with a strong commitment to environmental stewardship.As Metal Mesh continues to push the boundaries of innovation in the metal mesh industry, the company looks forward to the opportunity to partner with businesses and organizations that are seeking top-quality, reliable metal mesh solutions. The launch of the Advanced Mesh Pro is a testament to the company's dedication to providing superior products and exceptional service to their customers.For more information about Metal Mesh and their products, please visit their website or contact their customer service team. With a focus on quality, innovation, and customer satisfaction, Metal Mesh is poised to remain a leader in the metal mesh industry for years to come.