| Specification - Square weave sintered mesh | |||||

| Descriptsion | filter fineness | Structure | Thickness | Porosity | Weight |

| μm | mm | % | kg / ㎡ | ||

| SSM-S-0.5T | 2-100 | filter layer+60 | 0.5 | 60 | 1.6 |

| SSM-S-0.7T | 2-100 | 60+filter layer+60 | 0.7 | 56 | 2.4 |

| SSM-S-1.0T | 20-100 | 50+filter layer+20 | 1 | 58 | 3.3 |

| SSM-S-1.7T | 2-200 | 40+filter layer+20+16 | 1.7 | 54 | 6.2 |

| SSM-S-1.9T | 2-200 | 30+filter layer+60+20+16 | 1.9 | 52 | 5.3 |

| SSM-S-2.0T | 20-200 | filter layer+20+8.5 | 2 | 58 | 6.5 |

| SSM-S-2.5T | 2-200 | 80+filter layer+30+10+8.5 | 2.5 | 55 | 8.8 |

| Remarks:Other layer structure available on request | |||||

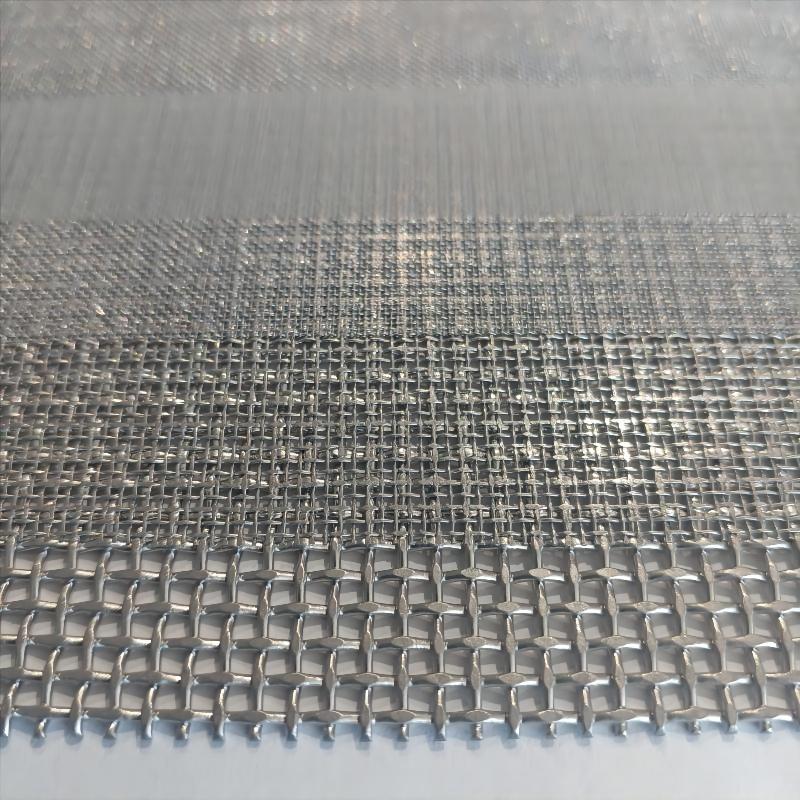

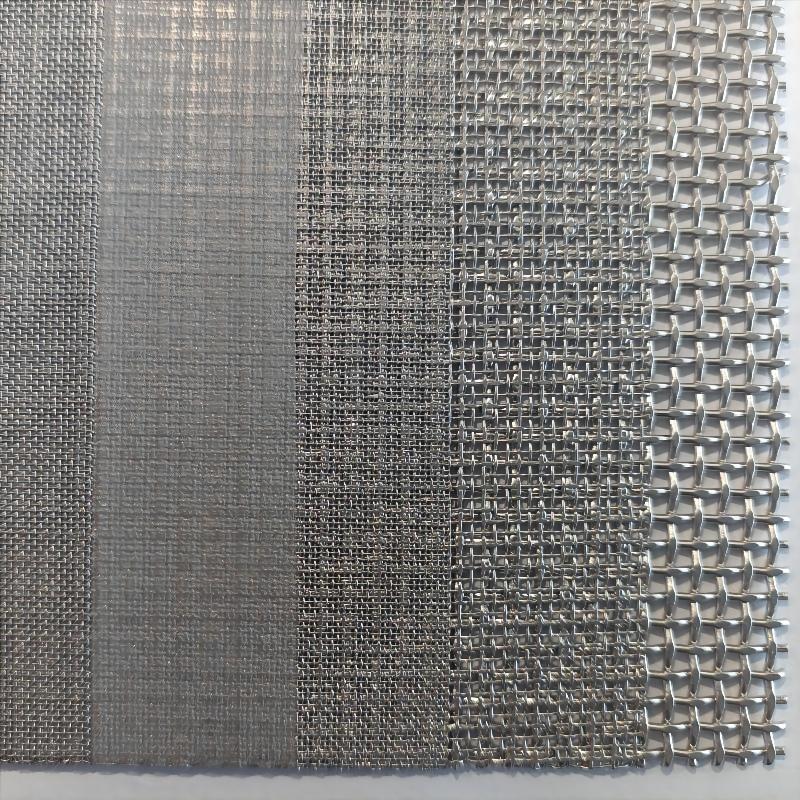

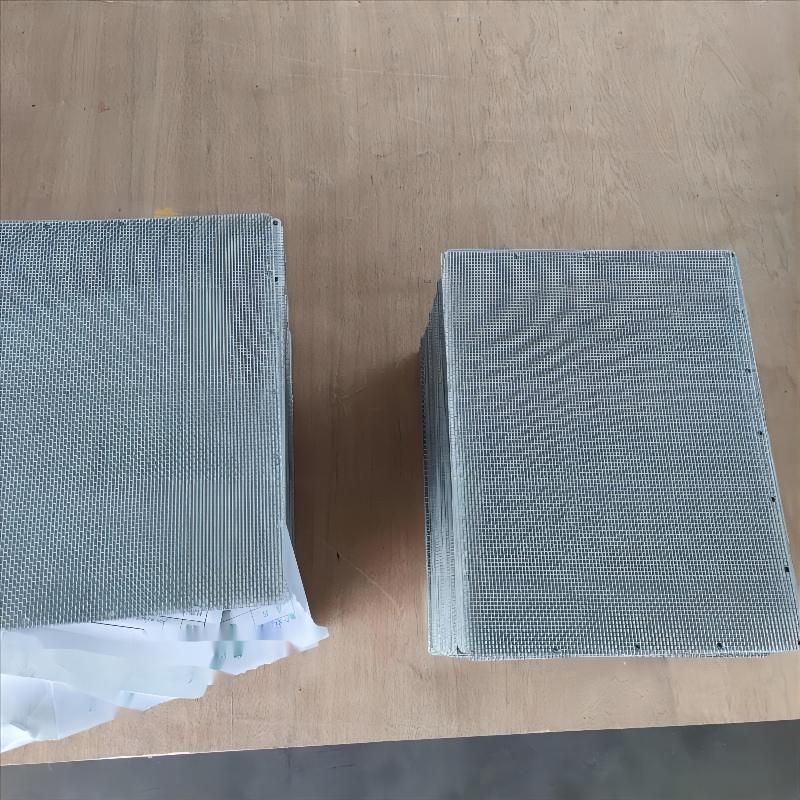

Model one

Model oneModel two

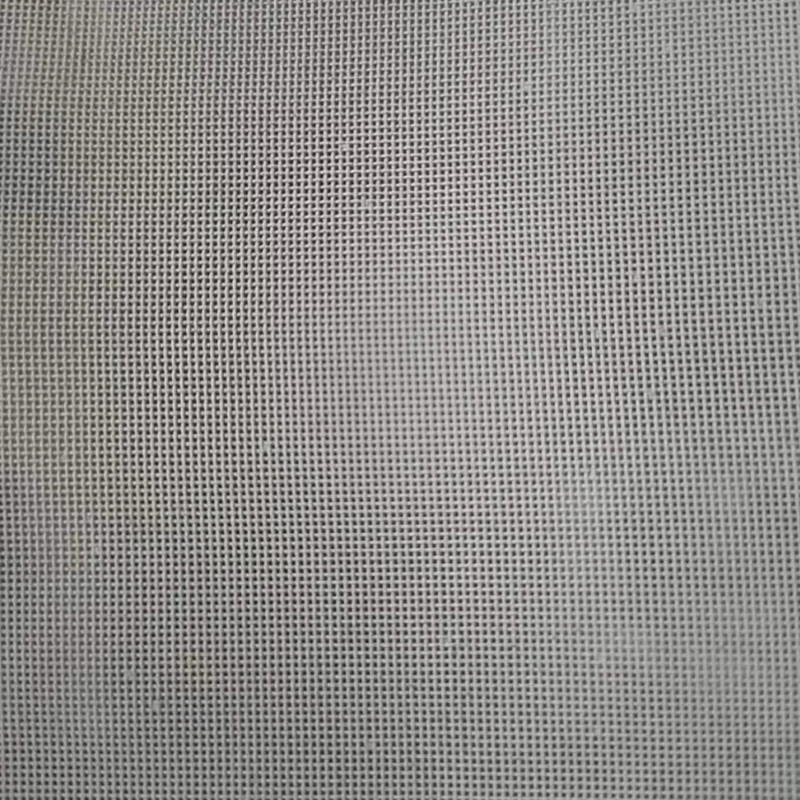

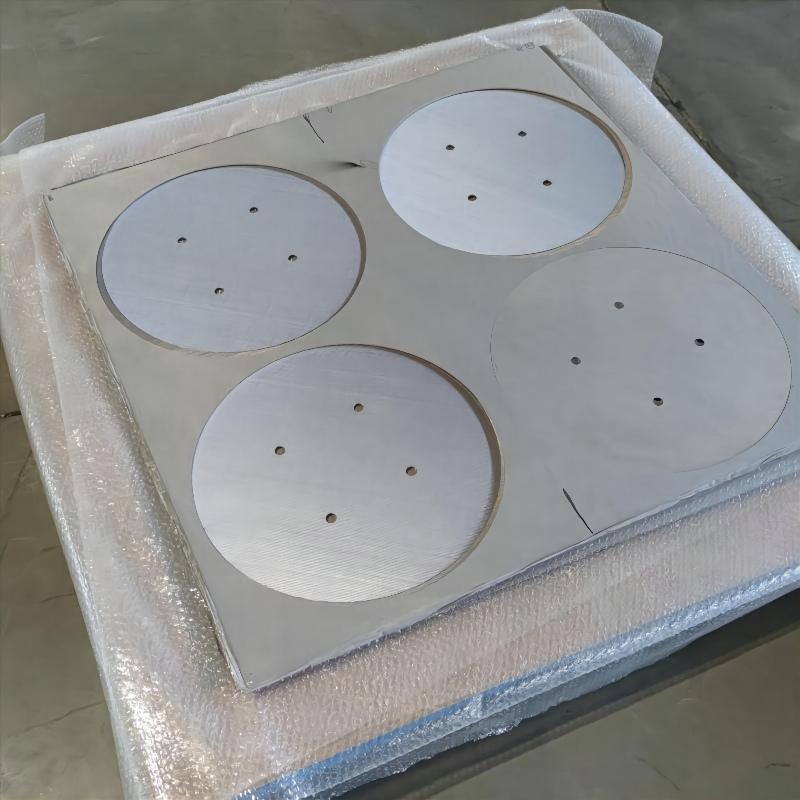

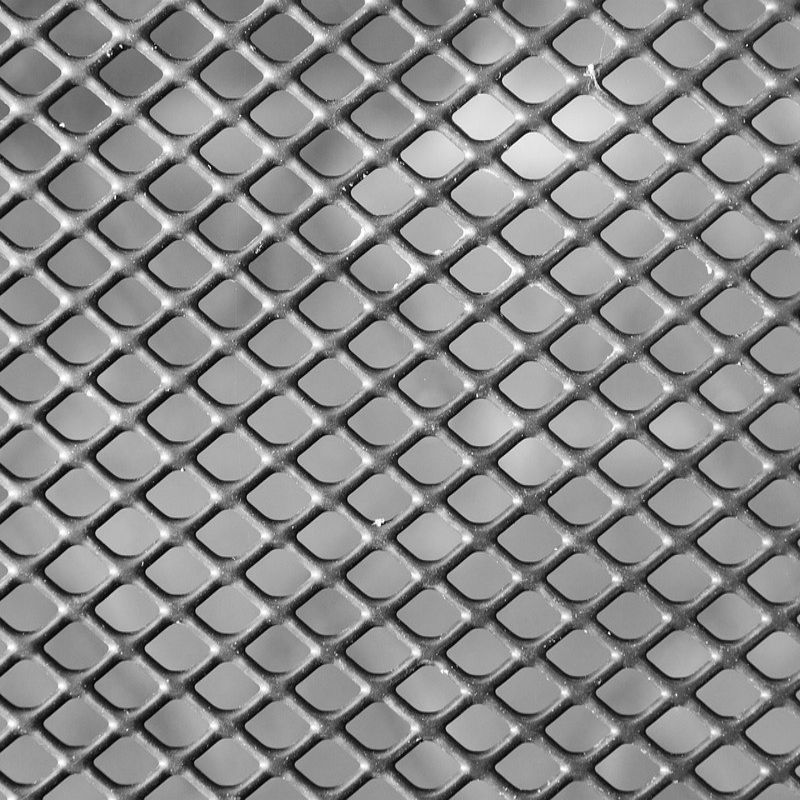

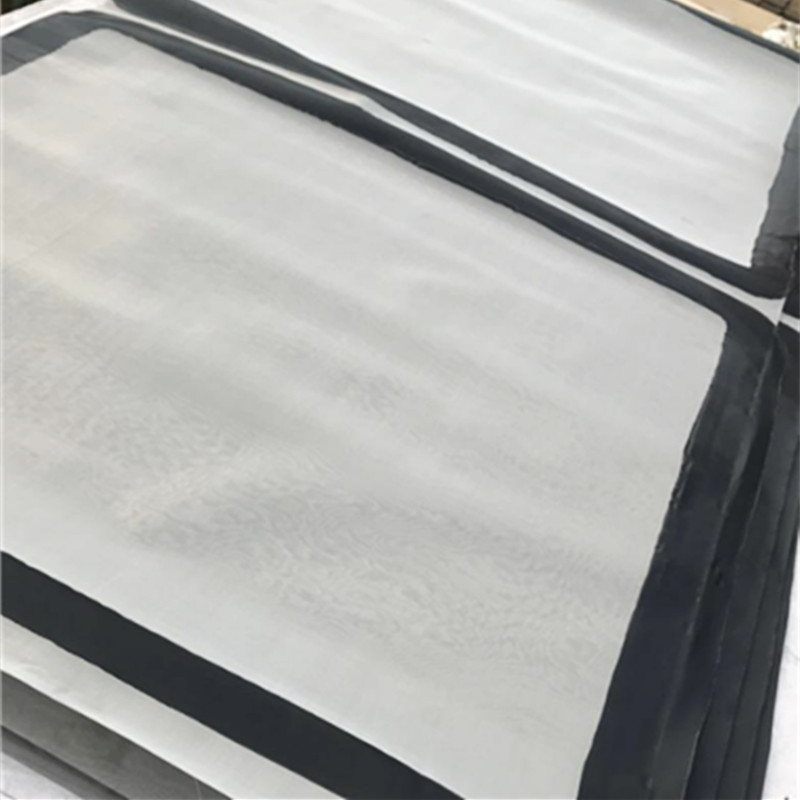

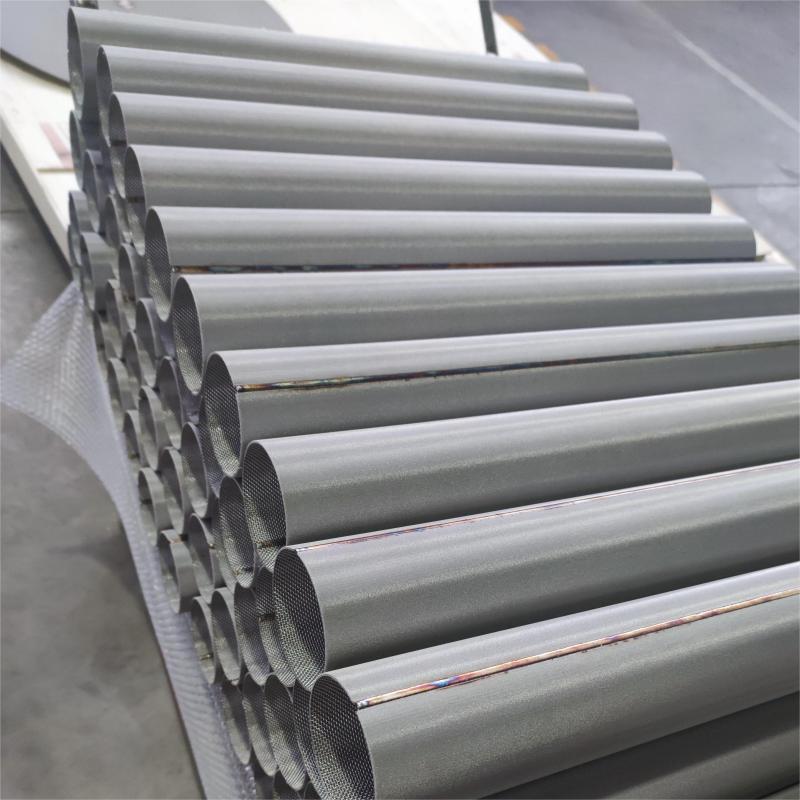

500mmx1000mm,1000mmx1000mm 600mmx1200mm,1200mmx1200mm 1200mmx1500mm,1500mmx2000mm Other size available on request.Square hole sintered mesh is a kind of sintered mesh that sinters multiple layers of plain woven square hole mesh together. Due to the high porosity of the square mesh, the sintered mesh produced has the characteristics of high permeability, low resistance, and large flow rate. Widely used in rectification, powder conveying, diffuse gas, drying, cooling, soaking, impedance and other functional requirements of the field. Features of square hole sintered mesh: 1. High porosity and uniform volume distribution; 2. Easy to backwash: Due to the surface filter structure with excellent countercurrent cleaning effect, the countercurrent cleaning effect is good, it can be used repeatedly, and the service life is long (can be cleaned by backwater, filtrate, ultrasonic, melting, baking, etc.) 3. Corrosion resistance, high temperature resistance, high precision: It can withstand the temperature from -200 ℃ to 600 ℃ and the filtration of acid-base environment, and can exert a uniform surface filtration performance for the filtration accuracy of 2-250 μm.

500mmx1000mm,1000mmx1000mm 600mmx1200mm,1200mmx1200mm 1200mmx1500mm,1500mmx2000mm Other size available on request.Square hole sintered mesh is a kind of sintered mesh that sinters multiple layers of plain woven square hole mesh together. Due to the high porosity of the square mesh, the sintered mesh produced has the characteristics of high permeability, low resistance, and large flow rate. Widely used in rectification, powder conveying, diffuse gas, drying, cooling, soaking, impedance and other functional requirements of the field. Features of square hole sintered mesh: 1. High porosity and uniform volume distribution; 2. Easy to backwash: Due to the surface filter structure with excellent countercurrent cleaning effect, the countercurrent cleaning effect is good, it can be used repeatedly, and the service life is long (can be cleaned by backwater, filtrate, ultrasonic, melting, baking, etc.) 3. Corrosion resistance, high temperature resistance, high precision: It can withstand the temperature from -200 ℃ to 600 ℃ and the filtration of acid-base environment, and can exert a uniform surface filtration performance for the filtration accuracy of 2-250 μm.