| Specification - Punching plate sintered wire mesh | ||||

| Description | filter fineness | Structure | Thickness | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60+filter layer+60+30+Φ4x5px1.0T | 1.5 | 57 |

| SSM-P-2.0T | 2-100 | 30+filter layer+30+Φ5x7px1.5T | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60+filter layer+60+30+Φ4x5px1.5T | 2.5 | 35 |

| SSM-P-3.0T | 2-200 | 60+filter layer+60+20+Φ6x8px2.0T | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30+filter layer+30+20+Φ8x10px2.5T | 4 | 50 |

| SSM-P-5.0T | 2-200 | 30+filter layer+30+20+16+10+Φ8x10px3.0T | 5 | 55 |

| SSM-P-6.0T | 2-250 | 30+filter layer+30+20+16+10+Φ8x10px4.0T | 6 | 50 |

| SSM-P-7.0T | 2-250 | 30+filter layer+30+20+16+10+Φ8x10px5.0T | 7 | 50 |

| SSM-P-8.0T | 2-250 | 30+filter layer+30+20+16+10+Φ8x10px6.0T | 8 | 50 |

| The thickness of the punching plate and structure of the wire mesh can be customized according to the user’s requirements. | ||||

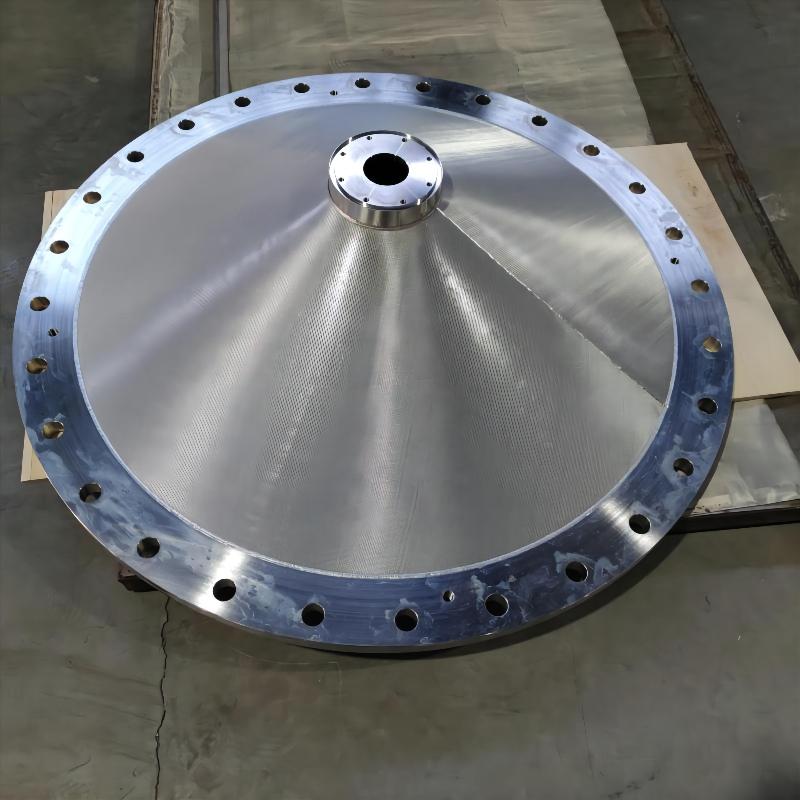

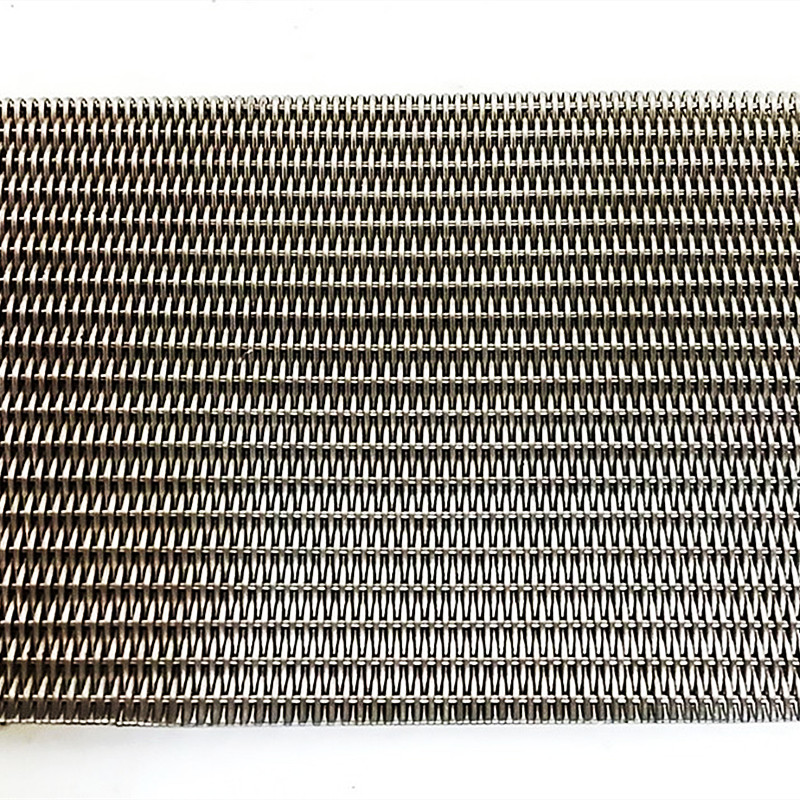

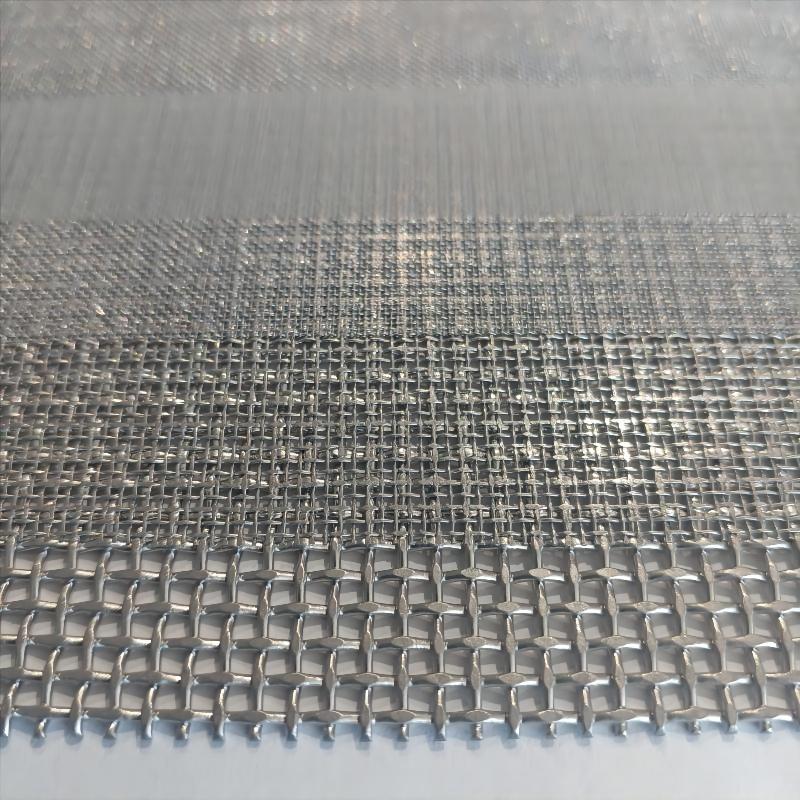

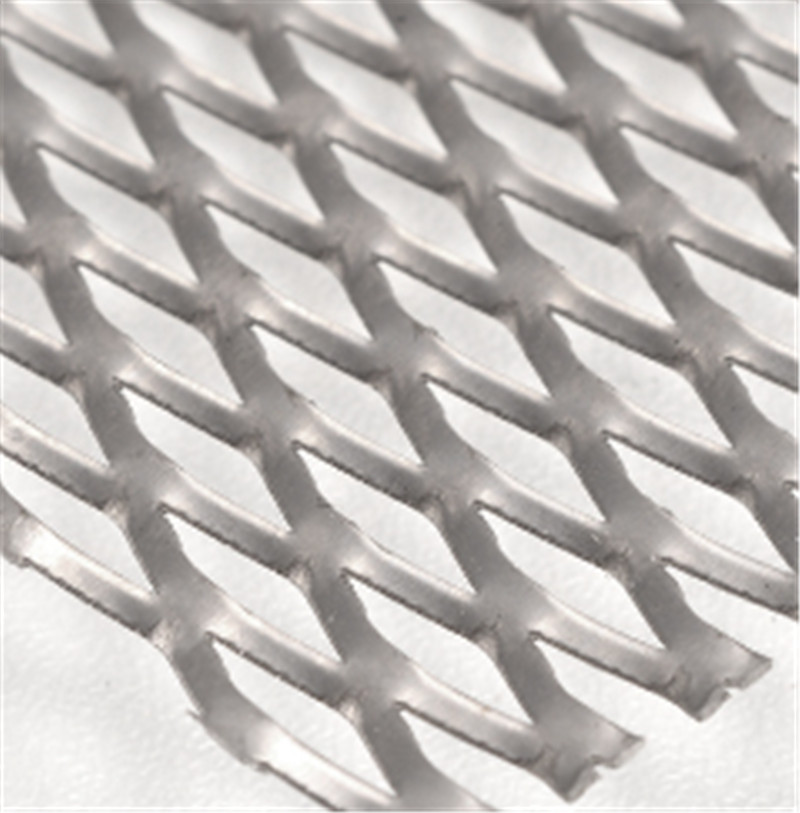

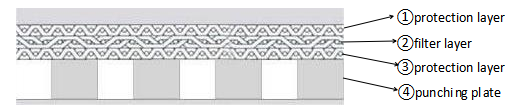

Remarks, if it is used in Multifunctional filter washing dryers, the filter plate structure can be standard five-layer and punching plate sintered together. That is 100+filter layer+100+12/64+64/12+4.0T(or Of other thickness punching plate) The thickness of punching plate is also depended on your pressure demand This product is ideal for high pressure environments or high pressure backwashing demand, effectively solve the continuous production of pharmaceutical and chemical industry and online backwashing, sterile production requirements.The standard five-layer sintered mesh filter element is mainly rolled by the standard five-layer sintered mesh filter material. The standard five-layer sintered wire mesh is made of five layers of stainless steel wire mesh superimposed and vacuum sintered. The filter element made of standard five-layer sintered mesh has the characteristics of strong corrosion resistance, good permeability, high strength, easy cleaning and back cleaning, uniform filtration accuracy, hygienic and clean filter material, and non-shedding wire mesh. The meshes of each layer of the sintered mesh filter element are interlaced to form a uniform and ideal filter structure, which makes the material have advantages that cannot be compared with ordinary metal mesh, such as high strength, good rigidity, and mesh. shape stability etc. Due to the reasonable matching and design of the pore size, permeability and strength characteristics of the material, it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability, and the comprehensive performance is better. Higher than other types of filter materials. 1. Product features: 1) The five-layer sintered mesh is composed of a protective layer, a filter layer, a dispersion layer and two skeleton layers; 2) High strength: after sintering the five-layer wire mesh, it has high mechanical strength and compressive strength; 3) High precision: It can exert uniform surface filtration performance for the filtration particle size of 1 to 200um; 4) Heat resistance: It can be used for continuous filtration from -200 degrees to up to 650 degrees; 5) Cleanability: Due to the surface filter structure with better countercurrent cleaning effect, the cleaning is simple. 6) It has good permeability and high strength, no need to add support structure, no material falling off normally, strong corrosion resistance, easy to clean and not easy to damage. 2.The main purpose: 1) Used as a dispersed cooling material in high temperature environment; 2) Used for gas distribution, orifice plate material for liquidized bed; 3) For high-precision, high-reliability high-temperature filter materials; 4) For high pressure backwash oil filter 5) Used for filtration of polyester, oil products, pharmaceuticals, food and beverage, chemical and chemical fiber products, and also for water treatment and gas filtration. Note: Dimensions can be produced according to customer requirements. Can be processed into tubular, disc, candle and other filter elements.

Remarks, if it is used in Multifunctional filter washing dryers, the filter plate structure can be standard five-layer and punching plate sintered together. That is 100+filter layer+100+12/64+64/12+4.0T(or Of other thickness punching plate) The thickness of punching plate is also depended on your pressure demand This product is ideal for high pressure environments or high pressure backwashing demand, effectively solve the continuous production of pharmaceutical and chemical industry and online backwashing, sterile production requirements.The standard five-layer sintered mesh filter element is mainly rolled by the standard five-layer sintered mesh filter material. The standard five-layer sintered wire mesh is made of five layers of stainless steel wire mesh superimposed and vacuum sintered. The filter element made of standard five-layer sintered mesh has the characteristics of strong corrosion resistance, good permeability, high strength, easy cleaning and back cleaning, uniform filtration accuracy, hygienic and clean filter material, and non-shedding wire mesh. The meshes of each layer of the sintered mesh filter element are interlaced to form a uniform and ideal filter structure, which makes the material have advantages that cannot be compared with ordinary metal mesh, such as high strength, good rigidity, and mesh. shape stability etc. Due to the reasonable matching and design of the pore size, permeability and strength characteristics of the material, it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability, and the comprehensive performance is better. Higher than other types of filter materials. 1. Product features: 1) The five-layer sintered mesh is composed of a protective layer, a filter layer, a dispersion layer and two skeleton layers; 2) High strength: after sintering the five-layer wire mesh, it has high mechanical strength and compressive strength; 3) High precision: It can exert uniform surface filtration performance for the filtration particle size of 1 to 200um; 4) Heat resistance: It can be used for continuous filtration from -200 degrees to up to 650 degrees; 5) Cleanability: Due to the surface filter structure with better countercurrent cleaning effect, the cleaning is simple. 6) It has good permeability and high strength, no need to add support structure, no material falling off normally, strong corrosion resistance, easy to clean and not easy to damage. 2.The main purpose: 1) Used as a dispersed cooling material in high temperature environment; 2) Used for gas distribution, orifice plate material for liquidized bed; 3) For high-precision, high-reliability high-temperature filter materials; 4) For high pressure backwash oil filter 5) Used for filtration of polyester, oil products, pharmaceuticals, food and beverage, chemical and chemical fiber products, and also for water treatment and gas filtration. Note: Dimensions can be produced according to customer requirements. Can be processed into tubular, disc, candle and other filter elements.