The Latest Advancements in Sintered Metal Candle Filter Technology Revealed

By:Admin

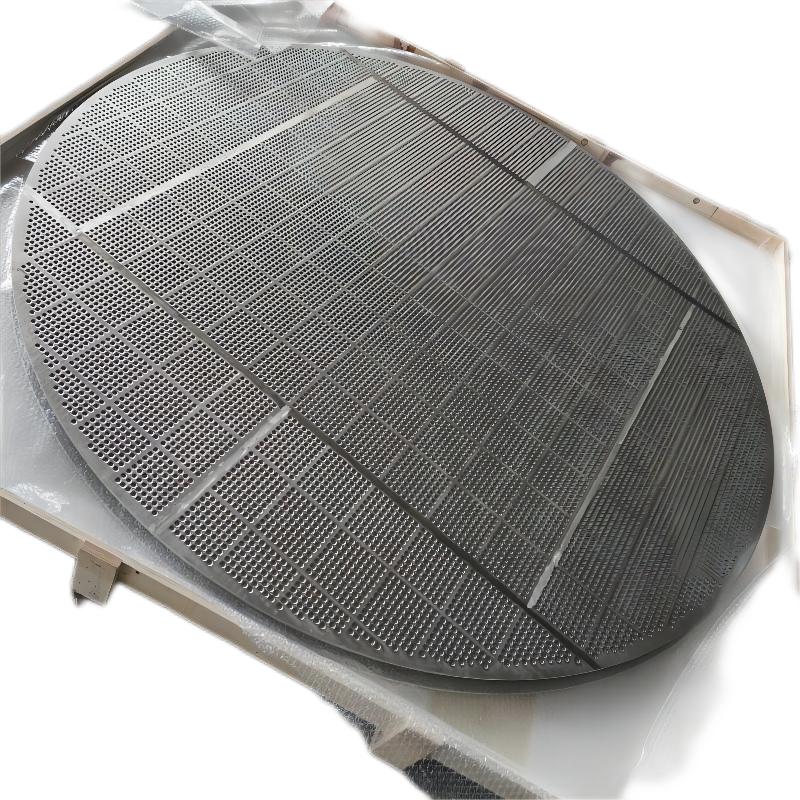

Candle filtration is a popular and effective method of filtering liquids. In recent times, the use of sintered metal candle filters has revolutionized the filtration industry by setting a new standard of efficiency and effectiveness. Sintered metal candle filters are made from fine metal powders that are formed into a filter element under high temperature and pressure conditions. These filters are used in various industries including petrochemical refineries, oil and gas production, food and beverage processing, and pharmaceutical manufacturing.

Sintered metal candle filters are designed to remove impurities from liquids by trapping them in the pores of the filter element. These filters have a high dirt-holding capacity and offer excellent purification efficiency. They can filter out particles as small as 0.5 microns. Additionally, sintered metal candle filters operate at low pressure drop, which means that they save energy and reduce operating costs.

One company that has been at the forefront of producing sintered metal candle filters is {company name}. They have been supplying sintered metal filters to various industries for more than a decade. Their filters are known for their high quality, durability, and reliability. The company has invested heavily in research and development to improve the performance of their filters, and as a result, their products are highly sought after in the market.

In addition to producing sintered metal candle filters, {company name} also provides filter cleaning and reconditioning services. This is important because filters that are not cleaned and maintained properly can become clogged with dirt and other impurities. This can lead to reduced filter efficiency or even filter failure. {Company name}’s cleaning and reconditioning services help to prolong the lifespan of the filter element and ensure that it operates at optimal efficiency.

Sintered metal candle filters from {company name} have been used in various applications across different industries. For example, they have been used in the petrochemical industry to remove impurities from the oil before it is processed further. They have also been used in the food and beverage industry to remove solids, bacteria, and other contaminants from liquids such as juice, beer, and wine. In the pharmaceutical industry, sintered metal candle filters have been used to remove impurities from drugs, vaccines, and other medical products.

One of the benefits of using sintered metal candle filters from {company name} is that they are customizable. The company can produce filters of different sizes, shapes, and specifications to meet the specific needs of different customers. This ensures that their filters can be used in a wide range of applications.

Sintered metal candle filters from {company name} have been well received by their customers. One of their clients, a large oil and gas company, reported that the filters improved their production efficiency by reducing the downtime caused by frequent filter changes. Another customer, a pharmaceutical manufacturing company, reported that {company name}’s filters helped them to meet the regulatory requirements for purity and quality of their products.

In conclusion, sintered metal candle filters have set a new standard for filtration efficiency and effectiveness. Companies such as {company name} have been instrumental in producing high-quality sintered metal candle filters that are used in various industries. The durability, reliability, and customizability of their filters have made them a popular choice for many customers. With their commitment to research and development, {company name} is poised to continue supplying the market with innovative sintered metal candle filters that meet the evolving needs of different industries.

Company News & Blog

Silver Coated Aluminum Powder - High Quality & Purity - 25g, -200 Mesh, 99.9%

Aluminum is one of the most versatile metals that has continued to revolutionize modern industries, from transportation to construction and even aerospace. The use of aluminum in various industries has become increasingly popular over recent decades, thanks to its unique properties, such as its durability, strength, and lightweight nature.Leading in the production of aluminum products is Alfa Aesar, a leading manufacturer of research chemicals and materials. Alfa Aesar has been in the industry for over 50 years, providing high-quality aluminum products that meet the needs and requirements of different industries.One of their most popular aluminum products is their silver-coated aluminum powder, typically -200 mesh and 99.9% pure (metals basis), and contains 19-21% wt of silver (Ag). This product is perfect for industries that require an aluminum product with high electrical conductivity, including the electrical and electronics industry, aerospace, and defense industry.Aluminum products typically possess a good electrical conductivity level; however, by adding a thin layer of silver, the electrical conductivity is improved further. This makes silver-coated aluminum an excellent material for producing electrical contacts and conductors.Additionally, the coating of silver provides a high level of corrosion resistance, improving the durability and longevity of products made with this silver-coated aluminum powder. This property is vital, particularly for products used in the construction industry, where exposure to harsh weather conditions is expected.The use of Alfa Aesar's silver-coated aluminum powder is not limited to the electrical and electronics industry, aerospace, and defense industry; it is also applicable in the production of automotive parts, additive manufacturing processes, and coatings. This further emphasizes the versatility of aluminum products and Alfa Aesar's dedication to providing high-quality materials that meet the various needs of modern industries.Alfa Aesar's manufacturing processes are environmentally friendly and comply with industry standards. The company has a long-standing passion for innovation, and their team of experienced engineers and scientists continually work towards developing high-performance products that meet global customer demands.The company's customer service team is knowledgeable and always ready to provide needed technical support to ensure that customers get the best aluminum products that align with their business needs. Customers can also access educational and technical resources made available on their website to improve their understanding of the products.Alfa Aesar's dedication to producing high-quality, reliable aluminum products has earned them international recognition and numerous awards, making them a leader in the industry. Their commitment to research and development, coupled with their adherence to industry standards, ensures that the company continues to provide top-quality products and services to their customers globally.In conclusion, aluminum products are increasingly becoming popular in various industries, and Alfa Aesar's silver-coated aluminum powder is one of the most sought-after products. Its unique properties make it an excellent material for producing electrical contacts and conductors, automotive parts, additive manufacturing processes, and coatings. Alfa Aesar's commitment to innovation, high-quality production, and excellent customer service has placed them among the top manufacturers of aluminum products globally.

Understanding the Benefits of Backwashing Filters for Cleaner Water

Title: Advanced Backwashing Filters Revolutionize Water Filtration TechnologiesIntroduction:Backwashing filters have revolutionized the field of water filtration, providing an efficient and effective solution for removing impurities and ensuring clean water supply. One company at the forefront of this innovative technology is **Company X**, a renowned leader in producing high-quality water filtration systems. With their cutting-edge backwashing filters, **Company X** has transformed the way we approach water treatment, ensuring the safety and purity of our water resources.Body:1. Background and Importance of Water FiltrationWater is a valuable resource, and access to clean and safe water is essential for human health and wellbeing. However, water sources are often contaminated with various impurities such as sediment, bacteria, and chemicals. Failure to remove these contaminants can have severe health consequences, making water filtration a critical process. Backwashing filters offer an efficient and reliable solution to this challenge, enabling the removal of impurities and ensuring our water is clean and safe for consumption.2. Understanding Backwashing FiltersBackwashing filters employ a unique filtration process that involves reversing the flow of water through the filtration media. This technique enhances the cleaning and filtering capabilities of the system, improving the overall effectiveness of water treatment. By backwashing, the filters remove accumulated impurities and prevent the formation of biofilms, which can potentially host harmful bacteria and other pathogens.3. Advancements in Backwashing Filter Technology**Company X**, a renowned pioneer in the water filtration industry, has introduced several groundbreaking advancements in backwashing filter technology. Their filters incorporate innovative materials and designs that offer superior filtration efficiency compared to traditional filtration systems. The advanced filtration media can effectively remove particles as small as a fraction of a micron, ensuring the utmost purity of the filtered water.4. Features and Benefits of **Company X**'s Backwashing FiltersOne of the key features that sets **Company X**'s backwashing filters apart is their self-cleaning capability. The filters automatically initiate the backwashing process at preset intervals, guaranteeing continuous and efficient filtration without the need for manual intervention. This not only saves time and effort but also improves the longevity and performance of the filtration system.Moreover, **Company X**'s filters boast a compact design, allowing for easy installation even in limited spaces. The filters are also highly customizable, addressing various filtration requirements, including residential, commercial, and industrial applications. With their modular design, **Company X**'s filters are easily scalable, ensuring flexibility in accommodating different water volumes and treatment needs.5. Applications of Backwashing FiltersThe applications of backwashing filters span across various industries and sectors. In households, these filters provide clean drinking water, safeguarding the health of families. In agricultural and irrigation systems, backwashing filters ensure the removal of contaminants, preventing clogging and damage to irrigation equipment. Industrial facilities can benefit from backwashing filters by eliminating impurities and improving the efficiency of processes. Additionally, backwashing filters play a crucial role in water treatment plants, ensuring the delivery of safe and potable water to communities.6. Environmental Impact and Sustainability**Company X** is dedicated to sustainability, and their backwashing filters align with this commitment. The filters reduce water wastage by utilizing efficient backwashing techniques and conserving water resources. By preventing the need for frequent filter replacements and maintenance, **Company X**'s filters also contribute to reducing waste generation while maintaining optimal performance.Conclusion:With their state-of-the-art backwashing filters, **Company X** continues to drive innovation in the field of water filtration. These advanced systems offer effective and efficient removal of contaminants, ensuring clean and safe water for various applications. Through their commitment to sustainability and technological excellence, **Company X** is shaping the future of water treatment and securing our access to a vital resource - clean water.

Discover the Benefits of Sintered Filter Cartridges for Exceptional Filtration

Title: Groundbreaking Sintered Filter Cartridge Revolutionizes Filtration TechnologyIntroduction:(Filter Company), a leader in innovative filtration solutions, has unveiled its latest groundbreaking product - the Sintered Filter Cartridge. This revolutionary filtration technology is set to redefine industry standards by providing superior performance, efficiency, and durability.The Sintered Filter Cartridge is designed to meet the increasing demands of various industries, including water treatment, pharmaceuticals, chemicals, food and beverage, and more. Through cutting-edge manufacturing techniques, (Filter Company) has successfully developed a versatile and highly effective filtration solution that ensures the highest level of filtration efficiency.Unmatched Filtration Efficiency:One of the key features that sets the Sintered Filter Cartridge apart from conventional filters is its exceptional filtration efficiency. The cartridge is manufactured using the sintering process, which involves compacting and bonding metal or ceramic particles under extremely high pressure and temperature. This results in a highly porous structure with interconnected channels, enabling the filter to provide a larger surface area for efficient particle retention.With its advanced filtration mechanism, the Sintered Filter Cartridge can effectively remove suspended solids, sediments, colloidal particles, and even microorganisms from liquids and gases. This level of filtration efficiency not only guarantees the purity of the final product but also ensures compliance with stringent regulatory standards.Unparalleled Durability:In addition to its outstanding filtration capabilities, the Sintered Filter Cartridge is engineered to withstand extreme operating conditions. The sintering process grants the cartridge exceptional mechanical strength, making it highly resistant to pressure, temperature, and chemical exposure. This durability translates into a longer lifespan and reduced maintenance costs, making it a cost-effective solution for businesses.Moreover, the cartridge's robust construction reduces the risk of breakage or structural damage, ensuring uninterrupted filtration operations even under challenging circumstances. This makes it an ideal choice for industrial applications that demand reliable and long-lasting filtration solutions.Versatile Applications:The Sintered Filter Cartridge caters to a wide range of applications across various industries. Its adaptability allows it to be used for both liquid and gas filtration processes. It proves to be an excellent choice for applications such as water and wastewater treatment, pharmaceutical manufacturing, biotechnology processes, chemical and petrochemical plants, food and beverage production, and many more.The flexible design of the Sintered Filter Cartridge enables customization, with different shapes, sizes, and configurations available to suit specific filtration requirements. This adaptability ensures seamless integration into existing filtration systems, thereby minimizing downtime during installation and enhancing operational efficiency.Commitment to Quality and Sustainability:(Filter Company) is dedicated to delivering the highest-quality filtration solutions to its customers while prioritizing environmental sustainability. The Sintered Filter Cartridge incorporates materials that are highly recyclable, reducing waste generation and promoting a cleaner and greener future.By continuously investing in research and development, (Filter Company) ensures that its filtration products remain at the forefront of technological advancements. The Sintered Filter Cartridge stands as a testament to the company's commitment to innovation and its aim to provide efficient and sustainable solutions to meet the evolving needs of various industries.Conclusion:The introduction of the Sintered Filter Cartridge by (Filter Company) represents a significant leap forward in filtration technology. Its remarkable filtration efficiency, exceptional durability, and versatility across industries make it an indispensable tool for businesses seeking reliable and cutting-edge filtration solutions.(Filter Company)'s commitment to quality, performance, and sustainability solidifies its position as a leader in the field of filtration technology. With the new Sintered Filter Cartridge, businesses can expect enhanced filtration performance, reduced maintenance costs, and the assurance of complying with stringent regulatory standards.

Premium Quality Cartridge Filter Element for Sale

Cartridge Filter Element: Ensuring Clean and Pure Industrial Liquid FiltrationCartridge filtration solutions are popular among industries as they offer several advantages over other filtration options. It is an effective method to remove contaminants from industrial liquids, gases and other fluids. It is a vital element in processes such as wastewater treatment, food and beverage processing, chemical processing, and pharmaceutical manufacturing. Cartridge filter elements have high demand in the market due to their efficiency and durability.The cartridge filter element manufacturer has been providing cartridge filter elements for more than 20 years. They have extensive experience in this field and cater to various industries such as food and beverage, automotive, chemical, and healthcare. They manufacture different types of filter elements, including industrial cartridge filters, spun-bonded filter cartridges and other specialty cartridges that suit a variety of applications.The company has a team of experienced and skilled professionals. They work in tandem to ensure the quality and reliability of the final product. The team comprises engineers, technicians, and quality controllers, and they use the latest techniques and equipment to manufacture high-quality filtration products.The cartridge filter element manufacturer uses a variety of filter media that include cellulose, polyester, polypropylene, and others to make their filter elements. The filter media have different properties and are suitable for different processes.The filter media used by the manufacturer is of the highest quality, ensuring maximum filtration efficiency. The filters are designed to remove a wide variety of impurities, including particles of different sizes, air, oil, and water droplets.The company offers a range of filter cartridges to suit different industrial applications, including air, gas, and liquid filtration. The filtration products are available in a range of micron ratings, and the company also provides custom micron ratings for specific applications.Cartridge filter elements are easy to install and maintain. They are also cost-effective compared to other filtration systems. The replacement of filter cartridges is simple and can be done quickly, ensuring minimal downtime in production processes.In addition, the company provides technical support to customers who require assistance in selecting the right filter element for their application. They also provide training to the maintenance and operation teams of the customers to ensure the long-term effectiveness of the filtration systems.The cartridge filter element manufacturer complies with the highest industry standards, including ISO 9001, ensuring the products are of the highest quality. They also regularly upgrade their manufacturing processes to keep up with the latest filtration technology.The company strongly believes in customer satisfaction and ensures that their products meet the needs and requirements of customers. They offer flexible payment options, on-time delivery, and excellent after-sales service.In conclusion, cartridge filter elements are essential for industries that require clean and pure liquids in their processes. The cartridge filter element manufacturer is a reliable and experienced supplier of filtration products, catering to various industries. Their products are of high quality and have a long lifespan, ensuring maximum filtration efficiency. They offer cost-effective solutions and excellent technical support to their customers. The company's commitment to customer satisfaction makes them a preferred supplier of filtration products in the market. Contact them today to know more about their products and services.

Importance of Fuel Filter for Efficient Engine Performance

Title: Fuel Filter: The Silent Hero Ensuring Optimal Engine PerformanceIntroduction:Maintaining a vehicle for smooth and efficient performance requires regular inspection and upkeep of its various components. One critical component that often goes unnoticed but plays a pivotal role in optimizing engine efficiency is the fuel filter. This essential device, positioned between the fuel tank and the fuel injection system, diligently works to cleanse the fuel entering the engine, ensuring its vital role in achieving seamless performance. In this blog, we will explore the significance of the fuel filter, its functions, and how it promotes optimal engine performance. So, let's dive in and discover the importance of this unsung hero!Understanding the Fuel Filter:The fuel filter is a robust and intricate device designed to safeguard your vehicle's engine from the detrimental effects of contaminants present in the fuel. Even though gasoline and diesel are refined extensively, impurities such as dirt, rust, and other particles can still manage to find their way into the fuel, risking the efficiency and performance of your engine. The fuel filter acts as a knight in shining armor, intercepting these impurities and ensuring only clean fuel reaches the injection system, hence preventing fuel delivery issues and potential engine damage.Significance of Clean Fuel Delivery:Clean fuel is vital for maximizing engine performance and longevity. A clogged fuel filter restricts the smooth flow of fuel, affecting the fuel pressure and ultimately delivering an inadequate amount to the engine. This deficiency in fuel supply can lead to a host of problems like reduced power, sluggish acceleration, misfiring, increased emissions, and even engine stalling. By maintaining a clear and unobstructed pathway for fuel, the fuel filter eliminates these risks, ensuring uninterrupted fuel delivery and preserving your engine's health.Key Functions of the Fuel Filter:1. Filtration: The primary function of the fuel filter is to capture and trap contaminants present in the fuel. Made of fine materials like cellulose or synthetic fibers, the filter allows clean fuel to pass through, while effectively retaining harmful particles that can hamper the engine's optimal performance.2. Water Separation: Another crucial role of the fuel filter is to separate any water or moisture that may be present in the fuel. Water infiltration can have adverse effects on the engine's combustion process, causing rusting and corrosion within the fuel system. The fuel filter equipped with a water separator ensures that only dry fuel reaches the engine, minimizing potential damage.3. System Protection: In addition to safeguarding the engine, the fuel filter also plays a role in extending the life of other fuel system components such as the fuel injectors, fuel pump, and other sensitive parts. By filtering out contaminants, the fuel filter prevents these components from unnecessary wear and tear, reducing maintenance costs in the long run.Importance of Regular Fuel Filter Maintenance:To ensure the fuel filter continues to function optimally, regular maintenance is paramount. Over time, the accumulation of debris and contaminants within the filter itself can lead to clogging, reducing the fuel flow and compromising engine performance. Including fuel filter inspection and replacement as a part of routine vehicle maintenance ensures a cleaner and uninterrupted fuel supply, preventing potential breakdowns and costly repairs.Conclusion:The fuel filter might appear insignificant compared to other prominent vehicle components, but its role in ensuring engine performance and longevity is invaluable. By diligently filtering fuel, removing impurities, and maintaining an unobstructed fuel flow, it serves as the unsung hero of your vehicle. A clean fuel filter guarantees optimal engine performance, enhanced fuel efficiency, and reduced maintenance costs. Therefore, prioritize regular fuel filter maintenance, and let this humble yet critical device pave the way for a smooth and hassle-free driving experience.Keywords: Fuel filter, fuel tank, filter system, engine performance, fuel delivery, clean fuel, contaminants, vehicle maintenance, fuel flow, optimal performance, engine efficiency, fuel injectors, fuel pump, vehicle components, engine longevity.

Where to Find Quality Expanded Metal Sheets for Your Needs

If you're a BBQ enthusiast, then you know how important it is to have the right tools at your disposal. Whether you're a seasoned grill master or just starting out, one tool you shouldn't overlook is a sheet of expanded metal. This versatile material is perfect for a variety of BBQ-related tasks and can help you take your grilling game to the next level. In this blog post, we'll explore some of the best places to pick up a sheet of expanded metal and why it's such an essential tool for BBQ enthusiasts.Why Choose Expanded Metal for BBQ?Before we dive into where to pick up a sheet of expanded metal, let's first discuss why it's such an important tool for BBQ enthusiasts. First and foremost, expanded metal is incredibly durable and long-lasting. It can withstand high temperatures and won't warp or bend over time. This makes it an excellent choice for a variety of BBQ-related tasks, including smoking, grilling, and even making your own custom grates.Additionally, expanded metal is incredibly versatile. It's available in a range of sizes and thicknesses, making it easy to find the perfect sheet for your needs. Whether you're looking to create a custom grill grate or need a non-stick surface for smoking delicate fish, expanded metal has you covered.Where to Buy Expanded Metal for BBQNow that you understand why expanded metal is such an important tool for BBQ enthusiasts, let's discuss where to pick up a sheet of this versatile material. There are a few different options to consider, depending on your needs and budget.Online RetailersOne of the easiest and most convenient ways to purchase expanded metal for BBQ is to shop online. There are a number of retailers that specialize in metalworking supplies, including expanded metal sheets. By shopping online, you can easily compare prices and find the perfect sheet for your needs. Some popular options include Amazon, Home Depot, and Lowes. Just be sure to read reviews and check the dimensions carefully before making your purchase.Local Metalworking ShopsAnother option for purchasing expanded metal for BBQ is to visit a local metalworking shop. These businesses specialize in creating and selling metal products and are often willing to sell small sheets of expanded metal to the public. By shopping locally, you can support small businesses in your community and often find higher-quality materials than what's available at big-box stores.Scrap YardsFinally, another option for picking up expanded metal for BBQ is to visit a scrap yard. These facilities often have a range of metal materials available for purchase at a discounted price. While the exact size and thickness of the sheet you find may vary, this can be a great budget-friendly option for those looking to experiment with expanded metal without breaking the bank.ConclusionIn conclusion, expanded metal is an essential tool for BBQ enthusiasts. It's durable, versatile, and perfect for a variety of tasks. Whether you're looking to create custom grates or need a non-stick surface for smoking delicate foods, expanded metal has you covered. By shopping online, visiting local metalworking shops, or checking out scrap yards, you can easily find the perfect sheet of expanded metal for your BBQ needs. So, what are you waiting for? Start grilling like a pro today with expanded metal!

Revolutionary Woven Steel Mesh Screen: Unveiling the Future of Security and Durability

Title: Innovative Woven Steel Mesh Screen Sets New Industry StandardsIntroduction:In an era dominated by technological advancements and rapid innovation, it is refreshing to see traditional industries embracing modern solutions to enhance their efficiency, durability, and versatility. One such industry is that of steel mesh screens, which are widely used in various applications ranging from security fencing to industrial machinery. Today, we will dive into the news about an innovative woven steel mesh screen that is set to revolutionize the industry, making it more resilient, cost-effective, and aesthetically appealing.Paragraph 1:In recent years, {Company Name} has emerged as a leading player in the field of steel mesh screens, consistently introducing groundbreaking developments to overcome limitations associated with traditional wire mesh screens. The latest offering from {Company Name} is a result of their dedication to research and development, aiming to provide customers with a more robust and efficient solution for their screening needs.Paragraph 2:One of the standout features of this new woven steel mesh screen is its unparalleled strength. The screen is engineered using advanced weaving techniques, coupled with high-quality steel wire to ensure maximum durability and resistance against wear and tear, making it suitable for even the most demanding environments. This innovation will greatly benefit industries such as mining, construction, and agriculture, where durability is a key factor in material selection.Paragraph 3:Furthermore, this woven steel mesh screen offers superior security features. It acts as an effective barrier while maintaining visibility, making it ideal for applications such as perimeter fencing, where both security and aesthetic appeal are important. This screen also enhances safety within industrial settings by preventing foreign objects from entering machinery or work areas, reducing potential accidents and equipment damage.Paragraph 4:Aside from incorporating strength and security, the new woven steel mesh screen boasts exceptional versatility. With customizable designs and sizes, {Company Name} caters to the unique requirements of its diverse clientele. The company's state-of-the-art manufacturing facilities ensure precise dimensions and reliable consistency, guaranteeing an optimal fit for any project. This flexibility opens doors for various applications, including architectural designs, animal enclosures, and filtration systems, to name just a few.Paragraph 5:Environmental considerations are at the forefront of this innovative steel mesh screen. {Company Name} understands the importance of sustainability in today's world and has implemented environmentally friendly manufacturing practices. The woven steel mesh screen is made from recycled materials, reducing waste and minimizing the industry's carbon footprint. By choosing this product, customers can contribute to a greener future while benefiting from its performance and longevity.Paragraph 6:In terms of market competitiveness, the new woven steel mesh screen positions {Company Name} as a key industry player. By combining cutting-edge manufacturing techniques, robust materials, and a commitment to customer satisfaction, the company has set a new standard for woven steel mesh screens. With a dedicated research and development team continuously exploring innovative solutions, {Company Name} ensures that its products remain at the forefront of technological advancements in the industry.Conclusion:The unveiling of this innovative woven steel mesh screen from {Company Name} marks a significant milestone in the evolution of the industry. Its exceptional strength, security features, versatility, and commitment to sustainability set it apart from traditional wire mesh screens. {Company Name} continues to reshape the landscape of steel mesh screens, empowering businesses and industries worldwide with more advanced and efficient solutions.

Flexible and Economical Expanded Metal Mesh and Sheet for Architectural Solutions

Italmesh Produces Recyclable and Flexible Expanded Metal Mesh for Architectural SolutionsItalmesh, an Italian company specialized in the production of expanded metal mesh and sheet, has introduced a range of architectural solutions that offer exceptional design flexibility, durability, recyclability, and cost-effectiveness.The company's expanded metal mesh and sheet products are made from high-quality materials such as aluminum, stainless steel, brass, and copper, and they are produced using state-of-the-art manufacturing processes that ensure superb precision and consistency.According to a company spokesperson, Italmesh's expanded metal mesh and sheet products are ideal for architects, designers, and building planners who desire innovative and sustainable solutions that can transform their building designs."Our expanded metal mesh and sheet products are designed to meet the needs of architects and designers who are looking for materials that offer tremendous design versatility, durability, and functionality. Our products are lightweight, recyclable, and easy to install, making them the perfect fit for building projects regardless of complexity," says the spokesperson.The company's expanded metal mesh and sheet products come in a wide range of patterns, sizes, and finishes, providing architects and designers with unlimited design possibilities.From facades, sunscreens, cladding, partitions, ceilings, and screening walls to various decorative applications, the versatility of Italmesh's expanded metal mesh and sheet products makes them ideal for various architectural solutions.The company's expanded metal mesh and sheet products are also environmentally friendly, as they are fully recyclable and require minimal maintenance. This means that architects and building planners can create beautiful, functional structures without causing unnecessary harm to the environment.Moreover, Italmesh's expanded metal mesh and sheet products are highly resistant to corrosion, weather, and fire. Because of their robustness and durability, these products can withstand even the harshest environmental conditions, ensuring that buildings remain protected and aesthetically pleasing for many years."We take pride in developing and producing exceptional expanded metal mesh and sheet products that help architects and designers to realize their visions for beautiful and sustainable buildings. Our products are not only functional and durable but also aesthetically pleasing, providing buildings with a stylish and contemporary edge," says the spokesperson.In summary, Italmesh's expanded metal mesh and sheet products offer architectural solutions that are versatile, innovative, durable, and sustainable. The products are easy to install, lightweight, and are available in a wide range of finishes, patterns, and sizes, providing architects and designers with unlimited design possibilities. Additionally, the products are recyclable and require minimal maintenance, making them an eco-friendly and cost-effective option for building projects. Architects, designers, and building planners can transform their building designs and create structures that are both functional and aesthetically appealing, thanks to Italmesh's expanded metal mesh and sheet products.

Production Line for Expanded Metal Mesh Architrave Beads for Expansion Joints

Expansion Joint Beads – The Backbone of a Strong ConstructionOne of the most important aspects of any construction project is ensuring its durability and longevity. An expansive joint is one of the solutions to the problem of cracks and movement in a building or structure over time. The perfect partner in achieving this is an expansion joint bead.Expansion joint beads, also known as casing beads, are a fundamental component that is used in building and construction projects that require joints. These are thin, durable metal strips that are designed to cover and seal the gaps created between different areas of a structure, such as floors, walls, and ceilings.Casing beads are most commonly used in the construction industry for exterior wall finishes, helping to create a smooth and protective finish around the windows and doors. These beads are also instrumental in reinforcing the integrity of the structure by creating a barrier between the wall surfaces and the window or door frames.Anber expanded metal mesh machine architrave beads production line is a prime example of a top-of-the-line manufacturing process that produces superior quality expansion joint beads. These beads are made from high-quality, corrosion-resistant raw materials and are manufactured through a meticulous, highly advanced production process. In this way, users of Anber Expanded Mesh Casing Bead can be assured of their quality and longevity.There are various types of casings available, such as PVC or plastic beads, but nothing compares to the strength and durability of metal casing beads. Metal joint expansion beads are generally more long-lasting and reliable and guarantee that the structure will remain stable for many years to come.Expanded Architrave Bead Machine offers an assortment of customization options that cater to different demands in constructing buildings. From standard sizes to varying lengths and widths, designs, and colors, it is an adaptable material that can provide an excellent aesthetic and practical finish to the surfaces.The benefits of using expansion joint beads are numerous. Here are some of the most notable:1. Durability: Metal casing beads, particularly those made of galvanized steel, are extremely durable and offer excellent resistance to rust and weather conditions.2. Strength: Casing beads serve as an additional support to the structure and provide extra durability.3. Easy to install: Joint expansion beads are straightforward to install and require no specialized tools or equipment.4. Cost-effective: Metal joint expansion beads offer better value for money than other types of casings due to their longevity and durability.5. Aesthetic finish: With the various options available, casing beads can add an elegant and professional finish to any construction project.In conclusion, it is essential to choose the right materials and ensure proper installation when working on any construction project. Expansion joint beads are an indispensable component in creating a strong and long-lasting structure. With a reliable and reputed supplier like Anber Expanded Mesh Casing Bead, construction professionals and DIY enthusiasts can achieve their desired results with ease and confidence.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.