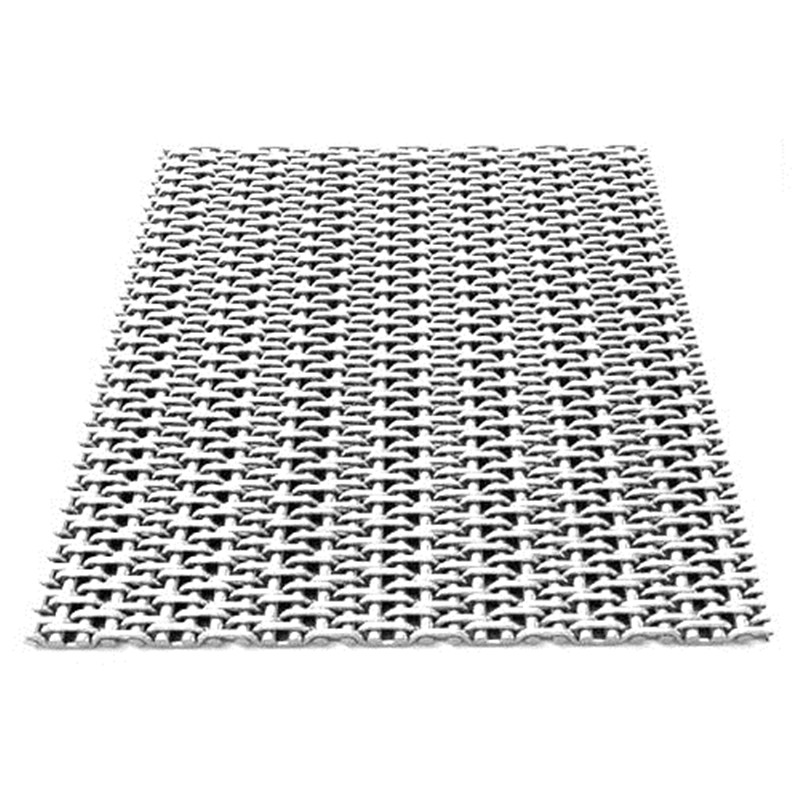

High-Quality Raised Expanded Metal Mesh for Various Applications

By:Admin

{Company Name} is a leading manufacturer of Raised Expanded Metal Mesh, offering a comprehensive range of products to meet the diverse needs of its customers. With state-of-the-art manufacturing facilities and a team of experienced professionals, {Company Name} is committed to delivering high-quality products that meet the highest standards of performance and reliability.

The Raised Expanded Metal Mesh offered by {Company Name} is designed to provide superior structural support and stability, making it an ideal choice for applications that require strength and durability. The raised surface of the metal mesh adds an extra layer of strength, making it suitable for use in walkways, ramps, and platforms where slip resistance and structural integrity are essential. Additionally, the unique design of the raised metal mesh allows for air and light to pass through, making it an ideal choice for architectural applications such as facades, cladding, and screening.

In addition to its structural advantages, Raised Expanded Metal Mesh also offers excellent versatility and flexibility. It can be easily fabricated and formed into various shapes and sizes to suit the specific needs of different applications. This flexibility allows {Company Name} to offer customized solutions to its customers, ensuring that they receive the perfect product for their unique requirements.

{Company Name} takes pride in its commitment to quality and customer satisfaction. The Raised Expanded Metal Mesh produced by the company is manufactured using high-quality materials and advanced production techniques to ensure superior performance and longevity. Additionally, {Company Name} is dedicated to providing exceptional customer service, working closely with its clients to understand their needs and deliver tailored solutions that meet and exceed their expectations.

As a leading manufacturer of Raised Expanded Metal Mesh, {Company Name} is continuously innovating and developing new products to meet the evolving needs of its customers. The company invests in research and development to stay ahead of industry trends and offer cutting-edge solutions that deliver maximum value to its clients. With a focus on quality, innovation, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses across various industries.

Whether it's for architectural, industrial, or agricultural applications, {Company Name} is the go-to source for high-quality Raised Expanded Metal Mesh. With its unwavering commitment to excellence and a dedication to meeting the unique needs of its customers, {Company Name} is poised to continue leading the way in the industry and providing innovative solutions that deliver lasting performance and reliability.

In conclusion, Raised Expanded Metal Mesh offered by {Company Name} is a versatile and durable material that is ideal for a wide range of applications. With a focus on quality, innovation, and customer satisfaction, {Company Name} is dedicated to delivering high-performance products that meet and exceed the expectations of its clients. As a trusted leader in the industry, {Company Name} is well-positioned to continue providing innovative solutions and setting the standard for excellence in Raised Expanded Metal Mesh.

Company News & Blog

High-Quality Sintered Brass Filter for Various Applications

Sintered Brass Filter: A Breakthrough in Filtration TechnologyThe filtration industry is constantly evolving, with companies developing innovative products to meet the ever-growing demand for improved filtration solutions. One such breakthrough in filtration technology is the Sintered Brass Filter, a revolutionary product that offers enhanced performance and durability. Sintered Brass Filter, produced by a leading manufacturer in the filtration industry, is a game-changer in the field of liquid and gas filtration. The filter is made from high-quality brass material that has been sintered to create a porous structure, allowing for the efficient and precise filtration of particles and impurities from a wide range of liquids and gases. The unique manufacturing process of the Sintered Brass Filter results in a rigid and durable structure that can withstand high temperatures and pressures, making it ideal for use in demanding industrial applications.The benefits of the Sintered Brass Filter are numerous. Its high filtration efficiency ensures that even the smallest particles are effectively captured, providing a clean and pure output. This makes it a valuable asset in industries such as petrochemical, pharmaceutical, food and beverage, and automotive, where the quality of the final product is of utmost importance. Additionally, the durability of the Sintered Brass Filter means that it has a long service life, reducing maintenance and replacement costs for end-users.Moreover, the versatile nature of the Sintered Brass Filter makes it suitable for a wide range of applications. Whether it is used for filtering corrosive chemicals, separating solids from liquids, or purifying gases, the filter can be customized to meet specific requirements, thanks to its exceptional design flexibility. This adaptability is a testament to the innovative engineering and manufacturing capabilities of the company behind the Sintered Brass Filter.Speaking of the company, {} is a renowned leader in the filtration industry, with a rich history of providing cutting-edge filtration solutions to its customers worldwide. With a strong focus on research and development, the company has consistently delivered top-quality products that meet the diverse needs of various industries. The Sintered Brass Filter is a testament to the company's commitment to innovation and excellence, as it showcases their ability to push the boundaries of filtration technology.Furthermore, {} is dedicated to providing comprehensive support to its customers, offering technical expertise and personalized solutions to ensure that their filtration challenges are effectively addressed. Their strong emphasis on customer satisfaction has cemented their reputation as a trusted partner in the filtration industry, with a track record of delivering value and reliability.As the demand for advanced filtration solutions continues to grow, the introduction of the Sintered Brass Filter is poised to make a significant impact in the industry. Its combination of high performance, durability, and versatility sets a new standard for filtration technology, providing a competitive edge to businesses across various sectors. With {} at the forefront of this innovation, the future of filtration looks promising, with the Sintered Brass Filter leading the way towards cleaner, safer, and more efficient processes.In conclusion, the Sintered Brass Filter represents a milestone in filtration technology, offering a superior solution for the purification of liquids and gases. Its innovative design, coupled with the expertise of {}, is set to redefine the standards of filtration performance and reliability. As industries strive for higher efficiency and quality in their processes, the Sintered Brass Filter stands ready to meet their needs, setting a new benchmark for filtration excellence.

Sintered Brass Filter: A Guide to Its Function, Benefits, and Applications

Sintered Brass Filter Creating a Revolution in Filtration TechnologyAs innovation continues to drive advancements in various industries, filtration technology has not been left behind. One such breakthrough is the introduction of the Sintered Brass Filter, a game-changer in the field of filtration. This state-of-the-art filter is set to revolutionize its respective industry and provide unparalleled solutions to businesses and consumers alike.The Sintered Brass Filter, developed by a renowned global corporation (brand name omitted), incorporates cutting-edge technology and the highest-quality materials to deliver exceptional performance. This filter distinguishes itself from conventional filtration methods, elevating the standards of efficiency, durability, and precision.What sets the Sintered Brass Filter apart from other filters is its unique manufacturing process. It is produced using sintering technology, a process that involves compacting and forming metal powder into a solid structure without melting it completely. This technique creates a highly porous structure with interconnected pores of varying sizes, resulting in exceptional filtration capabilities.The use of brass in the manufacturing process further enhances the filter's properties. Brass is known for its superior strength and durability, making the Sintered Brass Filter resistant to corrosion, pressure, and temperature fluctuations. This ensures that the filter can withstand demanding operating conditions and maintain its performance over an extended period.The Sintered Brass Filter also offers an unrivaled level of filtration precision. Its porous structure and unique design allow for effective particle removal, regardless of size. This makes it ideal for a wide range of applications, including gas, liquid, and air filtration. Whether it is removing contaminants from drinking water or ensuring the purity of industrial gases, the Sintered Brass Filter delivers exceptional filtration efficiency.Additionally, this filter's design allows for easy cleaning and maintenance. Unlike many traditional filters that require frequent replacements, the Sintered Brass Filter can be cleaned and reused multiple times without compromising its performance. This not only reduces operational costs but also minimizes waste, making it an environmentally-friendly choice.The versatility of the Sintered Brass Filter extends to its compatibility with various filtration systems and equipment. It can be seamlessly integrated into existing setups or used as a standalone filter, depending on the specific requirements of the application. This flexibility ensures ease of use and installation, allowing businesses and consumers to experience the benefits of this revolutionary filtration technology without major disruptions.With the introduction of the Sintered Brass Filter, (brand name omitted) solidifies its position as an industry leader in filtration solutions. The company's commitment to innovation and dedication to meeting customer needs have resulted in the development of this groundbreaking filter. Moreover, their expertise and extensive research in the field of filtration have allowed them to push the boundaries of what is possible, setting a new benchmark for the industry.In conclusion, the Sintered Brass Filter is a remarkable breakthrough in filtration technology. Its advanced manufacturing process, exceptional durability, precision, and versatility make it a solution of choice for various industries. As it continues to gain recognition and popularity, the Sintered Brass Filter is undoubtedly revolutionizing filtration systems across the globe, improving efficiency and providing cleaner, purer substances to businesses and consumers alike.

Discover Woven Wire Mesh: Free Download with Aperture Size Calculator, Open Area & Weight Estimation

: Understanding the Different ApplicationsWoven wire screens have been a fundamental component of many industrial processes and equipment for decades. From pharmaceutical and food processing to mining and petrochemicals, a wide range of industries rely on these products to filter, separate, and sort materials. In this blog, we will delve deeper into woven wire screens, their uses, and their benefits.What is Woven Wire Screen?Woven wire screen is a mesh fabric made from wire strands interwoven at right angles. These strands can be made from various metals such as stainless steel, brass, copper, and aluminum. The wire strands may have different diameters and weaves, depending on the intended application.Applications of Woven Wire ScreensWoven wire screens are commonly used in various applications, including:1. Screening and SeparationWoven wire screens are used as industrial filters for screening and separating materials. These screens are used in mining equipment, vibratory machines, and in the production of plastics, ceramics, and other materials. By filtering out unwanted particles and materials, these screens ensure the quality and purity of end products.2. SiftingWoven wire screens are also used for sifting in the food, pharmaceutical, and chemical industries. These screens can be used to sift, sort, and grade materials in a specific size range.3. Security FencingWoven wire screens can provide enhanced security by preventing unauthorized entry, theft and vandalism. They are commonly used to protect residential properties, commercial establishments, and industrial facilities.4. Insects and Pest ControlWoven wire screens can be used for insect and pest control in residential and commercial facilities.Benefits of Woven Wire ScreensWoven wire screens are widely used in various industries due to their numerous benefits, including:1. High DurabilityWoven wire screens are highly durable and can withstand harsh environmental conditions. They are resistant to corrosion, abrasion, and high temperatures.2. High PrecisionWoven wire screens are available in various mesh sizes, making them suitable for precise screening and separation of materials.3. Low MaintenanceWoven wire screens require minimal maintenance and can be easily cleaned and reused.4. Cost-effectiveWoven wire screens are cost-effective compared to other screening and separating products. They also have a long lifespan, which makes them a more economical option in the long run.ConclusionWoven wire screens are vital components of many industrial processes and equipment. They are used in various industries for screening, separating, sifting, and security purposes. With their high durability, precision, low-maintenance, and cost-effectiveness, woven wire screens are a reliable and efficient solution in numerous settings.If you are in the market for woven wire screens, Robinson Wire Cloth Ltd. offers a range of quality products for any industrial application. Visit our online shop or contact us for more information.

Durable Stainless Steel Mesh Screen for Various Applications

Fine Steel Mesh Screen is a leading company in the manufacturing of high-quality steel mesh screens. This company has a strong reputation in the industry for producing durable and reliable screens that are used in various applications such as filtration, separation, and sieving.The Fine Steel Mesh Screen is made from high-grade stainless steel, which gives it excellent strength and corrosion resistance. This makes it ideal for use in harsh and demanding environments where other materials might fail. The company's commitment to using only the best materials and adhering to strict quality control processes ensures that their screens meet the highest standards and exceed customer expectations.One of the key advantages of the Fine Steel Mesh Screen is its versatility. It can be customized to meet specific customer requirements, including different weave patterns, wire diameters, and aperture sizes. This flexibility makes it suitable for a wide range of applications across various industries, including mining, agriculture, food processing, and pharmaceuticals.In addition to its high-quality products, Fine Steel Mesh Screen also prides itself on providing excellent customer service. Their team of experienced professionals is dedicated to understanding the unique needs of each customer and providing tailored solutions to meet those needs. Whether it's a small order for a specialized application or a large-scale project requiring custom-designed screens, the company is committed to delivering the best possible outcome for their customers.Furthermore, Fine Steel Mesh Screen places a strong emphasis on innovation and continuous improvement. They invest heavily in research and development to stay ahead of industry trends and technology advancements. This commitment to innovation has led to the development of new and improved screen designs that offer enhanced performance and durability.In line with their commitment to sustainability, Fine Steel Mesh Screen also focuses on eco-friendly manufacturing processes. They strive to minimize their environmental impact by optimizing their production methods and using energy-efficient technologies. This dedication to sustainability is reflected in their products, which are designed to have a longer lifespan and reduce the need for frequent replacements.The Fine Steel Mesh Screen has gained a strong reputation for reliability and performance in the industry. Their screens are trusted by customers around the world who rely on them for critical applications where failure is not an option. This trust is a result of the company's unwavering commitment to quality, innovation, and customer satisfaction.Looking ahead, Fine Steel Mesh Screen is poised for continued growth and success. With a focus on meeting the evolving needs of their customers and staying at the forefront of technological advancements, the company is well-positioned to maintain its leadership in the industry.In conclusion, Fine Steel Mesh Screen is a company that stands out for its commitment to quality, innovation, and customer satisfaction. With a strong reputation built on high-quality products, excellent customer service, and a dedication to sustainability, the company is poised for continued success in the industry. Their versatile and reliable mesh screens continue to serve as a trusted solution for a wide range of applications, making them an essential partner for businesses across various industries.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.

High-Quality Ultra Fine Wire Mesh for Various Industries

We are proud to announce the launch of our latest innovation in wire mesh technology – Ultra Fine Wire Mesh. This new product is set to revolutionize the industry with its exceptional performance and unmatched quality. The Ultra Fine Wire Mesh is designed to meet the needs of a wide range of applications, from filtration and separation to particle size analysis and fluidization. With its precision-engineered design and superior durability, this new wire mesh is the perfect solution for demanding industrial and commercial environments.Our company has been at the forefront of wire mesh manufacturing for over a decade. With a focus on innovation and quality, we have established ourselves as a trusted leader in the industry. Our commitment to excellence has driven us to continuously invest in research and development, leading to the creation of cutting-edge products like the Ultra Fine Wire Mesh. We take pride in delivering solutions that exceed our customers' expectations and are confident that this new product will set a new standard in wire mesh technology.The Ultra Fine Wire Mesh is meticulously engineered using the latest manufacturing techniques and highest quality materials. It features an ultra-fine mesh design that ensures optimum performance in applications requiring precise particle separation and filtering. The wire mesh is also highly resistant to corrosion and wear, making it suitable for use in even the harshest industrial environments. Additionally, our wire mesh is available in a variety of materials, including stainless steel, copper, and nickel, to meet the specific needs of our customers.One of the key advantages of the Ultra Fine Wire Mesh is its versatility. It can be tailored to meet the exact specifications of our customers, whether they require a specific size, shape, or material. This level of customization ensures that our wire mesh can be seamlessly integrated into a wide range of applications, such as pharmaceuticals, food and beverage processing, and chemical manufacturing. The Ultra Fine Wire Mesh is also easy to install and maintain, providing a cost-effective and efficient solution for our customers.In addition to its exceptional performance, the Ultra Fine Wire Mesh is also environmentally friendly. We are committed to sustainability, and our wire mesh is fully recyclable, reducing waste and minimizing our environmental impact. We also adhere to strict quality control measures throughout the manufacturing process to ensure that our products meet the highest industry standards. As a result, our customers can trust that they are receiving a product that is not only reliable and efficient but also environmentally responsible.We are excited to offer the Ultra Fine Wire Mesh to our customers and believe that it will deliver maximum value and performance for a wide range of applications. Whether our customers require precise particle separation, efficient fluidization, or reliable filtration, our wire mesh can meet their needs with ease. We are confident that this innovative product will set a new benchmark in the industry and reaffirm our position as a leader in wire mesh manufacturing.In conclusion, the Ultra Fine Wire Mesh represents the next generation of wire mesh technology. With its exceptional performance, unmatched quality, and environmental sustainability, this product is poised to make a significant impact in the industry. Our dedication to innovation and excellence has led to the development of a product that delivers maximum value for our customers. The Ultra Fine Wire Mesh is a testament to our commitment to pushing the boundaries of wire mesh technology and providing our customers with the best solutions for their industrial and commercial needs. We are excited to introduce this new product and look forward to its success in the market.

Highly Efficient Sintered Candle Filter for Dispersion and Backwash Applications

and Dispersion and BackwashSintered Candle Filter: A Reliable Solution for Dispersion and BackwashThe process of filtration plays a vital role in many industries, especially where the quality of the product is critical. With the advancement in technology, various types of filters are introduced to meet the specific needs of different applications. Among them, sintered candle filter has gained much importance in recent years due to its high filtration efficiency and chemical resistance. This blog will discuss the significance of sintered candle filter, particularly for dispersion and backwash applications.What is a Sintered Candle Filter?A sintered candle filter is a type of ceramic filter that consists of a cylindrical shape with a porous structure. It is made of alumina, zirconia, or silicon carbide and is sintered at high temperatures to form a rigid and durable structure. The porous structure of the filter allows the fluid to pass through while retaining the particles and impurities. The filtration process occurs through surface filtration or depth filtration, depending on the pore structure of the filter.Significance of Sintered Candle Filter for DispersionDispersion is a critical process in many industries, including pharmaceutical, chemical, and food processing. It involves the mixing of two or more components to form a homogeneous solution. The quality and consistency of the final product depend on the proper mixing and dispersion of the components. Sintered candle filters are widely used for dispersion applications due to their high filtration efficiency and uniform pore size distribution. The uniform pore size distribution ensures the proper dispersion of the components by retaining the large particles and allowing the smaller particles to pass through. Moreover, the chemical resistance of the filter ensures the compatibility with a wide range of chemicals, enabling the filter to withstand aggressive chemical environments.Significance of Sintered Candle Filter for BackwashBackwash is a process used for cleaning the filter media to remove the impurities and particles accumulated during the filtration process. It involves reversing the flow of the fluid to dislodge the particles and flush them out of the filter. Sintered candle filters are widely used for backwash applications due to their rigid and durable structure and high resistance to thermal and chemical shock. The high filtration efficiency of the filter ensures the proper removal of the impurities during backwash, resulting in a clean and efficient filtration process.ConclusionSintered candle filters have gained much importance in recent years due to their high filtration efficiency, uniform pore size distribution, and chemical resistance. The significance of these filters for dispersion and backwash applications makes them a reliable solution for many industries. The proper selection of the filter material and pore size is crucial to ensure the optimal performance of the filter. Therefore, it is essential to consider the specific needs of the application before selecting the filter. So, the sintered candle filter is a great choice for industries looking for an efficient and reliable filtration solution for dispersion and backwash applications.

Metal Wire Mesh Production: Industrial and Conveyor Belt Mesh from Special Weaving Machines

: A Strong and Versatile Material for Diverse Applications Industrial metal mesh, also known as wire mesh or wire cloth, is a versatile material that is widely used in various industries, including construction, mining, oil and gas, agriculture, automotive, and many others. It is made by weaving or welding metal wires together to create a grid-like pattern that can be customized to meet specific requirements. In this blog, we will explore the benefits and applications of industrial metal mesh and why it is a popular choice for many industrial applications.Benefits of Industrial Metal MeshIndustrial metal mesh offers several advantages that make it a sought-after material for a wide range of applications. Some of the key benefits of industrial metal mesh include:1. Strength and Durability: Industrial metal mesh is known for its strength and durability, making it ideal for use in heavy-duty applications that require a robust material.2. Versatility: Industrial metal mesh is available in a range of materials, such as stainless steel, galvanized steel, brass, and copper, as well as different wire sizes, weaves, and coatings. This versatility allows it to be used in numerous applications, from filtration to decoration.3. Easy to Customize: Industrial metal mesh can be easily customized based on specific requirements, such as size, shape, and opening, to ensure it meets the exact specifications needed to get the job done.4. Cost-Effective: Industrial metal mesh is a cost-effective solution compared to other materials, such as solid metal, and can help companies save money on manufacturing and maintenance costs.Applications of Industrial Metal MeshIndustrial metal mesh is used in a wide range of applications across various industries, such as:1. Filtration: Industrial metal mesh is used in filtration systems to remove unwanted particles from liquids and gases. It is commonly used in industries such as chemical processing, food and beverage, and pharmaceuticals.2. Separation: Industrial metal mesh is used for separating and grading materials. For example, it is used in mining and construction industries to separate rocks and gravel.3. Security: Industrial metal mesh is used as a security barrier, such as window screens, fencing, and cages, in prisons, airports, and other high-security areas.4. Conveyor Belts: Industrial metal mesh is used as a conveyor belt material in the food and beverage industry, where hygiene is critical, as it is easy to clean and doesn't harbor bacteria.5. Decoration: Industrial metal mesh is also used as a decorative material in architecture and interior design. It can be used as cladding, facades, and partitions to add visual interest to a space.ConclusionIndustrial metal mesh is a versatile material that offers a range of benefits and can be used in various applications. Its strength, durability, versatility, easy customization, and cost-effectiveness make it an attractive choice for many industrial applications. Whether you are looking for a filtration system, separation solution, security barrier, conveyor belt material, or decorative element, industrial metal mesh can meet your needs. If you need help selecting the right industrial metal mesh for your application, contact a reputable manufacturer or supplier for expert advice.

High-Quality Woven Wire Mesh in Various Materials Available for Fast Shipping in Australia

Woven metal mesh is a versatile and practical solution for a wide range of applications. It is a durable and reliable material that comes in different sizes and grades to suit different needs. In Australia, Arrow Metal is a renowned supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel. In this blog, we will explore the benefits and uses of woven metal mesh and how Arrow Metal can support your project needs.Benefits of Woven Metal MeshWoven metal mesh is a popular choice for a variety of reasons. First and foremost, it is a robust and durable material that can withstand adverse weather conditions, high temperatures, and heavy usage. This makes it an ideal choice for outdoor and industrial applications. Woven metal mesh is also resistant to corrosion and erosion, making it suitable for harsh and corrosive environments.Another advantage of woven metal mesh is its versatility. Depending on the size and grade of the mesh, it can be used for different purposes, such as filtration, ventilation, security, and decoration. It can be easily cut, bent, and molded to different shapes and sizes to fit the project requirements. Furthermore, woven metal mesh allows for the passage of light, air, and sound, which makes it an excellent choice for architectural and design applications.Uses of Woven Metal MeshWoven metal mesh has a wide range of applications in different industries, such as architecture, construction, mining, manufacturing, and agriculture. It can be used for the following purposes:Filtration: Woven metal mesh can be used as a filter for liquids, gases, and solids. It can be used in industries such as food and beverage, pharmaceuticals, and mining to filter impurities and contaminants.Ventilation: Woven metal mesh can be used as a screen or grille to allow for ventilation and air circulation. It can be used in buildings, automotive, and HVAC systems to regulate the temperature and humidity.Security: Woven metal mesh can be used as a barrier or fence to provide security and safety. It can be used in prisons, military facilities, and airports to prevent unauthorized access and intrusion.Decoration: Woven metal mesh can be used as a decorative element in architectural and interior design. It can be used as a facade, ceiling, or partition to create a unique and modern look.Arrow Metal and Woven Metal MeshArrow Metal is a leading supplier of woven metal mesh in Australia. They stock a large range of quality woven wire mesh in brass and 304 and 316 stainless steel, ready to ship throughout Australia. Their woven metal mesh comes in different sizes, patterns, and grades to suit different applications and budgets.Arrow Metal has a team of experts who can provide tailored advice and solutions for your project needs. They can work with you to choose the right woven metal mesh for your application and provide custom fabrication and installation services. Whether you need a small sample or a large quantity of woven metal mesh, Arrow Metal can support your needs with prompt delivery, competitive pricing, and excellent customer service.ConclusionWoven metal mesh is a versatile and practical material that can be used for a variety of applications. It is a durable and reliable solution that can withstand harsh conditions and provide security, ventilation, filtration, and decoration. Arrow Metal is a trusted supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel in Australia. They can provide tailored advice and solutions for your project needs and deliver quality products and services. Contact Arrow Metal today to learn more about their woven metal mesh offerings and how they can support your project.

Exploring the Benefits of Sintered Stainless Steel Mesh: A Comprehensive Guide

Stainless Steel Sintered Mesh: A Versatile Solution for Filtration NeedsAs industries continue to evolve, the demand for reliable and efficient filtration solutions is on the rise. In response, many companies are constantly seeking innovative techniques to ensure the highest standards of filtration. One such solution that has gained prominence in recent years is Stainless Steel Sintered Mesh. This revolutionary product has emerged as a versatile solution, catering to a range of filtration needs across various industries.Stainless Steel Sintered Mesh, developed by (brand name), has quickly become the go-to choice for professionals seeking efficient and durable filtration solutions. Made using a unique sintering process, this mesh surpasses traditional filtration methods in terms of performance and longevity. Let us delve deeper into the features and applications of this cutting-edge product.Manufactured from stainless steel, the sintered mesh is characterized by its interconnected network of metal fibers. These fibers are formed through a powdered metallurgy process, resulting in a porous structure that offers optimum filtration efficiency. The sintering process ensures robustness, enabling the mesh to withstand extreme operating conditions and resist corrosion.One of the key advantages of Stainless Steel Sintered Mesh is its exceptional filtration capabilities. The interconnected pores in the mesh allow for precise filtration, making it suitable for applications that require fine particle separation and removal. This mesh is highly effective in industries such as petrochemicals, pharmaceuticals, food and beverage, water treatment, and many more.The mesh can effectively filter solids, liquids, and gases, making it a versatile solution for a wide range of filtration needs. Additionally, its high structural integrity ensures minimal pressure drop and consistent flow rates, enhancing overall filtration efficiency. The ability to achieve high filtration rates while maintaining optimal flow characteristics sets Stainless Steel Sintered Mesh apart from other filtration solutions in the market.Furthermore, the sintered mesh can be custom-designed to meet specific filtration requirements. With varying pore sizes and thicknesses available, this product can be tailored to achieve precise filtration goals. Whether it is removing impurities from chemicals or maintaining a sterile environment in pharmaceutical processes, Stainless Steel Sintered Mesh offers a reliable solution.The exceptional durability of this mesh is a testament to its quality. Stainless steel, known for its corrosion resistance and mechanical strength, ensures that the mesh retains its filtration efficiency even under harsh operating conditions. This longevity translates into reduced maintenance costs and increased productivity for industries that rely on effective filtration.In addition to its filtration properties, Stainless Steel Sintered Mesh is also recognized for its ease of cleaning. The open structure of the mesh allows for thorough cleaning, ensuring the longevity of the product. The ability to easily clean and reuse the mesh makes it a cost-effective and sustainable filtration solution.With its impressive features and diverse applications, Stainless Steel Sintered Mesh has become the preferred choice for professionals seeking efficient and reliable filtration solutions. The numerous advantages, including high filtration efficiency, customizability, durability, and ease of maintenance, make it an ideal choice for a wide range of industries.As the demand for stringent filtration requirements continues to grow, Stainless Steel Sintered Mesh is poised to be at the forefront of providing cutting-edge solutions. With its innovative technology and commitment to quality, (brand name) has established itself as a leading provider in the field of filtration. The company's dedication to research and development ensures that their products are continually improving to meet the evolving industry demands.In conclusion, Stainless Steel Sintered Mesh offers a versatile and efficient solution for various filtration needs across industries. Its exceptional filtration capabilities, customizability, durability, and ease of maintenance make it a reliable choice for professionals. With (brand name) leading the way in innovation and quality, this product is set to revolutionize the field of filtration.