Durable Steel Mesh Grates: An Essential Component for Enhanced Safety and Performance

By:Admin

Steel Mesh Grate, a leading provider of high-quality steel mesh gratings, has been serving the construction and engineering industries for over 30 years. The company is known for delivering durable and excellent quality products to its clients across a range of industries. Steel Mesh Grate's commitment to producing innovative solutions for its clients has made it an industry leader.

As a global provider of steel mesh gratings, the company has a broad range of products and services that can be used to meet the most complex steel mesh grating requirements. The company's product line includes steel grates, trench covers, and handrails, among others. These products are used in a wide range of industries, including construction, engineering, mining, and transportation.

Steel Mesh Grate has an extensive client base that includes some of the biggest names in the industry. The company has established a reputation for fast turnaround times and a commitment to quality. Clients can rely on Steel Mesh Grate to deliver their products on time and within budget.

Steel Mesh Grate's success can be attributed to the expertise and knowledge of its team. The company has built a team of experts who are well-versed in the nuances of the steel mesh grating industry. The team is committed to providing excellent customer service and ensuring that their client's requirements are met.

One of Steel Mesh Grate's most popular products is its steel grates. These grates are designed to withstand heavy foot traffic, making them ideal for commercial and industrial settings. They are also incredibly durable, making them a great choice for outdoor applications.

The company's trench covers are another popular product, particularly in the construction industry. These covers are used to cover trenches, manholes, and other openings in the ground. They help to prevent accidents and injuries by making it impossible for people to fall into the opening.

Steel Mesh Grate is committed to sustainability and ensuring that its products are environmentally-friendly. The company uses recycled materials in its products wherever possible, and it also implements environmentally-friendly practices in its manufacturing processes.

In addition to its range of products, Steel Mesh Grate also offers installation services to its clients. The company's team of experts can install steel mesh grates, trench covers, and handrails quickly and efficiently. Clients can rely on Steel Mesh Grate to complete their installation projects on time and within budget.

Steel Mesh Grate is constantly innovating and developing new solutions to meet its clients' needs. The company is always looking for ways to improve its products, services, and processes. This commitment to innovation has helped to keep Steel Mesh Grate at the forefront of the industry.

As a leading provider of steel mesh gratings, Steel Mesh Grate is well-positioned to continue to grow and expand. The company's commitment to quality, sustainability, and innovation has helped it to establish a loyal client base and maintain a competitive edge in the industry. With its team of experts and its broad range of products and services, Steel Mesh Grate is poised for continued success in the years to come.

Company News & Blog

Top Quality Wire Mesh for Vents – The Perfect Ventilation Solution" can be rewritten as "High-Quality Wire Mesh for Vents: The Ultimate Solution for Adequate Ventilation.

In recent news, a growing prevalence of wire mesh for vents has become apparent in various industries. The use of wire mesh in ventilation systems is gaining popularity as it offers a durable and efficient solution to protect against debris and pests. While the utilization of wire mesh in ventilation systems is not new, it is being deployed more extensively as a practical approach for businesses that want to improve indoor air quality while avoiding the costs of significant repairs and maintenance.Industrial experts indicate that wire mesh ventilation systems provide superior protection against unwanted debris, insects, and wildlife while allowing sufficient air circulation. Wire mesh contributes to a ventilation system's overall health and prevents various system damages by creating a barrier for unwanted debris. As such, it is common to find wire mesh on outdoor dryer vents, air conditioning units, and air ducts in commercial properties and residential homes. The benefits of wire mesh in ventilation systems are numerous, and it's quickly becoming a go-to solution for businesses in various industries.One company that has garnered a reputation for providing high-quality wire mesh products is a leading supplier (brand name removed). The company prides itself on providing bespoke solutions that cater to its customers' specific needs, providing a range of high-quality wire mesh, from stainless steel, nickel, copper, brass to bronze, and mesh sizes ranging from coarse to fine. This diverse range of wire mesh products allows businesses to choose what meshes work well with their unique ventilation systems.Furthermore, the company's high-quality wire mesh provides a significant advantage over other wire mesh brands currently available in the market. Each product is engineered to provide the ideal balance between air penetration and filtrate skills. This optimal balance leads to reduced energy costs while maintaining a clean, correctly functioning ventilation system. Additionally, (brand name removed) boasts of a state-of-the-art manufacturing process that guarantees the wire mesh's durability and efficiency. The company employs a rigorous quality control process to ensure it delivers only the best wire mesh products to clients. This obsessive attention to detail ensures that each customer gets the highest quality wire mesh solutions.Clients who have worked with the company praise the excellent customer service and cost-effective solutions provided. Customers who need bespoke solutions to complex ventilation systems appreciate the company's commitment to providing customized wire mesh products that meet their needs. In addition, the company's understanding and knowledge of the wire mesh industry ensure that clients who purchase wire mesh for their ventilation system can rely on (brand name removed)'s expertise in recommending the appropriate products for the specific application.Moreover, (brand name removed) takes an eco-friendly approach to manufacturing its wire mesh, ensuring that its production process is conscious of its environmental impact. The company employs ethical and sustainable sourcing of raw materials, and they prioritize reusing and recycling where possible. The production process also prioritizes reducing the carbon footprint, which helps reduce carbon emissions.In conclusion, wire mesh for vents and ventilation systems is a wise investment, and its popularity in various industries continues to increase. The practicality of wire mesh has been established, and the versatility it provides in the ventilation industry is unmatched. As such, businesses looking to maintain healthy indoor air quality and avoid costly maintenance repairs should consider wire mesh products. In particular, (brand name removed) offers a premium solution to wire mesh products that provide both cost-effective and high-quality solutions for businesses in various industries. By prioritizing the needs of the customer, (brand name removed) sets the standard for quality and excellence in wire mesh products.

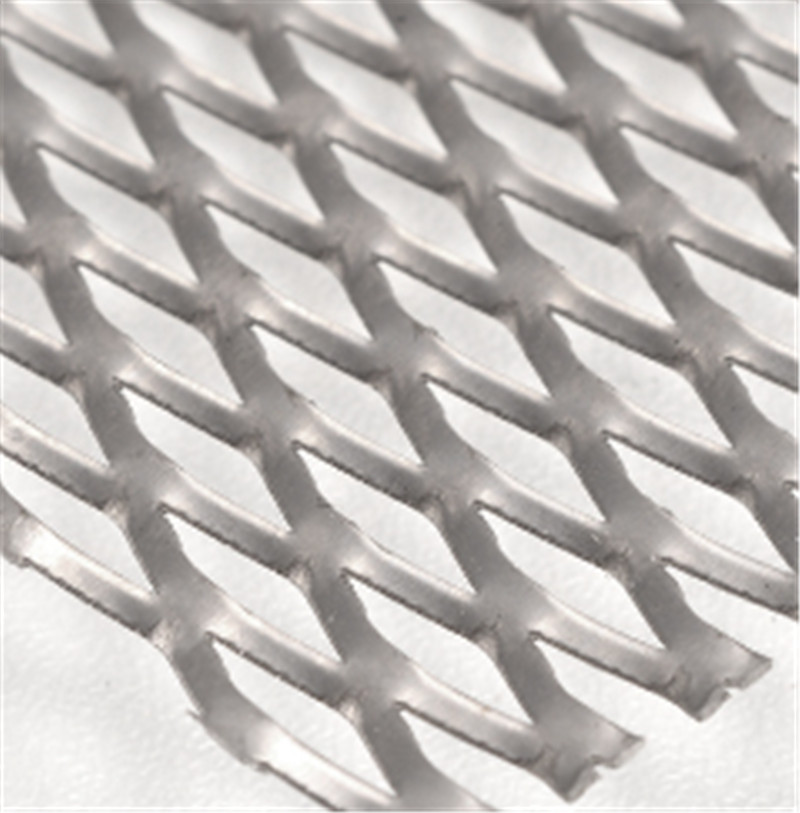

High-quality Steel Expanded Metal Offers Superior Strength and Durability - Read the Latest News

Title: Innovations in Steel Expanded Metal Technology Revolutionize the Construction IndustryIntroduction:In an era of rapid advancements, Steel Expanded Metal has emerged as a transformative material in the construction industry. With its unique characteristics and impressive versatility, it has revolutionized the way infrastructure projects are designed and executed. This article will explore the advancements in Steel Expanded Metal technology and delve into the innovative solutions it provides, contributing to the sustainability and efficiency of construction projects worldwide.Paragraph 1: What is Steel Expanded Metal?Steel Expanded Metal is a revolutionary material formed by stretching and slitting metal sheets, creating a mesh-like pattern with diamond-shaped openings. The process enhances the material's structural integrity while maintaining its lightweight nature. It can be manufactured using various metals such as stainless steel, carbon steel, and aluminum. Steel Expanded Metal is renowned for its strength, durability, and cost-effectiveness, making it a preferred choice in construction projects globally.Paragraph 2: The Advantages of Steel Expanded MetalSteel Expanded Metal offers numerous advantages over traditional materials used in construction. It provides exceptional load-bearing capacity, allowing architects and engineers to create large-scale structures while reducing support requirements. Its lightweight properties make transportation and installation easier, reducing overall project costs and construction time.Additionally, Steel Expanded Metal offers transparency, allowing natural light and ventilation to pass through, optimizing energy consumption and enhancing the eco-friendliness of buildings. It is also highly resistant to corrosion, ensuring long-term durability and reducing maintenance costs. These benefits have led to its widespread adoption in a variety of applications, including flooring, fencing, walls, partitions, ceiling panels, and façade systems.Paragraph 3: Applications of Steel Expanded MetalSteel Expanded Metal's versatility enables its integration into a wide range of construction applications. In the realm of infrastructure, it is widely used in the creation of robust walkways, platforms, and ramps, where its load-bearing capacity and anti-slip properties are essential. Expanded metal gratings, composed of steel meshes, have become indispensable in industrial settings, where they ensure worker safety by providing secure flooring in hazardous environments.Moreover, the construction industry has embraced Steel Expanded Metal in architectural applications. Its malleability allows for the creation of intricate and aesthetically pleasing structures, adding a unique touch to modern buildings. Expanded metal mesh finds extensive use in decorative facades, sunscreens, and shading elements, enhancing both the visual appeal and functionality of buildings.Paragraph 4: Environmental Sustainability and SafetyThe construction industry has set ambitious sustainability goals for the future, and Steel Expanded Metal plays a significant role in achieving them. Through its light-transmitting properties, it reduces the need for artificial lighting during daylight hours, leading to reduced energy consumption and lower carbon emissions. Its open design also enhances natural ventilation, reducing the reliance on air conditioning systems.Furthermore, Steel Expanded Metal is recyclable, making it an environmentally friendly choice. It can be reprocessed and repurposed for other applications, reducing waste and conserving resources. Steel Expanded Metal's inherent fire-resistant properties contribute to building safety, improving fire regulations compliance and ensuring occupant protection.Conclusion:In conclusion, Steel Expanded Metal has transformed the construction industry by providing innovative solutions to the challenges faced in infrastructure development. Its unique characteristics, including strength, durability, and versatility, have given architects and engineers the freedom to create novel designs while maintaining structural integrity. The material's applications range from gratings and walkways to decorative facades and sunscreens, ultimately enhancing the functionality and aesthetic appeal of modern buildings. Embracing Steel Expanded Metal's sustainability and safety features, the construction industry is moving towards environmentally responsible practices. As this technology continues to evolve, we can expect even more groundbreaking applications and benefits across the architecture and construction sectors.

Understanding the Definition and Applications of Wire Mesh

and Fine Wire Mesh.Wire mesh is a versatile material that finds applications across various industries due to its structural strength, durability, and low cost. It consists of intertwined wires that form a grid-like pattern with uniform gaps between each wire. These gaps can range from small to large, depending on the type of wire mesh used.Coarse Wire Mesh, as the name suggests, has relatively larger gaps as compared to other wire mesh variants. It is commonly used for industrial purposes such as filtration, reinforcement, and security fencing. Coarse Wire Mesh is made using thicker wires, which offer higher stability and strength, ensuring that it can withstand heavy loads.Fine Wire Mesh, on the other hand, has smaller gaps and thinner wire diameters, making it more flexible and pliable. This type of wire mesh is mainly used for architectural purposes such as interior design, decorative components, and artistic installations. Fine Wire Mesh is available in various materials such as stainless steel, brass, aluminum, and copper, making it suitable for different design requirements.Wire mesh finds applications in diverse industries such as agriculture, construction, automotive, and food processing. It is commonly used for insect screening, air filtration, safety guards, and insulation. Wire mesh is also used in the production of concrete, where it acts as a reinforcement material, helping to increase its strength.Apart from its industrial and architectural applications, wire mesh is also used in the creation of innovative products such as wire mesh baskets and wire mesh shelves. These products are widely used in retail stores for displaying merchandise and organizing storage spaces.In conclusion, wire mesh is a versatile material that has found widespread usage across various industries due to its strength, durability, and low cost. Its ability to adapt to different applications and design requirements makes it a popular choice for architects, engineers, and designers. Whether it's Coarse Wire Mesh or Fine Wire Mesh, wire mesh continues to play an essential role in our daily lives.

Carbon Steel Wire Mesh: A Versatile and Reliable Wire Mesh Solution.

The Carbon Steel Wire Mesh industry has been experiencing a significant boom for the past few years. This growth comes as no surprise, given the increasing demand for strong and durable materials to serve various construction and industrial purposes.One of the leading companies responsible for this boom is {company name}. This renowned manufacturer of Carbon Steel Wire Mesh has been providing top-quality products to clients for several years. The company is known for its extensive range of products that meet the specific needs of various industries such as construction, mining, and agriculture.Their Carbon Steel Wire Mesh is composed of high-quality carbon steel wire, engineered to withstand rough handling, harsh weather conditions, and varying degrees of tension. This makes it an ideal material for various applications such as fencing, filter screens, and concrete reinforcement.In addition to their reputable products, {company name} is recognized for its commitment to maintaining high standards of quality and reliability. The company's team consists of skilled and experienced professionals who use cutting-edge technologies to manufacture top-notch products. They are dedicated to providing excellent customer service and helping clients choose the best product for their specific needs.{Company name} is also known for its strict adherence to safety protocols and ethical practices. They understand the importance of ensuring the safety of their employees and customers, as well as keeping the environment safe. As such, they take every measure to minimize their environmental impact, promote sustainability, and maintain a safe working environment.Furthermore, the company continuously invests in research and development to improve their products and stay ahead of their competitors. In the industry, {Company name} is regarded as a pioneer in Carbon Steel Wire Mesh and has been at the forefront of developing innovative products that are stronger, more durable, and more cost-effective.Recently, {company name} announced that it had expanded its range of products to include Galvanized Wire Mesh. This move is part of the company's strategy to offer a more extensive range of quality products that meet the specific needs of its clients. Galvanized Wire Mesh is an excellent alternative to carbon steel wire mesh, and it comes with several advantages, such as corrosion resistance, enhanced durability, and a longer lifespan.The company's CEO, {name}, expressed his excitement about the development, stating that the company's continued growth and success have been made possible by an unrelenting focus on customer satisfaction and a commitment to providing quality products. He emphasized that the expansion of their product portfolio is a reflection of the company's mission to meet the ever-evolving needs of customers.{company name}'s decision to include Galvanized Wire Mesh in its product range comes at a time when the market is experiencing significant demand for corrosion-resistant material. The company's customers are expected to benefit significantly from this development, as the new product offering presents new opportunities for cost savings without sacrificing quality.In conclusion, {company name} has been a leader in Carbon Steel Wire Mesh manufacturing for several years. The quality of their products, commitment to customer satisfaction, and adherence to ethical practices have earned them an excellent reputation among their customers and peers. The company's decision to expand its product range to include Galvanized Wire Mesh is a testament to its dedication to meeting the ever-changing needs of its clients while maintaining its commitment to providing top-quality products.

Highly Efficient Sintered Candle Filter for Dispersion and Backwash Applications

and Dispersion and BackwashSintered Candle Filter: A Reliable Solution for Dispersion and BackwashThe process of filtration plays a vital role in many industries, especially where the quality of the product is critical. With the advancement in technology, various types of filters are introduced to meet the specific needs of different applications. Among them, sintered candle filter has gained much importance in recent years due to its high filtration efficiency and chemical resistance. This blog will discuss the significance of sintered candle filter, particularly for dispersion and backwash applications.What is a Sintered Candle Filter?A sintered candle filter is a type of ceramic filter that consists of a cylindrical shape with a porous structure. It is made of alumina, zirconia, or silicon carbide and is sintered at high temperatures to form a rigid and durable structure. The porous structure of the filter allows the fluid to pass through while retaining the particles and impurities. The filtration process occurs through surface filtration or depth filtration, depending on the pore structure of the filter.Significance of Sintered Candle Filter for DispersionDispersion is a critical process in many industries, including pharmaceutical, chemical, and food processing. It involves the mixing of two or more components to form a homogeneous solution. The quality and consistency of the final product depend on the proper mixing and dispersion of the components. Sintered candle filters are widely used for dispersion applications due to their high filtration efficiency and uniform pore size distribution. The uniform pore size distribution ensures the proper dispersion of the components by retaining the large particles and allowing the smaller particles to pass through. Moreover, the chemical resistance of the filter ensures the compatibility with a wide range of chemicals, enabling the filter to withstand aggressive chemical environments.Significance of Sintered Candle Filter for BackwashBackwash is a process used for cleaning the filter media to remove the impurities and particles accumulated during the filtration process. It involves reversing the flow of the fluid to dislodge the particles and flush them out of the filter. Sintered candle filters are widely used for backwash applications due to their rigid and durable structure and high resistance to thermal and chemical shock. The high filtration efficiency of the filter ensures the proper removal of the impurities during backwash, resulting in a clean and efficient filtration process.ConclusionSintered candle filters have gained much importance in recent years due to their high filtration efficiency, uniform pore size distribution, and chemical resistance. The significance of these filters for dispersion and backwash applications makes them a reliable solution for many industries. The proper selection of the filter material and pore size is crucial to ensure the optimal performance of the filter. Therefore, it is essential to consider the specific needs of the application before selecting the filter. So, the sintered candle filter is a great choice for industries looking for an efficient and reliable filtration solution for dispersion and backwash applications.

High-Quality Stainless Steel Sintered Filter for Efficient Air and Exhaust Filtration

, Stainless Steel Filter Cartridge, Exhaust Filter Cartridge, and Filtration Technology.In today's industrial and technological world, air and exhaust filters play an essential role in ensuring efficient and effective processes in various industries. One crucial aspect of these filters is their ability to deliver high-quality air or extract impurities from exhaust, hence the need for high-quality filters like the Stainless Steel Sintered Filter, Stable Drop Air Filter Cartridge, Exhaust Filter Cartridge, and Exhaust Fi from Filtration Technology Manufacture Co.,Ltd.The sintered air filter, specifically, is an innovative and effective filtration solution that produces clean, filtered air of high purity, even in the harshest environments. It utilizes a patented process that involves compressing a fine stainless steel wire mesh into a porous structure that creates tiny filter channels to trap any particles or debris present. This results in a highly efficient, low-pressure drop air filter that has a long lifespan, making it an ideal filter for many industrial applications.Stainless steel filter cartridges are also innovative and high-quality filters that effectively remove impurities from liquids and industrial gases. Made from stainless steel mesh, these filter cartridges are highly durable, corrosion-resistant, and have a long lifespan compared to other filter types. They are widely used in various industrial applications, including the chemical, oil and gas, food and beverage, and pharmaceutical industries.Exhaust filter cartridges are another type of filter that play an essential role in purifying the air from exhaust. These filters are designed to capture harmful contaminants and impurities that are present in exhaust gases before they are released into the atmosphere. Filtration Technology Manufacture Co., Ltd offers a broad range of exhaust filter cartridges suitable for various applications.Filtration Technology Manufacture Co., Ltd is a leader in the design and manufacture of high-quality filtration solutions for industrial applications. With a team of experienced engineers, the company provides customized filtration solutions to meet the unique needs of their clients. Their filters are made from high-quality materials, and they are rigorously tested to ensure they meet the stringent quality standards.In conclusion, air and exhaust filters play a critical role in ensuring efficient and effective processes in various industries. The Stainless Steel Sintered Filter, Stable Drop Air Filter Cartridge, Exhaust Filter Cartridge, and Exhaust Fi filters from Filtration Technology Manufacture Co., Ltd offer effective and innovative filtration solutions suitable for various applications. Whether you seek sintered air filters, stainless steel filter cartridges, exhaust filter cartridges, or any other filtration solutions, Filtration Technology Manufacture Co., Ltd is the go-to manufacturer for quality and reliable filtration solutions.

Exploring the Applications and Benefits of Fine Woven Wire Mesh

[Company Introduction]Founded in [year], [Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With our state-of-the-art facilities and innovative technologies, we have successfully established a reputation for producing high-quality wire mesh solutions tailored to meet the diverse needs of various industries worldwide. Our commitment to excellence, customer satisfaction, and continuous improvement has made us a preferred choice for businesses seeking reliable and customized wire mesh solutions.[News Content]Title: Industry Leader [Company Name] Unveils Innovative Fine Woven Wire Mesh Solution[City, Date] - As consumer demands for advanced technological products continue to rise, companies across various industries are constantly seeking innovative materials to meet these requirements. Recognizing this need, [Company Name], a renowned manufacturer of wire mesh products, is delighted to unveil its latest development in the form of an advanced fine woven wire mesh solution.The newly launched product, designed to cater to the demanding requirements of multiple industries, signifies a significant leap forward in terms of technological advancement and reliability. Fine woven wire mesh is widely used in sectors such as automotive, aerospace, architecture, and industrial applications. Its unique characteristics, including superior strength, durability, and precision, make it an ideal choice for a wide range of applications.[Company Name]'s fine woven wire mesh is manufactured using the latest state-of-the-art techniques, ensuring impeccable quality and consistency. The production process involves meticulously weaving individual wires together, resulting in a tightly-knit and durable mesh structure. This level of precision guarantees the product's capability to withstand extreme temperatures, high pressure, and harsh environmental conditions.One of the key advantages of [Company Name]'s fine woven wire mesh is its versatility. With customizable parameters such as wire diameter, mesh count, and material selection, customers can easily select the perfect solution to meet their specific project requirements. Whether it's filtration, separation, protection, or reinforcement, the fine woven wire mesh can be tailored to deliver exceptional results.Moreover, [Company Name] recognizes the importance of sustainability and environmental responsibility. The newly developed fine woven wire mesh is engineered using eco-friendly materials, ensuring compliance with the latest industry standards and regulations. This eco-conscious approach aligns with the company's commitment to creating a greener tomorrow while providing advanced solutions to meet current market needs.In addition to the impeccable quality of the fine woven wire mesh, [Company Name] offers comprehensive technical support and assistance to its customers. With dedicated teams of experts, the company ensures that customers receive the necessary guidance in selecting the most suitable wire mesh solution and provides valuable insights into its application and performance."We are thrilled to introduce our latest fine woven wire mesh solution to the market," says [Name], [Company Name]'s CEO. "Through years of research and development, we have created a product that not only meets the demanding requirements of various industries but also contributes to a sustainable environment. Our team is dedicated to providing innovative and customized solutions to our esteemed clients, ensuring their success in their respective fields."As industries continue to evolve and demand cutting-edge materials, [Company Name] reaffirms its commitment to pushing the boundaries of technological advancements in the wire mesh industry. With its latest fine woven wire mesh solution, the company positions itself as a reliable partner in meeting customers' evolving needs and contributing to the overall progress of industries globally.About [Company Name]:[Company Name] is a global leader in the manufacturing and distribution of fine woven wire mesh products. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as an industry leader over the years. From automotive to architectural applications, [Company Name] provides reliable and customized wire mesh solutions to various industries across the globe.Press Contact:[Name][Job Title][Company Name][Phone Number][Email]

Nickel Mesh and Screen: Material, Specification, Packing - Corrosion and Acid Resistant Filter Mesh for High Temperature Filtration

article about the benefits of using nickel wire mesh and screen in various industrial applications.Nickel wire mesh and screen have become increasingly popular in various industrial applications, thanks to their unique properties. As a manufacturer and supplier of high-quality nickel wire mesh, {company name} understands the numerous benefits that this material provides for industrial filtration and screening processes.Nickel wire mesh is highly durable and resistant to both corrosion and acid, making it an ideal material for use in harsh and high-temperature environments. This property makes nickel wire mesh and screen suitable for use in various industries, such as chemical and petrochemical production, power generation, and mining.One of the primary benefits of using nickel wire mesh is its high-level filtration. Nickel wire mesh filters and screens are capable of separating and removing very fine particles from liquids or gases, making them an essential material in many manufacturing and industrial processes. In these industries, even the tiniest of impurities can cause machinery to malfunction or fail, leading to costly repairs, downtime, and potential safety hazards.Nickel wire mesh and screen also exhibit excellent electrical conductivity properties. This makes them ideal for use in electrical and electronic industries, where they can be used as electrodes or screens for electromagnetic shielding. Since nickel has good magnetic properties, it is also used in electrical transformers and inductors.In addition to its unique properties, nickel wire mesh and screen are available in different specifications and mesh sizes. This versatility makes it possible for {company name} to offer a wide range of custom nickel wire mesh products tailored to meet specific industry requirements. Customers can choose from woven, knitted, perforated, or expanded nickel wire mesh depending on their application needs.To ensure the safety of nickel wire mesh products during transportation or storage, {company name} pays significant attention to the packing requirements. The company uses durable packing materials and techniques to ensure its products remain in good condition and reach customers in perfect condition.In conclusion, nickel wire mesh and screen are versatile materials that offer a range of benefits for various industrial applications. With their high durability, resistance to corrosion and acid, and excellent filtration properties, nickel wire mesh has become an essential material in industries such as chemical production, power generation, and mining, among others. As a reputable manufacturer and supplier of nickel wire mesh products, {company name} is dedicated to providing its customers with high-quality custom nickel wire mesh products and excellent customer service.

New Cone-Shaped Filter Simplifies Coffee Brewing Process

Title: Innovative Cone Shape Filter Revolutionizes the Filtering IndustryIntroduction to the Company: (Company name)With a strong commitment to innovation and excellence, (Company name) has emerged as a frontrunner in the field of filtration solutions. Leveraging cutting-edge technology and extensive research, the company is dedicated to providing quality products that exceed customer expectations. (Company name) has recently introduced an incredible breakthrough in the form of its revolutionary Cone Shape Filter, offering unparalleled filtration performance and efficiency. This groundbreaking product is poised to reshape the landscape of the filtering industry.Body:1. The Need for Advanced Filtration SolutionsAs industries continue to evolve, the demand for advanced filtration solutions has grown significantly. Traditional filter products have often struggled to effectively remove impurities and deliver optimal results. Recognizing this gap in the market, (Company name) embarked on a mission to create a filtering solution that would address these limitations. Through relentless research and development efforts, the company successfully developed the Cone Shape Filter.2. Introducing the Cone Shape FilterThe Cone Shape Filter, a marvel of engineering, incorporates state-of-the-art technology and design to deliver an unprecedented level of efficiency and performance. Unlike conventional filters, the cone-shaped design provides a larger filtration area, enabling it to trap a greater amount of impurities. This increased surface area ensures improved filtration effectiveness and prolonged filter life.3. Unparalleled Filtration EfficiencyThe Cone Shape Filter utilizes an advanced, multi-layered filtration system that guarantees high efficiency. The layers are designed to capture different sizes of particles, allowing the filter to effectively remove even the tiniest impurities from the media being filtered. This enhanced filtration capability ensures superior quality outputs and prevents potential damages to sensitive equipment or systems.4. Versatility and AdaptabilityThe innovative design of the Cone Shape Filter makes it highly versatile and adaptable to diverse industrial applications. With adaptable connectors and fittings, it can be easily integrated into existing filtration systems, catering to the specific requirements of different industries. This flexibility ensures a seamless and efficient upgrade for companies seeking to enhance their filtration processes.5. Benefits and AdvantagesThe Cone Shape Filter offers numerous benefits and advantages over traditional filters:a) Enhanced Filtration Performance: The larger surface area and multi-layered filtration system dramatically improve the filter's ability to trap impurities, resulting in cleaner and purer filtrate.b) Extended Filter Life: The design of the Cone Shape Filter reduces clogging and extends the lifespan of the filter, resulting in reduced maintenance and replacement costs.c) Cost Savings: With its efficient filtration and extended filter life, the Cone Shape Filter helps businesses save on operating expenses.d) Improved System Efficiency: By eliminating or reducing impurities, the Cone Shape Filter ensures the optimum performance and longevity of equipment and machinery.e) Environmental Sustainability: As the Cone Shape Filter reduces the frequency of filter replacements, it significantly reduces waste generation, contributing to a greener environment.6. Positive Industry Reception and Future ProspectsSince its introduction, the Cone Shape Filter has garnered significant attention and acclaim within the industry. Businesses across various sectors have embraced this innovative solution due to its unmatched filtration performance and cost-effective advantages. The positive feedback from early adopters further strengthens (Company name)'s position as a leader in the filtration industry.Moving forward, (Company name) has plans to expand its product line and explore additional applications for the Cone Shape Filter. The company's dedication to continuous improvement and providing innovative solutions to its customers ensures that they remain at the forefront of filtration technology.Conclusion:The introduction of the Cone Shape Filter by (Company name) marks a major milestone in the filtration industry. Its revolutionary design, coupled with unmatched filtration efficiency, offers businesses a superior solution for their filtration needs. As the product gains wider adoption, it is poised to transform the way industries approach filtration processes. With (Company name)'s mission to innovate and excel, the future looks promising for both the company and the filtering industry as a whole.

New Woven Wire Mesh Filter Offers Efficient Filtration Solution

Woven Wire Mesh Filter Revolutionizing Filtration ProcessesIn modern industries, filtration plays an essential role in maintaining efficiency, quality, and safety. One company, renowned for its innovative solutions, has introduced a groundbreaking product - the Woven Wire Mesh. This filter, without compromise in performance and durability, has garnered significant attention from various sectors.The Woven Wire Mesh filter is engineered to meet the diverse filtration needs across industries such as oil and gas, pharmaceuticals, water treatment, and many others. This revolutionary filter provides efficient and reliable separation of solids from liquids, offering unmatched durability and longevity compared to traditional filtration methods.One of the key features that make this filter stand out is its design. The Woven Wire Mesh filter is constructed using a diverse range of materials, such as stainless steel, copper, bronze, and nickel alloys. This allows for customization to suit specific filtration requirements, making it an ideal choice for a wide array of applications. Additionally, its unique weave pattern enhances strength, ensuring long-lasting performance even under extreme conditions.Notably, the Woven Wire Mesh filter successfully eliminates the limitations imposed by conventional filters. Its precise design and manufacturing process enable it to trap and retain particles of varying sizes, down to sub-micron levels. Thanks to its superior filtration capabilities, it ensures excellent product quality, prevents equipment damage, and increases overall operational efficiency.The Woven Wire Mesh filter's applications are seemingly endless. In the oil and gas sector, it effectively separates impurities from crude oil, lubricants, and hydraulic fluids, reducing equipment wear and energy consumption. In the pharmaceutical industry, it is utilized for sterilizing liquids, thus ensuring the safety and purity of medications. Moreover, this versatile filter is employed in wastewater treatment plants to remove solids, improving water quality and environmental sustainability.To accommodate the demanding needs of various industries, the company behind the Woven Wire Mesh filter offers a range of customization options. Customers can select the filter's material, aperture size, and wire diameter to perfectly match specific filtration requirements. This flexibility enables seamless integration into existing systems and maximizes filtration efficiency.Furthermore, the company's commitment to quality is exemplified by its rigorous testing procedures. Every Woven Wire Mesh filter undergoes comprehensive performance tests to meet international standards. Additionally, the company adheres to strict quality control protocols throughout the manufacturing process, ensuring consistent and reliable products.Apart from its superior filtration capabilities and stringent quality control, the Woven Wire Mesh filter also offers distinct economic advantages. Due to its exceptional durability and longevity, it significantly reduces maintenance and replacement costs compared to conventional disposable filters. Additionally, its high filtration efficiency minimizes production downtime and maximizes productivity, yielding substantial cost savings over time.In conclusion, the Woven Wire Mesh filter is a game-changer in the field of filtration. Its innovative design, customized solutions, and exceptional performance have ushered in a new era of efficiency and reliability. With its vast array of applications, this revolutionary filter is set to transform filtration processes across industries. As the demand for superior filtration solutions continues to rise, the Woven Wire Mesh filter stands at the forefront, providing unmatched quality and innovation.