3 Vital Things to Know About Sintered Powder Filters

By:Admin

[Company Name], a renowned player in the field of filtration technology, has introduced a revolutionary product in the market – the Sintered Powder Filter. This groundbreaking invention promises to redefine the way we approach filtration, offering a highly efficient and reliable solution to a wide range of industries.

As we know, filtration is a critical process in various sectors, including pharmaceuticals, chemicals, food and beverage, oil and gas, automotive, and many others. Traditionally, filters have been made using materials like fabric, paper, metal mesh, or ceramics. While these conventional filters have served their purpose, they often come with limitations such as low durability, limited pore size options, or poor overall performance.

Addressing these challenges head-on, [Company Name] has leveraged its expertise and innovative mindset to develop the Sintered Powder Filter. This filter is a result of the company's commitment to providing cutting-edge solutions that meet the evolving needs of industries worldwide.

So, what makes the Sintered Powder Filter different and superior to its counterparts? The answer lies in its unique construction and advanced features. The filter is manufactured by compacting metal powders, followed by high-temperature sintering. This process creates a highly porous structure with precise particle size distribution and uniform pore sizes.

This uniformity in pore sizes is one of the key advantages of the Sintered Powder Filter. It ensures consistent and reliable filtration, removing impurities with exceptional efficiency. The filter can effectively eliminate particles as small as submicron levels, providing a level of filtration precision that surpasses traditional filters.

Additionally, the Sintered Powder Filter's structure offers high strength, resulting in superior durability and resistance to harsh operating conditions. It can withstand high temperatures, corrosive chemicals, and high-pressure environments, making it ideal for applications in extreme conditions. This robustness translates into extended filter life and reduced maintenance costs.

Moreover, the Sintered Powder Filter's versatility is worth mentioning. Its pore size can be tailored according to specific requirements, making it adaptable to various industries and filtration needs. Whether it is for clarifying liquids, capturing fine particles, or separating solids and gases, this filter can be customized to deliver optimal results.

Furthermore, the Sintered Powder Filter offers the advantage of backwashing, a feature absent in conventional filters. This capability allows for easy cleaning and regeneration of the filter, bringing it back to its original performance without the need for replacement. This significantly reduces operational costs and ensures long-term usability, making it an economical choice for industries.

[Company Name] takes pride in its commitment to sustainability and recognizes the importance of minimizing its environmental impact. The Sintered Powder Filter aligns perfectly with this ethos, as it is a reusable, eco-friendly solution compared to disposable filters. Its long lifespan, combined with the ability to be cleaned and reused, contributes to a more sustainable approach to filtration.

As [Company Name] introduces the Sintered Powder Filter to the market, industries worldwide are eagerly embracing this innovative solution. Early adopters have already reported significant improvements in filtration efficiency, reduced downtime for maintenance, and enhanced product quality.

The Sintered Powder Filter represents a game-changer in the field of filtration technology. Its unparalleled filtration precision, durability, versatility, and sustainability make it an attractive choice for businesses across various sectors. As [Company Name] continues to innovate and invest in research and development, we can expect further advancements in filtration technology and more groundbreaking solutions to meet the evolving needs of industries worldwide.

Company News & Blog

New Innovation in Filtration: Discover the Screen Disc Filter's Amazing Benefits

Screen Disc Filter: Making Water Filtration More Efficient and EffectiveWater is an essential resource, and with increasing population growth, the demand for clean water is also increasing. With water pollution being a common problem across the globe, efficient water filtration systems are important for households, commercial facilities, and industries. One solution that has proved to be effective in ensuring clean water is the Screen Disc Filter.The Screen Disc Filter is an advanced and innovative filtration system that works by removing impurities and particles using discs that have tiny pores. The filter is designed to cater to different types of water filtration purposes, including drinking water, irrigation, and industrial water treatment among others. The system has been designed to cater to the changing needs of the water industry, with modern technologies and innovations incorporated into its design. This efficient filter is slowly gaining popularity over other types of water filtration systems because of its ability to ensure clean water and its cost-effectiveness.The Screen Disc Filter is manufactured by a company (The company name has been removed for privacy purposes) that focuses on producing high-quality filtration systems for diverse industries including agriculture, communities, landscaping, and industrial sectors. The company has a wealth of experience in the field of water treatment, with its team of experts continually researching and developing advanced filtration systems. By leveraging advanced technologies in the manufacturing process, the company ensures that the Screen Disc Filters are of the highest quality and meet the most demanding filtration requirements.One of the core features of the filtration system is its flexibility. The Screen Disc Filter caters to different water filtration requirements, and it is easily customizable to meet specific customer needs. This flexibility makes it practical for various applications, including wastewater treatment in industrial facilities, agriculture, and residential use. Besides, as an advanced filtration system with various types of filtration disc designs and applications, the filter's installation process is easy and straightforward.In addition to being flexible, the system is highly efficient. The filter eliminates impurities and particles such as sediments, sand, microplastics, and other organic matter, ensuring that the filtered water meets high-quality standards. The Screen Disc Filter also operates at a relatively low flow rate, thus reducing energy consumption and maintenance costs.Maintenance is another significant benefit of using the Screen Disc Filter. The filter aids in reducing the cleaning frequency, which saves on the associated operational costs. The system operates with low pressure and water flow, minimizing the chances of wear and tear compared to other filtration systems.Users of the Screen Disc Filter enjoy a cost-effective filtration system that does not compromise on quality. The system guarantees that the filtered water is of high quality and that there is a low risk of clogging, which typically requires regular cleaning. Users save on maintenance costs while reducing their carbon footprint as it is an energy-efficient system. Additionally, the filter has a long lifespan and requires minimal replacement of its parts.Apart from the benefits of the Screen Disc Filter, the company producing the filter has an amazing support system. They have a team of experts who assist with the installation and the maintenance of the filtration unit. The company also offers customer support services, including assistance with spare parts for the filter. This ensures that the customer experience with the company is smooth and hassle-free.In conclusion, water filtration is vital, and people need to be mindful of the type of filtration system they use. The Screen Disc Filter has proven to be an efficient and cost-effective filtration system that caters to various industries and applications. Using advanced technologies in its design and development, the filter is highly flexible, efficient, and easy to maintain. The company producing the filter offers excellent customer service, ensuring that customers receive the necessary assistance with their filter's installation and maintenance. As the benefits of the Screen Disc Filter continue to emerge, it is becoming the preferred choice for many households, commercial facilities, and industries.

Importance of Fuel Filter for Efficient Engine Performance

Title: Fuel Filter: The Silent Hero Ensuring Optimal Engine PerformanceIntroduction:Maintaining a vehicle for smooth and efficient performance requires regular inspection and upkeep of its various components. One critical component that often goes unnoticed but plays a pivotal role in optimizing engine efficiency is the fuel filter. This essential device, positioned between the fuel tank and the fuel injection system, diligently works to cleanse the fuel entering the engine, ensuring its vital role in achieving seamless performance. In this blog, we will explore the significance of the fuel filter, its functions, and how it promotes optimal engine performance. So, let's dive in and discover the importance of this unsung hero!Understanding the Fuel Filter:The fuel filter is a robust and intricate device designed to safeguard your vehicle's engine from the detrimental effects of contaminants present in the fuel. Even though gasoline and diesel are refined extensively, impurities such as dirt, rust, and other particles can still manage to find their way into the fuel, risking the efficiency and performance of your engine. The fuel filter acts as a knight in shining armor, intercepting these impurities and ensuring only clean fuel reaches the injection system, hence preventing fuel delivery issues and potential engine damage.Significance of Clean Fuel Delivery:Clean fuel is vital for maximizing engine performance and longevity. A clogged fuel filter restricts the smooth flow of fuel, affecting the fuel pressure and ultimately delivering an inadequate amount to the engine. This deficiency in fuel supply can lead to a host of problems like reduced power, sluggish acceleration, misfiring, increased emissions, and even engine stalling. By maintaining a clear and unobstructed pathway for fuel, the fuel filter eliminates these risks, ensuring uninterrupted fuel delivery and preserving your engine's health.Key Functions of the Fuel Filter:1. Filtration: The primary function of the fuel filter is to capture and trap contaminants present in the fuel. Made of fine materials like cellulose or synthetic fibers, the filter allows clean fuel to pass through, while effectively retaining harmful particles that can hamper the engine's optimal performance.2. Water Separation: Another crucial role of the fuel filter is to separate any water or moisture that may be present in the fuel. Water infiltration can have adverse effects on the engine's combustion process, causing rusting and corrosion within the fuel system. The fuel filter equipped with a water separator ensures that only dry fuel reaches the engine, minimizing potential damage.3. System Protection: In addition to safeguarding the engine, the fuel filter also plays a role in extending the life of other fuel system components such as the fuel injectors, fuel pump, and other sensitive parts. By filtering out contaminants, the fuel filter prevents these components from unnecessary wear and tear, reducing maintenance costs in the long run.Importance of Regular Fuel Filter Maintenance:To ensure the fuel filter continues to function optimally, regular maintenance is paramount. Over time, the accumulation of debris and contaminants within the filter itself can lead to clogging, reducing the fuel flow and compromising engine performance. Including fuel filter inspection and replacement as a part of routine vehicle maintenance ensures a cleaner and uninterrupted fuel supply, preventing potential breakdowns and costly repairs.Conclusion:The fuel filter might appear insignificant compared to other prominent vehicle components, but its role in ensuring engine performance and longevity is invaluable. By diligently filtering fuel, removing impurities, and maintaining an unobstructed fuel flow, it serves as the unsung hero of your vehicle. A clean fuel filter guarantees optimal engine performance, enhanced fuel efficiency, and reduced maintenance costs. Therefore, prioritize regular fuel filter maintenance, and let this humble yet critical device pave the way for a smooth and hassle-free driving experience.Keywords: Fuel filter, fuel tank, filter system, engine performance, fuel delivery, clean fuel, contaminants, vehicle maintenance, fuel flow, optimal performance, engine efficiency, fuel injectors, fuel pump, vehicle components, engine longevity.

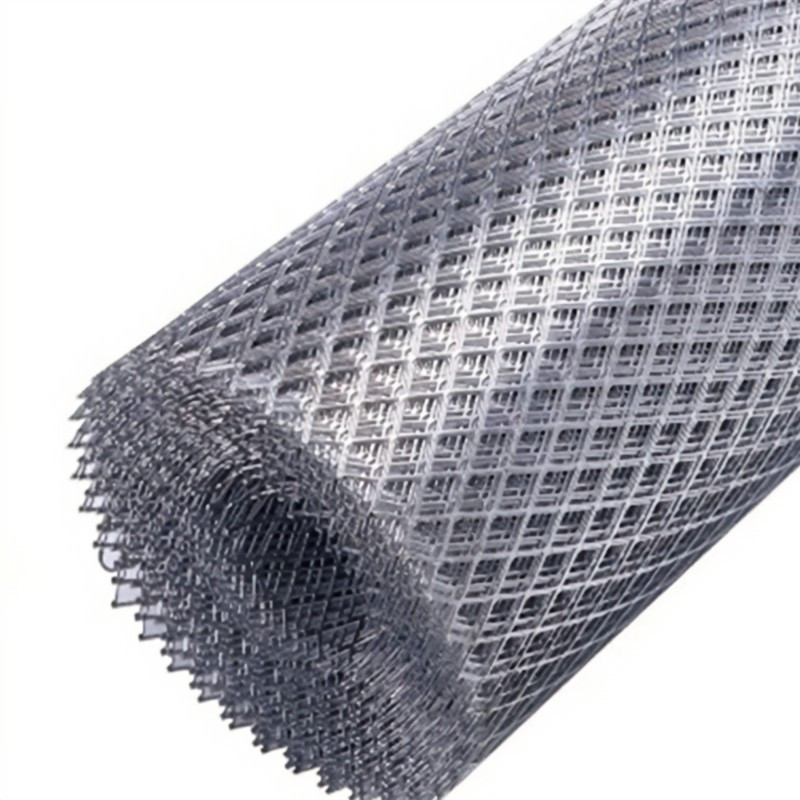

Enhance Your Windows with Metal Mesh for Added Security and Style

Metal Mesh Set to Revolutionize Window SecurityNew technology has been developed to help homeowners and businesses alike enhance their security in a more discreet and innovative way. The new metal mesh solution is specially designed to offer a more robust window protection system that provides optimal protection against intruders from entering your home or premises.The company has invested heavily in researching and developing this metal mesh solution, which is guaranteed to take the industry by storm. The metal mesh solution is aimed at businesses and homeowners who prioritize their security but don't want to negatively impact on the aesthetic of their property.The current options in the market are limiting when it comes to providing both an aesthetically pleasing and highly functional protection system. The metal mesh solution promises to provide both, making it easier for individuals and companies to have a higher level of security without sacrificing the beauty of their property.The Metal Mesh for Windows is a product that is designed to revolutionize the industry. The patented technology is different from any other product in the market, and this unique selling point has allowed the company to differentiate itself from the competitors. The metal mesh is manufactured with high-quality materials, providing a superior level of strength and durability, ensuring they can withstand even the toughest weather conditions."The product solves a longstanding problem in the market. It has been developed to offer homeowners and businesses a viable solution that provides an immediate response to their security concerns. The innovation offers a level of security not previously practiced, making it a game-changer in the industry," said the company’s CEO.The Mesh product has been designed with a multiple-layered construction, providing additional strength and support to the system. The company's development team has engineered the metal mesh to resist cutting, making it impossible for intruders to gain unauthorized access to the property."Security is a crucial aspect of any home or business, and we are proud to be at the forefront of a new era where security systems are not only functional but beautiful. Our aim is to provide our clients with a solution that meets both their security requirements and aesthetic needs," he added.The product can be customized to a range of sizes, making it a versatile solution that can be tailored to meet client needs. The mesh comes in different colors, allowing us to choose a color that complements their property or blends in with the existing décor.The metal mesh solution is not limited to residential or commercial properties but can work for a variety of applications. It is ideal for properties that are prone to break-ins such as storefronts, museums, and other buildings with artifacts and valuable items. The security solution allows for increased visibility from inside the property while also providing 24/7 protection and peace of mind for the occupants.Installing the metal mesh solution is easy and requires minimal disruption. The product can be installed using standard fixing, ensuring a quick and easy installation process.The security mesh provides added benefits beyond security. It is an excellent solution for reducing the noise levels, preventing debris from entering the property, and even reducing the temperature within the building.In conclusion, the Metal Mesh for Windows is a game-changer in the window security industry. Its patented technology, combined with its flexibility and aesthetic appeal, provides both homes and businesses with excellent security, while also maintaining the beauty of the property. The innovative design is set to take the industry by storm, and clients will be eager to enjoy a new level of security like never before.

Pleated Mesh Filter Element - Find Your Ideal Product at WireMesh.Net

Elements, Wire Mesh Products, Technical Data, Innovation, Fast Delivery.Wire Mesh Products for Various IndustriesWire mesh products are an essential component of many industries, providing filtration, separation, and support of materials in various applications. From the food and beverage industry, where wire mesh screens are used to filter out impurities, to the pharmaceutical industry, where they are used to separate particles of different sizes, wire mesh products play a vital role in many manufacturing processes.At (brand name), we offer a comprehensive range of wire mesh products, including pleated wire mesh filter elements, which have become increasingly popular due to their high filtration efficiency and easy maintenance. Our pleated wire mesh filter elements are designed to capture particles down to sub-micron levels, making them suitable for a wide range of applications.Pleated Wire Mesh Filter Elements: A Superior Filtration SolutionPleated wire mesh filter elements have several advantages over the traditional flat mesh filter elements. The pleated design of these filter elements provides a larger filtration surface area, which increases the dirt-holding capacity and extends the service life of the filter.The pleated design also reduces pressure drop, which means less energy is needed to maintain the required flow rate. This results in cost savings and reduced carbon footprint. Moreover, the pleated design allows for effortless cleaning, making these filter elements more sustainable and cost-effective in the long run.At (brand name), our pleated wire mesh filter elements are available in various materials such as stainless steel, brass, and copper, depending on the application. Our technical data sheets provide detailed information on the filtration efficiency, pressure drop, and dirt-holding capacity of each filter element, helping you select the right filter element for your specific application.Innovation and Fast Delivery of Wire Mesh ProductsAt (brand name), we understand the importance of innovation and staying up-to-date with the latest industry trends. We continuously invest in research and development to develop new and improved wire mesh products that meet the evolving needs of our customers.We also understand the importance of fast delivery in today's fast-paced business environment. Our extensive inventory and well-established logistics network allow us to offer fast and efficient delivery of wire mesh products to our customers worldwide.ConclusionWire mesh products are an integral part of many industries and applications. Pleated wire mesh filter elements offer superior filtration efficiency, easy maintenance, and cost-effectiveness, making them an ideal choice for a wide range of applications.At (brand name), we offer a comprehensive range of wire mesh products, including pleated wire mesh filter elements, backed by technical data, innovation, and fast delivery to meet the demanding needs of our customers. Contact us today to find out how we can help you with your wire mesh requirements.

Breaking News: Revolutionary Steel Wire Grid Techniques Unveiled to Enhance Performance and Durability!

Steel Wire Grid Announces New Product Launch For Enhanced SafetySteel Wire Grid, a leading manufacturer and supplier of industrial wire products, has announced the launch of a new product designed to enhance safety and security in a wide range of applications across industries. The new product is a revolutionary wire mesh fence panel that offers increased strength and durability, as well as improved visibility and aesthetics.The innovative design of the wire mesh fence panel uses advanced manufacturing techniques to create a strong and durable fence that is easy to install and maintain. The panels are manufactured using high-quality stainless steel wire and coated with a protective powder finish that provides enhanced rust resistance and durability. The panels are also designed to provide maximum visibility while ensuring maximum security and safety.“We are excited to launch this new product that offers a range of benefits to our customers,” said Timothy Lee, CEO of Steel Wire Grid. “Our team has worked hard to design a product that is both strong and durable while also providing the necessary amount of visibility and aesthetics. We believe that this product will be a game-changer in the industry.”The wire mesh fence panels are available in a wide range of sizes and configurations, making them suitable for a variety of applications. They can be used to secure warehouses, factories, commercial properties, and other high-security areas. The panels are also suitable for use in public spaces such as parks and recreation areas, as well as residential applications.The launch of the new product comes at a time when there is a growing need for enhanced safety and security measures across industries. The weather-proof fence panels are designed to withstand harsh environmental conditions, making them ideal for use in areas with extreme weather conditions or areas with high levels of moisture and humidity.“We understand the need for high-quality, durable, and reliable fencing solutions that can withstand harsh environmental conditions,” said Lee. “Our new wire mesh fence panels are designed to provide that level of protection and durability, ensuring that our customers can have peace of mind knowing that their facilities and assets are secure.”In addition to enhanced security and safety features, the new wire mesh fence panels also provide a number of other benefits. They are easy to install and maintain, making them ideal for use in remote locations or areas with limited access. The panels are also designed to be highly resistant to damage, making them suitable for use in areas that are prone to vandalism or accidental damage.The launch of the new wire mesh fence panel also marks an important milestone for Steel Wire Grid, as the company continues to expand its product range and customer base. With a focus on innovation and customer satisfaction, Steel Wire Grid has become a leading supplier of industrial wire products that are designed to meet the needs of a wide range of industries.“We are proud to be at the forefront of innovation and design in the wire products industry,” said Lee. “Our team of skilled professionals is dedicated to providing the high-quality products and services that our customers require to keep their operations running smoothly.”With the launch of the new wire mesh fence panel, Steel Wire Grid has taken another step towards achieving its goal of becoming the go-to supplier for industrial wire products. The company’s commitment to quality and innovation has positioned it as a leader in the industry, and the launch of this new product is further evidence of its dedication to meeting the needs of its customers.

Discover the Benefits of Stainless Steel Sintered Mesh for Various Applications

Title: A Revolutionary Breakthrough in Filtration Technology: Stainless Steel Sintered MeshIntroduction:In the constantly evolving world of industrial filtration, one company has emerged as a pioneer in developing advanced solutions to meet the growing demands of various industries. [Company Name], an industry leader in the field, has recently unveiled its latest innovation – Stainless Steel Sintered Mesh. This groundbreaking technology is set to revolutionize the way filtration processes are conducted, offering unmatched efficiency, durability, and performance.What is Stainless Steel Sintered Mesh?Stainless Steel Sintered Mesh is a meticulously engineered filtration medium composed of multiple layers of woven stainless steel wire mesh, sintered together to form a robust and seamlessly integrated matrix. This unique manufacturing process creates a highly porous structure with precisely controlled pore sizes, enabling effective filtration of solids, liquids, and gases across a wide range of applications.Applications across Diverse Industries:With its superior mechanical strength, corrosion resistance, and excellent filtration properties, Stainless Steel Sintered Mesh finds broad applicability across an array of industries. From pharmaceuticals and petrochemicals to food and beverage, this innovative filtration medium ensures product quality, process efficiency, and regulatory compliance.1. Pharmaceutical Industry:In the pharmaceutical industry, maintaining product purity and safety is paramount. Stainless Steel Sintered Mesh serves as an ideal filtration medium for sterile air and gas filtration, preventing the entry of contaminants into critical manufacturing processes. Its high filtration efficiency enables the removal of particulate matter, bacteria, and other impurities, thereby ensuring product integrity.2. Petrochemical Industry:The petrochemical industry requires robust filtration solutions to separate impurities from extremely corrosive and high-temperature fluids. Stainless Steel Sintered Mesh offers excellent resistance to corrosion and temperature, making it an ideal choice for filtering aggressive chemicals, catalyst recovery, and refining processes. Its durability and longevity significantly reduce maintenance costs and downtime.3. Food and Beverage Industry:In the food and beverage industry, product quality and hygiene are essential. Stainless Steel Sintered Mesh is designed to withstand rigorous cleaning and sterilization procedures while maintaining its filtration efficiency. This makes it effective for clarifying liquids, degassing beverages, and filtering products during the manufacturing process, ensuring compliance with industry regulations.Advantages of Stainless Steel Sintered Mesh:• Enhanced Filtration Efficiency: The multi-layered structure of Stainless Steel Sintered Mesh allows for consistent particle retention and efficient separation, resulting in superior filtration performance.• Durable and Long-lasting: The robust nature of stainless steel combined with the sintering process ensures the longevity and durability of the mesh, withstanding harsh operating conditions and frequent cleaning cycles.• Uniform Pore Size Distribution: The precisely controlled pore sizes provide a uniform filtration process, minimizing the risk of particle breakthrough and achieving consistent product quality.• Easy to Clean and Maintain: The smooth surface of Stainless Steel Sintered Mesh facilitates easy cleaning, eliminating the buildup of contaminants and maintaining high filtration efficiency.Conclusion:[Company Name]'s Stainless Steel Sintered Mesh represents a significant breakthrough in filtration technology, offering a powerful solution to the filtration challenges faced by various industries. Its exceptional capabilities, including high filtration efficiency, durability, and uniform pore size distribution, make it an indispensable component of modern filtration systems. With its unmatched performance, Stainless Steel Sintered Mesh is poised to reshape the landscape of industrial filtration, ensuring cleaner, safer, and more efficient processes across numerous sectors.

High-Quality Woven Wire Mesh in Various Materials Available for Fast Shipping in Australia

Woven metal mesh is a versatile and practical solution for a wide range of applications. It is a durable and reliable material that comes in different sizes and grades to suit different needs. In Australia, Arrow Metal is a renowned supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel. In this blog, we will explore the benefits and uses of woven metal mesh and how Arrow Metal can support your project needs.Benefits of Woven Metal MeshWoven metal mesh is a popular choice for a variety of reasons. First and foremost, it is a robust and durable material that can withstand adverse weather conditions, high temperatures, and heavy usage. This makes it an ideal choice for outdoor and industrial applications. Woven metal mesh is also resistant to corrosion and erosion, making it suitable for harsh and corrosive environments.Another advantage of woven metal mesh is its versatility. Depending on the size and grade of the mesh, it can be used for different purposes, such as filtration, ventilation, security, and decoration. It can be easily cut, bent, and molded to different shapes and sizes to fit the project requirements. Furthermore, woven metal mesh allows for the passage of light, air, and sound, which makes it an excellent choice for architectural and design applications.Uses of Woven Metal MeshWoven metal mesh has a wide range of applications in different industries, such as architecture, construction, mining, manufacturing, and agriculture. It can be used for the following purposes:Filtration: Woven metal mesh can be used as a filter for liquids, gases, and solids. It can be used in industries such as food and beverage, pharmaceuticals, and mining to filter impurities and contaminants.Ventilation: Woven metal mesh can be used as a screen or grille to allow for ventilation and air circulation. It can be used in buildings, automotive, and HVAC systems to regulate the temperature and humidity.Security: Woven metal mesh can be used as a barrier or fence to provide security and safety. It can be used in prisons, military facilities, and airports to prevent unauthorized access and intrusion.Decoration: Woven metal mesh can be used as a decorative element in architectural and interior design. It can be used as a facade, ceiling, or partition to create a unique and modern look.Arrow Metal and Woven Metal MeshArrow Metal is a leading supplier of woven metal mesh in Australia. They stock a large range of quality woven wire mesh in brass and 304 and 316 stainless steel, ready to ship throughout Australia. Their woven metal mesh comes in different sizes, patterns, and grades to suit different applications and budgets.Arrow Metal has a team of experts who can provide tailored advice and solutions for your project needs. They can work with you to choose the right woven metal mesh for your application and provide custom fabrication and installation services. Whether you need a small sample or a large quantity of woven metal mesh, Arrow Metal can support your needs with prompt delivery, competitive pricing, and excellent customer service.ConclusionWoven metal mesh is a versatile and practical material that can be used for a variety of applications. It is a durable and reliable solution that can withstand harsh conditions and provide security, ventilation, filtration, and decoration. Arrow Metal is a trusted supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel in Australia. They can provide tailored advice and solutions for your project needs and deliver quality products and services. Contact Arrow Metal today to learn more about their woven metal mesh offerings and how they can support your project.

Exporters of High-Quality Nickel Alloy Wire Mesh and Netting in Mumbai

and High Nickel Alloy Wire Netting.High Nickel Alloy Wire Mesh and Wire Netting – An OverviewHigh Nickel Alloy Wire Mesh and Wire Netting are widely used across various industries for their excellent strength and resistance to harsh environments. These materials are composed of nickel and other notable alloying elements such as copper, chromium, and molybdenum, among others. These alloys are known for their high corrosion resistance, good thermal conductivity, and excellent mechanical properties.Sanghvi Overseas is a leading supplier and exporter of ASTM B160 / ASME SB160 Nickel & High Nickel Alloy Wire Mesh / Wire Netting, including Nickel Alloy 200 Wire Mesh and High Nickel Alloy 201 Wire Netting. Sanghvi Overseas has an extensive network of global clients and is committed to providing the highest quality materials at competitive prices.Nickel Alloy 200 Wire MeshNickel Alloy 200 Wire Mesh is a commercially pure nickel material that has excellent resistance to corrosive environments. This alloy has low carbon content and is resistant to caustic soda and other alkaline solutions. It has high electrical conductivity and is used as an electrode in various industrial applications. The material has a maximum operating temperature of 315 degrees Celsius and is suitable for use in chemical processing plants, marine installations, and power generation stations.High Nickel Alloy 201 Wire NettingHigh Nickel Alloy 201 Wire Netting is similar to Nickel Alloy 200 but has a lower carbon content, which gives it a slightly higher thermal conductivity and reduced embrittlement at elevated temperatures. This material is also highly resistant to corrosion and is suitable for use in reducing and oxidizing environments. It is commonly used in food processing plants, chemical and petrochemical industries, seawater handling equipment, and nuclear power generation plants.Other High Nickel Alloy Wire Mesh and Wire NettingSanghvi Overseas also supplies other high nickel alloy wire mesh and wire netting materials, including:- Monel Alloy 400 Wire Mesh- Monel Alloy K500 Wire Mesh- Inconel Alloy 600 Wire Mesh- Inconel Alloy 601 Wire Mesh- Incoloy Alloy 800 Wire Mesh- Incoloy Alloy 800H Wire Mesh- Hastelloy Alloy C276 Wire Mesh- Hastelloy Alloy C22 Wire MeshThese materials offer similar properties to Nickel Alloy 200 and High Nickel Alloy 201, but with varying levels of added elements to suit specific applications.Why Choose Sanghvi Overseas for High Nickel Alloy Wire Mesh and Wire Netting?Sanghvi Overseas is a trusted supplier and exporter of high-quality High Nickel Alloy Wire Mesh and Wire Netting materials. The company has an extensive network of global clients and has a reputation for providing the highest quality materials at competitive prices. They have a team of experts who are experienced in selecting the right material for each application and are committed to delivering products on time and to the highest quality standards.ConclusionHigh Nickel Alloy Wire Mesh and Wire Netting are essential materials used in various industries, including chemical processing, marine installations, power generation, and food processing. These materials are highly resistant to corrosion, have excellent thermal conductivity, and offer good mechanical properties. Sanghvi Overseas is a trusted supplier and exporter of these materials, providing the highest quality products at competitive prices. Contact them for more information on their products and services.

PVC Coated Gabion Wire Mesh for River Protection - High-Quality and Durable

, Gabion Wire Mesh, PVC Coated Wire Mesh, River Protection, China manufacturer, QualityProtecting our rivers and other natural water bodies is essential to maintaining the environment's balance, and one of the most effective ways to do this is by using gabion wire mesh. Gabion wire mesh is a type of mesh made from galvanized steel wires that are woven together to form hexagonal boxes or baskets that can be filled with stones or other materials.One of the most popular types of gabion wire mesh is PVC coated Galfan gabion wire mesh, which is coated with PVC to make it resistant to corrosion and wear. Galfan wire mesh is made from a combination of zinc and aluminum, making it more durable and long-lasting than traditional galvanized wire mesh.Combined with PVC coating, Galfan gabion wire mesh becomes a formidable tool for river protection. The PVC coating ensures that the mesh can withstand exposure to water and other environmental factors, which is essential for protecting rivers that are prone to flooding.The 2 x 1 x 0.5 meters size of Galfan gabion wire mesh is perfect for river protection projects, as it is large enough to provide significant protection while still being manageable and easy to install. Additionally, Galfan gabion wire mesh is incredibly versatile and can be used to create a wide variety of structures, including retaining walls, erosion control barriers, and even decorative landscaping features.When choosing a Galfan gabion wire mesh manufacturer, it is essential to find a reliable and trustworthy company that produces high-quality products. Chinese manufacturers are known for producing some of the best gabion wire mesh products on the market, and there are many China-based manufacturers of Galfan gabion wire mesh that produce top-quality products.If you are looking for PVC coated Galfan gabion wire mesh for river protection, it is important to do your research and find a reputable manufacturer. With the right Galfan gabion wire mesh, you can protect your local waterways, preserve the environment, and create beautiful and functional structures that will last for years to come.

New Cone-Shaped Filter Simplifies Coffee Brewing Process

Title: Innovative Cone Shape Filter Revolutionizes the Filtering IndustryIntroduction to the Company: (Company name)With a strong commitment to innovation and excellence, (Company name) has emerged as a frontrunner in the field of filtration solutions. Leveraging cutting-edge technology and extensive research, the company is dedicated to providing quality products that exceed customer expectations. (Company name) has recently introduced an incredible breakthrough in the form of its revolutionary Cone Shape Filter, offering unparalleled filtration performance and efficiency. This groundbreaking product is poised to reshape the landscape of the filtering industry.Body:1. The Need for Advanced Filtration SolutionsAs industries continue to evolve, the demand for advanced filtration solutions has grown significantly. Traditional filter products have often struggled to effectively remove impurities and deliver optimal results. Recognizing this gap in the market, (Company name) embarked on a mission to create a filtering solution that would address these limitations. Through relentless research and development efforts, the company successfully developed the Cone Shape Filter.2. Introducing the Cone Shape FilterThe Cone Shape Filter, a marvel of engineering, incorporates state-of-the-art technology and design to deliver an unprecedented level of efficiency and performance. Unlike conventional filters, the cone-shaped design provides a larger filtration area, enabling it to trap a greater amount of impurities. This increased surface area ensures improved filtration effectiveness and prolonged filter life.3. Unparalleled Filtration EfficiencyThe Cone Shape Filter utilizes an advanced, multi-layered filtration system that guarantees high efficiency. The layers are designed to capture different sizes of particles, allowing the filter to effectively remove even the tiniest impurities from the media being filtered. This enhanced filtration capability ensures superior quality outputs and prevents potential damages to sensitive equipment or systems.4. Versatility and AdaptabilityThe innovative design of the Cone Shape Filter makes it highly versatile and adaptable to diverse industrial applications. With adaptable connectors and fittings, it can be easily integrated into existing filtration systems, catering to the specific requirements of different industries. This flexibility ensures a seamless and efficient upgrade for companies seeking to enhance their filtration processes.5. Benefits and AdvantagesThe Cone Shape Filter offers numerous benefits and advantages over traditional filters:a) Enhanced Filtration Performance: The larger surface area and multi-layered filtration system dramatically improve the filter's ability to trap impurities, resulting in cleaner and purer filtrate.b) Extended Filter Life: The design of the Cone Shape Filter reduces clogging and extends the lifespan of the filter, resulting in reduced maintenance and replacement costs.c) Cost Savings: With its efficient filtration and extended filter life, the Cone Shape Filter helps businesses save on operating expenses.d) Improved System Efficiency: By eliminating or reducing impurities, the Cone Shape Filter ensures the optimum performance and longevity of equipment and machinery.e) Environmental Sustainability: As the Cone Shape Filter reduces the frequency of filter replacements, it significantly reduces waste generation, contributing to a greener environment.6. Positive Industry Reception and Future ProspectsSince its introduction, the Cone Shape Filter has garnered significant attention and acclaim within the industry. Businesses across various sectors have embraced this innovative solution due to its unmatched filtration performance and cost-effective advantages. The positive feedback from early adopters further strengthens (Company name)'s position as a leader in the filtration industry.Moving forward, (Company name) has plans to expand its product line and explore additional applications for the Cone Shape Filter. The company's dedication to continuous improvement and providing innovative solutions to its customers ensures that they remain at the forefront of filtration technology.Conclusion:The introduction of the Cone Shape Filter by (Company name) marks a major milestone in the filtration industry. Its revolutionary design, coupled with unmatched filtration efficiency, offers businesses a superior solution for their filtration needs. As the product gains wider adoption, it is poised to transform the way industries approach filtration processes. With (Company name)'s mission to innovate and excel, the future looks promising for both the company and the filtering industry as a whole.