Top 5 Uses for Brass Mesh Screen in Everyday Life

By:Admin

In today's fast-paced world, industrial and commercial applications require high-quality materials that can withstand tough conditions and deliver exceptional performance. This is where Brass Mesh Screen comes into play – a versatile solution that is widely recognized for its durability and versatility in various industries. (Company name) has been a leading provider of Brass Mesh Screen, catering to the needs of industries worldwide.

The Brass Mesh Screen, offered by (Company name), is a highly sought-after product due to its unique properties and applications across diverse industries. From filtration and separation to decorative and architectural purposes, the Brass Mesh Screen is a preferred choice for companies looking for reliable and high-quality mesh solutions.

With a strong emphasis on quality and innovation, (Company name) has established itself as a trusted supplier of Brass Mesh Screen in the global market. The company's dedication to excellence and customer satisfaction has positioned it as a preferred partner for businesses seeking top-quality mesh solutions.

The Brass Mesh Screen offered by (Company name) is made from high-grade brass, ensuring superior strength and longevity. This makes it an ideal choice for applications that require resistance to corrosion, wear, and tear. In addition, the mesh screen is available in a variety of sizes and specifications to meet the specific needs of different industries.

One of the key advantages of Brass Mesh Screen is its versatility, making it suitable for a wide range of applications. It is widely used in the automotive industry for radiator grilles and air vents, in the architectural industry for decorative facades and interior design elements, and in the chemical industry for filtration and screening purposes.

Furthermore, the Brass Mesh Screen has found extensive use in the food and beverage industry for sieving and sifting applications, and in the aerospace industry for its lightweight and high-strength properties. Its conductivity and malleability also make it a preferred choice in electrical and electronic applications.

(Company name) takes pride in its ability to deliver customized Brass Mesh Screen solutions to meet the unique requirements of its customers. With a team of skilled engineers and technicians, the company offers comprehensive design and manufacturing capabilities to create bespoke mesh screen solutions for specific applications.

As part of its commitment to sustainability, (Company name) employs environmentally friendly manufacturing processes and sources raw materials from reputable suppliers. This underscores the company's dedication to ethical and responsible business practices, ensuring that its Brass Mesh Screen is not only high-performing but also environmentally conscious.

The Brass Mesh Screen offered by (Company name) is renowned for its reliability and consistency, meeting the stringent quality standards of various industries. With a focus on continuous improvement and technological advancement, the company remains at the forefront of innovation in the mesh solutions industry.

In conclusion, (Company name) has solidified its position as a leading provider of Brass Mesh Screen, serving the needs of diverse industries with its high-quality and versatile solutions. With an unwavering commitment to excellence and customer satisfaction, the company continues to be a trusted partner for businesses seeking top-tier mesh products for their industrial and commercial applications.

Company News & Blog

Breaking News: Revolutionary Steel Wire Grid Techniques Unveiled to Enhance Performance and Durability!

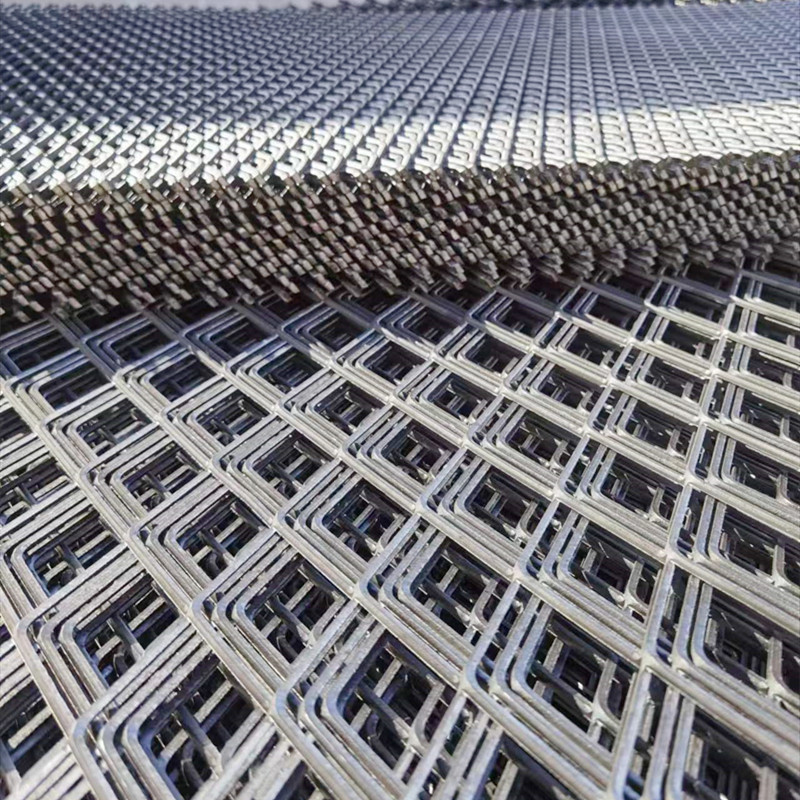

Steel Wire Grid Announces New Product Launch For Enhanced SafetySteel Wire Grid, a leading manufacturer and supplier of industrial wire products, has announced the launch of a new product designed to enhance safety and security in a wide range of applications across industries. The new product is a revolutionary wire mesh fence panel that offers increased strength and durability, as well as improved visibility and aesthetics.The innovative design of the wire mesh fence panel uses advanced manufacturing techniques to create a strong and durable fence that is easy to install and maintain. The panels are manufactured using high-quality stainless steel wire and coated with a protective powder finish that provides enhanced rust resistance and durability. The panels are also designed to provide maximum visibility while ensuring maximum security and safety.“We are excited to launch this new product that offers a range of benefits to our customers,” said Timothy Lee, CEO of Steel Wire Grid. “Our team has worked hard to design a product that is both strong and durable while also providing the necessary amount of visibility and aesthetics. We believe that this product will be a game-changer in the industry.”The wire mesh fence panels are available in a wide range of sizes and configurations, making them suitable for a variety of applications. They can be used to secure warehouses, factories, commercial properties, and other high-security areas. The panels are also suitable for use in public spaces such as parks and recreation areas, as well as residential applications.The launch of the new product comes at a time when there is a growing need for enhanced safety and security measures across industries. The weather-proof fence panels are designed to withstand harsh environmental conditions, making them ideal for use in areas with extreme weather conditions or areas with high levels of moisture and humidity.“We understand the need for high-quality, durable, and reliable fencing solutions that can withstand harsh environmental conditions,” said Lee. “Our new wire mesh fence panels are designed to provide that level of protection and durability, ensuring that our customers can have peace of mind knowing that their facilities and assets are secure.”In addition to enhanced security and safety features, the new wire mesh fence panels also provide a number of other benefits. They are easy to install and maintain, making them ideal for use in remote locations or areas with limited access. The panels are also designed to be highly resistant to damage, making them suitable for use in areas that are prone to vandalism or accidental damage.The launch of the new wire mesh fence panel also marks an important milestone for Steel Wire Grid, as the company continues to expand its product range and customer base. With a focus on innovation and customer satisfaction, Steel Wire Grid has become a leading supplier of industrial wire products that are designed to meet the needs of a wide range of industries.“We are proud to be at the forefront of innovation and design in the wire products industry,” said Lee. “Our team of skilled professionals is dedicated to providing the high-quality products and services that our customers require to keep their operations running smoothly.”With the launch of the new wire mesh fence panel, Steel Wire Grid has taken another step towards achieving its goal of becoming the go-to supplier for industrial wire products. The company’s commitment to quality and innovation has positioned it as a leader in the industry, and the launch of this new product is further evidence of its dedication to meeting the needs of its customers.

High-Quality Heavy Gauge Stainless Steel Welded Wire Mesh Fencing Manufacturer in China

Fencing, Stainless Steel Fencing, Welded Wire Mesh Fencing, China Manufacturer, High Quality.Heavy Gauge Wire Mesh Fencing: The Ultimate Fencing Solution for Security and DurabilityFencing is an inevitable part of any property, be it residential, commercial, or industrial. A good quality fence not only adds to the property's aesthetic value but also ensures security, privacy, and safety. However, choosing the right type of fencing can be a daunting task, given the plethora of options available in the market. Amongst all, heavy gauge wire mesh fencing made of stainless steel has gained popularity owing to its numerous advantages over other fencing materials.Heavy gauge wire mesh fencing is a type of fencing that consists of a series of metal wires that are welded together to form a mesh-like structure. These meshes are made of high-quality stainless steel and come in various sizes and gauges to suit different fencing needs. The wires used in the mesh are so tightly woven that it ensures maximum stability and strength, making it difficult for intruders to breach the fence.One of the most significant advantages of heavy gauge wire mesh fencing is its durability. Stainless steel is known for its corrosion-resistant properties, making it an ideal material for outdoor fences that need to withstand harsh weather conditions. The fence's longevity is further enhanced by the thickness of the wires used, which can vary from 4mm to 10mm. The heavier the gauge, the stronger the fence.Another advantage of heavy gauge wire mesh fencing is its versatility. It can be used for various applications, such as perimeter fencing, animal enclosures, security fences, and even decorative fences. The mesh's open structure allows for airflow, making it suitable for areas that require ventilation. The fence's transparency ensures that it does not obstruct the view, making it ideal for places like parks, gardens, and public spaces.When it comes to security, heavy gauge wire mesh fencing is second to none. The tightly woven mesh structure makes it difficult for intruders to climb or cut through the fence. It also provides a clear view of the surroundings, making it easier to monitor any suspicious activities. Moreover, the fence's height can be customized to suit specific security requirements, making it an effective security solution.Apart from its functional benefits, heavy gauge wire mesh fencing made of stainless steel also adds to the property's aesthetic value. The mesh's clean and modern look complements any property style, making it an excellent choice for contemporary buildings. It also comes in various finishes, such as polished, brushed, or painted, giving property owners a wide range of design options to choose from.In conclusion, heavy gauge wire mesh fencing made of stainless steel is an excellent choice for property owners who value security, durability, versatility, and aesthetics. Its superior strength, longevity, and customization options make it the ultimate fencing solution for various applications. With China's leading manufacturers offering high-quality heavy gauge stainless steel welded wire mesh fencing, there is no reason why property owners should compromise on quality and security.

Discover the Advantages of Expanded Metal for Improved Functionality and Design

Title: Innovative Expanded Metal Technology Revolutionizes Industries Introduction:Expanded metal, a versatile material known for its durability and strength, has experienced a groundbreaking development with the advent of Square Expanded Metal (SEM) technology. This advanced form of expanded metal has revolutionized industries and created new possibilities in sectors such as construction, automotive, agriculture, and manufacturing. SEM has rapidly gained popularity due to its exceptional features, including enhanced stability, design flexibility, and cost-effectiveness. This article will delve into the intricacies of Square Expanded Metal technology and highlight its numerous applications worldwide.1. Overview of Square Expanded Metal (SEM):Square Expanded Metal is a cutting-edge innovation that has transformed traditional expanded metal structures. It is created by expanding and stretching a flat sheet of metal, resulting in a mesh-like pattern of interconnected strands. SEM, however, incorporates square-shaped openings rather than the conventional diamond shape, providing many advantages over its predecessors. These openings allow for improved load distribution, better ventilation, and greater visibility, further enhancing structural integrity.2. Unparalleled Strength and Durability:One of the primary reasons for SEM's popularity is its exceptional strength and durability. It is manufactured using high-quality materials such as stainless steel, aluminum, or carbon steel. This ensures its resistance against corrosion, weathering, and wear and tear. SEM products are extensively tested under rigorous conditions to ensure their strength fluctuations and load-bearing capacities, making them an ideal choice in high-stress applications.3. Design Flexibility and Customizability:SEM enables unparalleled design flexibility, allowing for limitless architectural possibilities. Its square-shaped openings allow light, air, and sound to pass through, making it suitable for applications such as fences, facades, partitions, safety structures, and decorative elements. Additionally, SEM can be customized to match specific design requirements, including various dimensions, thickness, pattern size, and material finishes, meeting the demands of a wide range of applications.4. Sectors Benefiting from Square Expanded Metal:4.1 Construction Industry:Square Expanded Metal finds extensive use in the construction industry due to its versatility and strength. SEM structures can be utilized in building facades, balconies, staircases, and elevated walkways, providing both functionality and aesthetic appeal. The material's lightweight nature allows for easier installation, reducing construction time and costs significantly.4.2 Automotive Industry:The automotive sector benefits from SEM's superior strength-to-weight ratio, allowing manufacturers to create lightweight components without compromising safety. SEM is frequently used in automobile grilles, radiator covers, engine covers, and interior trim components, providing protection without impeding ventilation.4.3 Agricultural Applications:Square Expanded Metal is extensively employed in the agricultural sector for livestock enclosures, fences, and gates. Its sturdy construction effectively safeguards animals from escaping and protects valuable crops from potential damage, ensuring a secure environment for farmers.4.4 Manufacturing Sector:Square Expanded Metal is highly prevalent in the manufacturing sector as machine guards, safety screens, and conveyor belts. The material's inherent durability and ease of customization make it a dependable choice for ensuring worker safety and enhancing productivity.5. SEM - Advantages and Promising Future:The adoption of SEM has numerous advantages, including cost-effectiveness, sustainable manufacturing practices, high usability, and low maintenance requirements. These factors, coupled with SEM's ability to adapt to changing industry needs, ensure a promising future for this revolutionary technology.Conclusion:Square Expanded Metal technology has disrupted industries by offering unparalleled design flexibility, enhanced strength, and cost-effectiveness. Its versatile applications in construction, automotive, agriculture, and manufacturing sectors have revolutionized traditional manufacturing practices and opened new avenues for creativity and innovation. SEM's incredible popularity can be attributed to its durability, customizability, and inherent benefits. As we move towards a more interconnected world, Square Expanded Metal technology continues to shape industries, optimize processes, and inspire groundbreaking possibilities.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.

Durable and Versatile Expanded Metal Wire Mesh for Various Applications

Expanded Metal Wire Mesh is a versatile and widely used material in various industries for its strength, durability, and cost-effective nature. It is made by slitting and stretching a sheet of metal to create diamond-shaped openings and has a wide range of applications including security, machinery guards, fencing, and architectural and decorative purposes.With the increasing demand for high-quality Expanded Metal Wire Mesh products, the company {} has been at the forefront of providing top-notch solutions to meet the needs of its customers. The company has been in the industry for over 20 years, and its experience and expertise have made it a trusted name in the manufacturing and supply of Expanded Metal Wire Mesh.The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and a team of skilled professionals who ensure that every product meets the highest quality standards. The company offers a wide range of Expanded Metal Wire Mesh products, including standard, flattened, and expanded grating, as well as customized solutions to meet specific requirements.One of the key advantages of the company's Expanded Metal Wire Mesh products is their durability and strength. The materials used in the manufacturing process are of the highest quality and undergo strict quality control measures to ensure that the final product is robust and long-lasting. This makes the company's products suitable for a wide range of applications, from heavy-duty industrial use to architectural and decorative purposes.In addition to its durability, the company's Expanded Metal Wire Mesh products also offer excellent ventilation, making them ideal for applications where airflow and visibility are important. This feature is particularly beneficial in machinery guards, fencing, and security applications where maintaining airflow and visibility is essential.Furthermore, the company's Expanded Metal Wire Mesh products are also highly cost-effective. The manufacturing process allows for maximum material utilization, minimizing waste and reducing production costs. This cost-efficiency is passed on to the customers, making the company's products an economical choice for both small and large-scale projects.The company's commitment to customer satisfaction is evident in its dedication to providing exceptional service and support. Its team of professionals works closely with customers to understand their specific needs and provide tailored solutions that meet and exceed expectations. From initial inquiry to after-sales support, the company ensures that customers receive the attention and assistance they require throughout the process.The company's reputation for reliability and excellence has made it a preferred choice for customers across various industries, including construction, manufacturing, architecture, and security. Its Expanded Metal Wire Mesh products have been used in a wide range of projects, from simple fencing and machinery guards to complex architectural and industrial applications.In conclusion, {} has established itself as a leading provider of high-quality Expanded Metal Wire Mesh products. With its commitment to excellence, state-of-the-art manufacturing facilities, and a dedicated team of professionals, the company continues to set the standard for quality and reliability in the industry. Whether for industrial, architectural, or decorative purposes, customers can rely on the company to deliver top-notch solutions that meet their specific requirements.

Sintered Metal Mesh: The Latest in Advanced Mesh Technology

Sintered Metal Mesh: Innovating Filtration SolutionsThe global demand for sintered metal mesh has been steadily increasing in recent years, driven by its wide range of applications in industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and environmental protection. One company at the forefront of this trend is a leading manufacturer of sintered metal mesh, which has been providing innovative filtration solutions to its customers for over a decade.The sintered metal mesh produced by the company is widely recognized for its superior performance, durability, and efficiency in a variety of filtration and separation processes. The unique structure of the sintered metal mesh allows for precise control of pore size and distribution, making it an ideal choice for applications that require high levels of purity and consistency. In addition, the company's sintered metal mesh products are known for their excellent mechanical strength and thermal stability, making them suitable for use in demanding operating conditions.One of the key advantages of the company's sintered metal mesh is its ability to offer a high level of customization to meet the specific needs of different industries and applications. With a wide range of materials, including stainless steel, nickel, titanium, and other alloys, as well as various pore sizes and thickness options, the company can tailor its sintered metal mesh products to meet the exact requirements of its customers. This flexibility has allowed the company to establish itself as a trusted partner for many businesses seeking reliable and efficient filtration solutions.In addition to its standard sintered metal mesh products, the company also offers customization services, allowing customers to work closely with its engineering team to develop bespoke filtration solutions that meet their unique requirements. This collaborative approach has proven to be particularly valuable for customers with complex filtration challenges, as it enables them to leverage the company's expertise and experience in sintered metal mesh to develop tailored solutions that address their specific needs.Furthermore, the company's commitment to quality and innovation is reflected in its investment in research and development. Its state-of-the-art manufacturing facilities and laboratories are equipped with the latest technologies and equipment, allowing the company to continuously improve its sintered metal mesh products and develop new solutions to meet the evolving needs of its customers. By staying at the forefront of technological advancements in sintered metal mesh manufacturing, the company has been able to maintain its position as a leader in the industry and provide its customers with cutting-edge filtration solutions.The company's dedication to sustainability and environmental responsibility is another key aspect of its business philosophy. All of its sintered metal mesh products are manufactured using environmentally friendly processes and materials, and the company is committed to minimizing its environmental impact throughout the entire supply chain. This focus on sustainability has resonated with many customers who are increasingly seeking filtration solutions that align with their own corporate sustainability goals.Looking ahead, the company remains focused on driving innovation and providing superior filtration solutions to its customers. With a strong commitment to quality, customization, and sustainability, the company is well-positioned to continue leading the way in the sintered metal mesh industry and meeting the diverse needs of its global customer base.In conclusion, the demand for sintered metal mesh continues to grow across a wide range of industries, driven by its superior performance and versatility in filtration and separation processes. As a leading manufacturer of sintered metal mesh, the company has established itself as a trusted partner for businesses seeking reliable, efficient, and customized filtration solutions. With a strong focus on quality, innovation, and sustainability, the company is well-equipped to meet the evolving needs of its customers and maintain its position as a leader in the sintered metal mesh industry.

Carbon Steel Wire Mesh: A Versatile and Reliable Wire Mesh Solution.

The Carbon Steel Wire Mesh industry has been experiencing a significant boom for the past few years. This growth comes as no surprise, given the increasing demand for strong and durable materials to serve various construction and industrial purposes.One of the leading companies responsible for this boom is {company name}. This renowned manufacturer of Carbon Steel Wire Mesh has been providing top-quality products to clients for several years. The company is known for its extensive range of products that meet the specific needs of various industries such as construction, mining, and agriculture.Their Carbon Steel Wire Mesh is composed of high-quality carbon steel wire, engineered to withstand rough handling, harsh weather conditions, and varying degrees of tension. This makes it an ideal material for various applications such as fencing, filter screens, and concrete reinforcement.In addition to their reputable products, {company name} is recognized for its commitment to maintaining high standards of quality and reliability. The company's team consists of skilled and experienced professionals who use cutting-edge technologies to manufacture top-notch products. They are dedicated to providing excellent customer service and helping clients choose the best product for their specific needs.{Company name} is also known for its strict adherence to safety protocols and ethical practices. They understand the importance of ensuring the safety of their employees and customers, as well as keeping the environment safe. As such, they take every measure to minimize their environmental impact, promote sustainability, and maintain a safe working environment.Furthermore, the company continuously invests in research and development to improve their products and stay ahead of their competitors. In the industry, {Company name} is regarded as a pioneer in Carbon Steel Wire Mesh and has been at the forefront of developing innovative products that are stronger, more durable, and more cost-effective.Recently, {company name} announced that it had expanded its range of products to include Galvanized Wire Mesh. This move is part of the company's strategy to offer a more extensive range of quality products that meet the specific needs of its clients. Galvanized Wire Mesh is an excellent alternative to carbon steel wire mesh, and it comes with several advantages, such as corrosion resistance, enhanced durability, and a longer lifespan.The company's CEO, {name}, expressed his excitement about the development, stating that the company's continued growth and success have been made possible by an unrelenting focus on customer satisfaction and a commitment to providing quality products. He emphasized that the expansion of their product portfolio is a reflection of the company's mission to meet the ever-evolving needs of customers.{company name}'s decision to include Galvanized Wire Mesh in its product range comes at a time when the market is experiencing significant demand for corrosion-resistant material. The company's customers are expected to benefit significantly from this development, as the new product offering presents new opportunities for cost savings without sacrificing quality.In conclusion, {company name} has been a leader in Carbon Steel Wire Mesh manufacturing for several years. The quality of their products, commitment to customer satisfaction, and adherence to ethical practices have earned them an excellent reputation among their customers and peers. The company's decision to expand its product range to include Galvanized Wire Mesh is a testament to its dedication to meeting the ever-changing needs of its clients while maintaining its commitment to providing top-quality products.

Find Affordable and High-Quality Powder Coating Mesh for Your Projects

[Company Introduction][Company Name] is a leading provider of innovative solutions in the realm of powder coating technology. With decades of experience and a commitment to excellence, we have established ourselves as a market leader in delivering high-quality and reliable powder coating mesh that meets the diverse needs of our global clientele.Our extensive range of powder coating mesh is designed to enhance the coating process by ensuring uniformity, durability, and efficiency. We take pride in offering our customers a comprehensive selection of mesh options that cater to a variety of applications in industries such as automotive, architectural, furniture, and more.At [Company Name], we understand the significance of powder coating mesh in achieving flawless finishes and lasting protection. With an unwavering focus on research and development, we invest heavily in advanced technologies and stringent quality control measures to provide our customers with superior products that consistently perform as expected.[News Content]Title: [Company Name] Launches Next-Generation Powder Coating Mesh for Enhanced Coating Efficiency[Location], [Date] - [Company Name], a trusted name in the powder coating industry, has unveiled its latest range of cutting-edge powder coating mesh, designed to revolutionize the coating process and deliver exceptional results.With an increasing demand for enhanced coating efficiency, [Company Name] has risen to the challenge by developing a range of mesh solutions that significantly improve the overall coating experience. The newly launched powder coating mesh is engineered to offer unparalleled uniformity, durability, and ease of use.One of the key features of the next-generation mesh is its advanced airflow design, which maximizes the powder penetration while minimizing the risk of overspray. This innovation not only ensures an even coating but also reduces wastage, resulting in substantial cost savings for businesses.Moreover, the powder coating mesh is manufactured using high-quality materials that are resistant to corrosion and wear. This enables the mesh to withstand even the harshest treatment, guaranteeing a long service life and consistent performance, even in demanding industrial environments.To cater to different coating requirements, [Company Name] offers a wide range of mesh sizes and configurations. From coarse to fine mesh, customers can choose the most suitable option based on their specific application and desired coating thickness. With this level of customization, businesses can achieve precise and accurate coating results."We are proud to introduce our latest powder coating mesh range, which represents a significant leap forward in terms of coating efficiency," said [Company Spokesperson], [Position] of [Company Name]. "Our goal has always been to provide solutions that enhance productivity and quality, and this new range of mesh is a testament to our dedication to customer satisfaction."As part of its commitment to delivering exceptional customer service, [Company Name] offers comprehensive technical support and guidance to ensure optimal usage of the powder coating mesh. With a team of experts readily available, customers can benefit from professional advice on selecting the right mesh, troubleshooting, and maximizing their coating efficiency.In conclusion, [Company Name]'s latest range of powder coating mesh redefines the standards of coating excellence. With its advanced features and customized options, businesses across different industries can experience enhanced efficiency, reliability, and cost savings. As a market leader in powder coating technology, [Company Name] continues to push the boundaries of innovation, enabling its customers to achieve superior coating results while staying ahead of the competition.

Discover the Versatility and Durability of Wire Mesh Products

Title: Innovations in Wire Mesh Technology Revolutionize Various IndustriesIntroduction:Wire mesh is a versatile material that has found applications in numerous industries such as construction, agriculture, filtration, and automotive. In recent years, Cooper Wire Mesh, a leading manufacturer in the wire mesh industry, has emerged as a pioneer in developing innovative wire mesh solutions that cater to the ever-evolving needs of these industries.1. Application in the Construction Industry:Cooper Wire Mesh has revolutionized the construction industry with its cutting-edge wire mesh products. Their high-quality and durable wire mesh materials have become an integral component in reinforced concrete structures. By enhancing the strength and stability of the construction materials, Cooper Wire Mesh ensures the safety and longevity of buildings, bridges, and other infrastructure projects.Furthermore, their wire mesh solutions also offer effective solutions for designing and constructing spectacular architectural facades. The versatility of Cooper Wire Mesh enables architects to create unique, visually appealing designs while still maintaining structural integrity.2. Advancements in Agricultural Applications:In the agricultural sector, Cooper Wire Mesh has introduced several innovative solutions to address the challenges faced by farmers globally. Their wire mesh fencing and netting products provide effective protection against pests, predators, and environmental factors that can harm crops. These solutions have proven crucial in ensuring increased crop yield and reducing crop loss due to unwanted intrusions.Additionally, Cooper Wire Mesh has developed state-of-the-art mesh systems for enclosing livestock and creating animal enclosures. These mesh solutions offer both strength and flexibility, ensuring the safety and well-being of livestock while allowing for easy maintenance and cost-effective installation.3. Filtration Solutions for Enhanced Industrial Performance:Cooper Wire Mesh has also been at the forefront of developing advanced filtration solutions for various industrial applications. Their wire mesh filters and screens are designed to meet specific requirements, ensuring superior performance and durability.These filtration products find extensive use in oil and gas, chemical processing, and pharmaceutical industries, where the removal of impurities and contaminants from liquids and gases is crucial. Cooper Wire Mesh's technological advancements has led to the development of mesh materials with precise pore sizes and enhanced filtration efficiency, leading to improved product quality and reduced maintenance costs.4. Revolutionizing the Automotive Industry:With increasing emphasis on high-performance and lightweight vehicles, Cooper Wire Mesh has made significant contributions to the automotive industry. Their wire mesh materials are used as reinforcing elements in the production of automobile parts, providing better structural integrity and crash-resistance. Additionally, Cooper Wire Mesh's mesh grilles and protective mesh solutions have gained popularity in the automotive sector for their aesthetic appeal and protection against debris.Conclusion:The innovative wire mesh solutions created by Cooper Wire Mesh have undoubtedly transformed a wide range of industries, from construction and agriculture to filtration and automotive sectors. By constantly pushing boundaries and developing cutting-edge technologies, Cooper Wire Mesh has become the go-to supplier for wire mesh solutions worldwide. With their dedication to quality, reliability, and customer-centric approach, Cooper Wire Mesh is sure to continue revolutionizing the industries they serve.

3 Vital Things to Know About Sintered Powder Filters

Sintered Powder Filter Revolutionizes Filtration Technology: A Breakthrough by an Innovative Company[Company Name], a renowned player in the field of filtration technology, has introduced a revolutionary product in the market – the Sintered Powder Filter. This groundbreaking invention promises to redefine the way we approach filtration, offering a highly efficient and reliable solution to a wide range of industries.As we know, filtration is a critical process in various sectors, including pharmaceuticals, chemicals, food and beverage, oil and gas, automotive, and many others. Traditionally, filters have been made using materials like fabric, paper, metal mesh, or ceramics. While these conventional filters have served their purpose, they often come with limitations such as low durability, limited pore size options, or poor overall performance.Addressing these challenges head-on, [Company Name] has leveraged its expertise and innovative mindset to develop the Sintered Powder Filter. This filter is a result of the company's commitment to providing cutting-edge solutions that meet the evolving needs of industries worldwide.So, what makes the Sintered Powder Filter different and superior to its counterparts? The answer lies in its unique construction and advanced features. The filter is manufactured by compacting metal powders, followed by high-temperature sintering. This process creates a highly porous structure with precise particle size distribution and uniform pore sizes.This uniformity in pore sizes is one of the key advantages of the Sintered Powder Filter. It ensures consistent and reliable filtration, removing impurities with exceptional efficiency. The filter can effectively eliminate particles as small as submicron levels, providing a level of filtration precision that surpasses traditional filters.Additionally, the Sintered Powder Filter's structure offers high strength, resulting in superior durability and resistance to harsh operating conditions. It can withstand high temperatures, corrosive chemicals, and high-pressure environments, making it ideal for applications in extreme conditions. This robustness translates into extended filter life and reduced maintenance costs.Moreover, the Sintered Powder Filter's versatility is worth mentioning. Its pore size can be tailored according to specific requirements, making it adaptable to various industries and filtration needs. Whether it is for clarifying liquids, capturing fine particles, or separating solids and gases, this filter can be customized to deliver optimal results.Furthermore, the Sintered Powder Filter offers the advantage of backwashing, a feature absent in conventional filters. This capability allows for easy cleaning and regeneration of the filter, bringing it back to its original performance without the need for replacement. This significantly reduces operational costs and ensures long-term usability, making it an economical choice for industries.[Company Name] takes pride in its commitment to sustainability and recognizes the importance of minimizing its environmental impact. The Sintered Powder Filter aligns perfectly with this ethos, as it is a reusable, eco-friendly solution compared to disposable filters. Its long lifespan, combined with the ability to be cleaned and reused, contributes to a more sustainable approach to filtration.As [Company Name] introduces the Sintered Powder Filter to the market, industries worldwide are eagerly embracing this innovative solution. Early adopters have already reported significant improvements in filtration efficiency, reduced downtime for maintenance, and enhanced product quality.The Sintered Powder Filter represents a game-changer in the field of filtration technology. Its unparalleled filtration precision, durability, versatility, and sustainability make it an attractive choice for businesses across various sectors. As [Company Name] continues to innovate and invest in research and development, we can expect further advancements in filtration technology and more groundbreaking solutions to meet the evolving needs of industries worldwide.