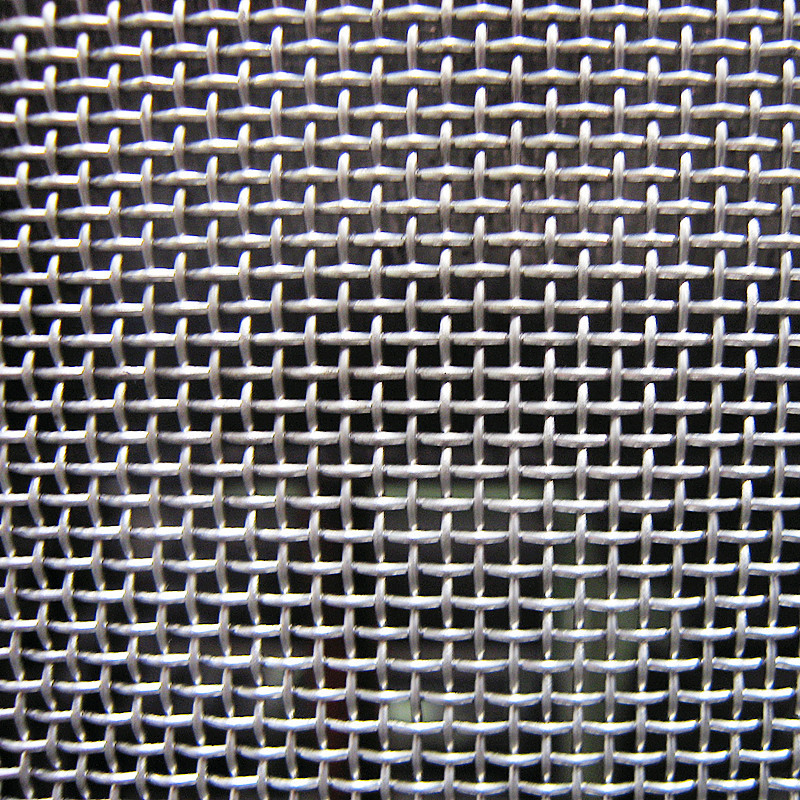

Quality Crimped Woven Wire Mesh: A Versatile and Durable Option

By:Admin

With a history of over (X) years in the industry, () has been a leading manufacturer and supplier of Crimped Woven Wire Mesh. The company has built a strong reputation for delivering high-quality products that meet the needs of their diverse customer base. Their commitment to innovation and excellence has enabled them to stay ahead of the competition and provide cutting-edge solutions for various industries.

The Crimped Woven Wire Mesh from () is manufactured using premium quality materials and advanced production techniques. This ensures that the mesh is strong, durable, and able to withstand heavy loads and harsh environmental conditions. The company's state-of-the-art manufacturing facilities and quality control processes further guarantee that every product meets the highest standards of quality and performance.

One of the key advantages of the Crimped Woven Wire Mesh from () is its versatility. It can be customized to meet the specific requirements of different applications, including size, shape, and material. This flexibility allows customers to find the perfect solution for their individual needs, whether it's for industrial filtration, architectural design, or agricultural purposes.

In addition to its strength and durability, ()'s Crimped Woven Wire Mesh also offers excellent corrosion resistance. This makes it suitable for outdoor and marine applications where exposure to harsh elements is a concern. Furthermore, the mesh can be easily cleaned and maintained, ensuring long-term performance and cost-efficiency.

With a strong commitment to customer satisfaction, () provides comprehensive support and technical expertise to help customers find the right solution for their needs. Their team of skilled professionals is dedicated to understanding the unique requirements of each project and offering tailored recommendations and solutions. This personalized approach has earned () a loyal customer base and established the company as a trusted partner in the industry.

The applications of Crimped Woven Wire Mesh are vast and diverse. It is commonly used in the mining and aggregate industries for screening and separating materials, as well as in the construction and architecture sectors for decorative and functional purposes. Additionally, the mesh is essential in the agriculture and food processing industries for filtration and separation processes.

As the demand for high-quality Crimped Woven Wire Mesh continues to grow, () remains at the forefront of the industry, offering innovative solutions and outstanding customer service. Their dedication to excellence, combined with their commitment to continuous improvement, ensures that they will continue to be a leading provider of woven wire mesh for years to come.

In conclusion, Crimped Woven Wire Mesh is a versatile and essential product that serves a wide range of applications in various industries. With its strength, durability, and flexibility, it offers a reliable solution for filtration, screening, and protection needs. ()'s extensive experience and commitment to quality make them a trusted source for high-quality Crimped Woven Wire Mesh. Their dedication to customer satisfaction and technical expertise further solidify their position as a leading provider in the industry.

Company News & Blog

Quality Crimped Woven Wire Mesh: A Versatile and Durable Option

Crimped Woven Wire Mesh is an essential product in various industries and applications. It is a versatile material that offers strength, durability, and flexibility, making it suitable for a wide range of uses such as filtration, screening, and protection. With its unique crimped design, this woven wire mesh provides a higher level of stability and support, making it ideal for heavy-duty applications.With a history of over (X) years in the industry, () has been a leading manufacturer and supplier of Crimped Woven Wire Mesh. The company has built a strong reputation for delivering high-quality products that meet the needs of their diverse customer base. Their commitment to innovation and excellence has enabled them to stay ahead of the competition and provide cutting-edge solutions for various industries.The Crimped Woven Wire Mesh from () is manufactured using premium quality materials and advanced production techniques. This ensures that the mesh is strong, durable, and able to withstand heavy loads and harsh environmental conditions. The company's state-of-the-art manufacturing facilities and quality control processes further guarantee that every product meets the highest standards of quality and performance.One of the key advantages of the Crimped Woven Wire Mesh from () is its versatility. It can be customized to meet the specific requirements of different applications, including size, shape, and material. This flexibility allows customers to find the perfect solution for their individual needs, whether it's for industrial filtration, architectural design, or agricultural purposes.In addition to its strength and durability, ()'s Crimped Woven Wire Mesh also offers excellent corrosion resistance. This makes it suitable for outdoor and marine applications where exposure to harsh elements is a concern. Furthermore, the mesh can be easily cleaned and maintained, ensuring long-term performance and cost-efficiency.With a strong commitment to customer satisfaction, () provides comprehensive support and technical expertise to help customers find the right solution for their needs. Their team of skilled professionals is dedicated to understanding the unique requirements of each project and offering tailored recommendations and solutions. This personalized approach has earned () a loyal customer base and established the company as a trusted partner in the industry.The applications of Crimped Woven Wire Mesh are vast and diverse. It is commonly used in the mining and aggregate industries for screening and separating materials, as well as in the construction and architecture sectors for decorative and functional purposes. Additionally, the mesh is essential in the agriculture and food processing industries for filtration and separation processes.As the demand for high-quality Crimped Woven Wire Mesh continues to grow, () remains at the forefront of the industry, offering innovative solutions and outstanding customer service. Their dedication to excellence, combined with their commitment to continuous improvement, ensures that they will continue to be a leading provider of woven wire mesh for years to come.In conclusion, Crimped Woven Wire Mesh is a versatile and essential product that serves a wide range of applications in various industries. With its strength, durability, and flexibility, it offers a reliable solution for filtration, screening, and protection needs. ()'s extensive experience and commitment to quality make them a trusted source for high-quality Crimped Woven Wire Mesh. Their dedication to customer satisfaction and technical expertise further solidify their position as a leading provider in the industry.

A Comprehensive Guide to Aeration Filters: Everything You Need to Know

[News Title]Aeration Filters: Enhancing Water Quality and Promoting Sustainable Solutions[News Intro]In an effort to address growing concerns about water pollution and promote sustainable solutions, a revolutionary innovation has emerged in the industry of water filtration. Aeration Filters, a breakthrough technology developed by an industry-leading company, have gained significant attention for their ability to enhance water quality and improve environmental sustainability. With their unique design and cutting-edge functionality, Aeration Filters are set to revolutionize the way we filter water and contribute to a cleaner and safer future.[Company Introduction]Having made a significant impact in the field of water filtration for over a decade, the company behind Aeration Filters is renowned for their dedication to providing innovative and sustainable solutions. With a team of highly skilled engineers and scientists, this industry leader has consistently pushed the boundaries of technology to tackle global water challenges. Their unwavering commitment to research and development has led to groundbreaking advancements, positioning them as pioneers in the industry.[Pioneering Aeration Filters]Aeration Filters, the latest brainchild of the innovative company, are designed to create a natural oxygenation process to enhance water quality. Unlike traditional filtration methods, which solely focus on removing impurities, Aeration Filters integrate aeration into the process to achieve a dual purpose: filtration and oxygenation. By infusing water with oxygen, these filters not only remove harmful contaminants but also rejuvenate water sources, promoting the growth of beneficial organisms and ensuring a healthier aquatic ecosystem.The unique design of Aeration Filters allows for the efficient removal of a wide range of impurities, including sediment, chlorine, heavy metals, and organic compounds. Through innovative engineering, the filters can extract these pollutants while simultaneously introducing oxygen into the water, reinvigorating it with natural elements essential for aquatic life and overall well-being. This approach to water filtration sets Aeration Filters apart from conventional solutions, highlighting their potential to revolutionize the industry and empower communities worldwide.[Advantages and Benefits]The incorporation of aeration into water filtration offers numerous advantages and benefits. Firstly, the enhanced oxygenation provided by Aeration Filters leads to cleaner, better-tasting water. By removing unwanted particles and odors, these filters improve the aesthetic properties of water, encouraging increased consumption and promoting overall wellness.Moreover, Aeration Filters contribute to the protection of the environment and the conservation of water resources. By revitalizing water sources and fostering the growth of beneficial organisms, these filters promote biodiversity and ecological balance. The use of Aeration Filters ensures a sustainable approach to water filtration, as it minimizes the need for chemical additives and reduces the strain on natural resources.Furthermore, Aeration Filters have been proven effective in reducing the spread of waterborne diseases. By eliminating harmful microbes and bacteria, these filters play a crucial role in ensuring access to safe drinking water in both urban and rural areas. With communities around the world grappling with waterborne illnesses, the introduction of Aeration Filters brings hope for improved public health outcomes.Additionally, the longevity and durability of Aeration Filters contribute to their cost-effectiveness. Designed to withstand rigorous environments, these filters require minimal maintenance and have a considerably longer lifespan than traditional alternatives. This ensures long-term savings while reducing the carbon footprint associated with filter replacement.[Conclusion]As water pollution continues to pose a significant threat to communities and ecosystems worldwide, innovations such as Aeration Filters offer a glimmer of hope. With their ability to enhance water quality, promote sustainability, and foster healthier environments, these filters have the potential to reshape the water filtration landscape. The company behind Aeration Filters, driven by a commitment to technological excellence and environmental consciousness, stands poised to revolutionize the industry, paving the way for a cleaner and safer future.

Durable Steel Mesh Grates: An Essential Component for Enhanced Safety and Performance

Steel Mesh Grate: Delivering Quality and Durability to CustomersSteel Mesh Grate, a leading provider of high-quality steel mesh gratings, has been serving the construction and engineering industries for over 30 years. The company is known for delivering durable and excellent quality products to its clients across a range of industries. Steel Mesh Grate's commitment to producing innovative solutions for its clients has made it an industry leader.As a global provider of steel mesh gratings, the company has a broad range of products and services that can be used to meet the most complex steel mesh grating requirements. The company's product line includes steel grates, trench covers, and handrails, among others. These products are used in a wide range of industries, including construction, engineering, mining, and transportation.Steel Mesh Grate has an extensive client base that includes some of the biggest names in the industry. The company has established a reputation for fast turnaround times and a commitment to quality. Clients can rely on Steel Mesh Grate to deliver their products on time and within budget.Steel Mesh Grate's success can be attributed to the expertise and knowledge of its team. The company has built a team of experts who are well-versed in the nuances of the steel mesh grating industry. The team is committed to providing excellent customer service and ensuring that their client's requirements are met.One of Steel Mesh Grate's most popular products is its steel grates. These grates are designed to withstand heavy foot traffic, making them ideal for commercial and industrial settings. They are also incredibly durable, making them a great choice for outdoor applications.The company's trench covers are another popular product, particularly in the construction industry. These covers are used to cover trenches, manholes, and other openings in the ground. They help to prevent accidents and injuries by making it impossible for people to fall into the opening.Steel Mesh Grate is committed to sustainability and ensuring that its products are environmentally-friendly. The company uses recycled materials in its products wherever possible, and it also implements environmentally-friendly practices in its manufacturing processes.In addition to its range of products, Steel Mesh Grate also offers installation services to its clients. The company's team of experts can install steel mesh grates, trench covers, and handrails quickly and efficiently. Clients can rely on Steel Mesh Grate to complete their installation projects on time and within budget.Steel Mesh Grate is constantly innovating and developing new solutions to meet its clients' needs. The company is always looking for ways to improve its products, services, and processes. This commitment to innovation has helped to keep Steel Mesh Grate at the forefront of the industry.As a leading provider of steel mesh gratings, Steel Mesh Grate is well-positioned to continue to grow and expand. The company's commitment to quality, sustainability, and innovation has helped it to establish a loyal client base and maintain a competitive edge in the industry. With its team of experts and its broad range of products and services, Steel Mesh Grate is poised for continued success in the years to come.

Discover the Benefits of Stainless Steel Sintered Mesh for Various Applications

Title: A Revolutionary Breakthrough in Filtration Technology: Stainless Steel Sintered MeshIntroduction:In the constantly evolving world of industrial filtration, one company has emerged as a pioneer in developing advanced solutions to meet the growing demands of various industries. [Company Name], an industry leader in the field, has recently unveiled its latest innovation – Stainless Steel Sintered Mesh. This groundbreaking technology is set to revolutionize the way filtration processes are conducted, offering unmatched efficiency, durability, and performance.What is Stainless Steel Sintered Mesh?Stainless Steel Sintered Mesh is a meticulously engineered filtration medium composed of multiple layers of woven stainless steel wire mesh, sintered together to form a robust and seamlessly integrated matrix. This unique manufacturing process creates a highly porous structure with precisely controlled pore sizes, enabling effective filtration of solids, liquids, and gases across a wide range of applications.Applications across Diverse Industries:With its superior mechanical strength, corrosion resistance, and excellent filtration properties, Stainless Steel Sintered Mesh finds broad applicability across an array of industries. From pharmaceuticals and petrochemicals to food and beverage, this innovative filtration medium ensures product quality, process efficiency, and regulatory compliance.1. Pharmaceutical Industry:In the pharmaceutical industry, maintaining product purity and safety is paramount. Stainless Steel Sintered Mesh serves as an ideal filtration medium for sterile air and gas filtration, preventing the entry of contaminants into critical manufacturing processes. Its high filtration efficiency enables the removal of particulate matter, bacteria, and other impurities, thereby ensuring product integrity.2. Petrochemical Industry:The petrochemical industry requires robust filtration solutions to separate impurities from extremely corrosive and high-temperature fluids. Stainless Steel Sintered Mesh offers excellent resistance to corrosion and temperature, making it an ideal choice for filtering aggressive chemicals, catalyst recovery, and refining processes. Its durability and longevity significantly reduce maintenance costs and downtime.3. Food and Beverage Industry:In the food and beverage industry, product quality and hygiene are essential. Stainless Steel Sintered Mesh is designed to withstand rigorous cleaning and sterilization procedures while maintaining its filtration efficiency. This makes it effective for clarifying liquids, degassing beverages, and filtering products during the manufacturing process, ensuring compliance with industry regulations.Advantages of Stainless Steel Sintered Mesh:• Enhanced Filtration Efficiency: The multi-layered structure of Stainless Steel Sintered Mesh allows for consistent particle retention and efficient separation, resulting in superior filtration performance.• Durable and Long-lasting: The robust nature of stainless steel combined with the sintering process ensures the longevity and durability of the mesh, withstanding harsh operating conditions and frequent cleaning cycles.• Uniform Pore Size Distribution: The precisely controlled pore sizes provide a uniform filtration process, minimizing the risk of particle breakthrough and achieving consistent product quality.• Easy to Clean and Maintain: The smooth surface of Stainless Steel Sintered Mesh facilitates easy cleaning, eliminating the buildup of contaminants and maintaining high filtration efficiency.Conclusion:[Company Name]'s Stainless Steel Sintered Mesh represents a significant breakthrough in filtration technology, offering a powerful solution to the filtration challenges faced by various industries. Its exceptional capabilities, including high filtration efficiency, durability, and uniform pore size distribution, make it an indispensable component of modern filtration systems. With its unmatched performance, Stainless Steel Sintered Mesh is poised to reshape the landscape of industrial filtration, ensuring cleaner, safer, and more efficient processes across numerous sectors.

Get Tantalum Aluminide at Competitive Prices and Fast Delivery Times

Introduction:Tantalum Aluminide is a popular material in the manufacturing industry due to its unique chemical and physical properties. It is a corrosion-resistant metal that is commonly used in a wide range of applications, including aerospace, chemical processing, and medical implants. In this blog, we will discuss the properties, applications, and benefits of Tantalum Aluminide in detail. We will also take a brief look at Tantalum Wire Mesh, another popular material used in various industrial applications.Properties of Tantalum Aluminide:Tantalum Aluminide is a silvery grey, ductile, and metallic alloy composed of tantalum and aluminum. The combination of tantalum and aluminum provides excellent mechanical strength, high-temperature stability, and corrosion resistance. Tantalum Aluminide has a low density of 8.4 g/cm³, making it a suitable material for lightweight applications. It has a melting point of 2250 °C and a Young’s modulus of around 330 GPa. Additionally, Tantalum Aluminide has a low coefficient of thermal expansion, which makes it an ideal material for high-temperature environments.Applications of Tantalum Aluminide:Tantalum Aluminide has numerous applications due to its unique properties. It is commonly used in aerospace components such as turbine blades, heat shields, and exhaust nozzles. It is also used in chemical processing as a catalyst support or coating. In the medical industry, Tantalum Aluminide is used in implants and prosthetic devices due to its biocompatibility and corrosion resistance. Moreover, Tantalum Aluminide is used as a protective coating in nuclear power plants and other high-temperature environments.Benefits of Tantalum Aluminide:Tantalum Aluminide has numerous benefits that make it popular in the manufacturing industry. Some of the benefits of using Tantalum Aluminide include:1. Corrosion Resistance: Tantalum Aluminide is highly resistant to corrosion and can withstand harsh chemical environments. This property makes it ideal for use in chemical processing and medical implants.2. High-Temperature Stability: Tantalum Aluminide can withstand high temperatures without losing its strength or ductility. This property makes it an excellent material for use in aerospace and nuclear power plants.3. Lightweight: Tantalum Aluminide has a low density, making it lightweight and a suitable material for applications where weight is a concern.4. Biocompatibility: Tantalum Aluminide is biocompatible and can be used in medical implants and prosthetic devices without causing any adverse reactions.Tantalum Wire Mesh:Tantalum wire mesh is another popular material used in the manufacturing industry that is made up of pure tantalum wire. Tantalum wire mesh has many unique properties that make it ideal for various applications. Some of the properties of Tantalum wire mesh include:1. Excellent Corrosion Resistance: Tantalum wire mesh is highly resistant to corrosion and can withstand harsh chemical environments.2. High-Temperature Stability: Tantalum wire mesh can withstand high temperatures without losing its strength or ductility.3. Lightweight: Tantalum wire mesh has a very low density, making it ideal for lightweight applications.4. Good Electrical Conductivity: Tantalum wire mesh has a high electrical conductivity, making it suitable for electrical and electronic applications.Conclusion:In conclusion, Tantalum Aluminide and Tantalum wire mesh are two popular materials used in the manufacturing industry. Both materials possess unique properties that make them ideal for various applications. Tantalum Aluminide is commonly used in aerospace, chemical processing, and medical implants, while Tantalum wire mesh is used in electrical and electronic applications. The benefits of using Tantalum Aluminide and Tantalum wire mesh include high-temperature stability, corrosion resistance, and lightweight. SAM is a leading supplier of Tantalum Aluminide, including Tantalum wire mesh, with competitive pricing and excellent lead times.

Top Quality Security Fencing Wire Mesh for High-Level Protection

Wire Mesh – Security Fencing Wire Mesh: Ensuring Safety and ProtectionIn a world where security and safety are crucial, wire mesh has become an integral part of many structures. Wire mesh fences provide an effective barrier against intruders, protecting both property and people. With its ability to deter unauthorized entry, it has become a popular choice for residential, commercial, and industrial properties. Wire mesh is a durable and cost-effective option for enhancing security and privacy, making it an ideal solution for many applications.Alex Manufacturer, a leading company in the wire mesh industry, produces high-quality anti-climb and anti-cut fence, stainless steel high-security window screens, metal wire mesh, stainless wire mesh, fencing mesh, and razor wire. The company has been in the wire mesh industry for several years, producing innovative and state-of-the-art solutions to meet the changing demands and requirements of its clients.With its commitment to excellence and dedication to meeting customer needs, Alex Manufacturer has gained a reputation for producing top-quality products that exceed customer expectations. The company's wire mesh products are renowned for their high strength, durability, and resistance to wear and tear. They are designed for use in a wide range of applications, including perimeter security, access control, and protective enclosures.Wire mesh fences are highly effective when it comes to deterring intruders. They are designed to be difficult to climb or cut, making it challenging for unauthorized persons to gain access to the property. Wire mesh fences come in a variety of configurations, including welded and woven options. Welded wire mesh fences are more robust and more rigid than woven options and are ideal for applications where strength is paramount, such as industrial properties or commercial premises.Alex Manufacturer's anti-climb and anti-cut fence is one of its most popular products. The fence is designed with closely spaced vertical and horizontal wires, making it difficult for anyone to climb or cut through the fence. The anti-climb and anti-cut fence is available in a range of heights and configurations to meet specific customer needs.Another innovative product from Alex Manufacturer is the stainless steel high-security window screen. The product is designed to protect doors and windows from unauthorized entry and intrusion. The screen is made from high-strength stainless steel wire, which provides an effective barrier against break-ins while maintaining visibility and ventilation.Metal wire mesh is another product that has gained popularity in recent years. The mesh is typically made from steel wire and comes in various configurations, including welded and woven options. Metal wire mesh is used in a wide range of applications, including outdoor enclosures, machinery guards, and safety barriers.Stainless wire mesh is a specialized type of wire mesh made from high-quality stainless steel wire. The mesh is corrosion-resistant and has excellent strength and durability. Stainless wire mesh is often used in applications where hygiene and cleanliness are of the utmost importance, such as food processing facilities and laboratories.Fencing mesh is a multi-purpose product that is used to create barriers in a variety of applications. The mesh is typically made from high-quality steel wire and is available in a range of configurations, including welded and woven options. Fencing mesh is ideal for creating temporary enclosures at construction sites, events, and public spaces.Razor wire is a specialized type of wire that is used in high-security applications. The wire features sharp blades that are designed to deter intruders from climbing over or cutting through the fence. Razor wire is often used in prisons, military facilities, and other high-security installations.In conclusion, wire mesh is an essential product that provides security and protection to a wide range of applications. Alex Manufacturer is a leading company in the wire mesh industry, producing high-quality products that meet the changing demands and requirements of its clients. With its commitment to excellence, Alex Manufacturer has gained a reputation for producing innovative and state-of-the-art solutions that exceed customer expectations.

Discover Woven Wire Mesh: Free Download with Aperture Size Calculator, Open Area & Weight Estimation

: Understanding the Different ApplicationsWoven wire screens have been a fundamental component of many industrial processes and equipment for decades. From pharmaceutical and food processing to mining and petrochemicals, a wide range of industries rely on these products to filter, separate, and sort materials. In this blog, we will delve deeper into woven wire screens, their uses, and their benefits.What is Woven Wire Screen?Woven wire screen is a mesh fabric made from wire strands interwoven at right angles. These strands can be made from various metals such as stainless steel, brass, copper, and aluminum. The wire strands may have different diameters and weaves, depending on the intended application.Applications of Woven Wire ScreensWoven wire screens are commonly used in various applications, including:1. Screening and SeparationWoven wire screens are used as industrial filters for screening and separating materials. These screens are used in mining equipment, vibratory machines, and in the production of plastics, ceramics, and other materials. By filtering out unwanted particles and materials, these screens ensure the quality and purity of end products.2. SiftingWoven wire screens are also used for sifting in the food, pharmaceutical, and chemical industries. These screens can be used to sift, sort, and grade materials in a specific size range.3. Security FencingWoven wire screens can provide enhanced security by preventing unauthorized entry, theft and vandalism. They are commonly used to protect residential properties, commercial establishments, and industrial facilities.4. Insects and Pest ControlWoven wire screens can be used for insect and pest control in residential and commercial facilities.Benefits of Woven Wire ScreensWoven wire screens are widely used in various industries due to their numerous benefits, including:1. High DurabilityWoven wire screens are highly durable and can withstand harsh environmental conditions. They are resistant to corrosion, abrasion, and high temperatures.2. High PrecisionWoven wire screens are available in various mesh sizes, making them suitable for precise screening and separation of materials.3. Low MaintenanceWoven wire screens require minimal maintenance and can be easily cleaned and reused.4. Cost-effectiveWoven wire screens are cost-effective compared to other screening and separating products. They also have a long lifespan, which makes them a more economical option in the long run.ConclusionWoven wire screens are vital components of many industrial processes and equipment. They are used in various industries for screening, separating, sifting, and security purposes. With their high durability, precision, low-maintenance, and cost-effectiveness, woven wire screens are a reliable and efficient solution in numerous settings.If you are in the market for woven wire screens, Robinson Wire Cloth Ltd. offers a range of quality products for any industrial application. Visit our online shop or contact us for more information.

Understanding the Applications and Benefits of Sintered Wire Mesh

Title: Innovative Sintered Wire Mesh: Revolutionizing Filtration SolutionsIntroduction:In today's fast-paced and constantly evolving world, industries and businesses are in a constant quest for innovation and efficiency. One such innovation is the revolutionary Sintered Wire Mesh (SWF), a game-changing filtration technology that is transforming the way various industries filter their fluids and gases. This article aims to shed light on the unparalleled capabilities of SWF and its potential to enhance filtration solutions across multiple sectors.I. Understanding Sintered Wire Mesh:Sintered Wire Mesh, a high-precision filter medium, is manufactured by sintering multiple layers of stainless-steel wires together. The meticulously engineered mesh creates a porous structure that ensures a highly uniform filtration, reinforcing its resistance to pressure, temperature, corrosion, and mechanical stresses.In its sintered form, the filter's intrinsic characteristics allow for precise control over filtration precision, making it ideal for industrial applications that demand exceptional filtration efficiency and reliability.II. Unmatched Filtration Performance:SWF delivers unparalleled filtration performance, making it a preferred choice for industries spanning oil and gas, petrochemicals, pharmaceuticals, food and beverage, automotive, and many more. The advanced sintering process allows customization of pore sizes, ensuring optimal removal of contaminants while fulfilling specific application requirements.1. Enhanced Filtration Efficiency: SWF offers exceptional filtration efficiency due to its uniform pore size distribution, minimizing the risk of particle breakthrough and delivering superior removal of solids and other impurities.2. Reduced Pressure Drop: SWF's unique filter structure guarantees enhanced flow rates, reducing pressure drop across the filtration system. Lower energy consumption and increased efficiency equate to cost savings for industries.3. Excellent Mechanical Strength: The sintering process endows the SWF with high mechanical strength and stability, making it resistant to vibrations, shocks, and fluctuating pressures. This allows for consistent performance in demanding environments.III. Versatile Applications of SWF:Sintered Wire Mesh has found wide-ranging applications across various industries, revolutionizing conventional filtration methods.1. Oil and Gas: SWF ensures the removal of contaminants such as sand, sediments, and solids from crude oil, enhancing the quality and purity of refined petroleum products.2. Pharmaceutical and Medical: Filtration is crucial in the pharmaceutical industry. SWF's precise filtration capabilities are ideal for applications ranging from sterile gas or air filtration to the removal of particulates from liquids used in drug manufacturing.3. Food and Beverage: SWF ensures product safety and purity by effectively removing unwanted particles, yeast, bacteria, and other contaminants from beverages, oils, dairy products, and food processing.4. Chemical and Petrochemical: SWF plays a vital role in refining procedures, handling corrosive chemicals by effectively filtering out contaminants, scale particles, catalysts, and other impurities.5. Automotive and Aerospace: SWF contributes to the purification of fluids used in lubrication systems, coolants, and hydraulic fluids, improving the overall efficiency and lifespan of the machinery.IV. Conclusion:The game-changing technology of Sintered Wire Mesh has transformed the filtration landscape for various industries, offering enhanced filtration precision, improved flow rates, reduced energy consumption, and extended equipment life. With its versatile applications and customizable solutions, SWF is empowering businesses to achieve higher quality standards while reducing operational costs.As industries increasingly recognize the importance of efficient filtration, SWF is poised to revolutionize filtration solutions, ensuring a cleaner and more sustainable future for us all.

Aluminum Alloy Expandable Electric Folding Gate with Mesh Screen

Screen Electric Retractable Gate, Expandable Electric Retractable Gate, Folding Electric Retractable Gate, Quality Electric Retractable Gate, Aluminium Alloy Electric Retractable Gate.Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen - A Perfect Solution for Safety and SecurityAre you tired of traditional gates that require a lot of effort to open and close? Do you want to upgrade your home or office security with a modern gate that is both functional and stylish? Look no further than the Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen.This gate is the ultimate solution for convenience, safety, and security. It is made of high-quality aluminium alloy, which makes it durable and strong. It is also expandable, which means it can fit any size of the entrance, making it perfect for homes, businesses, and institutions.The gate is designed with a foldable feature that allows for easy opening and closing. You don't have to worry about getting out of your car to manually open and close the gate. With just a click of a button, the gate will fold and unfold automatically, giving you easy access.Another outstanding feature of this gate is the mesh screen. The mesh screen adds an extra layer of security to your entrance, ensuring that no unwanted visitors can enter your property. The mesh screen also allows for proper air circulation, making your space well ventilated.At (remove brand name), we are committed to providing high-quality electric retractable gates that meet the needs of our customers. Our Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen has undergone rigorous testing to ensure that it meets the highest quality standards.Our gate is easy to install and maintain. With proper care and maintenance, this gate will last you for years to come, providing you with maximum security and convenience.In conclusion, if you are looking for a modern, stylish, and functional gate that provides maximum security and convenience, the Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is the perfect solution. It is made of high-quality materials, easy to install and maintain, and has a mesh screen for added security. Contact us today and upgrade your security with this amazing gate.

Discover the Versatility and Benefits of Metal Mesh Grid in Various Applications

Title: Innovative Metal Mesh Grid Developed to Revolutionize Industrial ApplicationsIntroduction:In this rapidly evolving world of advanced technology, companies strive to make groundbreaking innovations that cater to the growing demands of various industries. One such company, (Company Name), has recently introduced a revolutionary Metal Mesh Grid that promises to revolutionize industrial applications with its exceptional efficiency and durability. Combining state-of-the-art technology with years of expert research, this new product is set to transform multiple sectors, from transportation to telecommunications and more.I. The Development of the Metal Mesh Grid:The (Company Name) Metal Mesh Grid represents a significant advancement in the field of industrial materials. Built upon meticulous research and development, this cutting-edge grid has been engineered to surpass traditional alternatives in terms of efficiency, strength, and versatility. The company's team of skilled engineers, scientists, and innovators have employed advanced manufacturing techniques and materials to create a product that delivers exceptional performance across numerous applications.II. Unparalleled Performance and Reliability:The Metal Mesh Grid boasts several features that set it apart from conventional grids used in industrial settings. Firstly, it exhibits remarkable strength, ensuring enhanced durability under challenging conditions. This makes it suitable for a wide range of applications, including automotive manufacturing, telecommunications infrastructure development, aerospace engineering, and electrical components production.Furthermore, the Metal Mesh Grid offers outstanding electrical conductivity and thermal management capabilities. Its advanced design allows for efficient heat dissipation, reducing the risk of component failure and increasing the overall operational lifespan of various devices and systems. By utilizing this grid, industries can enhance their productivity, reduce maintenance costs, and increase overall efficiency.III. Versatility and Adaptability:One of the most striking aspects of the Metal Mesh Grid is its adaptability to numerous industrial sectors. Whether in the automotive industry, where it enhances structural integrity and electromagnetic shielding, or in telecommunications, where it ensures seamless wireless connectivity, this grid emerges as a game-changer. This exceptional versatility offers industries the opportunity to improve their products and operations across various applications.IV. Environmental Sustainability:In addition to its remarkable performance, the Metal Mesh Grid also incorporates a commitment to sustainability. It is manufactured using environmentally friendly materials and processes, aligning with the company's dedication to reducing the ecological impact of industrial production. By incorporating this grid into their operations, companies can contribute to a greener future while maximizing efficiency and performance.V. Industry Adoption and Future Prospects:Given its numerous advantages, the Metal Mesh Grid is already gaining traction among influential players in various industries. Collaborations with leading automobile manufacturers, technology giants, and infrastructure developers are underway, further cementing its position as an indispensable component in industrial applications.Looking ahead, the company remains committed to continuous innovation and improvement. With ongoing research and development efforts, they aim to expand the range of applications for the Metal Mesh Grid, ensuring its relevance and significance across diverse industries in the future.Conclusion:The emergence of the groundbreaking Metal Mesh Grid from (Company Name) signifies a significant leap forward in industrial material engineering. With exceptional strength, versatility, and environmental sustainability, this innovative product has the potential to revolutionize industries ranging from transportation to telecommunications. As companies across various sectors adopt this grid, they can benefit from enhanced performance, increased operational lifespan, and reduced environmental impact. As research and development continue, the future possibilities of the Metal Mesh Grid remain boundless, promising to reshape industrial applications for many years to come.