New Screen Disc Filter Technology for Improved Water Filtration

By:Admin

The Screen Disc Filter is designed to remove impurities and contaminants from water, ensuring clean and safe drinking water for consumers. The filter utilizes a unique disc design that provides a large filtration area, resulting in high flow capacity and low pressure drop. This allows for maximum filtration efficiency while minimizing energy consumption.

One of the key features of the Screen Disc Filter is its self-cleaning mechanism, which helps to maintain consistent filtration performance over time. The self-cleaning process is automated, reducing the need for manual maintenance and ensuring that the filter remains operational for extended periods without interruption. This is particularly important in industrial and municipal water treatment systems, where reliable filtration is critical to ensuring the safety and quality of water supplies.

In addition to its high performance and reliability, the Screen Disc Filter is also highly versatile, capable of handling a wide range of water sources and operating conditions. Whether used in agricultural irrigation systems, industrial wastewater treatment plants, or residential water filtration systems, this product can adapt to various requirements and provide consistent filtration performance.

The company behind the Screen Disc Filter has a strong track record of delivering high-quality water treatment solutions to customers around the world. With decades of experience and expertise in the industry, the company has established itself as a trusted provider of innovative and reliable filtration technologies.

In addition to the Screen Disc Filter, the company offers a comprehensive range of water treatment products and services, including membrane filtration systems, ultraviolet disinfection systems, and water quality monitoring solutions. These products are designed to meet the diverse needs of customers across different industries and applications, providing effective and sustainable solutions for water treatment challenges.

The company is committed to environmental sustainability and social responsibility, ensuring that its products and operations adhere to the highest standards of quality, safety, and environmental protection. By partnering with the company, customers can be assured that they are investing in water treatment solutions that are not only effective and reliable, but also environmentally friendly and compliant with regulatory requirements.

As global demand for clean and safe water continues to grow, innovative filtration technologies like the Screen Disc Filter will play a crucial role in meeting this demand. With its advanced design, high performance, and versatility, this product is poised to make a significant impact in improving water quality and ensuring the availability of clean and safe water for communities and industries around the world.

In conclusion, the Screen Disc Filter, developed by a leading company in the water treatment industry, represents a significant advancement in water filtration technology. With its high performance, reliability, and versatility, this product is well-positioned to address the growing demand for clean and safe water in a wide range of applications. By partnering with this company, customers can expect to benefit from innovative and sustainable water treatment solutions that meet the highest standards of quality and environmental responsibility.

Company News & Blog

Premium Quality Cartridge Filter Element for Sale

Cartridge Filter Element: Ensuring Clean and Pure Industrial Liquid FiltrationCartridge filtration solutions are popular among industries as they offer several advantages over other filtration options. It is an effective method to remove contaminants from industrial liquids, gases and other fluids. It is a vital element in processes such as wastewater treatment, food and beverage processing, chemical processing, and pharmaceutical manufacturing. Cartridge filter elements have high demand in the market due to their efficiency and durability.The cartridge filter element manufacturer has been providing cartridge filter elements for more than 20 years. They have extensive experience in this field and cater to various industries such as food and beverage, automotive, chemical, and healthcare. They manufacture different types of filter elements, including industrial cartridge filters, spun-bonded filter cartridges and other specialty cartridges that suit a variety of applications.The company has a team of experienced and skilled professionals. They work in tandem to ensure the quality and reliability of the final product. The team comprises engineers, technicians, and quality controllers, and they use the latest techniques and equipment to manufacture high-quality filtration products.The cartridge filter element manufacturer uses a variety of filter media that include cellulose, polyester, polypropylene, and others to make their filter elements. The filter media have different properties and are suitable for different processes.The filter media used by the manufacturer is of the highest quality, ensuring maximum filtration efficiency. The filters are designed to remove a wide variety of impurities, including particles of different sizes, air, oil, and water droplets.The company offers a range of filter cartridges to suit different industrial applications, including air, gas, and liquid filtration. The filtration products are available in a range of micron ratings, and the company also provides custom micron ratings for specific applications.Cartridge filter elements are easy to install and maintain. They are also cost-effective compared to other filtration systems. The replacement of filter cartridges is simple and can be done quickly, ensuring minimal downtime in production processes.In addition, the company provides technical support to customers who require assistance in selecting the right filter element for their application. They also provide training to the maintenance and operation teams of the customers to ensure the long-term effectiveness of the filtration systems.The cartridge filter element manufacturer complies with the highest industry standards, including ISO 9001, ensuring the products are of the highest quality. They also regularly upgrade their manufacturing processes to keep up with the latest filtration technology.The company strongly believes in customer satisfaction and ensures that their products meet the needs and requirements of customers. They offer flexible payment options, on-time delivery, and excellent after-sales service.In conclusion, cartridge filter elements are essential for industries that require clean and pure liquids in their processes. The cartridge filter element manufacturer is a reliable and experienced supplier of filtration products, catering to various industries. Their products are of high quality and have a long lifespan, ensuring maximum filtration efficiency. They offer cost-effective solutions and excellent technical support to their customers. The company's commitment to customer satisfaction makes them a preferred supplier of filtration products in the market. Contact them today to know more about their products and services.

Discover High-Quality Expanded Metal Sizes from Top Chinese Manufacturers and Suppliers

Expanded metal sizes refer to the dimensions of wire mesh that is expanded to create a strong and versatile material. This type of metal mesh is created through a process called expansion, where the metal is slit and stretched to create an interlocking pattern of diamond-shaped openings. These openings are then flattened to create a finished product that is used in a variety of applications.If you’re looking for expanded metal sizes, you’ve come to the right place. China is home to some of the best manufacturers of this versatile material. Let’s take a closer look at what expanded metal is, the different sizes available, and why it’s such a popular material.What is Expanded Metal?Expanded metal is a type of metal mesh that is created by a process called expansion. This process involves slitting and stretching the metal to create a continuous pattern of diamond-shaped openings. The openings are then flattened to create a finished product.Expanded metal is known for its strength, versatility, and durability. It can be used in a variety of applications, including fencing, grating, flooring, stair treads, walkways, and more.What are the Different Sizes of Expanded Metal?Expanded metal is available in many different sizes, allowing it to be used in a variety of applications. The size of the expanded metal is determined by the width of the strand and the size of the opening. The most common sizes available include:- Standard: This is the most common size of expanded metal and is typically used for general applications. The strand width is usually between 1/16 and 1/2 inch, and the opening size ranges from 1/4 x 3/4 inch to 1-1/2 x 3 inches.- Flattened: Flattened expanded metal is created by flattening the standard expanded metal. This creates a smooth surface that is ideal for certain applications, such as walkways or decking. The strand width is between 1/4 and 1/2 inch, and the opening size ranges from 1/2 x 1-1/2 inch to 1-1/2 x 3 inches.- Heavy-duty: Heavy-duty expanded metal is designed for applications that require a high degree of strength and durability. The strand width is between 1/2 and 1 inch, and the opening size ranges from 1 x 2 inches to 2 x 4 inches.Why is Expanded Metal Such a Popular Material?Expanded metal is a popular material for a variety of reasons. First, it’s strong and durable. Its interlocking pattern provides strength and stability, making it ideal for use in applications that require a high degree of strength.Second, it’s versatile. Expanded metal can be used in a wide range of applications, from fencing and grating to walkways and stair treads. Its versatility makes it an attractive material for architects, designers, and builders who want a material that can be used in many different ways.Finally, expanded metal is easy to work with. It can be cut, shaped, and welded to fit specific applications. This makes it an ideal material for custom projects where specific dimensions are required.Expanded metal sizes are an important consideration when choosing this versatile material. Whether you’re looking for standard, flattened, or heavy-duty expanded metal, China is home to some of the best manufacturers of this material. With its strength, versatility, and durability, expanded metal is an ideal choice for a wide range of applications.

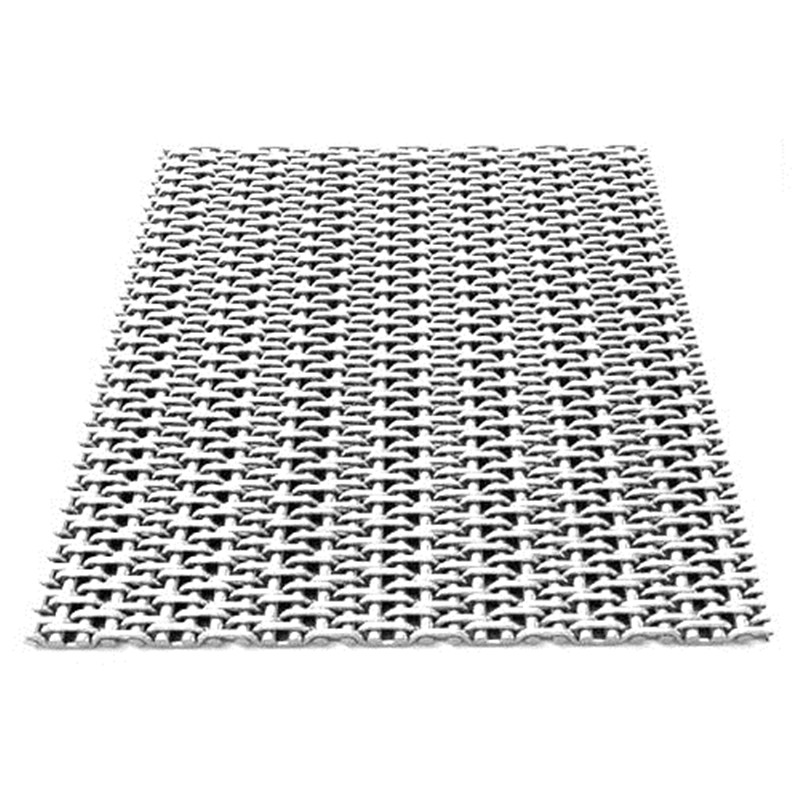

Discover the Benefits of Woven Wire Screens for Your Needs

article:Woven Wire Screen: The Ultimate Solution for Material SeparationIndustries engaged in the handling of materials know the significance of an effective and reliable screening solution for a successful operation. A woven wire screen (name removed) has emerged as a popular and versatile option for material separation across various sectors. With its unique design and superior quality, this screen is increasingly becoming an essential component for the material handling industry.Origin and Evolution of Woven Wire ScreenWoven wire screens are made of wires woven together in a mesh pattern. The earliest type of woven screen was made of horsehair in 1808. However, the first patent for a woven wire mesh was issued in 1871. Over the years, this screen has undergone immense development and innovations. Today, modern weaving techniques and technology have made it possible to produce woven wire screens with precision, efficiency, and consistency.Woven Wire Screen: The Ultimate Solution for Material SeparationWoven wire screens find immense applicability across a wide range of industries. The mining, aggregate, and construction industries use woven wire screens to sort and separate granular materials like ore, rock, gravel, and sand. The food processing industry uses it to filter liquids, powders, and solids. Similarly, the pharmaceutical industry utilizes it for separating solids from liquids. The pulp and paper mills use woven wire screens for screening wood chips, pulp, and waste products.Woven Wire Screen: A Versatile SolutionOne of the significant advantages of woven wire screens is its versatility. It is available in a wide range of shapes, sizes, and materials. The shape and size of the screen depend on the specific demand for the application. The available materials range from carbon steel, high-strength steel alloys, and stainless steel, making it an adaptable solution for any screening need.DurabilityWoven wire screens are tested for durability and strength. Material handling processes can often be harsh, with excessive vibration, high velocity, and abrasive material. A high-quality woven wire screen can withstand extreme conditions, minimizing the risk of screen failure and product contamination. Its durability will not allow for frequent screen replacements, which leads to a considerable saving in both time and money.Easy to MaintainAnother advantage of using a woven wire screen is its ease of maintenance. It can be cleaned and washed effortlessly. The structure of the screen makes it simple to access and inspect regularly. This makes it easy to monitor the progress of the screening process, and any issues detected early and rectified immediately.Superior ScreeningThe unique design of the woven wire screen ensures complete accuracy and superior screening. It provides consistency in the size of the screened material and reduces over-sizing, improving the process and output.Woven Wire Screen: The Name to TrustWhen it comes to woven wire screens, (name removed) is the name to trust. The company is a global leader in manufacturing high-quality woven wire screen and custom screen products. Their commitment to quality and customer satisfaction is reflected in their continuous innovation and investment in modern technology. Established in 1864, the company has a rich history of providing long-lasting and efficient woven wire screens to various industries.Continuous Innovation(Name removed) has over 150 years of experience in the manufacturing of woven wire screens. Over the years, the company has invested in modern technology to produce the highest quality screen wire available. The company has a team of experts that continuously research and strive for new and innovative ways to improve the design and quality of their woven wire screens.Customized SolutionsThe company offers a range of customizable solutions according to the customers' precise requirements, ensuring that the woven wire screen is tailored to meet the exacting demands of the screening application.Exceptional Customer Support(Name removed) is dedicated to providing exceptional customer support. They offer a range of services ranging from on-site support to 24/7 technical support, all aimed at ensuring that their clients receive assistance to meet their screening needs.ConclusionWoven wire screens are an essential component of any material handling operation. Their versatility, durability, ease of maintenance, and superior screening qualities make them the preferred option for industries globally. With companies like (name removed), committed to designing and producing high-quality woven wire screens, industries can have peace of mind, knowing that they have a reliable solution to their screening needs.

Brass Filter Screen Mesh with High Porosity and Smooth Surface for Copper Wire Mesh Screen

and Brass Copper Wire Mesh ScreenBrass Filter Screen Mesh and Brass Copper Wire Mesh Screen: What Are They and Where Are They Used?When it comes to industrial and commercial processes, the use of filters is integral in ensuring that the final product meets quality standards. Filters come in different materials and sizes depending on the application. However, one material that has stood the test of time is brass. Brass is an alloy of copper and zinc with distinct properties that make it preferred in different industries.One of the popular uses of brass is in the manufacture of filter screens. Brass filter screen mesh is produced by weaving or knitting brass wires of different thicknesses and porosity levels. The result is a durable and high-performance filter that can withstand harsh operating conditions.Typically, brass filter screen mesh is used in liquid filtration applications, such as water treatment and oil refining. The mesh’s porosity allows it to trap impurities while letting the filtered liquid through. Moreover, brass is resistant to corrosion, making it ideal for use in corrosive fluids.Another brass wire mesh common in industrial applications is the brass copper wire mesh screen. This type of mesh is produced by interweaving copper and brass wires to create a unique blend of mechanical and electrical properties. Brass copper wire mesh screen is highly conductive and has excellent electromagnetic shielding properties.Brass copper wire mesh screen is used in electronic devices, such as smartphones and computers, to shield against electromagnetic interference. Furthermore, it is used in filtration applications where high electrical conductivity is required, such as in the manufacture of batteries.In conclusion, brass filter screen mesh and brass copper wire mesh screen are an integral part of many industrial processes. Brass’s distinct properties make it an ideal material for different applications, including filtration and electromagnetic shielding. The next time you come across a brass filter or mesh screen, you now know what it is and where it is used.

New Innovation in Filtration: Discover the Screen Disc Filter's Amazing Benefits

Screen Disc Filter: Making Water Filtration More Efficient and EffectiveWater is an essential resource, and with increasing population growth, the demand for clean water is also increasing. With water pollution being a common problem across the globe, efficient water filtration systems are important for households, commercial facilities, and industries. One solution that has proved to be effective in ensuring clean water is the Screen Disc Filter.The Screen Disc Filter is an advanced and innovative filtration system that works by removing impurities and particles using discs that have tiny pores. The filter is designed to cater to different types of water filtration purposes, including drinking water, irrigation, and industrial water treatment among others. The system has been designed to cater to the changing needs of the water industry, with modern technologies and innovations incorporated into its design. This efficient filter is slowly gaining popularity over other types of water filtration systems because of its ability to ensure clean water and its cost-effectiveness.The Screen Disc Filter is manufactured by a company (The company name has been removed for privacy purposes) that focuses on producing high-quality filtration systems for diverse industries including agriculture, communities, landscaping, and industrial sectors. The company has a wealth of experience in the field of water treatment, with its team of experts continually researching and developing advanced filtration systems. By leveraging advanced technologies in the manufacturing process, the company ensures that the Screen Disc Filters are of the highest quality and meet the most demanding filtration requirements.One of the core features of the filtration system is its flexibility. The Screen Disc Filter caters to different water filtration requirements, and it is easily customizable to meet specific customer needs. This flexibility makes it practical for various applications, including wastewater treatment in industrial facilities, agriculture, and residential use. Besides, as an advanced filtration system with various types of filtration disc designs and applications, the filter's installation process is easy and straightforward.In addition to being flexible, the system is highly efficient. The filter eliminates impurities and particles such as sediments, sand, microplastics, and other organic matter, ensuring that the filtered water meets high-quality standards. The Screen Disc Filter also operates at a relatively low flow rate, thus reducing energy consumption and maintenance costs.Maintenance is another significant benefit of using the Screen Disc Filter. The filter aids in reducing the cleaning frequency, which saves on the associated operational costs. The system operates with low pressure and water flow, minimizing the chances of wear and tear compared to other filtration systems.Users of the Screen Disc Filter enjoy a cost-effective filtration system that does not compromise on quality. The system guarantees that the filtered water is of high quality and that there is a low risk of clogging, which typically requires regular cleaning. Users save on maintenance costs while reducing their carbon footprint as it is an energy-efficient system. Additionally, the filter has a long lifespan and requires minimal replacement of its parts.Apart from the benefits of the Screen Disc Filter, the company producing the filter has an amazing support system. They have a team of experts who assist with the installation and the maintenance of the filtration unit. The company also offers customer support services, including assistance with spare parts for the filter. This ensures that the customer experience with the company is smooth and hassle-free.In conclusion, water filtration is vital, and people need to be mindful of the type of filtration system they use. The Screen Disc Filter has proven to be an efficient and cost-effective filtration system that caters to various industries and applications. Using advanced technologies in its design and development, the filter is highly flexible, efficient, and easy to maintain. The company producing the filter offers excellent customer service, ensuring that customers receive the necessary assistance with their filter's installation and maintenance. As the benefits of the Screen Disc Filter continue to emerge, it is becoming the preferred choice for many households, commercial facilities, and industries.

Durable Steel Mesh Grates: An Essential Component for Enhanced Safety and Performance

Steel Mesh Grate: Delivering Quality and Durability to CustomersSteel Mesh Grate, a leading provider of high-quality steel mesh gratings, has been serving the construction and engineering industries for over 30 years. The company is known for delivering durable and excellent quality products to its clients across a range of industries. Steel Mesh Grate's commitment to producing innovative solutions for its clients has made it an industry leader.As a global provider of steel mesh gratings, the company has a broad range of products and services that can be used to meet the most complex steel mesh grating requirements. The company's product line includes steel grates, trench covers, and handrails, among others. These products are used in a wide range of industries, including construction, engineering, mining, and transportation.Steel Mesh Grate has an extensive client base that includes some of the biggest names in the industry. The company has established a reputation for fast turnaround times and a commitment to quality. Clients can rely on Steel Mesh Grate to deliver their products on time and within budget.Steel Mesh Grate's success can be attributed to the expertise and knowledge of its team. The company has built a team of experts who are well-versed in the nuances of the steel mesh grating industry. The team is committed to providing excellent customer service and ensuring that their client's requirements are met.One of Steel Mesh Grate's most popular products is its steel grates. These grates are designed to withstand heavy foot traffic, making them ideal for commercial and industrial settings. They are also incredibly durable, making them a great choice for outdoor applications.The company's trench covers are another popular product, particularly in the construction industry. These covers are used to cover trenches, manholes, and other openings in the ground. They help to prevent accidents and injuries by making it impossible for people to fall into the opening.Steel Mesh Grate is committed to sustainability and ensuring that its products are environmentally-friendly. The company uses recycled materials in its products wherever possible, and it also implements environmentally-friendly practices in its manufacturing processes.In addition to its range of products, Steel Mesh Grate also offers installation services to its clients. The company's team of experts can install steel mesh grates, trench covers, and handrails quickly and efficiently. Clients can rely on Steel Mesh Grate to complete their installation projects on time and within budget.Steel Mesh Grate is constantly innovating and developing new solutions to meet its clients' needs. The company is always looking for ways to improve its products, services, and processes. This commitment to innovation has helped to keep Steel Mesh Grate at the forefront of the industry.As a leading provider of steel mesh gratings, Steel Mesh Grate is well-positioned to continue to grow and expand. The company's commitment to quality, sustainability, and innovation has helped it to establish a loyal client base and maintain a competitive edge in the industry. With its team of experts and its broad range of products and services, Steel Mesh Grate is poised for continued success in the years to come.

Versatile and Stylish Black Coated Wire Mesh: A Must-Have for Homes and Offices

Title: Innovative Black Coated Wire Mesh Revolutionizes the IndustryIntroduction:As the demand for reliable and durable wire mesh continues to rise across multiple sectors, the introduction of revolutionary black coated wire mesh by a prominent company promises to deliver exceptional performance and aesthetics. This innovative product boasts a range of features that make it a game-changer in the wire mesh industry. With its unique composition and cutting-edge technology, this mesh offers unparalleled strength, versatility, and longevity. In this article, we delve into the exceptional attributes of this black coated wire mesh and its potential applications across various industries.Paragraph 1:Black coated wire mesh, developed by the renowned manufacturer, is an innovative product designed to overcome the limitations associated with traditional wire meshes. Crafted from high-quality materials and coated with a durable black finish, this wire mesh offers not only superior functionality but also an impressive aesthetic appeal. The black color provides a modern and sleek appearance, making it an ideal choice for a range of applications.Paragraph 2:One of the key advantages of this black coated wire mesh lies in its exceptional strength and resilience. Manufactured using advanced techniques, this mesh can withstand heavy impact and high tension, making it suitable for demanding applications such as security fencing, animal enclosures, and industrial usage. The strength of this wire mesh ensures that it can effectively contain and protect without compromising on its structural integrity.Paragraph 3:Furthermore, the innovative composition of this black coated wire mesh exhibits outstanding resistance to corrosion, making it highly durable even in harsh environmental conditions. This unique feature allows the wire mesh to maintain its structural integrity for an extended period, reducing the need for frequent maintenance and replacement. Consequently, this black coated mesh offers long-term cost savings and increased operational efficiency, making it an economical choice for various industries.Paragraph 4:The versatility of this black coated wire mesh is another commendable aspect. Its applications extend beyond traditional uses, finding immense usability in architectural and interior design projects. From decorative wall panels to stylish room dividers, the sleek black finish adds a touch of elegance and modernity to any space. This opens up new possibilities for designers and architects to incorporate this black coated wire mesh in their creative endeavors.Paragraph 5:The implementation of this black coated wire mesh does not compromise on safety. With its tightly woven design and robust construction, it effectively prevents animals or objects from passing through while maintaining optimal visibility. This makes it an ideal choice for zoos, parks, and outdoor recreational areas, ensuring the safety of both animals and visitors.Paragraph 6:As sustainability and eco-friendliness increasingly become a priority, this black coated wire mesh aligns with these principles. Manufactured using environmentally friendly materials and employing responsible manufacturing processes, this wire mesh reduces its carbon footprint without compromising on quality or performance. This aspect makes it an attractive solution for eco-conscious projects and organizations.Conclusion:The introduction of this innovative black coated wire mesh has revolutionized the wire mesh industry. Its exceptional strength, durability, versatility, and aesthetic appeal have opened up new avenues for usage across various sectors. Whether it is for security, decorative, or architectural purposes, this black coated wire mesh offers a modern and reliable solution. With its efficient functionality, this wire mesh is set to transform industries and enhance safety and design options for years to come.

Discover the Latest Architecture Trends and News on Wire Mesh at ArchDaily

Wire Mesh: A Versatile and Functional MaterialWire mesh is a versatile material used in construction and architecture. This material is made by weaving or welding metal wires together to form a grid pattern. Wire mesh is used in a variety of applications and is favored by builders and architects for its durability, strength, and aesthetic appeal.Wire Mesh for Construction and ArchitectureWire mesh is used extensively in the construction industry for a range of applications. The mesh is used to reinforce concrete, which increases its strength and prevents cracking. Not only does this make the structure more durable, but it also increases its lifespan. Wire mesh is also used in drywall installation to provide support for the plaster or coating. Wire mesh is also used as a facade on buildings to create a unique architectural design.Wire mesh is also used in architecture to create interesting and attractive design features. The mesh can be used as a decorative element on walls, doors, and windows. It can also be used as a screen to provide privacy or to control light and shade. In addition to its aesthetic benefits, wire mesh can also be used as a sustainable design feature. Its open weave allows for ventilation and natural light, which can help reduce energy consumption.Applications of Wire MeshWire mesh is used in a variety of applications, from industrial to commercial to domestic. Some of these applications include:- Fencing: Wire mesh is commonly used in fencing for its strength and durability. It can be used for both security and aesthetic purposes.- Industrial: Wire mesh is used in industrial applications such as filtration, separation, and temperature control.- Agriculture: Wire mesh is used in agriculture for animal enclosures, pest control, and crop protection.- Transportation: Wire mesh is used in the transportation industry for security enclosures and cargo protection.Wire Mesh MaterialsWire mesh can be made from a variety of materials, including stainless steel, aluminum, copper, brass, and galvanized steel. Each material has its own unique properties, which makes them suitable for different applications. Stainless steel wire mesh, for example, is corrosion-resistant and is therefore used in applications where moisture is present. On the other hand, galvanized steel wire mesh is more affordable and is often used in industrial applications.ConclusionWire mesh is a versatile and functional material used in construction and architecture. Its strength, durability, and aesthetic appeal make it a popular choice for builders and architects. It is used in a wide range of applications and is made from a variety of materials. As technology advances, wire mesh will likely become an even more important material in construction and architecture. With its many benefits, it is easy to see why wire mesh is such a valuable component in the built environment.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.