High-Quality Sintered Mesh Filter for Industrial Applications

By:Admin

In the realm of industrial filtration, the importance of an efficient and reliable filtration system cannot be overstated. From the purification of water and chemicals to the separation of solids and gases, the need for a high-quality filtration system is paramount. This is where the Sintered Mesh Filter, offered by [Company], comes into play.

With a proven track record of delivering high-performance filtration solutions to a wide range of industries, [Company] has established itself as a leader in the field of filtration technology. The company's state-of-the-art manufacturing facilities and cutting-edge research and development capabilities have enabled it to produce innovative and high-quality filtration products that meet the ever-evolving needs of industrial applications.

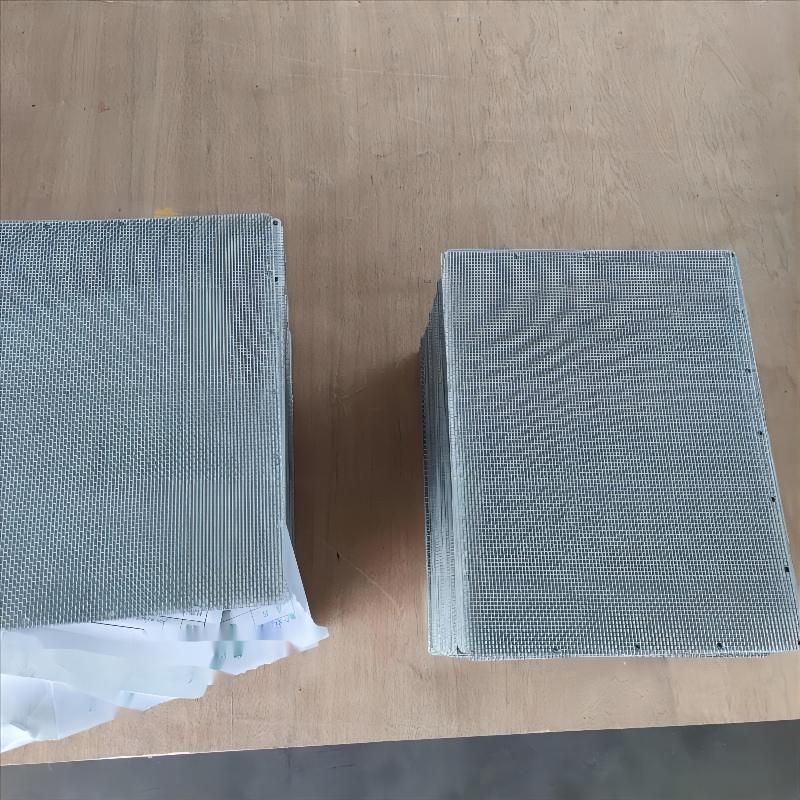

The Sintered Mesh Filter, in particular, has garnered widespread acclaim for its exceptional performance and durability. Constructed from multiple layers of woven wire mesh that are sintered together, this filter offers superior strength and precision filtration capabilities. The sintering process, which involves the fusion of metal particles at high temperatures, results in a filter with uniform pore sizes and excellent mechanical stability, making it suitable for high-pressure and high-temperature applications.

One of the key advantages of the Sintered Mesh Filter is its versatility. Available in a wide range of materials, including stainless steel, titanium, and nickel, this filter can be tailored to meet the specific requirements of various industries, from pharmaceuticals and food and beverage to petrochemical and automotive. Its ability to withstand corrosive chemicals, extreme temperatures, and high pressures makes it an ideal choice for demanding filtration applications.

Moreover, the Sintered Mesh Filter offers a high level of filtration efficiency. Its precisely engineered pore structure ensures the effective removal of contaminants, such as particles, debris, and impurities, while allowing for the smooth flow of fluids or gases. This results in enhanced product quality, reduced downtime, and increased operational efficiency for industrial processes.

In addition to its superior filtration performance, the Sintered Mesh Filter also boasts a long service life and low maintenance requirements. Its robust construction and resistance to wear and tear make it a cost-effective solution for businesses looking to minimize downtime and maintenance costs associated with filtration systems.

Furthermore, [Company] provides comprehensive technical support and customization services to its customers. With a team of experienced engineers and technical experts, the company collaborates closely with clients to understand their specific filtration needs and develop bespoke solutions. From customizing filter sizes and configurations to offering guidance on installation and maintenance, [Company] ensures that its customers receive the most suitable filtration solution for their applications.

As a testament to its commitment to quality and innovation, [Company] adheres to stringent quality control measures and industry standards in the manufacturing of its Sintered Mesh Filter. This includes rigorous testing and inspection processes to guarantee the reliability and consistency of the filters, ensuring that they meet the highest performance and safety requirements.

In conclusion, the Sintered Mesh Filter offered by [Company] is a testament to the company's dedication to providing superior filtration solutions to a diverse range of industries. With its unparalleled performance, durability, and customization capabilities, this filter stands out as the ultimate solution for industrial filtration needs. As businesses continue to seek efficient and reliable filtration systems, the Sintered Mesh Filter remains a frontrunner in delivering exceptional filtration performance for a wide array of applications.

For more information about the Sintered Mesh Filter and other filtration solutions offered by [Company], please visit [Company's website] or contact their sales team.

Company News & Blog

Durable Metal Mesh Sheets: A Versatile and Functional Material Option

Metal Mesh Sheets Supply Company Announces Expansion into New MarketsMetal Mesh Sheets Supply Company is excited to announce their expansion into new markets with the introduction of a wider range of products and services. With a strong foundation in the supply of metal mesh sheets, the company has built a reputation for providing high-quality products and exceptional customer service. Their expansion will allow them to reach new customers and offer a more extensive selection of metal mesh products to meet the growing demands of various industries.The company's metal mesh sheets are widely used in applications such as filtration, separation, protection, and reinforcement. With a diverse range of materials, sizes, and designs, Metal Mesh Sheets Supply Company has become a trusted supplier for businesses across various sectors, including construction, automotive, aerospace, and manufacturing. Their products have proven to be durable, reliable, and cost-effective, making them a go-to option for many businesses.In addition to their existing product line, Metal Mesh Sheets Supply Company will introduce new and innovative metal mesh products to cater to specific industry needs. This expansion will include the introduction of specialized mesh sheets for unique applications, such as architectural design, acoustic solutions, and decorative purposes. By expanding their product range, the company aims to provide comprehensive solutions for a wider range of customer requirements.To support their expansion, Metal Mesh Sheets Supply Company has invested in state-of-the-art manufacturing facilities and equipment to ensure the production of high-quality metal mesh products. Their commitment to quality and innovation is reflected in their continuous research and development efforts to improve and diversify their product offerings. With a team of experienced professionals, the company is well-positioned to meet the evolving needs of their customers and provide tailored solutions for specific applications.Furthermore, Metal Mesh Sheets Supply Company is also expanding their reach by establishing partnerships with distributors and suppliers in new regions. By collaborating with local businesses, the company aims to increase their market presence and provide efficient access to their products for customers worldwide. This strategic approach will not only benefit the company but also create opportunities for local businesses to offer a broader range of metal mesh solutions to their customers.As part of their expansion, Metal Mesh Sheets Supply Company is also enhancing their customer support services to ensure a seamless experience for their clients. From product inquiries to after-sales support, the company is dedicated to providing responsive and personalized assistance to their customers. Their knowledgeable staff will be readily available to offer technical advice, product recommendations, and assistance with custom orders to meet specific requirements.With their expansion into new markets, Metal Mesh Sheets Supply Company is poised to become a leading provider of metal mesh solutions across diverse industries. Their commitment to excellence, product innovation, and customer satisfaction sets them apart as a reliable partner for businesses seeking high-quality metal mesh products. As they continue to grow and evolve, the company remains focused on meeting the evolving needs of their customers and delivering exceptional value through their extensive product range and services.

Aluminium Alloy Expandable Electric Retractable Gate with Mesh Screen: High-Quality Option

Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen – A Revolutionary and Quality Solution for Your Home SecurityAs security concerns rise, people are opting for ways to safeguard their homes more than ever before. Gates, fences, and other such security measures are becoming increasingly popular. However, manual gates require a lot of effort, and installing traditional automatic gates can be quite costly. Here is where Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen comes to the rescue.Nowadays, the market is full of retractable gate options, but not all are created equal. Chinese electric retractable gate manufacturers have come up with an innovative and sophisticated solution to cater to the buyers' needs. The Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is an exceptional product that provides excellent security for your home's perimeter.This retractable gate, which is designed with a mesh screen, is made with high-quality materials, such as aluminum alloy. It is electric-powered, which allows for effortless operation from inside or outside the property. It has an expansion feature that allows it to adjust to different widths to accommodate different openings.The Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen provides an array of benefits that make it the ideal solution for almost any property, including residential and commercial properties. The retractable gate is durable, lightweight, and easy to install, making it a popular option for homeowners who want to ensure the safety of their properties without putting a dent in their pockets.Additionally, the mesh screen feature offers excellent visibility while providing the required security. This gate provides the perfect balance between visibility and security, ensuring that you have full control over who enters your property. The mesh screen is durable and can withstand harsh weather conditions, making it a low-maintenance security option.When it comes to security, sophistication, and durability, Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is unbeatable. It is cost-effective and offers many benefits, including;Enhanced SecuritySecurity is the number one reason homeowners choose to install retractable gates. The Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen offers enhanced security compared to traditional perimeter security measures.They are lightweight, strong, durable, and efficient in restricting access to your home or property. With a mesh screen feature, the gate provides a visual barrier that allows you to see who is outside while keeping unwanted visitors out.ConvenienceThe electric-powered feature makes the Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen a convenient option for homeowners. You can operate the gate with ease, making it hassle-free to come in or leave your property without a fuss.DurabilityThe Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is made of high-quality aluminum alloy. This material is strong, durable, and corrosion-resistant, ensuring the gate will last for years to come.Low-MaintenanceThe mesh screen feature in the gate ensures that the gate remains low-maintenance. The screen is durable and withstands harsh weather conditions without requiring regular maintenance.FlexibilityThe gate's expandable feature allows it to adjust to fit different widths, ensuring it can fit any opening. Therefore, it is an ideal option for properties with unique configurations, and it does not require any additional measures to ensure the gate is secure in a unique opening.ConclusionThe evolving world demands better security measures, and with Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen, you are sure to have that. This security solution provides durability, convenience, and is cost-effective.Chinese electric retractable gate manufacturers offer high-quality products that cater to different buyers' needs. The Aluminium Alloy Expandable Electric Retractable Gate Folding With Mesh Screen is a revolutionary security measure that ensures the safety of your property. It is an affordable option that gives homeowners peace of mind, knowing their properties are secured.

Get Tantalum Aluminide at Competitive Prices and Fast Delivery Times

Introduction:Tantalum Aluminide is a popular material in the manufacturing industry due to its unique chemical and physical properties. It is a corrosion-resistant metal that is commonly used in a wide range of applications, including aerospace, chemical processing, and medical implants. In this blog, we will discuss the properties, applications, and benefits of Tantalum Aluminide in detail. We will also take a brief look at Tantalum Wire Mesh, another popular material used in various industrial applications.Properties of Tantalum Aluminide:Tantalum Aluminide is a silvery grey, ductile, and metallic alloy composed of tantalum and aluminum. The combination of tantalum and aluminum provides excellent mechanical strength, high-temperature stability, and corrosion resistance. Tantalum Aluminide has a low density of 8.4 g/cm³, making it a suitable material for lightweight applications. It has a melting point of 2250 °C and a Young’s modulus of around 330 GPa. Additionally, Tantalum Aluminide has a low coefficient of thermal expansion, which makes it an ideal material for high-temperature environments.Applications of Tantalum Aluminide:Tantalum Aluminide has numerous applications due to its unique properties. It is commonly used in aerospace components such as turbine blades, heat shields, and exhaust nozzles. It is also used in chemical processing as a catalyst support or coating. In the medical industry, Tantalum Aluminide is used in implants and prosthetic devices due to its biocompatibility and corrosion resistance. Moreover, Tantalum Aluminide is used as a protective coating in nuclear power plants and other high-temperature environments.Benefits of Tantalum Aluminide:Tantalum Aluminide has numerous benefits that make it popular in the manufacturing industry. Some of the benefits of using Tantalum Aluminide include:1. Corrosion Resistance: Tantalum Aluminide is highly resistant to corrosion and can withstand harsh chemical environments. This property makes it ideal for use in chemical processing and medical implants.2. High-Temperature Stability: Tantalum Aluminide can withstand high temperatures without losing its strength or ductility. This property makes it an excellent material for use in aerospace and nuclear power plants.3. Lightweight: Tantalum Aluminide has a low density, making it lightweight and a suitable material for applications where weight is a concern.4. Biocompatibility: Tantalum Aluminide is biocompatible and can be used in medical implants and prosthetic devices without causing any adverse reactions.Tantalum Wire Mesh:Tantalum wire mesh is another popular material used in the manufacturing industry that is made up of pure tantalum wire. Tantalum wire mesh has many unique properties that make it ideal for various applications. Some of the properties of Tantalum wire mesh include:1. Excellent Corrosion Resistance: Tantalum wire mesh is highly resistant to corrosion and can withstand harsh chemical environments.2. High-Temperature Stability: Tantalum wire mesh can withstand high temperatures without losing its strength or ductility.3. Lightweight: Tantalum wire mesh has a very low density, making it ideal for lightweight applications.4. Good Electrical Conductivity: Tantalum wire mesh has a high electrical conductivity, making it suitable for electrical and electronic applications.Conclusion:In conclusion, Tantalum Aluminide and Tantalum wire mesh are two popular materials used in the manufacturing industry. Both materials possess unique properties that make them ideal for various applications. Tantalum Aluminide is commonly used in aerospace, chemical processing, and medical implants, while Tantalum wire mesh is used in electrical and electronic applications. The benefits of using Tantalum Aluminide and Tantalum wire mesh include high-temperature stability, corrosion resistance, and lightweight. SAM is a leading supplier of Tantalum Aluminide, including Tantalum wire mesh, with competitive pricing and excellent lead times.

High-Quality Sintered Porous Filter for Your Filtering Needs

Sintered Porous Filter: A Revolutionary Solution for Filtration NeedsIn the world of filtration, finding a solution that is both efficient and reliable can be a challenge. This is where the Sintered Porous Filter comes into play, offering a revolutionary approach to filtration technology. With its unique design and advanced functionality, the Sintered Porous Filter is poised to transform the industry and provide a game-changing solution for a wide range of filtration needs.One company at the forefront of this innovative technology is {}. With a strong focus on research and development, the company has been able to harness the power of sintering technology to create a product that exceeds the expectations of the market. By leveraging their expertise in materials science and engineering, they have been able to develop a porous filter that provides exceptional performance and durability.The Sintered Porous Filter is designed to offer a high level of filtration efficiency, making it an ideal choice for applications where precision and reliability are paramount. It is capable of removing contaminants and impurities from a wide range of fluids, including liquids and gases, making it a versatile solution for various industries. Whether it is used in automotive, aerospace, pharmaceutical, or any other sector, the Sintered Porous Filter delivers consistent and reliable filtration performance.What sets the Sintered Porous Filter apart from traditional filtration solutions is its unique manufacturing process. Through the use of sintering technology, the filter is created by compacting and forming metal or ceramic powders into a porous structure. This results in a material with interconnected pores that provide an extensive surface area for filtration, enabling efficient separation of particles and impurities. The end result is a durable and robust filter that can withstand harsh operating conditions while maintaining its superior performance.One of the key advantages of the Sintered Porous Filter is its ability to offer precise filtration control. With customizable pore sizes and an adjustable permeability range, the filter can be tailored to meet specific filtration requirements. This level of customization allows for greater flexibility in addressing diverse filtration challenges, ensuring that the filter can effectively cater to the unique needs of different applications.In addition to its outstanding filtration capabilities, the Sintered Porous Filter also offers excellent mechanical strength and thermal stability. This makes it suitable for use in demanding environments where high temperatures, pressures, or corrosive substances are present. Furthermore, its long-lasting performance and resistance to wear and tear make it a cost-effective solution that requires minimal maintenance, providing long-term value to users.As a leading provider of sintered porous filters, {} is committed to delivering high-quality filtration solutions that meet the highest standards of performance and reliability. The company's extensive expertise in materials engineering and manufacturing allows them to produce filters that exceed industry expectations, setting new benchmarks for filtration technology. With a focus on innovation and continuous improvement, the company is dedicated to staying ahead of the curve and pushing the boundaries of what is possible in the field of filtration.The introduction of the Sintered Porous Filter represents a significant milestone in the evolution of filtration technology. With its advanced design, customizable features, and exceptional performance, this innovative filter is set to revolutionize the way filtration challenges are addressed across various industries. As the demand for reliable and effective filtration solutions continues to grow, the Sintered Porous Filter stands out as a game-changing option that offers unparalleled performance and versatility. With companies like {} leading the way in its development and production, the Sintered Porous Filter is poised to make a lasting impact on the filtration industry and redefine the standards for filtration excellence.

3 Vital Things to Know About Sintered Powder Filters

Sintered Powder Filter Revolutionizes Filtration Technology: A Breakthrough by an Innovative Company[Company Name], a renowned player in the field of filtration technology, has introduced a revolutionary product in the market – the Sintered Powder Filter. This groundbreaking invention promises to redefine the way we approach filtration, offering a highly efficient and reliable solution to a wide range of industries.As we know, filtration is a critical process in various sectors, including pharmaceuticals, chemicals, food and beverage, oil and gas, automotive, and many others. Traditionally, filters have been made using materials like fabric, paper, metal mesh, or ceramics. While these conventional filters have served their purpose, they often come with limitations such as low durability, limited pore size options, or poor overall performance.Addressing these challenges head-on, [Company Name] has leveraged its expertise and innovative mindset to develop the Sintered Powder Filter. This filter is a result of the company's commitment to providing cutting-edge solutions that meet the evolving needs of industries worldwide.So, what makes the Sintered Powder Filter different and superior to its counterparts? The answer lies in its unique construction and advanced features. The filter is manufactured by compacting metal powders, followed by high-temperature sintering. This process creates a highly porous structure with precise particle size distribution and uniform pore sizes.This uniformity in pore sizes is one of the key advantages of the Sintered Powder Filter. It ensures consistent and reliable filtration, removing impurities with exceptional efficiency. The filter can effectively eliminate particles as small as submicron levels, providing a level of filtration precision that surpasses traditional filters.Additionally, the Sintered Powder Filter's structure offers high strength, resulting in superior durability and resistance to harsh operating conditions. It can withstand high temperatures, corrosive chemicals, and high-pressure environments, making it ideal for applications in extreme conditions. This robustness translates into extended filter life and reduced maintenance costs.Moreover, the Sintered Powder Filter's versatility is worth mentioning. Its pore size can be tailored according to specific requirements, making it adaptable to various industries and filtration needs. Whether it is for clarifying liquids, capturing fine particles, or separating solids and gases, this filter can be customized to deliver optimal results.Furthermore, the Sintered Powder Filter offers the advantage of backwashing, a feature absent in conventional filters. This capability allows for easy cleaning and regeneration of the filter, bringing it back to its original performance without the need for replacement. This significantly reduces operational costs and ensures long-term usability, making it an economical choice for industries.[Company Name] takes pride in its commitment to sustainability and recognizes the importance of minimizing its environmental impact. The Sintered Powder Filter aligns perfectly with this ethos, as it is a reusable, eco-friendly solution compared to disposable filters. Its long lifespan, combined with the ability to be cleaned and reused, contributes to a more sustainable approach to filtration.As [Company Name] introduces the Sintered Powder Filter to the market, industries worldwide are eagerly embracing this innovative solution. Early adopters have already reported significant improvements in filtration efficiency, reduced downtime for maintenance, and enhanced product quality.The Sintered Powder Filter represents a game-changer in the field of filtration technology. Its unparalleled filtration precision, durability, versatility, and sustainability make it an attractive choice for businesses across various sectors. As [Company Name] continues to innovate and invest in research and development, we can expect further advancements in filtration technology and more groundbreaking solutions to meet the evolving needs of industries worldwide.

High-Quality Sintered Filter Elements for Efficient Filtration

Sintered Filter Element Revolutionizes Filtration Technology for Various IndustriesInnovative filtration technology continues to play a crucial role in improving efficiency and ensuring the quality of processes across various industries. One such advancement is the Sintered Filter Element, a cutting-edge solution that has now revolutionized filtration systems.[DUMMY COMPANY NAME], a renowned industry leader in manufacturing filtration products, has introduced this groundbreaking Sintered Filter Element. With its exceptional performance and reliability, this new product is set to redefine the standards of filtration across multiple sectors.The Sintered Filter Element is meticulously engineered using state-of-the-art manufacturing techniques and high-quality materials. Its unique design ensures maximum filtration efficiency, while effectively removing particles, contaminants, and impurities from fluids and gases. This innovative product caters to diverse applications, ranging from chemical and pharmaceutical industries to oil and gas, water treatment, and many more.Standard filtration methods often struggle to achieve the desired level of purity and efficiency. The traditional filter mediums, such as paper and mesh, have limitations when it comes to durability, resistance to high temperatures, and the ability to withstand corrosive substances. However, the Sintered Filter Element tackles these challenges head-on, providing a robust and reliable solution.The use of sintered materials allows for greater versatility and enhanced performance. The filter element is designed to withstand extreme operating conditions, making it suitable for demanding industrial environments. Its resistance to high pressures, temperatures, and corrosive substances enables it to maintain optimal performance for prolonged periods. This aspect significantly reduces downtime, improving operational efficiency and minimizing maintenance costs.Moreover, the Sintered Filter Element offers a higher filtration capacity compared to traditional filters. The innovative design incorporates porous materials that efficiently trap particles while allowing the smooth flow of fluids or gases. This results in improved filtration accuracy and increased throughput, leading to enhanced product quality and reduced wastage.Another noteworthy feature of this filter element is its exceptional cleanability. The porous structure of the sintered material allows for effective backwashing, eliminating clogs and prolonging the lifespan of the filter. Its superior durability ensures repeated cleanings without compromising filtration efficiency, making it a cost-effective solution for companies in various sectors.When it comes to application-specific requirements, the Sintered Filter Element offers customizability and flexibility. [DUMMY COMPANY NAME], with decades of experience in the filtration industry, understands the unique needs of different sectors. The company collaborates closely with clients to develop tailored solutions that meet their specific filtration challenges. This, combined with the high degree of precision and quality control maintained throughout the manufacturing process, ensures the delivery of superior products.Additionally, [DUMMY COMPANY NAME] provides comprehensive technical support and after-sales services, guaranteeing customer satisfaction and peace of mind. The company's team of experts assists clients with installation, troubleshooting, and maintenance, ensuring optimal performance and longevity of the filter element.The introduction of the Sintered Filter Element by [DUMMY COMPANY NAME] marks a significant step towards revolutionizing filtration technology. With its impressive performance, durability, and customizability, this innovative product is poised to enhance operational efficiency and productivity across various industries. With a strong commitment to quality and customer satisfaction, [DUMMY COMPANY NAME] continues to be at the forefront of filtration solutions, driving progress for a cleaner and more efficient future.

PVC Coated Gabion Wire Mesh for River Protection - High-Quality and Durable

, Gabion Wire Mesh, PVC Coated Wire Mesh, River Protection, China manufacturer, QualityProtecting our rivers and other natural water bodies is essential to maintaining the environment's balance, and one of the most effective ways to do this is by using gabion wire mesh. Gabion wire mesh is a type of mesh made from galvanized steel wires that are woven together to form hexagonal boxes or baskets that can be filled with stones or other materials.One of the most popular types of gabion wire mesh is PVC coated Galfan gabion wire mesh, which is coated with PVC to make it resistant to corrosion and wear. Galfan wire mesh is made from a combination of zinc and aluminum, making it more durable and long-lasting than traditional galvanized wire mesh.Combined with PVC coating, Galfan gabion wire mesh becomes a formidable tool for river protection. The PVC coating ensures that the mesh can withstand exposure to water and other environmental factors, which is essential for protecting rivers that are prone to flooding.The 2 x 1 x 0.5 meters size of Galfan gabion wire mesh is perfect for river protection projects, as it is large enough to provide significant protection while still being manageable and easy to install. Additionally, Galfan gabion wire mesh is incredibly versatile and can be used to create a wide variety of structures, including retaining walls, erosion control barriers, and even decorative landscaping features.When choosing a Galfan gabion wire mesh manufacturer, it is essential to find a reliable and trustworthy company that produces high-quality products. Chinese manufacturers are known for producing some of the best gabion wire mesh products on the market, and there are many China-based manufacturers of Galfan gabion wire mesh that produce top-quality products.If you are looking for PVC coated Galfan gabion wire mesh for river protection, it is important to do your research and find a reputable manufacturer. With the right Galfan gabion wire mesh, you can protect your local waterways, preserve the environment, and create beautiful and functional structures that will last for years to come.

Nickel Mesh and Screen: Material, Specification, Packing - Corrosion and Acid Resistant Filter Mesh for High Temperature Filtration

article about the benefits of using nickel wire mesh and screen in various industrial applications.Nickel wire mesh and screen have become increasingly popular in various industrial applications, thanks to their unique properties. As a manufacturer and supplier of high-quality nickel wire mesh, {company name} understands the numerous benefits that this material provides for industrial filtration and screening processes.Nickel wire mesh is highly durable and resistant to both corrosion and acid, making it an ideal material for use in harsh and high-temperature environments. This property makes nickel wire mesh and screen suitable for use in various industries, such as chemical and petrochemical production, power generation, and mining.One of the primary benefits of using nickel wire mesh is its high-level filtration. Nickel wire mesh filters and screens are capable of separating and removing very fine particles from liquids or gases, making them an essential material in many manufacturing and industrial processes. In these industries, even the tiniest of impurities can cause machinery to malfunction or fail, leading to costly repairs, downtime, and potential safety hazards.Nickel wire mesh and screen also exhibit excellent electrical conductivity properties. This makes them ideal for use in electrical and electronic industries, where they can be used as electrodes or screens for electromagnetic shielding. Since nickel has good magnetic properties, it is also used in electrical transformers and inductors.In addition to its unique properties, nickel wire mesh and screen are available in different specifications and mesh sizes. This versatility makes it possible for {company name} to offer a wide range of custom nickel wire mesh products tailored to meet specific industry requirements. Customers can choose from woven, knitted, perforated, or expanded nickel wire mesh depending on their application needs.To ensure the safety of nickel wire mesh products during transportation or storage, {company name} pays significant attention to the packing requirements. The company uses durable packing materials and techniques to ensure its products remain in good condition and reach customers in perfect condition.In conclusion, nickel wire mesh and screen are versatile materials that offer a range of benefits for various industrial applications. With their high durability, resistance to corrosion and acid, and excellent filtration properties, nickel wire mesh has become an essential material in industries such as chemical production, power generation, and mining, among others. As a reputable manufacturer and supplier of nickel wire mesh products, {company name} is dedicated to providing its customers with high-quality custom nickel wire mesh products and excellent customer service.

Discover the Latest Architecture Trends and News on Wire Mesh at ArchDaily

Wire Mesh: A Versatile and Functional MaterialWire mesh is a versatile material used in construction and architecture. This material is made by weaving or welding metal wires together to form a grid pattern. Wire mesh is used in a variety of applications and is favored by builders and architects for its durability, strength, and aesthetic appeal.Wire Mesh for Construction and ArchitectureWire mesh is used extensively in the construction industry for a range of applications. The mesh is used to reinforce concrete, which increases its strength and prevents cracking. Not only does this make the structure more durable, but it also increases its lifespan. Wire mesh is also used in drywall installation to provide support for the plaster or coating. Wire mesh is also used as a facade on buildings to create a unique architectural design.Wire mesh is also used in architecture to create interesting and attractive design features. The mesh can be used as a decorative element on walls, doors, and windows. It can also be used as a screen to provide privacy or to control light and shade. In addition to its aesthetic benefits, wire mesh can also be used as a sustainable design feature. Its open weave allows for ventilation and natural light, which can help reduce energy consumption.Applications of Wire MeshWire mesh is used in a variety of applications, from industrial to commercial to domestic. Some of these applications include:- Fencing: Wire mesh is commonly used in fencing for its strength and durability. It can be used for both security and aesthetic purposes.- Industrial: Wire mesh is used in industrial applications such as filtration, separation, and temperature control.- Agriculture: Wire mesh is used in agriculture for animal enclosures, pest control, and crop protection.- Transportation: Wire mesh is used in the transportation industry for security enclosures and cargo protection.Wire Mesh MaterialsWire mesh can be made from a variety of materials, including stainless steel, aluminum, copper, brass, and galvanized steel. Each material has its own unique properties, which makes them suitable for different applications. Stainless steel wire mesh, for example, is corrosion-resistant and is therefore used in applications where moisture is present. On the other hand, galvanized steel wire mesh is more affordable and is often used in industrial applications.ConclusionWire mesh is a versatile and functional material used in construction and architecture. Its strength, durability, and aesthetic appeal make it a popular choice for builders and architects. It is used in a wide range of applications and is made from a variety of materials. As technology advances, wire mesh will likely become an even more important material in construction and architecture. With its many benefits, it is easy to see why wire mesh is such a valuable component in the built environment.

Top Quality Security Fencing Wire Mesh for High-Level Protection

Wire Mesh – Security Fencing Wire Mesh: Ensuring Safety and ProtectionIn a world where security and safety are crucial, wire mesh has become an integral part of many structures. Wire mesh fences provide an effective barrier against intruders, protecting both property and people. With its ability to deter unauthorized entry, it has become a popular choice for residential, commercial, and industrial properties. Wire mesh is a durable and cost-effective option for enhancing security and privacy, making it an ideal solution for many applications.Alex Manufacturer, a leading company in the wire mesh industry, produces high-quality anti-climb and anti-cut fence, stainless steel high-security window screens, metal wire mesh, stainless wire mesh, fencing mesh, and razor wire. The company has been in the wire mesh industry for several years, producing innovative and state-of-the-art solutions to meet the changing demands and requirements of its clients.With its commitment to excellence and dedication to meeting customer needs, Alex Manufacturer has gained a reputation for producing top-quality products that exceed customer expectations. The company's wire mesh products are renowned for their high strength, durability, and resistance to wear and tear. They are designed for use in a wide range of applications, including perimeter security, access control, and protective enclosures.Wire mesh fences are highly effective when it comes to deterring intruders. They are designed to be difficult to climb or cut, making it challenging for unauthorized persons to gain access to the property. Wire mesh fences come in a variety of configurations, including welded and woven options. Welded wire mesh fences are more robust and more rigid than woven options and are ideal for applications where strength is paramount, such as industrial properties or commercial premises.Alex Manufacturer's anti-climb and anti-cut fence is one of its most popular products. The fence is designed with closely spaced vertical and horizontal wires, making it difficult for anyone to climb or cut through the fence. The anti-climb and anti-cut fence is available in a range of heights and configurations to meet specific customer needs.Another innovative product from Alex Manufacturer is the stainless steel high-security window screen. The product is designed to protect doors and windows from unauthorized entry and intrusion. The screen is made from high-strength stainless steel wire, which provides an effective barrier against break-ins while maintaining visibility and ventilation.Metal wire mesh is another product that has gained popularity in recent years. The mesh is typically made from steel wire and comes in various configurations, including welded and woven options. Metal wire mesh is used in a wide range of applications, including outdoor enclosures, machinery guards, and safety barriers.Stainless wire mesh is a specialized type of wire mesh made from high-quality stainless steel wire. The mesh is corrosion-resistant and has excellent strength and durability. Stainless wire mesh is often used in applications where hygiene and cleanliness are of the utmost importance, such as food processing facilities and laboratories.Fencing mesh is a multi-purpose product that is used to create barriers in a variety of applications. The mesh is typically made from high-quality steel wire and is available in a range of configurations, including welded and woven options. Fencing mesh is ideal for creating temporary enclosures at construction sites, events, and public spaces.Razor wire is a specialized type of wire that is used in high-security applications. The wire features sharp blades that are designed to deter intruders from climbing over or cutting through the fence. Razor wire is often used in prisons, military facilities, and other high-security installations.In conclusion, wire mesh is an essential product that provides security and protection to a wide range of applications. Alex Manufacturer is a leading company in the wire mesh industry, producing high-quality products that meet the changing demands and requirements of its clients. With its commitment to excellence, Alex Manufacturer has gained a reputation for producing innovative and state-of-the-art solutions that exceed customer expectations.