High-Quality Metal Porous Sintered Filter for Industrial Use

By:Admin

In today’s fast-paced and evolving industrial landscape, companies are constantly looking for innovative solutions to improve their processes and efficiency. One such breakthrough technology is the Metal Porous Sintered Filter, which is poised to revolutionize the way industries approach filtration and separation. This advanced filtration technology is expected to bring about significant improvements in various industries, including petrochemical, pharmaceutical, food and beverage, and many more.

The Metal Porous Sintered Filter is a cutting-edge product offered by {Company Name}, a leading manufacturer and supplier of high-quality filtration products. With a strong commitment to research and development, {Company Name} has been at the forefront of providing innovative and effective filtration solutions for a wide range of applications. Their Metal Porous Sintered Filter is the latest addition to their impressive product portfolio, and it is set to redefine the standards of filtration efficiency and performance.

What sets the Metal Porous Sintered Filter apart from traditional filtration methods is its unique construction and material composition. Made from high-quality metal powders such as stainless steel, nickel, titanium, and other alloys, the filter is produced through a sintering process that creates a highly porous structure with interconnected pore networks. This results in a filter media with outstanding mechanical strength, thermal stability, and chemical resistance, making it ideal for demanding industrial environments.

One of the key advantages of the Metal Porous Sintered Filter is its exceptional filtration efficiency. The intricate network of interconnected pores provides a large surface area for effective particle retention, ensuring that even the smallest contaminants are captured and separated from the fluid or gas stream. This high level of filtration performance not only improves product quality but also extends the service life of downstream equipment and reduces maintenance costs.

Furthermore, the Metal Porous Sintered Filter offers superior flow characteristics, allowing for high flow rates with minimal pressure drop. This is particularly beneficial for applications where efficient fluid or gas flow is essential, such as in chemical processing, gas separation, and hydraulic systems. By optimizing flow dynamics, the filter contributes to enhanced process efficiency and productivity, thereby delivering tangible benefits to industrial operations.

In addition to its impressive filtration and flow capabilities, the Metal Porous Sintered Filter also stands out for its versatility. It can be custom-engineered to meet specific application requirements, including varying pore sizes, thicknesses, shapes, and sizes. This flexibility enables {Company Name} to tailor the filter design to the precise needs of their customers, ensuring an optimal filtration solution for diverse industrial processes.

The Metal Porous Sintered Filter has already been well-received by industry professionals, with its adoption growing across different sectors. In the petrochemical industry, it has been successfully deployed for catalyst recovery, polymer filtration, and gas-liquid separation, contributing to improved process efficiency and cost savings. Similarly, in the pharmaceutical and food and beverage sectors, the filter has proven invaluable for ensuring product purity and meeting stringent regulatory standards.

Looking ahead, the Metal Porous Sintered Filter is poised to play a pivotal role in shaping the future of filtration technology. As industries continue to prioritize efficiency, sustainability, and product quality, this advanced filtration solution offers a compelling value proposition. With {Company Name} leading the way in its development and application, the Metal Porous Sintered Filter is set to become an indispensable tool for businesses striving for excellence in their operations.

In conclusion, the Metal Porous Sintered Filter represents a significant milestone in the evolution of filtration technology. Its combination of superior filtration efficiency, robustness, and adaptability positions it as a game-changer for various industries. As {Company Name} continues to drive innovation and excellence in the field of filtration, the Metal Porous Sintered Filter stands out as a flagship product that sets new standards for performance and reliability. With its profound impact on industrial processes, this groundbreaking filter is poised to create a lasting legacy in the realm of filtration and separation.

Company News & Blog

Discover the Benefits of Sintered Filter Cartridges for Exceptional Filtration

Title: Groundbreaking Sintered Filter Cartridge Revolutionizes Filtration TechnologyIntroduction:(Filter Company), a leader in innovative filtration solutions, has unveiled its latest groundbreaking product - the Sintered Filter Cartridge. This revolutionary filtration technology is set to redefine industry standards by providing superior performance, efficiency, and durability.The Sintered Filter Cartridge is designed to meet the increasing demands of various industries, including water treatment, pharmaceuticals, chemicals, food and beverage, and more. Through cutting-edge manufacturing techniques, (Filter Company) has successfully developed a versatile and highly effective filtration solution that ensures the highest level of filtration efficiency.Unmatched Filtration Efficiency:One of the key features that sets the Sintered Filter Cartridge apart from conventional filters is its exceptional filtration efficiency. The cartridge is manufactured using the sintering process, which involves compacting and bonding metal or ceramic particles under extremely high pressure and temperature. This results in a highly porous structure with interconnected channels, enabling the filter to provide a larger surface area for efficient particle retention.With its advanced filtration mechanism, the Sintered Filter Cartridge can effectively remove suspended solids, sediments, colloidal particles, and even microorganisms from liquids and gases. This level of filtration efficiency not only guarantees the purity of the final product but also ensures compliance with stringent regulatory standards.Unparalleled Durability:In addition to its outstanding filtration capabilities, the Sintered Filter Cartridge is engineered to withstand extreme operating conditions. The sintering process grants the cartridge exceptional mechanical strength, making it highly resistant to pressure, temperature, and chemical exposure. This durability translates into a longer lifespan and reduced maintenance costs, making it a cost-effective solution for businesses.Moreover, the cartridge's robust construction reduces the risk of breakage or structural damage, ensuring uninterrupted filtration operations even under challenging circumstances. This makes it an ideal choice for industrial applications that demand reliable and long-lasting filtration solutions.Versatile Applications:The Sintered Filter Cartridge caters to a wide range of applications across various industries. Its adaptability allows it to be used for both liquid and gas filtration processes. It proves to be an excellent choice for applications such as water and wastewater treatment, pharmaceutical manufacturing, biotechnology processes, chemical and petrochemical plants, food and beverage production, and many more.The flexible design of the Sintered Filter Cartridge enables customization, with different shapes, sizes, and configurations available to suit specific filtration requirements. This adaptability ensures seamless integration into existing filtration systems, thereby minimizing downtime during installation and enhancing operational efficiency.Commitment to Quality and Sustainability:(Filter Company) is dedicated to delivering the highest-quality filtration solutions to its customers while prioritizing environmental sustainability. The Sintered Filter Cartridge incorporates materials that are highly recyclable, reducing waste generation and promoting a cleaner and greener future.By continuously investing in research and development, (Filter Company) ensures that its filtration products remain at the forefront of technological advancements. The Sintered Filter Cartridge stands as a testament to the company's commitment to innovation and its aim to provide efficient and sustainable solutions to meet the evolving needs of various industries.Conclusion:The introduction of the Sintered Filter Cartridge by (Filter Company) represents a significant leap forward in filtration technology. Its remarkable filtration efficiency, exceptional durability, and versatility across industries make it an indispensable tool for businesses seeking reliable and cutting-edge filtration solutions.(Filter Company)'s commitment to quality, performance, and sustainability solidifies its position as a leader in the field of filtration technology. With the new Sintered Filter Cartridge, businesses can expect enhanced filtration performance, reduced maintenance costs, and the assurance of complying with stringent regulatory standards.

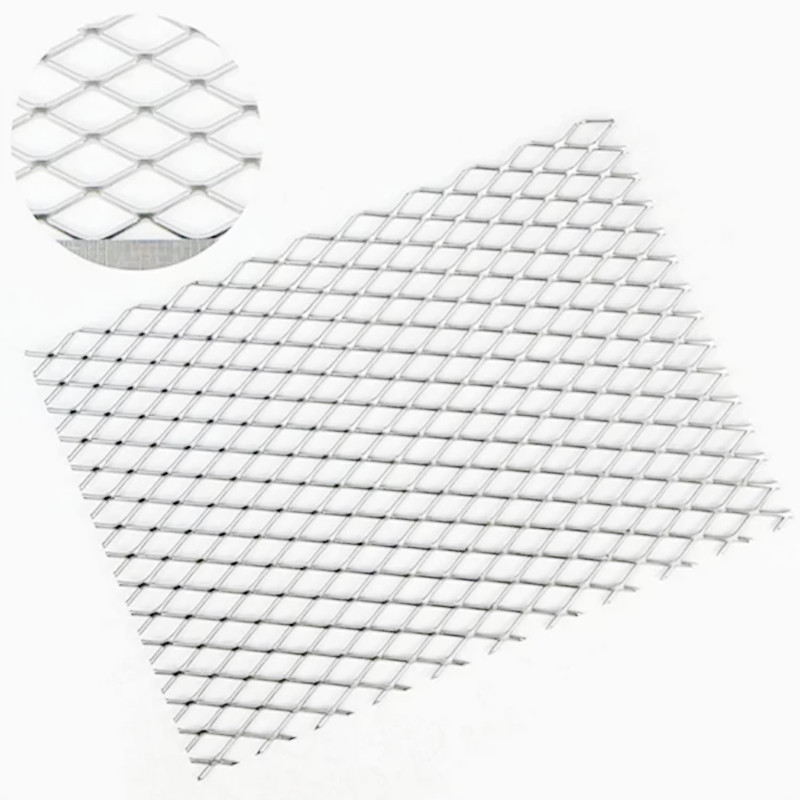

Durable and Versatile Wire Mesh for Various Applications

Galfan wire mesh is a revolutionary product that has gained significant attention in the market due to its superior quality and durability. Galfan wire mesh is a type of wire mesh that is made from a combination of zinc and aluminum, which makes it highly resistant to corrosion and wear. This innovative product has quickly become the go-to choice for a wide range of applications, including agricultural, industrial, and security purposes.The use of Galfan wire mesh has become increasingly popular due to its unique properties, which make it an ideal material for a variety of applications. This type of wire mesh is highly resistant to corrosion, making it suitable for use in harsh environments where traditional wire mesh may quickly deteriorate. Additionally, the combination of zinc and aluminum in Galfan wire mesh provides it with a high level of strength and durability, ensuring that it can withstand heavy loads and harsh weather conditions.One of the key features of Galfan wire mesh is its versatility. It can be easily customized to meet the specific requirements of different applications, and it is available in a wide range of sizes and specifications. This makes it suitable for use in a variety of industries, including agriculture, construction, mining, and security. Whether it is used as fencing material, for animal enclosures, or for industrial filtration, Galfan wire mesh has proven to be a reliable and cost-effective solution.The manufacturing process of Galfan wire mesh is also worth mentioning. The company utilizes state-of-the-art equipment and technology to produce high-quality wire mesh that meets the highest industry standards. The use of advanced manufacturing techniques ensures that the wire mesh is uniformly coated with the zinc and aluminum alloy, providing maximum protection against corrosion and wear. Additionally, the company's strict quality control measures guarantee that every roll of Galfan wire mesh meets the highest quality standards.In addition to its superior quality and durability, Galfan wire mesh also offers environmental benefits. The use of Galfan as a coating material reduces the environmental impact associated with traditional zinc-coated wire mesh. The use of Galfan also extends the service life of the wire mesh, reducing the need for frequent replacements and minimizing waste. This makes Galfan wire mesh a sustainable and eco-friendly choice for a wide range of applications.The company behind Galfan wire mesh takes pride in its commitment to customer satisfaction. They offer comprehensive customer support and technical assistance to ensure that their clients receive the best possible product for their specific needs. In addition to providing high-quality wire mesh, the company also offers custom fabrication services, allowing customers to order wire mesh that is tailored to their exact specifications.As the demand for high-quality, durable wire mesh continues to grow, Galfan wire mesh has emerged as a top choice for an increasing number of businesses and industries. With its unmatched resistance to corrosion, exceptional strength, and environmental benefits, Galfan wire mesh has proven to be a reliable and cost-effective solution for a wide range of applications. As the market for wire mesh continues to evolve, Galfan wire mesh is poised to remain a leader in the industry, providing unparalleled quality and performance to its customers.

Discover Woven Wire Mesh: Free Download with Aperture Size Calculator, Open Area & Weight Estimation

: Understanding the Different ApplicationsWoven wire screens have been a fundamental component of many industrial processes and equipment for decades. From pharmaceutical and food processing to mining and petrochemicals, a wide range of industries rely on these products to filter, separate, and sort materials. In this blog, we will delve deeper into woven wire screens, their uses, and their benefits.What is Woven Wire Screen?Woven wire screen is a mesh fabric made from wire strands interwoven at right angles. These strands can be made from various metals such as stainless steel, brass, copper, and aluminum. The wire strands may have different diameters and weaves, depending on the intended application.Applications of Woven Wire ScreensWoven wire screens are commonly used in various applications, including:1. Screening and SeparationWoven wire screens are used as industrial filters for screening and separating materials. These screens are used in mining equipment, vibratory machines, and in the production of plastics, ceramics, and other materials. By filtering out unwanted particles and materials, these screens ensure the quality and purity of end products.2. SiftingWoven wire screens are also used for sifting in the food, pharmaceutical, and chemical industries. These screens can be used to sift, sort, and grade materials in a specific size range.3. Security FencingWoven wire screens can provide enhanced security by preventing unauthorized entry, theft and vandalism. They are commonly used to protect residential properties, commercial establishments, and industrial facilities.4. Insects and Pest ControlWoven wire screens can be used for insect and pest control in residential and commercial facilities.Benefits of Woven Wire ScreensWoven wire screens are widely used in various industries due to their numerous benefits, including:1. High DurabilityWoven wire screens are highly durable and can withstand harsh environmental conditions. They are resistant to corrosion, abrasion, and high temperatures.2. High PrecisionWoven wire screens are available in various mesh sizes, making them suitable for precise screening and separation of materials.3. Low MaintenanceWoven wire screens require minimal maintenance and can be easily cleaned and reused.4. Cost-effectiveWoven wire screens are cost-effective compared to other screening and separating products. They also have a long lifespan, which makes them a more economical option in the long run.ConclusionWoven wire screens are vital components of many industrial processes and equipment. They are used in various industries for screening, separating, sifting, and security purposes. With their high durability, precision, low-maintenance, and cost-effectiveness, woven wire screens are a reliable and efficient solution in numerous settings.If you are in the market for woven wire screens, Robinson Wire Cloth Ltd. offers a range of quality products for any industrial application. Visit our online shop or contact us for more information.

Durable and Versatile Woven Wire Mesh for Various Applications

Woven wire mesh is a versatile material that has found applications in various industries, including construction, agriculture, mining, and architecture. The mesh is made by weaving wires together to create a durable and flexible material that can be used for a wide range of applications.One company that has been at the forefront of producing high-quality woven wire mesh is {}, a leading manufacturer and supplier of industrial wire mesh products. With over 20 years of experience in the industry, {} has established a reputation for delivering top-notch products that meet the highest standards of quality and performance.The company's woven wire mesh products are known for their durability, strength, and versatility. They are used in a wide range of applications, including filtration, screening, and separation. The mesh is available in various materials, including stainless steel, galvanized steel, and aluminum, and can be customized to meet the specific requirements of different industries.One of the key advantages of using woven wire mesh is its ability to withstand harsh environmental conditions, making it ideal for outdoor applications such as fencing, animal enclosures, and agricultural use. The mesh is also widely used in the construction industry for reinforcing concrete and providing structural support.In addition to its practical applications, woven wire mesh is also used for decorative purposes in architecture and interior design. Its intricate patterns and textures can add a unique aesthetic appeal to buildings and spaces, making it a popular choice for designers and architects.{} takes pride in its commitment to quality and customer satisfaction. The company's team of skilled professionals works closely with clients to understand their specific needs and provide tailored solutions that meet their requirements. By using advanced manufacturing techniques and adhering to strict quality control measures, {} ensures that its woven wire mesh products are of the highest quality and reliability.As a socially responsible company, {} is also focused on sustainability and environmental conservation. The company sources its materials from reputable suppliers and adheres to eco-friendly manufacturing practices to minimize its environmental impact. This commitment to sustainability has earned {} the trust and respect of its customers and partners.With a strong focus on innovation and continuous improvement, {} continues to expand its product range and explore new applications for woven wire mesh. The company invests in research and development to stay ahead of market trends and technological advancements, ensuring that its products remain at the forefront of the industry.In conclusion, woven wire mesh is a versatile and indispensable material that has a wide range of applications across different industries. As a leading manufacturer and supplier of industrial wire mesh products, {} has established itself as a trusted provider of high-quality woven wire mesh solutions. With a commitment to quality, customer satisfaction, and sustainability, {} continues to set the standard for excellence in the industry and looks set to maintain its position as a market leader for years to come.

Get Your Metal Mesh Today - Call for Assistance at 01954 261369

Martin Hale, a metal mesh expert with years of experience, has started a new business called Vulcan 502250, supplying top-notch metal mesh products to various industries nationwide. The business has been established with the aim of providing superior metal mesh products that surpass customer's expectations in terms of quality, durability, and affordability.Martin Hale has been in the metal mesh business for quite some time, and he has earned a reputable name in the industry as a metal mesh expert. He has a broad knowledge of the manufacturing process of metal mesh and is passionate about delivering products that meet clients' needs. The Vulcan 502250 is a testament to Martin's keen eye for quality, as he sources only the finest raw materials from well-known suppliers. The company uses state-of-the-art machinery and equipment to produce metal mesh products that can be customized to meet clients' specific requirements. The metal mesh comes in a wide variety of sizes, shapes, and types, including woven, welded, expanded, and perforated mesh.Vulcan 502250 products are ideal for a variety of applications in industries such as architecture, automotive, agriculture, mining, and construction. The metal mesh products can be used for fencing, ventilation, filtration, screening, and separators. The company's products are renowned for their versatility and durability, making them ideal for use in harsh environments and heavy-duty applications.Martin Hale has always been committed to providing excellent customer service. He has built a friendly and knowledgeable team that works diligently to ensure that clients get the assistance they need to make the best decisions. Vulcan 502250's team of experts is always ready to provide guidance on the selection, customization, and installation of metal mesh products.The customer-friendly approach of Vulcan 502250 has earned them a loyal and vast customer base across the UK. Many satisfied clients have praised Martin Hale for his professionalism, attention to detail, and consistency in delivering quality products and services.Martin Hale's Vulcan 502250 has implemented strict quality control measures to guarantee that all their products meet the required standards. The company's metal mesh products undergo rigorous testing procedures to ensure that they are strong, durable, and fit for purpose. These stringent measures guarantee that clients receive products that are reliable, efficient, and safe to use.Vulcan 502250 continually invests in research and development to improve its metal mesh products. The company collaborates with leading metal mesh experts and suppliers to stay updated on the latest industry advancements. This way, they remain at the forefront of product innovation and development.In conclusion, Vulcan 502250 is the go-to destination for individuals and companies in need of quality metal mesh products. The company's commitment to quality, customer service, and innovation has made it a leading metal mesh provider in the UK. Call them today on 01954 261369 to purchase your ideal metal mesh product.

High-Quality Woven Wire Mesh in Various Materials Available for Fast Shipping in Australia

Woven metal mesh is a versatile and practical solution for a wide range of applications. It is a durable and reliable material that comes in different sizes and grades to suit different needs. In Australia, Arrow Metal is a renowned supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel. In this blog, we will explore the benefits and uses of woven metal mesh and how Arrow Metal can support your project needs.Benefits of Woven Metal MeshWoven metal mesh is a popular choice for a variety of reasons. First and foremost, it is a robust and durable material that can withstand adverse weather conditions, high temperatures, and heavy usage. This makes it an ideal choice for outdoor and industrial applications. Woven metal mesh is also resistant to corrosion and erosion, making it suitable for harsh and corrosive environments.Another advantage of woven metal mesh is its versatility. Depending on the size and grade of the mesh, it can be used for different purposes, such as filtration, ventilation, security, and decoration. It can be easily cut, bent, and molded to different shapes and sizes to fit the project requirements. Furthermore, woven metal mesh allows for the passage of light, air, and sound, which makes it an excellent choice for architectural and design applications.Uses of Woven Metal MeshWoven metal mesh has a wide range of applications in different industries, such as architecture, construction, mining, manufacturing, and agriculture. It can be used for the following purposes:Filtration: Woven metal mesh can be used as a filter for liquids, gases, and solids. It can be used in industries such as food and beverage, pharmaceuticals, and mining to filter impurities and contaminants.Ventilation: Woven metal mesh can be used as a screen or grille to allow for ventilation and air circulation. It can be used in buildings, automotive, and HVAC systems to regulate the temperature and humidity.Security: Woven metal mesh can be used as a barrier or fence to provide security and safety. It can be used in prisons, military facilities, and airports to prevent unauthorized access and intrusion.Decoration: Woven metal mesh can be used as a decorative element in architectural and interior design. It can be used as a facade, ceiling, or partition to create a unique and modern look.Arrow Metal and Woven Metal MeshArrow Metal is a leading supplier of woven metal mesh in Australia. They stock a large range of quality woven wire mesh in brass and 304 and 316 stainless steel, ready to ship throughout Australia. Their woven metal mesh comes in different sizes, patterns, and grades to suit different applications and budgets.Arrow Metal has a team of experts who can provide tailored advice and solutions for your project needs. They can work with you to choose the right woven metal mesh for your application and provide custom fabrication and installation services. Whether you need a small sample or a large quantity of woven metal mesh, Arrow Metal can support your needs with prompt delivery, competitive pricing, and excellent customer service.ConclusionWoven metal mesh is a versatile and practical material that can be used for a variety of applications. It is a durable and reliable solution that can withstand harsh conditions and provide security, ventilation, filtration, and decoration. Arrow Metal is a trusted supplier of high-quality woven wire mesh in brass and 304 and 316 stainless steel in Australia. They can provide tailored advice and solutions for your project needs and deliver quality products and services. Contact Arrow Metal today to learn more about their woven metal mesh offerings and how they can support your project.

Affordable and Durable Lightweight Steel Mesh for Construction Projects

Innovative Lightweight Steel Mesh Revolutionizes Construction IndustryThe construction industry is constantly evolving with new technologies and materials that aim to improve efficiency and durability. Recently, a groundbreaking lightweight steel mesh has been introduced by a leading steel manufacturer, {Company Name}. This innovative product is set to revolutionize the construction industry and offer a wide range of benefits for various applications.{Company Name} has been a prominent player in the steel manufacturing industry for over two decades. With a strong emphasis on research and development, the company has continuously strived to introduce new and improved products that meet the evolving needs of the construction sector. The introduction of the lightweight steel mesh is a testament to their commitment to innovation and excellence.The lightweight steel mesh, which is made from high-quality steel, offers a multitude of advantages over traditional materials. Its superior strength-to-weight ratio makes it an ideal choice for various construction applications. The use of this innovative material can significantly reduce the overall weight of structures, thereby minimizing the load on supporting elements and reducing the overall construction costs.In addition to its lightweight properties, the steel mesh also boasts exceptional durability and resistance to corrosion. This ensures that structures built using this material will have a longer lifespan and require minimal maintenance, resulting in long-term cost savings for property owners and developers. Furthermore, the lightweight steel mesh is also highly versatile and can be tailored to suit specific project requirements, making it an ideal choice for a wide range of applications.One of the key advantages of the lightweight steel mesh is its environmental sustainability. With a growing focus on eco-friendly construction practices, this innovative material aligns with the industry's push towards more sustainable building solutions. Its lightweight nature reduces the overall environmental impact of construction projects, while its durability ensures that structures built using this material will have a reduced carbon footprint over their lifecycle.The introduction of the lightweight steel mesh has garnered significant attention within the construction industry, with developers and contractors expressing keen interest in adopting this innovative material for their upcoming projects. Its potential to enhance structural integrity, reduce construction costs, and contribute to sustainable building practices has positioned it as a game-changer in the industry.{Company Name} is committed to supporting its clients in integrating this revolutionary material into their projects. The company provides comprehensive technical support and consultation services to ensure that the lightweight steel mesh is seamlessly incorporated into construction plans, enabling clients to fully capitalize on the benefits it offers.The lightweight steel mesh has been met with enthusiasm from industry professionals, with many recognizing its potential to streamline construction processes and deliver superior results. As the demand for innovative and sustainable building materials continues to grow, the introduction of the lightweight steel mesh has positioned {Company Name} as a trailblazer in the construction sector.With its superior strength and durability, as well as its sustainable and cost-effective properties, the lightweight steel mesh is poised to redefine construction standards and set new benchmarks for excellence in the industry. As the uptake of this innovative material gains momentum, it is expected to become a staple in construction projects, offering a compelling solution for developers, contractors, and property owners alike.

Discover the Versatility and Benefits of Metal Mesh Grid in Various Applications

Title: Innovative Metal Mesh Grid Developed to Revolutionize Industrial ApplicationsIntroduction:In this rapidly evolving world of advanced technology, companies strive to make groundbreaking innovations that cater to the growing demands of various industries. One such company, (Company Name), has recently introduced a revolutionary Metal Mesh Grid that promises to revolutionize industrial applications with its exceptional efficiency and durability. Combining state-of-the-art technology with years of expert research, this new product is set to transform multiple sectors, from transportation to telecommunications and more.I. The Development of the Metal Mesh Grid:The (Company Name) Metal Mesh Grid represents a significant advancement in the field of industrial materials. Built upon meticulous research and development, this cutting-edge grid has been engineered to surpass traditional alternatives in terms of efficiency, strength, and versatility. The company's team of skilled engineers, scientists, and innovators have employed advanced manufacturing techniques and materials to create a product that delivers exceptional performance across numerous applications.II. Unparalleled Performance and Reliability:The Metal Mesh Grid boasts several features that set it apart from conventional grids used in industrial settings. Firstly, it exhibits remarkable strength, ensuring enhanced durability under challenging conditions. This makes it suitable for a wide range of applications, including automotive manufacturing, telecommunications infrastructure development, aerospace engineering, and electrical components production.Furthermore, the Metal Mesh Grid offers outstanding electrical conductivity and thermal management capabilities. Its advanced design allows for efficient heat dissipation, reducing the risk of component failure and increasing the overall operational lifespan of various devices and systems. By utilizing this grid, industries can enhance their productivity, reduce maintenance costs, and increase overall efficiency.III. Versatility and Adaptability:One of the most striking aspects of the Metal Mesh Grid is its adaptability to numerous industrial sectors. Whether in the automotive industry, where it enhances structural integrity and electromagnetic shielding, or in telecommunications, where it ensures seamless wireless connectivity, this grid emerges as a game-changer. This exceptional versatility offers industries the opportunity to improve their products and operations across various applications.IV. Environmental Sustainability:In addition to its remarkable performance, the Metal Mesh Grid also incorporates a commitment to sustainability. It is manufactured using environmentally friendly materials and processes, aligning with the company's dedication to reducing the ecological impact of industrial production. By incorporating this grid into their operations, companies can contribute to a greener future while maximizing efficiency and performance.V. Industry Adoption and Future Prospects:Given its numerous advantages, the Metal Mesh Grid is already gaining traction among influential players in various industries. Collaborations with leading automobile manufacturers, technology giants, and infrastructure developers are underway, further cementing its position as an indispensable component in industrial applications.Looking ahead, the company remains committed to continuous innovation and improvement. With ongoing research and development efforts, they aim to expand the range of applications for the Metal Mesh Grid, ensuring its relevance and significance across diverse industries in the future.Conclusion:The emergence of the groundbreaking Metal Mesh Grid from (Company Name) signifies a significant leap forward in industrial material engineering. With exceptional strength, versatility, and environmental sustainability, this innovative product has the potential to revolutionize industries ranging from transportation to telecommunications. As companies across various sectors adopt this grid, they can benefit from enhanced performance, increased operational lifespan, and reduced environmental impact. As research and development continue, the future possibilities of the Metal Mesh Grid remain boundless, promising to reshape industrial applications for many years to come.

Top Sintered Mesh Filter Disc: Enhance Filtration Efficiency with Advanced Technology

Title: Leading Manufacturer Unveils Cutting-Edge Sintered Mesh Filter Disc, Revolutionizing Filtration SystemsIntroduction:In the rapidly evolving world of filtration technology, renowned industry leader, Manufacturing Co., is making waves with its latest breakthrough - the groundbreaking Sintered Mesh Filter Disc. With an unwavering commitment to innovation and excellence, the company has once again raised the bar by revolutionizing filtration systems across various industries.Body:1. Unveiling the Sintered Mesh Filter Disc:Manufacturing Co. proudly presents the highly-anticipated Sintered Mesh Filter Disc, a cutting-edge product set to transform the way particles are filtered across numerous applications. This advanced filter disc combines superior materials, precision manufacturing, and innovative design to deliver unmatched performance, improved efficiency, and prolonged service life.2. Unparalleled Filtration Efficiency:The Sintered Mesh Filter Disc boasts an exceptionally high level of filtration efficiency, enabling it to remove even the tiniest particles with remarkable accuracy. The tightly-knit mesh structure ensures an optimal flow rate, allowing for efficient filtration while maintaining minimal pressure drop. This remarkable feature makes it an ideal choice for industries such as pharmaceuticals, petrochemicals, food and beverage, and wastewater treatment.3. Enhanced Durability and Longevity:Manufacturing Co.'s Sintered Mesh Filter Disc is built to withstand harsh conditions and extreme temperatures, making it a highly durable and reliable filtration solution. The carefully selected sintered mesh materials enable the disc to resist corrosion and oxidation, ensuring a prolonged service life compared to traditional filters. This longevity translates into significant cost savings for industries that heavily rely on filtration systems.4. Versatile Applications:The versatility of the Sintered Mesh Filter Disc is a standout feature, as it can be seamlessly integrated into various applications across diverse industries. Its exceptional filtration efficiency, coupled with the ability to withstand high pressure and temperature, makes it an excellent choice for applications such as gas and liquid separation, catalyst recovery, polymer filtration, and more. The adaptability and wide range of applications make this filter disc a truly indispensable component in numerous industrial processes.5. Quality Manufacturing Process:Manufacturing Co. employs state-of-the-art manufacturing techniques to ensure the highest level of quality and precision during the production of the Sintered Mesh Filter Disc. Relying on advanced sintering technology, the company achieves a perfectly uniform and robust mesh structure, resulting in consistent performance and exceptional product reliability. Additionally, a stringent quality control process is implemented at every stage to guarantee that each filter disc meets or exceeds industry standards.6. Commitment to Sustainability:As a responsible manufacturer, Manufacturing Co. prioritizes sustainability in every aspect of its operations. The Sintered Mesh Filter Disc reflects this commitment, as it is designed for ease of maintenance and cleaning, effectively reducing waste and minimizing the need for frequent replacements. With its exceptional durability and longevity, the filter disc plays a pivotal role in promoting eco-friendly practices within the industry.Conclusion:Manufacturing Co's introduction of the state-of-the-art Sintered Mesh Filter Disc marks a significant milestone in the evolution of filtration technology. Combining exceptional filtration efficiency, enhanced durability, and unmatched versatility, this groundbreaking product is set to revolutionize filtration systems across a wide range of industries. With a steadfast commitment to innovation and sustainability, Manufacturing Co. continues to be at the forefront of delivering cutting-edge solutions that address the evolving needs of global industries.

PVC Coated Gabion Wire Mesh for River Protection - High-Quality and Durable

, Gabion Wire Mesh, PVC Coated Wire Mesh, River Protection, China manufacturer, QualityProtecting our rivers and other natural water bodies is essential to maintaining the environment's balance, and one of the most effective ways to do this is by using gabion wire mesh. Gabion wire mesh is a type of mesh made from galvanized steel wires that are woven together to form hexagonal boxes or baskets that can be filled with stones or other materials.One of the most popular types of gabion wire mesh is PVC coated Galfan gabion wire mesh, which is coated with PVC to make it resistant to corrosion and wear. Galfan wire mesh is made from a combination of zinc and aluminum, making it more durable and long-lasting than traditional galvanized wire mesh.Combined with PVC coating, Galfan gabion wire mesh becomes a formidable tool for river protection. The PVC coating ensures that the mesh can withstand exposure to water and other environmental factors, which is essential for protecting rivers that are prone to flooding.The 2 x 1 x 0.5 meters size of Galfan gabion wire mesh is perfect for river protection projects, as it is large enough to provide significant protection while still being manageable and easy to install. Additionally, Galfan gabion wire mesh is incredibly versatile and can be used to create a wide variety of structures, including retaining walls, erosion control barriers, and even decorative landscaping features.When choosing a Galfan gabion wire mesh manufacturer, it is essential to find a reliable and trustworthy company that produces high-quality products. Chinese manufacturers are known for producing some of the best gabion wire mesh products on the market, and there are many China-based manufacturers of Galfan gabion wire mesh that produce top-quality products.If you are looking for PVC coated Galfan gabion wire mesh for river protection, it is important to do your research and find a reputable manufacturer. With the right Galfan gabion wire mesh, you can protect your local waterways, preserve the environment, and create beautiful and functional structures that will last for years to come.