Durable Wire Mesh Security Fence for Enhanced Protection and Safety

By:Admin

In today's uncertain times, ensuring the safety and security of businesses and residential areas is of utmost importance. With the rise in crime rates and security threats, it has become essential for property owners to invest in effective security measures. This is where the Wire Mesh Security Fence, offered by a leading company, comes into play.

The Wire Mesh Security Fence is a premium security solution that provides a high level of protection against unauthorized access and intruders. Made from high-quality steel wire, the fence is designed to be durable, robust, and tamper-resistant, making it an ideal choice for a wide range of applications, including commercial and industrial facilities, government buildings, and residential properties.

The company behind the Wire Mesh Security Fence is a renowned provider of innovative security solutions. With a reputation for delivering high-quality products and exceptional customer service, the company has established itself as a trusted partner for businesses and homeowners looking to enhance their security measures.

The Wire Mesh Security Fence is designed to meet the specific needs of different applications. The fence is available in a variety of heights, widths, and mesh sizes, allowing for customizability to suit the unique requirements of each property. Additionally, the fence can be further reinforced with additional security features, such as anti-climb spikes, barbed wire, and electronic detection systems, to provide an extra layer of protection.

One of the key advantages of the Wire Mesh Security Fence is its versatility. It can be installed in a variety of settings, including flat or sloping terrain, and can be adapted to accommodate changes in elevation and contours. This makes it an ideal choice for properties with diverse landscapes and architectural features.

Moreover, the Wire Mesh Security Fence is designed to be aesthetically pleasing, blending seamlessly with the surrounding environment while still maintaining a high level of security. The clean and modern design of the fence ensures that it does not detract from the overall look and feel of the property, making it an attractive choice for businesses and homeowners alike.

In addition to its security features, the Wire Mesh Security Fence is also easy to install and maintain. The fence is pre-fabricated and can be quickly and efficiently installed by a professional team, saving time and resources for property owners. Furthermore, the fence is designed to withstand harsh weather conditions and requires minimal maintenance, making it a cost-effective and long-term security solution.

The company behind the Wire Mesh Security Fence is committed to providing exceptional customer service and support throughout the entire process, from initial consultation to installation and ongoing maintenance. Their team of experienced professionals works closely with clients to understand their specific security needs and to develop customized solutions that best meet their requirements.

Overall, the Wire Mesh Security Fence is a reliable and effective security solution that offers peace of mind for businesses and homeowners. With its high level of protection, customizability, versatility, and aesthetic appeal, it is a top choice for anyone looking to enhance the security of their property.

To learn more about the Wire Mesh Security Fence and the company behind it, visit their website or contact them directly to discuss how the fence can benefit your property. Whether you are looking to protect your business, secure your home, or safeguard a public facility, the Wire Mesh Security Fence is the ideal choice for all your security needs.

Company News & Blog

Durable and Versatile Expanded Metal Mesh Cladding for Buildings

Expanded Metal Mesh Cladding: A Versatile and Sustainable Building SolutionIn today’s competitive and fast-paced construction industry, architects, designers, and developers are constantly seeking innovative and sustainable building materials that not only meet their aesthetic and functional requirements but also contribute to the overall sustainability and energy efficiency of the built environment. One such material that has gained significant popularity in recent years is expanded metal mesh cladding. This versatile and visually striking material has proven to be an excellent choice for a wide range of architectural applications, from façade cladding to interior partitioning, and has become a go-to solution for many design professionals seeking an innovative and sustainable alternative to traditional building materials.Expanded metal mesh cladding is a type of metal sheet that has been simultaneously slit and stretched into a diamond pattern, creating a lightweight and durable material with a unique visual appeal. Its open and transparent nature allows for natural ventilation and light transmission, making it an ideal choice for both exterior and interior applications. Additionally, the material’s inherent strength and rigidity make it suitable for a wide range of architectural applications, from decorative screens and sunshades to security fencing and building facades.One company at the forefront of manufacturing and supplying expanded metal mesh cladding products is {}. With a rich history and a strong commitment to quality and sustainability, {} has established itself as a leading provider of innovative architectural solutions that push the boundaries of design and construction. Their expanded metal mesh cladding products are known for their exceptional quality, versatility, and sustainability, making them a preferred choice for architects and designers around the world.{} has a wide range of expanded metal mesh cladding products, including standard and custom patterns, finishes, and colors, allowing for endless design possibilities. Whether it’s a striking façade for a commercial building, a decorative feature for a public space, or a functional partition for an interior space, {} offers a wide range of options to meet the unique requirements of every project. Their commitment to sustainability is evident in their use of recyclable materials, energy-efficient production processes, and emphasis on durability and longevity, ensuring that their expanded metal mesh cladding products contribute to the overall sustainability of the built environment.One of the key advantages of expanded metal mesh cladding is its ability to provide a balance between form and function. Its lightweight and open design allow for natural airflow and light penetration, reducing the need for artificial ventilation and lighting, thus contributing to energy efficiency and occupant comfort. Additionally, the material’s durability and low maintenance requirements make it a cost-effective and long-lasting solution for architectural applications, reducing the environmental impact associated with frequent maintenance and replacement of building materials.Another notable advantage of expanded metal mesh cladding is its adaptability to various design requirements. Whether it’s a sleek and modern aesthetic or a more traditional and intricate pattern, expanded metal mesh cladding can be customized to meet the unique design vision of each project. With the ability to be formed, shaped, and finished in a variety of ways, the material offers endless possibilities for creating visually striking and functional architectural elements that leave a lasting impression.As the demand for sustainable and innovative building materials continues to grow, expanded metal mesh cladding has emerged as a frontrunner in the architectural industry. Its versatility, sustainability, and visual appeal have made it a go-to choice for architects and designers looking to push the boundaries of design while prioritizing environmental responsibility. With a commitment to quality, innovation, and sustainability, {} is poised to continue leading the way in providing exceptional expanded metal mesh cladding solutions for the built environment.In conclusion, expanded metal mesh cladding is a versatile and sustainable building material that offers a range of benefits for architectural applications. With its unique visual appeal, durability, and adaptability, it has become a preferred choice for architects, designers, and developers seeking innovative and environmentally responsible solutions. With the leadership and expertise of companies like {}, expanded metal mesh cladding is set to play a significant role in shaping the future of sustainable and visually striking architecture.

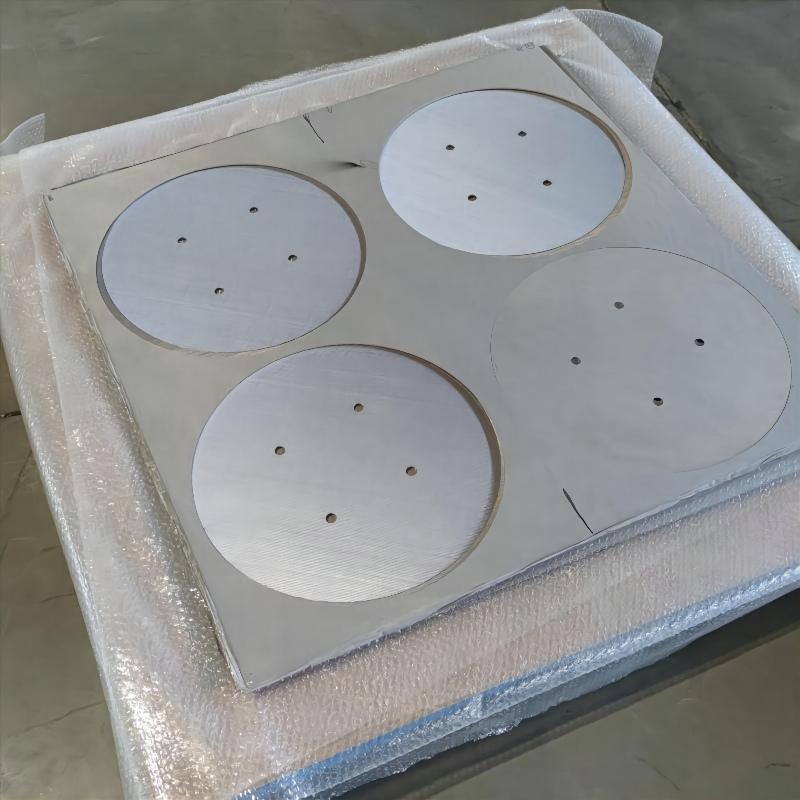

Durable and Reliable Metal Porous Sintered Filter for Industrial Use

Metal Porous Sintered Filter Enhances Filtration Efficiency for Various IndustriesIn today's rapidly evolving industrial landscape, the importance of efficient filtration solutions cannot be overstated. Whether it's in the automotive, aerospace, chemical, or petrochemical industries, the need for precise and reliable filtration systems is paramount. This is where the Metal Porous Sintered Filter, produced by a leading filtration technology company, comes into play. This innovative product has proven to be a game-changer for industries looking to enhance their filtration processes and ensure optimal performance.The Metal Porous Sintered Filter is a cutting-edge filtration solution that offers a combination of high efficiency, durability, and versatility. Its unique design and advanced materials make it an ideal choice for a wide range of applications. From removing impurities in liquids and gases to capturing particles of varying sizes, this filter excels in delivering superior performance across different industrial settings.The secret behind the success of the Metal Porous Sintered Filter lies in its construction. The filter is made from high-quality metal powders that are sintered together to create a porous structure with precise and uniform pore sizes. This sophisticated manufacturing process results in a filter that is capable of achieving exceptional levels of particle retention while maintaining high flow rates. Additionally, the filter's robust construction allows it to withstand extreme temperatures and corrosive environments, making it a reliable and long-lasting solution for demanding industrial applications.One of the key advantages of the Metal Porous Sintered Filter is its adaptability to diverse filtration requirements. With the ability to customize pore sizes, thickness, and overall dimensions, the filter can be tailored to meet specific filtration needs, ensuring optimal performance in different operating conditions. This flexibility makes it an ideal choice for industries that demand precision and reliability in their filtration processes.Furthermore, the Metal Porous Sintered Filter is designed to be easily integrated into existing filtration systems, allowing for seamless upgrades without the need for extensive retooling or modifications. This feature not only enhances the filter's convenience but also makes it a cost-effective solution for businesses looking to improve their filtration efficiency.The company behind the Metal Porous Sintered Filter has established itself as a leader in the field of filtration technology. With a strong focus on research and development, the company has continuously pushed the boundaries of filtration innovation, bringing to market products that set new standards for performance and reliability.With a team of highly skilled engineers and experts, the company is committed to providing comprehensive filtration solutions that address the evolving needs of modern industries. Moreover, the company's dedication to quality and customer satisfaction has earned it a reputation for excellence, with a growing list of clients who rely on its products to ensure the smooth operation of their processes.In addition to the Metal Porous Sintered Filter, the company offers a comprehensive range of filtration products and services, including custom filtration solutions, technical support, and maintenance services. This holistic approach allows the company to cater to the unique requirements of each customer, providing them with tailored solutions that deliver maximum value and performance.Looking ahead, the company remains focused on driving innovation in filtration technology, with a commitment to staying ahead of industry trends and continually raising the bar for filtration efficiency. By leveraging its expertise and resources, the company aims to further expand its product portfolio and enhance its capabilities, ensuring that it continues to be at the forefront of filtration innovation.In conclusion, the Metal Porous Sintered Filter represents a significant advancement in filtration technology, offering unparalleled efficiency, durability, and versatility for a wide range of industrial applications. Backed by a company with a proven track record of excellence and a commitment to innovation, this filter is poised to play a pivotal role in shaping the future of filtration. As industries continue to evolve and demand higher standards for filtration performance, the Metal Porous Sintered Filter stands ready to meet and exceed these expectations, providing businesses with a reliable and effective solution for their filtration needs.

Nickel Mesh and Screen: Material, Specification, Packing - Corrosion and Acid Resistant Filter Mesh for High Temperature Filtration

article about the benefits of using nickel wire mesh and screen in various industrial applications.Nickel wire mesh and screen have become increasingly popular in various industrial applications, thanks to their unique properties. As a manufacturer and supplier of high-quality nickel wire mesh, {company name} understands the numerous benefits that this material provides for industrial filtration and screening processes.Nickel wire mesh is highly durable and resistant to both corrosion and acid, making it an ideal material for use in harsh and high-temperature environments. This property makes nickel wire mesh and screen suitable for use in various industries, such as chemical and petrochemical production, power generation, and mining.One of the primary benefits of using nickel wire mesh is its high-level filtration. Nickel wire mesh filters and screens are capable of separating and removing very fine particles from liquids or gases, making them an essential material in many manufacturing and industrial processes. In these industries, even the tiniest of impurities can cause machinery to malfunction or fail, leading to costly repairs, downtime, and potential safety hazards.Nickel wire mesh and screen also exhibit excellent electrical conductivity properties. This makes them ideal for use in electrical and electronic industries, where they can be used as electrodes or screens for electromagnetic shielding. Since nickel has good magnetic properties, it is also used in electrical transformers and inductors.In addition to its unique properties, nickel wire mesh and screen are available in different specifications and mesh sizes. This versatility makes it possible for {company name} to offer a wide range of custom nickel wire mesh products tailored to meet specific industry requirements. Customers can choose from woven, knitted, perforated, or expanded nickel wire mesh depending on their application needs.To ensure the safety of nickel wire mesh products during transportation or storage, {company name} pays significant attention to the packing requirements. The company uses durable packing materials and techniques to ensure its products remain in good condition and reach customers in perfect condition.In conclusion, nickel wire mesh and screen are versatile materials that offer a range of benefits for various industrial applications. With their high durability, resistance to corrosion and acid, and excellent filtration properties, nickel wire mesh has become an essential material in industries such as chemical production, power generation, and mining, among others. As a reputable manufacturer and supplier of nickel wire mesh products, {company name} is dedicated to providing its customers with high-quality custom nickel wire mesh products and excellent customer service.

High-Quality Nickel Wire Mesh: Everything You Need to Know

Nickel Wire Mesh has become a vital component in the industrial and commercial sectors due to its versatile properties and high-quality performance. The mesh is made of pure nickel, which makes it highly resistant to corrosion, as well as offering excellent strength and durability. It is widely used in various applications such as filtration, separation, and sieving processes, across a wide range of industries including aerospace, automotive, chemical, and pharmaceutical.Company Introduction:Founded in 2005, our company has been a leading manufacturer and supplier of high-quality wire mesh products, including nickel wire mesh. Our state-of-the-art manufacturing facility is equipped with advanced technology and machinery to ensure precision and consistency in our products. We have a team of experienced engineers and technicians who are dedicated to ensuring that our products meet the highest quality standards and exceed customer expectations. With a strong commitment to innovation and customer satisfaction, we have built a reputation for delivering reliable and high-performance wire mesh solutions to our clients worldwide.The nickel wire mesh manufactured by our company is known for its exceptional resistance to extreme temperatures and chemicals, making it an ideal choice for demanding industrial applications. The mesh is available in various weave patterns and mesh sizes to suit specific requirements, and can also be custom-made to meet the unique needs of our customers.One of the key features of our nickel wire mesh is its ability to withstand harsh operating conditions without compromising its structural integrity. This makes it a preferred choice for applications that require high strength and long-term reliability, such as in the aerospace and automotive industries. Additionally, the corrosion-resistant properties of nickel make it an excellent material for filtration and separation processes in the chemical and pharmaceutical sectors, where purity and cleanliness are critical.Our commitment to quality and customer satisfaction extends beyond the manufacturing process. We provide comprehensive technical support and assistance to help our clients select the right nickel wire mesh product for their specific applications. Our team works closely with customers to understand their unique requirements and develop customized solutions that deliver optimum performance and value.In addition to our standard range of nickel wire mesh products, we also offer a range of value-added services including cutting, shaping, and finishing to ensure that our customers receive a complete wire mesh solution that meets their exact specifications. Our goal is to provide a seamless and hassle-free experience for our customers, from product selection to delivery and installation.As a socially responsible company, we prioritize sustainability and environmental stewardship in our manufacturing processes. We adhere to strict environmental standards and regulations to minimize our ecological footprint and ensure that our products are environmentally friendly. Our nickel wire mesh is produced using eco-friendly practices and materials, making it a sustainable choice for our environmentally-conscious customers.With a strong focus on innovation and continuous improvement, our company remains at the forefront of the wire mesh industry, offering cutting-edge solutions that meet the evolving needs of our customers. Our commitment to quality, reliability, and customer satisfaction has positioned us as a trusted partner for businesses across various industries, seeking high-performance wire mesh solutions.In conclusion, the versatility and performance of nickel wire mesh make it an indispensable material in the industrial and commercial sectors. With our company's dedication to quality, innovation, and customer satisfaction, we are proud to offer high-quality nickel wire mesh products that meet the highest standards and exceed expectations. Our commitment to sustainability and environmental responsibility further reinforces our position as a leading provider of premium wire mesh solutions for businesses worldwide.

Durable Stainless Steel Sintered Mesh for Various Applications

Stainless Steel Sintered Mesh: A High-Quality Solution for Filtration NeedsIn the world of industrial filtration, finding the right material for the job is crucial. Whether it's for separating solids from liquids or gases, having a reliable and efficient filtration system can make all the difference in the quality and functionality of a product. This is where stainless steel sintered mesh comes into play.Stainless steel sintered mesh is a high-quality and reliable material that is widely used in various industries for its excellent filtration properties. It is made by sintering multiple layers of woven wire mesh together, creating a strong and durable material that is ideal for various filtration applications.One company that has become a leading supplier of stainless steel sintered mesh is {}. With years of experience and expertise in the field of filtration, they have developed a range of high-quality sintered mesh products that are designed to meet the diverse needs of their customers.The company's stainless steel sintered mesh is known for its excellent filtration efficiency, high strength, and long service life. It is available in a variety of dimensions and pore sizes, making it suitable for a wide range of filtration applications, including oil and gas filtration, water treatment, pharmaceuticals, aerospace, and more.One of the key advantages of stainless steel sintered mesh is its ability to withstand high temperatures and corrosive environments. This makes it an ideal choice for applications that require resistance to heat, chemicals, and wear. Additionally, its uniform pore size distribution and high dirt holding capacity make it an efficient and cost-effective solution for filtration needs.In addition to their standard sintered mesh products, {} also offers custom sintered mesh solutions to meet specific customer requirements. Their team of experts works closely with clients to understand their filtration needs and provide tailored solutions that are designed to deliver optimum performance and efficiency.With a strong commitment to quality and customer satisfaction, {} has earned a reputation for delivering reliable and high-performance filtration products. Their stainless steel sintered mesh is manufactured using advanced production techniques and quality control processes to ensure consistent quality and performance.Furthermore, the company's dedication to innovation and continuous improvement has allowed them to stay at the forefront of the filtration industry. They invest in research and development to explore new technologies and materials, with the goal of bringing cutting-edge filtration solutions to the market.As a responsible and environmentally conscious company, {} also prioritizes sustainability in their manufacturing processes. They adhere to strict environmental standards and utilize eco-friendly practices to minimize their impact on the environment.Looking ahead, {} is poised to continue its leadership in the filtration industry, offering innovative and sustainable solutions that meet the evolving needs of their customers. With their commitment to quality, reliability, and customer satisfaction, they are well-positioned to be the go-to supplier for stainless steel sintered mesh and other filtration products.In conclusion, stainless steel sintered mesh is a high-quality and versatile material that is ideal for a wide range of filtration applications. With its excellent filtration properties and durability, it has become a popular choice for industries around the world. And with {}'s expertise and commitment to excellence, customers can trust that they are getting the best filtration solutions for their needs.

Porous Sintered Metal: A Comprehensive Guide

Porous sintered metal has revolutionized the way we think about filtration and separation processes. This innovative material is a game-changer in industries such as oil and gas, pharmaceuticals, food and beverage, and many others, offering efficient and cost-effective solutions for a wide range of applications.Porous sintered metal, also known as porous metal, is a versatile material made from powdered metal that is compacted and sintered together to create a structure with interconnected pores. This unique structure allows for the passage of gas or liquid while retaining solid particles, making it an ideal material for filtration and separation processes.The use of porous sintered metal has become increasingly popular due to its high strength, corrosion resistance, and temperature resistance. It is also highly customizable, allowing for the creation of filters with specific pore sizes and flow characteristics to suit individual process requirements.One company at the forefront of porous sintered metal technology is {}, a leading manufacturer and supplier of porous metal products. With decades of experience in the industry, {} has established itself as a trusted partner for businesses seeking reliable and efficient filtration solutions.{} offers a wide range of porous sintered metal products, including filter elements, filter discs, and filter plates, designed to meet the diverse needs of various industries. These products are manufactured using state-of-the-art sintering processes and are available in a variety of metals, such as stainless steel, bronze, and nickel, to ensure compatibility with different operating conditions and media.In addition to standard products, {} also specializes in custom filtration solutions, working closely with clients to develop tailored porous metal products that meet specific application requirements. From design and prototyping to production and testing, {} provides comprehensive support throughout the entire development process, ensuring that each custom filtration solution delivers optimum performance and reliability.One of the key advantages of partnering with {} is the company's commitment to quality and innovation. With a team of experienced engineers and metallurgists, {} continuously explores new technologies and materials to enhance the performance and efficiency of porous sintered metal products. This dedication to innovation has enabled {} to stay ahead of the competition and deliver cutting-edge filtration solutions to its customers.Furthermore, {} places a strong emphasis on customer satisfaction, offering technical assistance, responsive communication, and on-time delivery to ensure a seamless experience for its clients. The company's dedication to excellence has earned it a solid reputation in the industry, with a growing list of satisfied customers who rely on {} for their filtration needs.As the demand for efficient and reliable filtration solutions continues to grow, the use of porous sintered metal is expected to become even more widespread across different industries. With its unrivaled expertise and commitment to quality, {} is well-positioned to lead the way in this evolving field, providing innovative porous metal products that drive operational efficiency and cost savings for businesses worldwide.In conclusion, porous sintered metal has emerged as a groundbreaking material for filtration and separation applications, offering unmatched durability, versatility, and customization options. With its extensive experience, dedication to innovation, and focus on customer satisfaction, {} stands out as a leading provider of porous metal solutions, setting new standards for performance and reliability in the industry.

Exporters of High-Quality Nickel Alloy Wire Mesh and Netting in Mumbai

and High Nickel Alloy Wire Netting.High Nickel Alloy Wire Mesh and Wire Netting – An OverviewHigh Nickel Alloy Wire Mesh and Wire Netting are widely used across various industries for their excellent strength and resistance to harsh environments. These materials are composed of nickel and other notable alloying elements such as copper, chromium, and molybdenum, among others. These alloys are known for their high corrosion resistance, good thermal conductivity, and excellent mechanical properties.Sanghvi Overseas is a leading supplier and exporter of ASTM B160 / ASME SB160 Nickel & High Nickel Alloy Wire Mesh / Wire Netting, including Nickel Alloy 200 Wire Mesh and High Nickel Alloy 201 Wire Netting. Sanghvi Overseas has an extensive network of global clients and is committed to providing the highest quality materials at competitive prices.Nickel Alloy 200 Wire MeshNickel Alloy 200 Wire Mesh is a commercially pure nickel material that has excellent resistance to corrosive environments. This alloy has low carbon content and is resistant to caustic soda and other alkaline solutions. It has high electrical conductivity and is used as an electrode in various industrial applications. The material has a maximum operating temperature of 315 degrees Celsius and is suitable for use in chemical processing plants, marine installations, and power generation stations.High Nickel Alloy 201 Wire NettingHigh Nickel Alloy 201 Wire Netting is similar to Nickel Alloy 200 but has a lower carbon content, which gives it a slightly higher thermal conductivity and reduced embrittlement at elevated temperatures. This material is also highly resistant to corrosion and is suitable for use in reducing and oxidizing environments. It is commonly used in food processing plants, chemical and petrochemical industries, seawater handling equipment, and nuclear power generation plants.Other High Nickel Alloy Wire Mesh and Wire NettingSanghvi Overseas also supplies other high nickel alloy wire mesh and wire netting materials, including:- Monel Alloy 400 Wire Mesh- Monel Alloy K500 Wire Mesh- Inconel Alloy 600 Wire Mesh- Inconel Alloy 601 Wire Mesh- Incoloy Alloy 800 Wire Mesh- Incoloy Alloy 800H Wire Mesh- Hastelloy Alloy C276 Wire Mesh- Hastelloy Alloy C22 Wire MeshThese materials offer similar properties to Nickel Alloy 200 and High Nickel Alloy 201, but with varying levels of added elements to suit specific applications.Why Choose Sanghvi Overseas for High Nickel Alloy Wire Mesh and Wire Netting?Sanghvi Overseas is a trusted supplier and exporter of high-quality High Nickel Alloy Wire Mesh and Wire Netting materials. The company has an extensive network of global clients and has a reputation for providing the highest quality materials at competitive prices. They have a team of experts who are experienced in selecting the right material for each application and are committed to delivering products on time and to the highest quality standards.ConclusionHigh Nickel Alloy Wire Mesh and Wire Netting are essential materials used in various industries, including chemical processing, marine installations, power generation, and food processing. These materials are highly resistant to corrosion, have excellent thermal conductivity, and offer good mechanical properties. Sanghvi Overseas is a trusted supplier and exporter of these materials, providing the highest quality products at competitive prices. Contact them for more information on their products and services.

Durable and Versatile Woven Wire Mesh for Various Applications

Woven wire mesh is a versatile material that has found applications in various industries, including construction, agriculture, mining, and architecture. The mesh is made by weaving wires together to create a durable and flexible material that can be used for a wide range of applications.One company that has been at the forefront of producing high-quality woven wire mesh is {}, a leading manufacturer and supplier of industrial wire mesh products. With over 20 years of experience in the industry, {} has established a reputation for delivering top-notch products that meet the highest standards of quality and performance.The company's woven wire mesh products are known for their durability, strength, and versatility. They are used in a wide range of applications, including filtration, screening, and separation. The mesh is available in various materials, including stainless steel, galvanized steel, and aluminum, and can be customized to meet the specific requirements of different industries.One of the key advantages of using woven wire mesh is its ability to withstand harsh environmental conditions, making it ideal for outdoor applications such as fencing, animal enclosures, and agricultural use. The mesh is also widely used in the construction industry for reinforcing concrete and providing structural support.In addition to its practical applications, woven wire mesh is also used for decorative purposes in architecture and interior design. Its intricate patterns and textures can add a unique aesthetic appeal to buildings and spaces, making it a popular choice for designers and architects.{} takes pride in its commitment to quality and customer satisfaction. The company's team of skilled professionals works closely with clients to understand their specific needs and provide tailored solutions that meet their requirements. By using advanced manufacturing techniques and adhering to strict quality control measures, {} ensures that its woven wire mesh products are of the highest quality and reliability.As a socially responsible company, {} is also focused on sustainability and environmental conservation. The company sources its materials from reputable suppliers and adheres to eco-friendly manufacturing practices to minimize its environmental impact. This commitment to sustainability has earned {} the trust and respect of its customers and partners.With a strong focus on innovation and continuous improvement, {} continues to expand its product range and explore new applications for woven wire mesh. The company invests in research and development to stay ahead of market trends and technological advancements, ensuring that its products remain at the forefront of the industry.In conclusion, woven wire mesh is a versatile and indispensable material that has a wide range of applications across different industries. As a leading manufacturer and supplier of industrial wire mesh products, {} has established itself as a trusted provider of high-quality woven wire mesh solutions. With a commitment to quality, customer satisfaction, and sustainability, {} continues to set the standard for excellence in the industry and looks set to maintain its position as a market leader for years to come.

Innovative Disc Screen Filter Technology for Effective Filtration and Waste Management

Disc Screen Filter: A Game-Changer in Industrial Waste Water TreatmentIn today's world, companies are constantly searching for innovative and more efficient ways to treat industrial waste water, while also reducing their environmental impact. With the introduction of the Disc Screen Filter, companies now have a game-changing solution that not only meets the stringent regulatory requirements for waste water treatment, but also improves operational efficiency and reduces costs.The Disc Screen Filter, developed and manufactured by a leading environmental technology company, is a state-of-the-art filtration system designed to effectively remove solid waste particles from industrial waste water. It utilizes a series of rotating discs with fine mesh screens to capture and separate solid particles from the water stream. This unique filtration process ensures that even the smallest particles are effectively removed, resulting in high-quality treated water that meets regulatory standards.One of the key advantages of the Disc Screen Filter is its ability to handle a wide range of industrial waste water streams, including those with high levels of contaminants and varying particle sizes. This versatility makes it an ideal solution for industries such as food and beverage processing, pulp and paper manufacturing, mining, and chemical production, among others. Additionally, the system can be customized to accommodate specific flow rates and particle size distributions, providing companies with a tailored solution that meets their unique waste water treatment needs.In addition to its superior filtration capabilities, the Disc Screen Filter offers several operational benefits that can make a significant impact on a company's bottom line. The system is designed for continuous automated operation, minimizing the need for manual intervention and reducing labor costs. Furthermore, its compact design requires minimal space, making it suitable for both new and existing waste water treatment facilities. Its low energy consumption and minimal maintenance requirements further contribute to its cost-effectiveness, providing significant long-term savings for companies.Furthermore, the Disc Screen Filter is equipped with advanced monitoring and control systems that allow for real-time performance tracking and optimization. This technology not only ensures consistent and reliable operation but also provides valuable data for process analysis and improvements. With this level of automation and control, companies can achieve optimal waste water treatment efficiency while minimizing the risk of non-compliance with regulatory standards.The environmental benefits of the Disc Screen Filter cannot be overstated. By effectively removing solid waste particles from industrial waste water, the system helps companies reduce their environmental footprint and minimize the risk of contaminating natural water sources. This not only safeguards the local ecosystem but also enhances corporate sustainability credentials, which are increasingly important for companies seeking to demonstrate their commitment to environmental responsibility.It is clear that the Disc Screen Filter represents a significant advancement in industrial waste water treatment technology, offering a range of benefits that meet the needs of modern industry. Its robust filtration capabilities, operational efficiency, and environmental advantages make it an attractive solution for companies seeking to improve their waste water treatment processes.As sustainability and environmental stewardship continue to be key priorities for companies worldwide, the Disc Screen Filter has emerged as a valuable tool for achieving waste water treatment goals while also ensuring cost-effective and responsible operations. With its proven track record and ongoing innovation, the Disc Screen Filter is poised to play a pivotal role in the future of industrial waste water treatment.

Production Line for Expanded Metal Mesh Architrave Beads for Expansion Joints

Expansion Joint Beads – The Backbone of a Strong ConstructionOne of the most important aspects of any construction project is ensuring its durability and longevity. An expansive joint is one of the solutions to the problem of cracks and movement in a building or structure over time. The perfect partner in achieving this is an expansion joint bead.Expansion joint beads, also known as casing beads, are a fundamental component that is used in building and construction projects that require joints. These are thin, durable metal strips that are designed to cover and seal the gaps created between different areas of a structure, such as floors, walls, and ceilings.Casing beads are most commonly used in the construction industry for exterior wall finishes, helping to create a smooth and protective finish around the windows and doors. These beads are also instrumental in reinforcing the integrity of the structure by creating a barrier between the wall surfaces and the window or door frames.Anber expanded metal mesh machine architrave beads production line is a prime example of a top-of-the-line manufacturing process that produces superior quality expansion joint beads. These beads are made from high-quality, corrosion-resistant raw materials and are manufactured through a meticulous, highly advanced production process. In this way, users of Anber Expanded Mesh Casing Bead can be assured of their quality and longevity.There are various types of casings available, such as PVC or plastic beads, but nothing compares to the strength and durability of metal casing beads. Metal joint expansion beads are generally more long-lasting and reliable and guarantee that the structure will remain stable for many years to come.Expanded Architrave Bead Machine offers an assortment of customization options that cater to different demands in constructing buildings. From standard sizes to varying lengths and widths, designs, and colors, it is an adaptable material that can provide an excellent aesthetic and practical finish to the surfaces.The benefits of using expansion joint beads are numerous. Here are some of the most notable:1. Durability: Metal casing beads, particularly those made of galvanized steel, are extremely durable and offer excellent resistance to rust and weather conditions.2. Strength: Casing beads serve as an additional support to the structure and provide extra durability.3. Easy to install: Joint expansion beads are straightforward to install and require no specialized tools or equipment.4. Cost-effective: Metal joint expansion beads offer better value for money than other types of casings due to their longevity and durability.5. Aesthetic finish: With the various options available, casing beads can add an elegant and professional finish to any construction project.In conclusion, it is essential to choose the right materials and ensure proper installation when working on any construction project. Expansion joint beads are an indispensable component in creating a strong and long-lasting structure. With a reliable and reputed supplier like Anber Expanded Mesh Casing Bead, construction professionals and DIY enthusiasts can achieve their desired results with ease and confidence.