Durable Stainless Steel Metal Mesh for Various Applications

By:Admin

In recent years, industrial material technology has experienced significant advancements and innovations. One of the latest breakthroughs in this field is the development of stainless steel metal mesh, a versatile and durable material that has a wide range of applications in various industries. The development of this innovative material has been made possible through the dedicated efforts of skilled engineers and experts at [Company Name], a leading manufacturer and supplier of industrial materials.

[Company Name] has been at the forefront of industrial material innovation, constantly striving to develop and incorporate state-of-the-art technologies in its products. The development of stainless steel metal mesh is a testament to the company's commitment to pushing the boundaries of what is possible in the realm of industrial materials. This new material promises to revolutionize the way various industries approach their manufacturing processes and product development. Through its exceptional strength, durability, and versatility, stainless steel metal mesh has quickly become a highly sought-after material in the industrial sector.

Stainless steel metal mesh is a woven material made from high-quality stainless steel wires. The construction of the mesh involves intricate weaving patterns that ensure its strength and stability. This unique construction allows the metal mesh to withstand high temperatures, corrosion, and impact, making it suitable for a wide range of industrial applications. The material is available in various weave patterns and wire diameters, allowing for customization to meet specific project requirements.

One of the key features of stainless steel metal mesh is its exceptional durability. Unlike traditional materials, such as plastics or non-metallic meshes, stainless steel metal mesh is highly resistant to wear and tear, ensuring a longer service life and reducing the need for frequent replacements. This makes it an ideal material for applications that require reliability and longevity, such as filtration, screening, and sieving.

Furthermore, the versatility of stainless steel metal mesh makes it suitable for diverse industrial applications. It can be used in the construction of architectural facades, interior design elements, and industrial partitions. Additionally, the material is widely employed in the food and beverage, pharmaceutical, and chemical industries for filtration, sieving, and separation processes. Its resistance to corrosion and high temperatures makes it an ideal choice for applications that demand hygienic and sterile conditions.

The development of stainless steel metal mesh has opened up new possibilities for engineers, designers, and manufacturers, allowing them to explore innovative solutions in their respective fields. The material’s unique properties enable the creation of lightweight yet robust structures, offering new design possibilities for architects and builders. In the manufacturing sector, stainless steel metal mesh has become an essential material for process optimization, enhancing productivity and efficiency.

[Company Name] takes pride in its commitment to quality and innovation. The company's advanced manufacturing facilities and stringent quality control processes ensure that its stainless steel metal mesh meets the highest industry standards. With a focus on sustainability and environmental responsibility, [Company Name] is dedicated to developing materials that are not only durable and reliable but also eco-friendly.

In conclusion, the development of stainless steel metal mesh represents a significant milestone in the field of industrial materials. This versatile and durable material has the potential to revolutionize various industries and bring about new opportunities for innovation and growth. With [Company Name] at the forefront of this technological advancement, the industrial sector can look forward to a future filled with resilient, sustainable, and high-performance materials.

Company News & Blog

High-Quality Stainless Steel Mesh for Various Applications

Fine Stainless Steel Mesh is a leading manufacturer of high-quality stainless steel mesh products. The company is known for its dedication to providing customers with durable, reliable, and versatile mesh solutions for a wide range of applications. With a commitment to innovation and superior customer service, Fine Stainless Steel Mesh has established itself as a trusted industry leader.The company's stainless steel mesh products are widely used in industries such as aerospace, automotive, construction, and filtration. Their mesh products are known for their strength, durability, and corrosion resistance, making them the ideal choice for demanding applications. Fine Stainless Steel Mesh offers a wide range of mesh sizes and configurations to meet the unique needs of their customers.In addition to their standard stainless steel mesh products, Fine Stainless Steel Mesh also offers custom solutions tailored to specific customer requirements. Their team of experienced engineers and technicians work closely with each customer to develop and produce custom mesh products that meet their exact specifications. This dedication to meeting customer needs has earned Fine Stainless Steel Mesh a reputation for excellence in the industry.Fine Stainless Steel Mesh is also committed to sustainable and responsible manufacturing practices. The company prioritizes environmentally friendly processes and materials, ensuring that their products are not only high-quality, but also eco-friendly. This commitment to sustainability sets Fine Stainless Steel Mesh apart as a leader in responsible manufacturing.In recent news, Fine Stainless Steel Mesh has announced the launch of a new line of stainless steel mesh products that are designed for use in high-temperature applications. The new products are engineered to withstand extreme heat, making them perfect for use in industrial ovens, heat exchangers, and other high-temperature environments. This expansion of their product line demonstrates Fine Stainless Steel Mesh's ongoing commitment to meeting the evolving needs of their customers."We are thrilled to introduce our new line of high-temperature stainless steel mesh products," said the spokesperson for Fine Stainless Steel Mesh. "We recognize the demand for reliable mesh solutions that can perform in extreme heat, and we are proud to offer our customers a range of products that meet and exceed their expectations. With our new high-temperature mesh products, customers can trust that they are investing in quality, durability, and performance."Fine Stainless Steel Mesh's dedication to innovation and customer satisfaction has made them a trusted partner for businesses across the globe. Their extensive experience, commitment to quality, and focus on customer needs have cemented their reputation as a leading manufacturer of stainless steel mesh products.As the demand for high-quality stainless steel mesh continues to grow, Fine Stainless Steel Mesh remains at the forefront of the industry, providing customers with reliable solutions that meet the highest standards of quality and performance. With their new line of high-temperature stainless steel mesh products, the company is poised to further solidify their position as a leader in the industry.

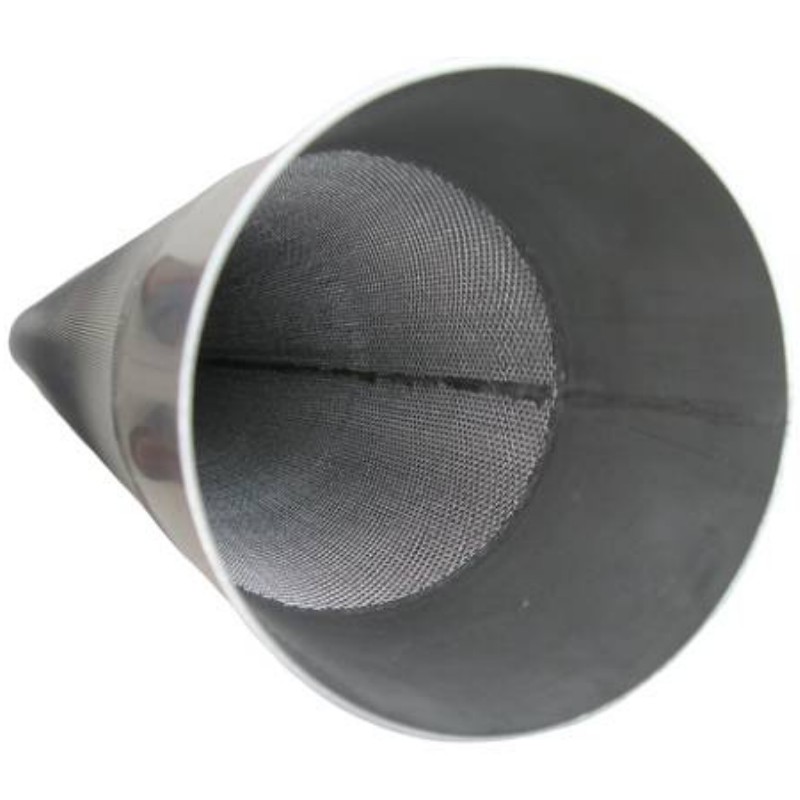

Top-Quality Stainless Steel Suction Strainer: A Reliable Solution for Effective Filtration

Stainless Steel Suction Strainers: A Reliable Solution for Industrial Filtration NeedsIndustrial filtration is an important process to maintain the quality and efficiency of machinery and equipment. Whether it is a chemical processing unit, water treatment plant, or any other manufacturing unit, the filtration process is essential to remove impurities and foreign particles from fluids and gases. To ensure proper filtration, the use of high-quality suction strainers is necessary. One such solution is Stainless Steel Suction Strainers, which are designed to provide reliable and efficient filtration in various industrial applications.Stainless Steel Suction Strainers are specially designed filters that are installed at the intake of suction lines to filter out contaminants from liquids before they enter the machine. They are typically made of high-quality stainless steel materials, which are known for their corrosion resistance, durability, and long-lasting performance. The strainers are available in various sizes and configurations to suit the specific filtration needs of different industries.One of the leading manufacturers of Stainless Steel Suction Strainers is a US-based company that has been in the industrial filtration business for over 60 years. The company has a wide range of suction strainers that are designed to meet the diverse filtration needs of various industries. Their products are known for their superior quality, high efficiency, and long-lasting performance.The Stainless Steel Suction Strainers offered by the company are made of premium quality stainless steel materials that are highly resistant to corrosion, rust, and abrasion. The strainers are available in various mesh sizes, ranging from coarse to fine, to ensure efficient filtration of various liquids and gases. They are available in different configurations such as inline, flanged, threaded, and custom designs that can be tailored to meet specific filtration needs.The Stainless Steel Suction Strainers offered by the company are manufactured using advanced technology and state-of-the-art equipment to ensure precision and accuracy in the design and assembly of each strainer. The company has a team of experienced and skilled engineers who use their expertise to design and manufacture innovative filtration solutions that meet the evolving needs of different industries. They also have in-house testing facilities that ensure the quality and performance of each product before it is released to the market.The Stainless Steel Suction Strainers offered by the company have many applications in various industries such as chemical processing, water treatment, oil and gas, pharmaceuticals, food and beverage, and many others. They are used to filter out particles such as sand, dirt, debris, and other impurities from liquids and gases. This helps to improve the quality of products, prevent equipment failure, and increase efficiency and productivity.One of the key advantages of using Stainless Steel Suction Strainers is their low maintenance requirements. They are easy to install and can be cleaned and maintained with minimal effort. The strainers are designed to withstand harsh environmental conditions and extended use without requiring frequent replacement. This makes them a cost-effective solution for industrial filtration needs.In conclusion, the Stainless Steel Suction Strainers offered by this US-based company are a reliable and efficient solution for various industrial filtration needs. Their superior quality, precision design, and advanced technology make them a preferred choice for industries such as chemical processing, water treatment, oil and gas, pharmaceuticals, food and beverage, and many others. With a commitment to innovation, quality, and customer satisfaction, this company is dedicated to providing the best filtration solutions that meet the evolving needs of different industries.

Discover the Benefits of Power Coated Metal Mesh for Various Applications

Metal Mesh With Power Coating - Reinventing Durability and Aesthetics in ConstructionIntroduction:In the fast-paced world of construction, innovation is key. As new technologies and materials continue to emerge, companies are constantly looking for ways to enhance both durability and aesthetics in their projects. One such groundbreaking development is the introduction of Metal Mesh With Power Coating, a revolutionary solution that promises to revolutionize the construction industry. By combining the strength of metal with the beauty of power coating, this product is poised to leave a lasting impact on the way buildings are designed and built.Metal Mesh:Metal mesh has long been admired for its strength and durability. Traditionally crafted using stainless steel, these meshes have found a wide range of applications within the construction industry. From facades to partitions, metal meshes provide a practical solution for airflow, light diffusion, and even security purposes. However, the limitation with these meshes has always been their lack of aesthetic appeal and resistance against corrosion.Power Coating:Enter power coating, a technique that has transformed the world of metal finishes. Power coating involves applying a layer of polymer resin to a surface, which is then cured under heat to form a hard, durable, and protective layer. This technique has become popular due to its ability to provide excellent corrosion resistance, weatherability, and a wide range of color options. While power coating has been predominantly used on metal surfaces, it has now found a new application in metal mesh, resulting in a game-changing combination.The Innovative Combination:By merging metal mesh with power coating, this innovative product offers a multitude of benefits for the construction industry. First and foremost, the power coating enhances the already robust properties of metal mesh. It provides an additional layer of protection against corrosion, extending the lifespan of the mesh significantly. Furthermore, the power coating offers resistance against fading and chipping, ensuring that the aesthetic appeal of the mesh remains intact over time.Aesthetics and Customization:One of the most noteworthy advantages of metal mesh with power coating is its ability to enhance the aesthetics of a building. The power coating not only provides protection but also opens up a world of design possibilities. With a wide array of colors and finishes available, architects and designers can now incorporate metal mesh seamlessly into their projects, transforming them into visually stunning masterpieces. The ability to customize the appearance of the mesh allows for greater flexibility and creativity, enabling architects to unleash their imagination like never before.Versatility and Applications:Metal mesh with power coating is a versatile product that can be applied to numerous areas in construction. From exterior facades to interior partitions, this product can seamlessly blend in with any architectural design. The mesh provides excellent airflow and light diffusion, creating an airy and visually appealing environment. Moreover, it can be employed as solar shading, offering energy efficiency benefits by reducing heat gain and glare on buildings. With these multifaceted benefits, metal mesh with power coating is quickly becoming the preferred choice for architects and builders worldwide.Sustainability and Environmental Impact:In an era where sustainability is of paramount importance, metal mesh with power coating aligns perfectly with the objectives of environmentally conscious construction. With its ability to optimize energy efficiency by reducing heat gain, this product aids in creating more sustainable buildings. Additionally, the power coating technique is inherently eco-friendly, employing minimal volatile organic compounds (VOCs) and generating minimal waste, making it a responsible choice for green building practices.Conclusion:With its exceptional combination of strength, durability, and aesthetic appeal, metal mesh with power coating is set to redefine the construction industry. By merging the benefits of metal mesh with the protective and visually enticing properties of power coating, this product opens up new frontiers for architects and designers. Its versatility, customization options, and sustainability make it an optimal choice for modern construction. As the industry continues to evolve, metal mesh with power coating will undoubtedly be at the forefront, bringing innovation, durability, and beauty to building projects around the globe.

Discover the Benefits of Sintered Filter Cartridges for Exceptional Filtration

Title: Groundbreaking Sintered Filter Cartridge Revolutionizes Filtration TechnologyIntroduction:(Filter Company), a leader in innovative filtration solutions, has unveiled its latest groundbreaking product - the Sintered Filter Cartridge. This revolutionary filtration technology is set to redefine industry standards by providing superior performance, efficiency, and durability.The Sintered Filter Cartridge is designed to meet the increasing demands of various industries, including water treatment, pharmaceuticals, chemicals, food and beverage, and more. Through cutting-edge manufacturing techniques, (Filter Company) has successfully developed a versatile and highly effective filtration solution that ensures the highest level of filtration efficiency.Unmatched Filtration Efficiency:One of the key features that sets the Sintered Filter Cartridge apart from conventional filters is its exceptional filtration efficiency. The cartridge is manufactured using the sintering process, which involves compacting and bonding metal or ceramic particles under extremely high pressure and temperature. This results in a highly porous structure with interconnected channels, enabling the filter to provide a larger surface area for efficient particle retention.With its advanced filtration mechanism, the Sintered Filter Cartridge can effectively remove suspended solids, sediments, colloidal particles, and even microorganisms from liquids and gases. This level of filtration efficiency not only guarantees the purity of the final product but also ensures compliance with stringent regulatory standards.Unparalleled Durability:In addition to its outstanding filtration capabilities, the Sintered Filter Cartridge is engineered to withstand extreme operating conditions. The sintering process grants the cartridge exceptional mechanical strength, making it highly resistant to pressure, temperature, and chemical exposure. This durability translates into a longer lifespan and reduced maintenance costs, making it a cost-effective solution for businesses.Moreover, the cartridge's robust construction reduces the risk of breakage or structural damage, ensuring uninterrupted filtration operations even under challenging circumstances. This makes it an ideal choice for industrial applications that demand reliable and long-lasting filtration solutions.Versatile Applications:The Sintered Filter Cartridge caters to a wide range of applications across various industries. Its adaptability allows it to be used for both liquid and gas filtration processes. It proves to be an excellent choice for applications such as water and wastewater treatment, pharmaceutical manufacturing, biotechnology processes, chemical and petrochemical plants, food and beverage production, and many more.The flexible design of the Sintered Filter Cartridge enables customization, with different shapes, sizes, and configurations available to suit specific filtration requirements. This adaptability ensures seamless integration into existing filtration systems, thereby minimizing downtime during installation and enhancing operational efficiency.Commitment to Quality and Sustainability:(Filter Company) is dedicated to delivering the highest-quality filtration solutions to its customers while prioritizing environmental sustainability. The Sintered Filter Cartridge incorporates materials that are highly recyclable, reducing waste generation and promoting a cleaner and greener future.By continuously investing in research and development, (Filter Company) ensures that its filtration products remain at the forefront of technological advancements. The Sintered Filter Cartridge stands as a testament to the company's commitment to innovation and its aim to provide efficient and sustainable solutions to meet the evolving needs of various industries.Conclusion:The introduction of the Sintered Filter Cartridge by (Filter Company) represents a significant leap forward in filtration technology. Its remarkable filtration efficiency, exceptional durability, and versatility across industries make it an indispensable tool for businesses seeking reliable and cutting-edge filtration solutions.(Filter Company)'s commitment to quality, performance, and sustainability solidifies its position as a leader in the field of filtration technology. With the new Sintered Filter Cartridge, businesses can expect enhanced filtration performance, reduced maintenance costs, and the assurance of complying with stringent regulatory standards.

Durable and Versatile Woven Wire Mesh Fencing for Your Property

Woven wire mesh fencing is a versatile and effective solution for a wide range of applications, from agricultural and industrial to residential and commercial. With its durability, strength, and flexibility, woven wire mesh fencing provides a secure and long-lasting barrier for properties of all sizes.One company that has been at the forefront of providing high-quality woven wire mesh fencing is {}. With over 20 years of experience in the industry, they have established themselves as a leading supplier of fencing solutions, offering a wide range of products to meet the needs of their diverse clientele.The woven wire mesh fencing provided by {} is known for its exceptional quality and performance. Made from high-grade materials, the fencing is designed to withstand the harshest weather conditions and resist corrosion, ensuring that it remains in top condition for years to come. Additionally, the fencing is available in a variety of mesh sizes and gauges, allowing customers to choose the perfect option for their specific requirements.One of the key advantages of woven wire mesh fencing is its versatility. It can be used for a variety of purposes, including securing perimeters, protecting livestock, and creating enclosures for gardens and other outdoor spaces. The strength and durability of the fencing make it an ideal choice for protecting valuable assets and ensuring the safety and security of properties.In addition to its practical benefits, woven wire mesh fencing also offers an aesthetic appeal. The clean lines and modern look of the fencing add a touch of sophistication to any property, making it a popular choice for both residential and commercial use. This combination of functionality and style makes woven wire mesh fencing a standout option for property owners looking for a fencing solution that is both practical and visually appealing.Furthermore, {} is committed to providing exceptional customer service, ensuring that their clients receive the support and assistance they need to make informed decisions about their fencing requirements. With a team of knowledgeable and experienced professionals, they are able to offer expert advice and guidance on the best fencing solutions for each individual project.As a company, {} is dedicated to upholding the highest standards of quality and reliability in all their products. They prioritize innovation and continuous improvement, constantly seeking new ways to enhance the performance and functionality of their woven wire mesh fencing. This commitment to excellence has earned them a reputation as a trusted and dependable supplier in the industry.In conclusion, woven wire mesh fencing is a highly effective and versatile solution for a wide range of applications, and {} is a leading provider of this fencing option. With their exceptional quality products, dedication to customer satisfaction, and commitment to excellence, they have become a go-to source for property owners in need of top-of-the-line fencing solutions. Whether for agricultural, industrial, residential, or commercial use, {} offers a range of woven wire mesh fencing options that are built to last and perform to the highest standards.

Premium Quality Cartridge Filter Element for Sale

Cartridge Filter Element: Ensuring Clean and Pure Industrial Liquid FiltrationCartridge filtration solutions are popular among industries as they offer several advantages over other filtration options. It is an effective method to remove contaminants from industrial liquids, gases and other fluids. It is a vital element in processes such as wastewater treatment, food and beverage processing, chemical processing, and pharmaceutical manufacturing. Cartridge filter elements have high demand in the market due to their efficiency and durability.The cartridge filter element manufacturer has been providing cartridge filter elements for more than 20 years. They have extensive experience in this field and cater to various industries such as food and beverage, automotive, chemical, and healthcare. They manufacture different types of filter elements, including industrial cartridge filters, spun-bonded filter cartridges and other specialty cartridges that suit a variety of applications.The company has a team of experienced and skilled professionals. They work in tandem to ensure the quality and reliability of the final product. The team comprises engineers, technicians, and quality controllers, and they use the latest techniques and equipment to manufacture high-quality filtration products.The cartridge filter element manufacturer uses a variety of filter media that include cellulose, polyester, polypropylene, and others to make their filter elements. The filter media have different properties and are suitable for different processes.The filter media used by the manufacturer is of the highest quality, ensuring maximum filtration efficiency. The filters are designed to remove a wide variety of impurities, including particles of different sizes, air, oil, and water droplets.The company offers a range of filter cartridges to suit different industrial applications, including air, gas, and liquid filtration. The filtration products are available in a range of micron ratings, and the company also provides custom micron ratings for specific applications.Cartridge filter elements are easy to install and maintain. They are also cost-effective compared to other filtration systems. The replacement of filter cartridges is simple and can be done quickly, ensuring minimal downtime in production processes.In addition, the company provides technical support to customers who require assistance in selecting the right filter element for their application. They also provide training to the maintenance and operation teams of the customers to ensure the long-term effectiveness of the filtration systems.The cartridge filter element manufacturer complies with the highest industry standards, including ISO 9001, ensuring the products are of the highest quality. They also regularly upgrade their manufacturing processes to keep up with the latest filtration technology.The company strongly believes in customer satisfaction and ensures that their products meet the needs and requirements of customers. They offer flexible payment options, on-time delivery, and excellent after-sales service.In conclusion, cartridge filter elements are essential for industries that require clean and pure liquids in their processes. The cartridge filter element manufacturer is a reliable and experienced supplier of filtration products, catering to various industries. Their products are of high quality and have a long lifespan, ensuring maximum filtration efficiency. They offer cost-effective solutions and excellent technical support to their customers. The company's commitment to customer satisfaction makes them a preferred supplier of filtration products in the market. Contact them today to know more about their products and services.

High-Quality Powder Sintered Filter for Efficient Filtration Operations

Powder Sintered Filter: Providing Efficient Filtration SolutionsIn today's fast-paced industrial environment, the need for efficient filtration solutions has become increasingly crucial. From the pharmaceutical and chemical industries to food and beverage production, the demand for high-quality filters that can ensure the purity of products has never been greater. This is where the Powder Sintered Filter, a revolutionary filtration technology, comes in. With its advanced design and superior functionality, the Powder Sintered Filter has become a go-to solution for businesses looking to maintain the highest standards of quality and purity in their production processes.The Powder Sintered Filter is a product of (company name), a leading manufacturer and supplier of filtration solutions for a wide range of industries. The company has been at the forefront of innovation in the field of filtration technology for over a decade, and its commitment to excellence and customer satisfaction has made it a trusted name in the industry.The Powder Sintered Filter is a versatile and highly efficient filtration solution that is capable of removing impurities and contaminants from liquids and gases with exceptional precision. Its unique design, which consists of a matrix of sintered metal powders, ensures a high degree of porosity and permeability, allowing for maximum filtration efficiency. Additionally, the filter's robust construction enables it to withstand high pressures and temperatures, making it suitable for a variety of demanding industrial applications.One of the key advantages of the Powder Sintered Filter is its ability to provide consistent and reliable filtration performance over an extended period of time. Unlike traditional filter media such as paper or cloth, which can degrade and lose effectiveness over time, the sintered metal powders used in this filter are highly durable and resistant to corrosion, ensuring long-lasting performance and minimal maintenance requirements. This durability also makes the filter a cost-effective solution for businesses looking to reduce their overall filtration expenses.Furthermore, the Powder Sintered Filter offers a high degree of customization, allowing businesses to tailor the filter's specifications to their specific requirements. Whether it's the pore size, shape, or overall dimensions, the filter can be customized to meet the unique needs of different industrial processes. This level of flexibility makes the filter a versatile and adaptable solution for a wide range of filtration applications.In addition to its advanced technological features, the Powder Sintered Filter is backed by (company name)'s unparalleled expertise and technical support. The company's team of experienced engineers and filtration experts are dedicated to providing the highest level of customer service, from initial product selection to ongoing maintenance and support. This commitment to customer satisfaction ensures that businesses can rely on the Powder Sintered Filter to deliver consistent and reliable filtration performance, day in and day out.With its advanced design, superior performance, and unwavering support from (company name), the Powder Sintered Filter has established itself as a trusted and dependable filtration solution for businesses across the globe. As industries continue to evolve and demand higher standards of quality and purity, the Powder Sintered Filter is poised to play a key role in meeting these growing filtration needs.In conclusion, the Powder Sintered Filter represents a significant advancement in the field of filtration technology, offering businesses a reliable and efficient solution for maintaining the highest standards of product purity. Backed by the expertise and support of (company name), the filter is set to make a lasting impact on the industrial landscape, providing businesses with the confidence and assurance they need to excel in today's competitive market.

Discover the Advantages of Building Wire Mesh for Your Construction Projects

Building Wire Mesh, also known as construction wire mesh, is an essential component in modern construction projects. It provides structural integrity, reinforcement, and safety to various construction applications. Due to its versatility, durability, and cost-effectiveness, Building Wire Mesh has become a popular choice for professionals in the construction industry.Building Wire Mesh is typically made from high-quality galvanized steel wire or annealed wire. These wires are woven or welded together to create a mesh with uniform openings. The size of the openings can vary depending on the specific requirements of the construction project. Building Wire Mesh is available in different dimensions, thicknesses, and configurations to meet the diverse needs of various construction applications.One of the primary uses of Building Wire Mesh is in concrete reinforcement. It is commonly used as a reinforcing material in concrete slabs, walls, columns, and foundations. By adding Building Wire Mesh to concrete structures, they become stronger, more resistant to cracking, and better able to withstand external forces such as earthquakes or heavy loads. The mesh provides structural stability and prevents the spread of cracks, ensuring the longevity and safety of the concrete structure.Another important application of Building Wire Mesh is in the construction of brickwork and masonry. The mesh is embedded within the mortar joints to enhance the structural integrity of the walls or partitions. This prevents the development of cracks and provides added strength to the masonry structure. Additionally, Building Wire Mesh helps to distribute the load evenly across the entire surface, reducing the risk of localized stress concentrations.In addition to reinforcement, Building Wire Mesh also serves as a safety measure in construction sites. It is widely used as a protective barrier to prevent falls from heights, protect workers from debris or falling objects, and secure the construction area. The mesh is often installed as a perimeter fence, scaffold enclosure, or safety netting. Its durability and high-tensile strength make it an ideal choice for ensuring the safety of workers and the public during construction operations.The versatility of Building Wire Mesh extends beyond construction applications. It is also used in various industrial sectors such as agriculture, transportation, and mining. In agriculture, the mesh is used for animal fencing, crop protection, and erosion control. In transportation, it is utilized for road reinforcement, bridge construction, and noise barriers. In mining, Building Wire Mesh is used in the production of screens, filters, and conveyor belts.Company Introduction will be inserted here:In conclusion, Building Wire Mesh plays a crucial role in modern construction projects. Its versatility, durability, and cost-effectiveness make it an essential component in various construction applications. With its ability to provide reinforcement, structural stability, and safety, Building Wire Mesh continues to be a sought-after choice by professionals in the construction industry. As it finds applications in not only construction but also other industrial sectors, the demand for Building Wire Mesh is expected to grow steadily in the coming years.

Expert Guide to Cutting Expanded Metal: Tips and Techniques

Cutting Expanded Metal is a process that involves removing metal material from a larger piece of material to create a pattern of openings. This method is often used in manufacturing, construction, and industrial applications to create lightweight but strong materials for various purposes. The process of Cutting Expanded Metal requires precision and expertise to ensure that the desired pattern is achieved without compromising the structural integrity of the material.One company that specializes in the Cutting Expanded Metal process is {}. Founded in 1990, {} has become a leading provider of metal processing and fabrication services. With state-of-the-art facilities and a team of highly skilled professionals, {} has gained a reputation for delivering high-quality products and exceptional customer service.The Cutting Expanded Metal process at {} involves using advanced machinery to accurately cut and shape metal materials according to the specific requirements of each project. Whether it's creating custom patterns, intricate designs, or standard shapes, {} has the capabilities to meet the diverse needs of its clients. The company's commitment to precision and excellence has made it a trusted partner for businesses in various industries, including construction, architecture, automotive, and aerospace.One of the key advantages of Cutting Expanded Metal is its versatility. By being able to remove material in a controlled manner, {} can produce expanded metal sheets with a wide range of open area percentages, strand widths, and pattern designs. This flexibility allows the company to cater to the unique demands of different applications, whether it's for filtration, ventilation, security, or decorative purposes.Moreover, the Cutting Expanded Metal process allows for the creation of lightweight materials that maintain high strength and durability. This makes expanded metal an ideal choice for applications where weight reduction is crucial without sacrificing structural integrity. In addition, the open design of expanded metal sheets allows for excellent airflow and visibility while providing security and protection.The skilled technicians at {} are dedicated to meeting the specific requirements of each project, whether it's a small-scale custom job or a large-scale industrial order. Their expertise in the Cutting Expanded Metal process ensures that the final products meet the highest standards of quality and precision. By utilizing advanced technology and industry best practices, {} is able to deliver efficient and cost-effective solutions that exceed client expectations.Furthermore, {} is committed to sustainability and environmental responsibility in its operations. The company strives to minimize waste and optimize material usage in the Cutting Expanded Metal process, contributing to a more environmentally friendly approach to metal fabrication. By prioritizing eco-friendly practices, {} aims to reduce its carbon footprint and promote a greener manufacturing industry.As {} continues to expand its capabilities and reach new milestones, the company remains dedicated to delivering innovative solutions and superior products to its clients. With a focus on quality, precision, and customer satisfaction, {} is a reliable partner for businesses seeking Cutting Expanded Metal and other metal fabrication services. Whether it's for architectural design, industrial equipment, or specialized applications, {} is poised to meet the evolving needs of the market with its expertise and commitment to excellence.

High-Quality Sintered Stainless Filter for Efficient Filtration

Sintered Stainless Filter, a company known for its innovative filtration solutions, has recently launched a new range of cutting-edge filters that are set to revolutionize the industry. With a focus on delivering superior performance and durability, the company has established itself as a leader in the field of sintered stainless steel filters.The newly launched filters are designed to meet the diverse needs of industries such as pharmaceutical, food and beverage, chemical, and automotive. They are engineered to deliver high levels of efficiency, reliability, and cost-effectiveness, making them an ideal choice for a wide range of applications.One of the key features of the new filters is their advanced sintering technology, which ensures a high level of porosity and uniformity in the filter media. This allows for superior filtration performance, with the ability to remove even the finest particles from the process stream.In addition to their exceptional filtration capabilities, the filters are also designed for easy maintenance and cleaning, enabling users to maximize their lifespan and minimize downtime. This is particularly beneficial for industries that rely on continuous and reliable filtration processes."Sintered Stainless Filter has always been committed to pushing the boundaries of filtration technology, and our new range of filters is a testament to that commitment," said a spokesperson for the company. "We have invested heavily in research and development to ensure that our filters not only meet but exceed the expectations of our customers."The company’s dedication to quality and innovation is further evident in its state-of-the-art manufacturing facilities and stringent quality control processes. This ensures that each filter that leaves the production line meets the highest standards of performance and reliability.Furthermore, the company’s team of highly skilled engineers and technical experts are on hand to provide comprehensive support and guidance to customers, from initial product selection to ongoing maintenance. This commitment to customer satisfaction sets Sintered Stainless Filter apart from its competitors, making it a trusted partner for businesses around the world.The launch of the new range of filters comes at a time when the demand for high-quality filtration solutions is on the rise. Industries are increasingly recognizing the importance of efficient and reliable filtration processes in ensuring the quality and safety of their products. With its cutting-edge filters, Sintered Stainless Filter is well-positioned to meet this growing demand and deliver unparalleled value to its customers.As the company continues to expand its product offering and reach new markets, it remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With its unwavering commitment to excellence, Sintered Stainless Filter is set to maintain its position as a leader in the field of sintered stainless steel filters.In conclusion, the launch of the new range of filters by Sintered Stainless Filter is a testament to the company’s ongoing dedication to pushing the boundaries of filtration technology. With their advanced sintering technology, superior performance, and commitment to customer satisfaction, the company is well-positioned to meet the diverse needs of industries around the world and set new standards for filtration excellence.