Durable Metal Mesh Sheets: A Versatile and Functional Material Option

By:Admin

Metal Mesh Sheets Supply Company is excited to announce their expansion into new markets with the introduction of a wider range of products and services. With a strong foundation in the supply of metal mesh sheets, the company has built a reputation for providing high-quality products and exceptional customer service. Their expansion will allow them to reach new customers and offer a more extensive selection of metal mesh products to meet the growing demands of various industries.

The company's metal mesh sheets are widely used in applications such as filtration, separation, protection, and reinforcement. With a diverse range of materials, sizes, and designs, Metal Mesh Sheets Supply Company has become a trusted supplier for businesses across various sectors, including construction, automotive, aerospace, and manufacturing. Their products have proven to be durable, reliable, and cost-effective, making them a go-to option for many businesses.

In addition to their existing product line, Metal Mesh Sheets Supply Company will introduce new and innovative metal mesh products to cater to specific industry needs. This expansion will include the introduction of specialized mesh sheets for unique applications, such as architectural design, acoustic solutions, and decorative purposes. By expanding their product range, the company aims to provide comprehensive solutions for a wider range of customer requirements.

To support their expansion, Metal Mesh Sheets Supply Company has invested in state-of-the-art manufacturing facilities and equipment to ensure the production of high-quality metal mesh products. Their commitment to quality and innovation is reflected in their continuous research and development efforts to improve and diversify their product offerings. With a team of experienced professionals, the company is well-positioned to meet the evolving needs of their customers and provide tailored solutions for specific applications.

Furthermore, Metal Mesh Sheets Supply Company is also expanding their reach by establishing partnerships with distributors and suppliers in new regions. By collaborating with local businesses, the company aims to increase their market presence and provide efficient access to their products for customers worldwide. This strategic approach will not only benefit the company but also create opportunities for local businesses to offer a broader range of metal mesh solutions to their customers.

As part of their expansion, Metal Mesh Sheets Supply Company is also enhancing their customer support services to ensure a seamless experience for their clients. From product inquiries to after-sales support, the company is dedicated to providing responsive and personalized assistance to their customers. Their knowledgeable staff will be readily available to offer technical advice, product recommendations, and assistance with custom orders to meet specific requirements.

With their expansion into new markets, Metal Mesh Sheets Supply Company is poised to become a leading provider of metal mesh solutions across diverse industries. Their commitment to excellence, product innovation, and customer satisfaction sets them apart as a reliable partner for businesses seeking high-quality metal mesh products. As they continue to grow and evolve, the company remains focused on meeting the evolving needs of their customers and delivering exceptional value through their extensive product range and services.

Company News & Blog

Discover the Advantages of Building Wire Mesh for Your Construction Projects

Building Wire Mesh, also known as construction wire mesh, is an essential component in modern construction projects. It provides structural integrity, reinforcement, and safety to various construction applications. Due to its versatility, durability, and cost-effectiveness, Building Wire Mesh has become a popular choice for professionals in the construction industry.Building Wire Mesh is typically made from high-quality galvanized steel wire or annealed wire. These wires are woven or welded together to create a mesh with uniform openings. The size of the openings can vary depending on the specific requirements of the construction project. Building Wire Mesh is available in different dimensions, thicknesses, and configurations to meet the diverse needs of various construction applications.One of the primary uses of Building Wire Mesh is in concrete reinforcement. It is commonly used as a reinforcing material in concrete slabs, walls, columns, and foundations. By adding Building Wire Mesh to concrete structures, they become stronger, more resistant to cracking, and better able to withstand external forces such as earthquakes or heavy loads. The mesh provides structural stability and prevents the spread of cracks, ensuring the longevity and safety of the concrete structure.Another important application of Building Wire Mesh is in the construction of brickwork and masonry. The mesh is embedded within the mortar joints to enhance the structural integrity of the walls or partitions. This prevents the development of cracks and provides added strength to the masonry structure. Additionally, Building Wire Mesh helps to distribute the load evenly across the entire surface, reducing the risk of localized stress concentrations.In addition to reinforcement, Building Wire Mesh also serves as a safety measure in construction sites. It is widely used as a protective barrier to prevent falls from heights, protect workers from debris or falling objects, and secure the construction area. The mesh is often installed as a perimeter fence, scaffold enclosure, or safety netting. Its durability and high-tensile strength make it an ideal choice for ensuring the safety of workers and the public during construction operations.The versatility of Building Wire Mesh extends beyond construction applications. It is also used in various industrial sectors such as agriculture, transportation, and mining. In agriculture, the mesh is used for animal fencing, crop protection, and erosion control. In transportation, it is utilized for road reinforcement, bridge construction, and noise barriers. In mining, Building Wire Mesh is used in the production of screens, filters, and conveyor belts.Company Introduction will be inserted here:In conclusion, Building Wire Mesh plays a crucial role in modern construction projects. Its versatility, durability, and cost-effectiveness make it an essential component in various construction applications. With its ability to provide reinforcement, structural stability, and safety, Building Wire Mesh continues to be a sought-after choice by professionals in the construction industry. As it finds applications in not only construction but also other industrial sectors, the demand for Building Wire Mesh is expected to grow steadily in the coming years.

Discover the Versatility and Elegance of Architectural Wire Mesh

Architectural Wire Mesh: Reimagining Spaces with Innovative Design SolutionsIntroduction:In today's ever-evolving world of architecture and interior design, cutting-edge materials and technology are reshaping the way we conceptualize and transform spaces. One such groundbreaking innovation is Architectural Wire Mesh, a versatile and transformative material that has gained significant popularity among architects, interior designers, and builders alike. By seamlessly blending functionality with aesthetic appeal, Architectural Wire Mesh is revolutionizing the way we envision and create stunning architectural designs.Unveiling Architectural Wire Mesh:Architectural Wire Mesh is a distinctive material that is woven or welded from metallic wires, resulting in an intricately patterned mesh. Engineered to perfection, this material offers a wide range of benefits, including unparalleled durability, strength, and flexibility. It provides a visually captivating and captivating solution for a myriad of architectural applications, such as facades, cladding, partitions, ceilings, and even furniture.Integration of Technology and Design:What sets Architectural Wire Mesh apart from traditional architectural materials is its seamless integration with modern technology and design techniques. By utilizing advanced computer-aided design software, architects and designers can effortlessly visualize the look and feel of architectural elements incorporating Wire Mesh. This enables them to experiment with various patterns, scales, and textures, resulting in truly unique and mesmerizing designs.Architectural Wire Mesh Opens Doors to Creativity:The versatility of Architectural Wire Mesh lies in its ability to adapt to diverse design concepts and aesthetics. Its malleable nature allows architects and designers to mold it into any desired shape, making it suitable for both intricate and minimalist architectural designs. The integration of Architectural Wire Mesh into buildings and interiors instantly elevates the ambiance, adding depth, character, and a touch of luxury to the space.Enhancing Functionality:Beyond its aesthetic appeal, Architectural Wire Mesh offers functional advantages as well. With its permeable nature, Wire Mesh allows for natural ventilation, lighting, and shading, reducing the need for artificial sources. Additionally, it possesses excellent acoustic properties, effectively blocking unwanted noise pollution. Furthermore, Architectural Wire Mesh ensures maximum security and safety, providing fire resistance and anti-vandalism properties.Applications in Architecture and Design:Architectural Wire Mesh finds applications in various architectural projects, catering to both residential and commercial spaces. The material can be seamlessly incorporated into intricate facades, creating visually stunning exteriors. Its use in interior design extends to creating unique room dividers, wall panels, and innovative ceiling designs. From contemporary office spaces to luxurious homes, Architectural Wire Mesh is redefining the boundaries of design possibilities.Sustainable Construction:In a world advancing towards sustainability, Architectural Wire Mesh aligns perfectly with the ethos of eco-friendly construction. Manufactured from recyclable and locally sourced materials, it minimizes the environmental impact, fostering a greener and more responsible architecture. The durability and longevity of the material further contribute to sustainability by reducing the need for frequent replacements.Collaboration with Architects and Designers:To realize the full potential of Architectural Wire Mesh, collaboration between manufacturers and architects/designers plays a crucial role. By actively working together from conceptualization to completion, architects and manufacturers can develop customized solutions that cater to the specific design requirements of each project. This collaborative approach ensures seamless integration of Architectural Wire Mesh into the architectural vision.Conclusion:Architectural Wire Mesh has undoubtedly revolutionized the architectural industry, offering a perfect blend of functionality and design. Its ability to transform spaces, combined with increased sustainability, makes it one of the most sought-after materials for modern builders and designers. With endless possibilities, Architectural Wire Mesh continues to push the boundaries of innovation, reimagining spaces and creating awe-inspiring designs that leave a lasting impact.

High-Quality Woven Wire Mesh Filter for Industrial Applications

Woven wire mesh filters are becoming increasingly popular in various industries due to their efficiency and durability. These filters are widely used for various applications such as water filtration, gas and liquid filtration, and air purification. With the increasing demand for high-quality filters, the market for woven wire mesh filters is expected to grow significantly in the coming years.One company that has been at the forefront of producing high-quality woven wire mesh filters is {Company Name}. With a strong emphasis on quality and innovation, {Company Name} has established itself as a leading manufacturer of woven wire mesh filters in the industry. The company's commitment to excellence and customer satisfaction has made them a trusted name in the field of filtration.{Company Name} offers a wide range of woven wire mesh filters that are designed to meet the diverse needs of their customers. The filters are available in various materials such as stainless steel, galvanized steel, and brass, and can be customized to meet specific requirements. Whether it's for industrial, commercial, or residential use, {Company Name}'s woven wire mesh filters are known for their durability and reliability.In addition to their standard product offerings, {Company Name} also provides custom fabrication services for customers with unique filtration needs. From custom sizes to specific mesh patterns, the company's team of experts work closely with clients to deliver tailor-made solutions that meet their exact specifications.One of the key features of {Company Name}'s woven wire mesh filters is their high level of filtration efficiency. The filters are designed to effectively remove impurities and contaminants from liquids and gases, ensuring a clean and safe end product. This level of performance is crucial for industries such as food and beverage, pharmaceuticals, and environmental engineering, where the quality of the filtration process is of utmost importance.Furthermore, {Company Name} prides itself on using only the highest quality materials and manufacturing processes to produce their filters. This dedication to quality ensures that their filters meet the strictest industry standards and can withstand the most demanding operating conditions. Customers can have peace of mind knowing that they are investing in filters that are built to last.Beyond their product offerings, {Company Name} is also committed to providing exceptional customer support and service. The company's team of experts is readily available to assist customers with technical inquiries, product selection, and after-sales support. This level of customer care has helped {Company Name} build long-lasting relationships with clients and solidify their reputation as a reliable filtration solutions provider.As the demand for high-quality woven wire mesh filters continues to grow, {Company Name} is well-positioned to meet the needs of their customers. With a steadfast dedication to quality, innovation, and customer satisfaction, the company is poised to remain a leader in the filtration industry for years to come. With their extensive product offerings, custom fabrication capabilities, and commitment to excellence, {Company Name} is the go-to source for all woven wire mesh filter needs.

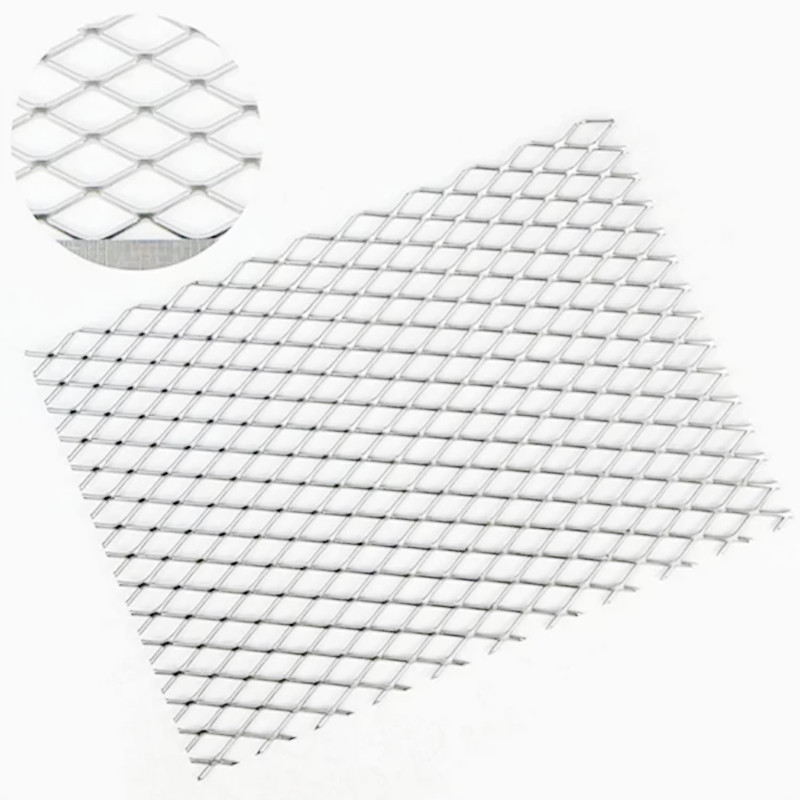

High-quality Steel Expanded Metal Offers Superior Strength and Durability - Read the Latest News

Title: Innovations in Steel Expanded Metal Technology Revolutionize the Construction IndustryIntroduction:In an era of rapid advancements, Steel Expanded Metal has emerged as a transformative material in the construction industry. With its unique characteristics and impressive versatility, it has revolutionized the way infrastructure projects are designed and executed. This article will explore the advancements in Steel Expanded Metal technology and delve into the innovative solutions it provides, contributing to the sustainability and efficiency of construction projects worldwide.Paragraph 1: What is Steel Expanded Metal?Steel Expanded Metal is a revolutionary material formed by stretching and slitting metal sheets, creating a mesh-like pattern with diamond-shaped openings. The process enhances the material's structural integrity while maintaining its lightweight nature. It can be manufactured using various metals such as stainless steel, carbon steel, and aluminum. Steel Expanded Metal is renowned for its strength, durability, and cost-effectiveness, making it a preferred choice in construction projects globally.Paragraph 2: The Advantages of Steel Expanded MetalSteel Expanded Metal offers numerous advantages over traditional materials used in construction. It provides exceptional load-bearing capacity, allowing architects and engineers to create large-scale structures while reducing support requirements. Its lightweight properties make transportation and installation easier, reducing overall project costs and construction time.Additionally, Steel Expanded Metal offers transparency, allowing natural light and ventilation to pass through, optimizing energy consumption and enhancing the eco-friendliness of buildings. It is also highly resistant to corrosion, ensuring long-term durability and reducing maintenance costs. These benefits have led to its widespread adoption in a variety of applications, including flooring, fencing, walls, partitions, ceiling panels, and façade systems.Paragraph 3: Applications of Steel Expanded MetalSteel Expanded Metal's versatility enables its integration into a wide range of construction applications. In the realm of infrastructure, it is widely used in the creation of robust walkways, platforms, and ramps, where its load-bearing capacity and anti-slip properties are essential. Expanded metal gratings, composed of steel meshes, have become indispensable in industrial settings, where they ensure worker safety by providing secure flooring in hazardous environments.Moreover, the construction industry has embraced Steel Expanded Metal in architectural applications. Its malleability allows for the creation of intricate and aesthetically pleasing structures, adding a unique touch to modern buildings. Expanded metal mesh finds extensive use in decorative facades, sunscreens, and shading elements, enhancing both the visual appeal and functionality of buildings.Paragraph 4: Environmental Sustainability and SafetyThe construction industry has set ambitious sustainability goals for the future, and Steel Expanded Metal plays a significant role in achieving them. Through its light-transmitting properties, it reduces the need for artificial lighting during daylight hours, leading to reduced energy consumption and lower carbon emissions. Its open design also enhances natural ventilation, reducing the reliance on air conditioning systems.Furthermore, Steel Expanded Metal is recyclable, making it an environmentally friendly choice. It can be reprocessed and repurposed for other applications, reducing waste and conserving resources. Steel Expanded Metal's inherent fire-resistant properties contribute to building safety, improving fire regulations compliance and ensuring occupant protection.Conclusion:In conclusion, Steel Expanded Metal has transformed the construction industry by providing innovative solutions to the challenges faced in infrastructure development. Its unique characteristics, including strength, durability, and versatility, have given architects and engineers the freedom to create novel designs while maintaining structural integrity. The material's applications range from gratings and walkways to decorative facades and sunscreens, ultimately enhancing the functionality and aesthetic appeal of modern buildings. Embracing Steel Expanded Metal's sustainability and safety features, the construction industry is moving towards environmentally responsible practices. As this technology continues to evolve, we can expect even more groundbreaking applications and benefits across the architecture and construction sectors.

Top 5 Uses for Brass Mesh Screen in Everyday Life

Brass Mesh Screen: The Versatile Solution for Industrial and Commercial ApplicationsIn today's fast-paced world, industrial and commercial applications require high-quality materials that can withstand tough conditions and deliver exceptional performance. This is where Brass Mesh Screen comes into play – a versatile solution that is widely recognized for its durability and versatility in various industries. (Company name) has been a leading provider of Brass Mesh Screen, catering to the needs of industries worldwide.The Brass Mesh Screen, offered by (Company name), is a highly sought-after product due to its unique properties and applications across diverse industries. From filtration and separation to decorative and architectural purposes, the Brass Mesh Screen is a preferred choice for companies looking for reliable and high-quality mesh solutions.With a strong emphasis on quality and innovation, (Company name) has established itself as a trusted supplier of Brass Mesh Screen in the global market. The company's dedication to excellence and customer satisfaction has positioned it as a preferred partner for businesses seeking top-quality mesh solutions.The Brass Mesh Screen offered by (Company name) is made from high-grade brass, ensuring superior strength and longevity. This makes it an ideal choice for applications that require resistance to corrosion, wear, and tear. In addition, the mesh screen is available in a variety of sizes and specifications to meet the specific needs of different industries.One of the key advantages of Brass Mesh Screen is its versatility, making it suitable for a wide range of applications. It is widely used in the automotive industry for radiator grilles and air vents, in the architectural industry for decorative facades and interior design elements, and in the chemical industry for filtration and screening purposes.Furthermore, the Brass Mesh Screen has found extensive use in the food and beverage industry for sieving and sifting applications, and in the aerospace industry for its lightweight and high-strength properties. Its conductivity and malleability also make it a preferred choice in electrical and electronic applications.(Company name) takes pride in its ability to deliver customized Brass Mesh Screen solutions to meet the unique requirements of its customers. With a team of skilled engineers and technicians, the company offers comprehensive design and manufacturing capabilities to create bespoke mesh screen solutions for specific applications.As part of its commitment to sustainability, (Company name) employs environmentally friendly manufacturing processes and sources raw materials from reputable suppliers. This underscores the company's dedication to ethical and responsible business practices, ensuring that its Brass Mesh Screen is not only high-performing but also environmentally conscious.The Brass Mesh Screen offered by (Company name) is renowned for its reliability and consistency, meeting the stringent quality standards of various industries. With a focus on continuous improvement and technological advancement, the company remains at the forefront of innovation in the mesh solutions industry.In conclusion, (Company name) has solidified its position as a leading provider of Brass Mesh Screen, serving the needs of diverse industries with its high-quality and versatile solutions. With an unwavering commitment to excellence and customer satisfaction, the company continues to be a trusted partner for businesses seeking top-tier mesh products for their industrial and commercial applications.

Brass Filter Screen Mesh with High Porosity and Smooth Surface for Copper Wire Mesh Screen

and Brass Copper Wire Mesh ScreenBrass Filter Screen Mesh and Brass Copper Wire Mesh Screen: What Are They and Where Are They Used?When it comes to industrial and commercial processes, the use of filters is integral in ensuring that the final product meets quality standards. Filters come in different materials and sizes depending on the application. However, one material that has stood the test of time is brass. Brass is an alloy of copper and zinc with distinct properties that make it preferred in different industries.One of the popular uses of brass is in the manufacture of filter screens. Brass filter screen mesh is produced by weaving or knitting brass wires of different thicknesses and porosity levels. The result is a durable and high-performance filter that can withstand harsh operating conditions.Typically, brass filter screen mesh is used in liquid filtration applications, such as water treatment and oil refining. The mesh’s porosity allows it to trap impurities while letting the filtered liquid through. Moreover, brass is resistant to corrosion, making it ideal for use in corrosive fluids.Another brass wire mesh common in industrial applications is the brass copper wire mesh screen. This type of mesh is produced by interweaving copper and brass wires to create a unique blend of mechanical and electrical properties. Brass copper wire mesh screen is highly conductive and has excellent electromagnetic shielding properties.Brass copper wire mesh screen is used in electronic devices, such as smartphones and computers, to shield against electromagnetic interference. Furthermore, it is used in filtration applications where high electrical conductivity is required, such as in the manufacture of batteries.In conclusion, brass filter screen mesh and brass copper wire mesh screen are an integral part of many industrial processes. Brass’s distinct properties make it an ideal material for different applications, including filtration and electromagnetic shielding. The next time you come across a brass filter or mesh screen, you now know what it is and where it is used.

Discover the Latest Architecture Trends and News on Wire Mesh at ArchDaily

Wire Mesh: A Versatile and Functional MaterialWire mesh is a versatile material used in construction and architecture. This material is made by weaving or welding metal wires together to form a grid pattern. Wire mesh is used in a variety of applications and is favored by builders and architects for its durability, strength, and aesthetic appeal.Wire Mesh for Construction and ArchitectureWire mesh is used extensively in the construction industry for a range of applications. The mesh is used to reinforce concrete, which increases its strength and prevents cracking. Not only does this make the structure more durable, but it also increases its lifespan. Wire mesh is also used in drywall installation to provide support for the plaster or coating. Wire mesh is also used as a facade on buildings to create a unique architectural design.Wire mesh is also used in architecture to create interesting and attractive design features. The mesh can be used as a decorative element on walls, doors, and windows. It can also be used as a screen to provide privacy or to control light and shade. In addition to its aesthetic benefits, wire mesh can also be used as a sustainable design feature. Its open weave allows for ventilation and natural light, which can help reduce energy consumption.Applications of Wire MeshWire mesh is used in a variety of applications, from industrial to commercial to domestic. Some of these applications include:- Fencing: Wire mesh is commonly used in fencing for its strength and durability. It can be used for both security and aesthetic purposes.- Industrial: Wire mesh is used in industrial applications such as filtration, separation, and temperature control.- Agriculture: Wire mesh is used in agriculture for animal enclosures, pest control, and crop protection.- Transportation: Wire mesh is used in the transportation industry for security enclosures and cargo protection.Wire Mesh MaterialsWire mesh can be made from a variety of materials, including stainless steel, aluminum, copper, brass, and galvanized steel. Each material has its own unique properties, which makes them suitable for different applications. Stainless steel wire mesh, for example, is corrosion-resistant and is therefore used in applications where moisture is present. On the other hand, galvanized steel wire mesh is more affordable and is often used in industrial applications.ConclusionWire mesh is a versatile and functional material used in construction and architecture. Its strength, durability, and aesthetic appeal make it a popular choice for builders and architects. It is used in a wide range of applications and is made from a variety of materials. As technology advances, wire mesh will likely become an even more important material in construction and architecture. With its many benefits, it is easy to see why wire mesh is such a valuable component in the built environment.

Exporters of High-Quality Nickel Alloy Wire Mesh and Netting in Mumbai

and High Nickel Alloy Wire Netting.High Nickel Alloy Wire Mesh and Wire Netting – An OverviewHigh Nickel Alloy Wire Mesh and Wire Netting are widely used across various industries for their excellent strength and resistance to harsh environments. These materials are composed of nickel and other notable alloying elements such as copper, chromium, and molybdenum, among others. These alloys are known for their high corrosion resistance, good thermal conductivity, and excellent mechanical properties.Sanghvi Overseas is a leading supplier and exporter of ASTM B160 / ASME SB160 Nickel & High Nickel Alloy Wire Mesh / Wire Netting, including Nickel Alloy 200 Wire Mesh and High Nickel Alloy 201 Wire Netting. Sanghvi Overseas has an extensive network of global clients and is committed to providing the highest quality materials at competitive prices.Nickel Alloy 200 Wire MeshNickel Alloy 200 Wire Mesh is a commercially pure nickel material that has excellent resistance to corrosive environments. This alloy has low carbon content and is resistant to caustic soda and other alkaline solutions. It has high electrical conductivity and is used as an electrode in various industrial applications. The material has a maximum operating temperature of 315 degrees Celsius and is suitable for use in chemical processing plants, marine installations, and power generation stations.High Nickel Alloy 201 Wire NettingHigh Nickel Alloy 201 Wire Netting is similar to Nickel Alloy 200 but has a lower carbon content, which gives it a slightly higher thermal conductivity and reduced embrittlement at elevated temperatures. This material is also highly resistant to corrosion and is suitable for use in reducing and oxidizing environments. It is commonly used in food processing plants, chemical and petrochemical industries, seawater handling equipment, and nuclear power generation plants.Other High Nickel Alloy Wire Mesh and Wire NettingSanghvi Overseas also supplies other high nickel alloy wire mesh and wire netting materials, including:- Monel Alloy 400 Wire Mesh- Monel Alloy K500 Wire Mesh- Inconel Alloy 600 Wire Mesh- Inconel Alloy 601 Wire Mesh- Incoloy Alloy 800 Wire Mesh- Incoloy Alloy 800H Wire Mesh- Hastelloy Alloy C276 Wire Mesh- Hastelloy Alloy C22 Wire MeshThese materials offer similar properties to Nickel Alloy 200 and High Nickel Alloy 201, but with varying levels of added elements to suit specific applications.Why Choose Sanghvi Overseas for High Nickel Alloy Wire Mesh and Wire Netting?Sanghvi Overseas is a trusted supplier and exporter of high-quality High Nickel Alloy Wire Mesh and Wire Netting materials. The company has an extensive network of global clients and has a reputation for providing the highest quality materials at competitive prices. They have a team of experts who are experienced in selecting the right material for each application and are committed to delivering products on time and to the highest quality standards.ConclusionHigh Nickel Alloy Wire Mesh and Wire Netting are essential materials used in various industries, including chemical processing, marine installations, power generation, and food processing. These materials are highly resistant to corrosion, have excellent thermal conductivity, and offer good mechanical properties. Sanghvi Overseas is a trusted supplier and exporter of these materials, providing the highest quality products at competitive prices. Contact them for more information on their products and services.

Discover the Benefits of Woven Wire Screens for Your Needs

article:Woven Wire Screen: The Ultimate Solution for Material SeparationIndustries engaged in the handling of materials know the significance of an effective and reliable screening solution for a successful operation. A woven wire screen (name removed) has emerged as a popular and versatile option for material separation across various sectors. With its unique design and superior quality, this screen is increasingly becoming an essential component for the material handling industry.Origin and Evolution of Woven Wire ScreenWoven wire screens are made of wires woven together in a mesh pattern. The earliest type of woven screen was made of horsehair in 1808. However, the first patent for a woven wire mesh was issued in 1871. Over the years, this screen has undergone immense development and innovations. Today, modern weaving techniques and technology have made it possible to produce woven wire screens with precision, efficiency, and consistency.Woven Wire Screen: The Ultimate Solution for Material SeparationWoven wire screens find immense applicability across a wide range of industries. The mining, aggregate, and construction industries use woven wire screens to sort and separate granular materials like ore, rock, gravel, and sand. The food processing industry uses it to filter liquids, powders, and solids. Similarly, the pharmaceutical industry utilizes it for separating solids from liquids. The pulp and paper mills use woven wire screens for screening wood chips, pulp, and waste products.Woven Wire Screen: A Versatile SolutionOne of the significant advantages of woven wire screens is its versatility. It is available in a wide range of shapes, sizes, and materials. The shape and size of the screen depend on the specific demand for the application. The available materials range from carbon steel, high-strength steel alloys, and stainless steel, making it an adaptable solution for any screening need.DurabilityWoven wire screens are tested for durability and strength. Material handling processes can often be harsh, with excessive vibration, high velocity, and abrasive material. A high-quality woven wire screen can withstand extreme conditions, minimizing the risk of screen failure and product contamination. Its durability will not allow for frequent screen replacements, which leads to a considerable saving in both time and money.Easy to MaintainAnother advantage of using a woven wire screen is its ease of maintenance. It can be cleaned and washed effortlessly. The structure of the screen makes it simple to access and inspect regularly. This makes it easy to monitor the progress of the screening process, and any issues detected early and rectified immediately.Superior ScreeningThe unique design of the woven wire screen ensures complete accuracy and superior screening. It provides consistency in the size of the screened material and reduces over-sizing, improving the process and output.Woven Wire Screen: The Name to TrustWhen it comes to woven wire screens, (name removed) is the name to trust. The company is a global leader in manufacturing high-quality woven wire screen and custom screen products. Their commitment to quality and customer satisfaction is reflected in their continuous innovation and investment in modern technology. Established in 1864, the company has a rich history of providing long-lasting and efficient woven wire screens to various industries.Continuous Innovation(Name removed) has over 150 years of experience in the manufacturing of woven wire screens. Over the years, the company has invested in modern technology to produce the highest quality screen wire available. The company has a team of experts that continuously research and strive for new and innovative ways to improve the design and quality of their woven wire screens.Customized SolutionsThe company offers a range of customizable solutions according to the customers' precise requirements, ensuring that the woven wire screen is tailored to meet the exacting demands of the screening application.Exceptional Customer Support(Name removed) is dedicated to providing exceptional customer support. They offer a range of services ranging from on-site support to 24/7 technical support, all aimed at ensuring that their clients receive assistance to meet their screening needs.ConclusionWoven wire screens are an essential component of any material handling operation. Their versatility, durability, ease of maintenance, and superior screening qualities make them the preferred option for industries globally. With companies like (name removed), committed to designing and producing high-quality woven wire screens, industries can have peace of mind, knowing that they have a reliable solution to their screening needs.

High-Quality Heavy Gauge Stainless Steel Welded Wire Mesh Fencing Manufacturer in China

Fencing, Stainless Steel Fencing, Welded Wire Mesh Fencing, China Manufacturer, High Quality.Heavy Gauge Wire Mesh Fencing: The Ultimate Fencing Solution for Security and DurabilityFencing is an inevitable part of any property, be it residential, commercial, or industrial. A good quality fence not only adds to the property's aesthetic value but also ensures security, privacy, and safety. However, choosing the right type of fencing can be a daunting task, given the plethora of options available in the market. Amongst all, heavy gauge wire mesh fencing made of stainless steel has gained popularity owing to its numerous advantages over other fencing materials.Heavy gauge wire mesh fencing is a type of fencing that consists of a series of metal wires that are welded together to form a mesh-like structure. These meshes are made of high-quality stainless steel and come in various sizes and gauges to suit different fencing needs. The wires used in the mesh are so tightly woven that it ensures maximum stability and strength, making it difficult for intruders to breach the fence.One of the most significant advantages of heavy gauge wire mesh fencing is its durability. Stainless steel is known for its corrosion-resistant properties, making it an ideal material for outdoor fences that need to withstand harsh weather conditions. The fence's longevity is further enhanced by the thickness of the wires used, which can vary from 4mm to 10mm. The heavier the gauge, the stronger the fence.Another advantage of heavy gauge wire mesh fencing is its versatility. It can be used for various applications, such as perimeter fencing, animal enclosures, security fences, and even decorative fences. The mesh's open structure allows for airflow, making it suitable for areas that require ventilation. The fence's transparency ensures that it does not obstruct the view, making it ideal for places like parks, gardens, and public spaces.When it comes to security, heavy gauge wire mesh fencing is second to none. The tightly woven mesh structure makes it difficult for intruders to climb or cut through the fence. It also provides a clear view of the surroundings, making it easier to monitor any suspicious activities. Moreover, the fence's height can be customized to suit specific security requirements, making it an effective security solution.Apart from its functional benefits, heavy gauge wire mesh fencing made of stainless steel also adds to the property's aesthetic value. The mesh's clean and modern look complements any property style, making it an excellent choice for contemporary buildings. It also comes in various finishes, such as polished, brushed, or painted, giving property owners a wide range of design options to choose from.In conclusion, heavy gauge wire mesh fencing made of stainless steel is an excellent choice for property owners who value security, durability, versatility, and aesthetics. Its superior strength, longevity, and customization options make it the ultimate fencing solution for various applications. With China's leading manufacturers offering high-quality heavy gauge stainless steel welded wire mesh fencing, there is no reason why property owners should compromise on quality and security.