Discover the Advantages of Building Wire Mesh for Your Construction Projects

By:Admin

Building Wire Mesh is typically made from high-quality galvanized steel wire or annealed wire. These wires are woven or welded together to create a mesh with uniform openings. The size of the openings can vary depending on the specific requirements of the construction project. Building Wire Mesh is available in different dimensions, thicknesses, and configurations to meet the diverse needs of various construction applications.

One of the primary uses of Building Wire Mesh is in concrete reinforcement. It is commonly used as a reinforcing material in concrete slabs, walls, columns, and foundations. By adding Building Wire Mesh to concrete structures, they become stronger, more resistant to cracking, and better able to withstand external forces such as earthquakes or heavy loads. The mesh provides structural stability and prevents the spread of cracks, ensuring the longevity and safety of the concrete structure.

Another important application of Building Wire Mesh is in the construction of brickwork and masonry. The mesh is embedded within the mortar joints to enhance the structural integrity of the walls or partitions. This prevents the development of cracks and provides added strength to the masonry structure. Additionally, Building Wire Mesh helps to distribute the load evenly across the entire surface, reducing the risk of localized stress concentrations.

In addition to reinforcement, Building Wire Mesh also serves as a safety measure in construction sites. It is widely used as a protective barrier to prevent falls from heights, protect workers from debris or falling objects, and secure the construction area. The mesh is often installed as a perimeter fence, scaffold enclosure, or safety netting. Its durability and high-tensile strength make it an ideal choice for ensuring the safety of workers and the public during construction operations.

The versatility of Building Wire Mesh extends beyond construction applications. It is also used in various industrial sectors such as agriculture, transportation, and mining. In agriculture, the mesh is used for animal fencing, crop protection, and erosion control. In transportation, it is utilized for road reinforcement, bridge construction, and noise barriers. In mining, Building Wire Mesh is used in the production of screens, filters, and conveyor belts.

Company Introduction will be inserted here:

In conclusion, Building Wire Mesh plays a crucial role in modern construction projects. Its versatility, durability, and cost-effectiveness make it an essential component in various construction applications. With its ability to provide reinforcement, structural stability, and safety, Building Wire Mesh continues to be a sought-after choice by professionals in the construction industry. As it finds applications in not only construction but also other industrial sectors, the demand for Building Wire Mesh is expected to grow steadily in the coming years.

Company News & Blog

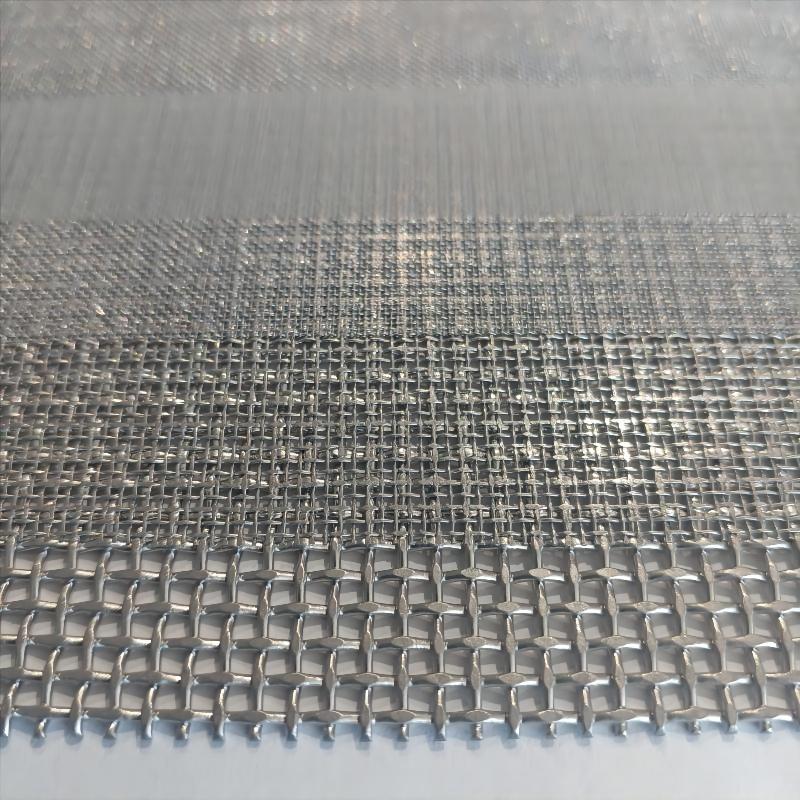

Discover the Durability and Versatility of Square Woven Wire Mesh for Your Project

RELEASE DATE: September 1, 2021Square woven wire mesh is a versatile material that can be used in a variety of applications, from industrial filtration to landscaping and gardening. With its durable and rust-resistant qualities, square woven wire mesh has become a popular choice for many different industries.In a recent announcement from (company name removed), they have made a significant investment in their square woven wire mesh line to meet the growing demand for this material. (Company name removed) is a leading manufacturer and distributor of industrial wire mesh products, with a focus on providing high-quality materials to industries worldwide.The company offers a variety of square woven wire mesh products, including both standard and custom sizes. Their square woven wire mesh is made from high-quality stainless steel wire, ensuring strength, durability, and corrosion resistance. The company also offers a range of aperture sizes and wire diameters to meet specific project requirements.Square woven wire mesh is commonly used in industrial filtration applications, including the oil and gas, chemical, and food processing industries. With its precise filtration capabilities, square woven wire mesh can effectively remove impurities and contaminants from liquids and gases, ensuring a high level of purity in the final product.In addition to its industrial applications, square woven wire mesh is also commonly used in landscaping and gardening. This material can be used to create garden fencing, trellises, and plant supports, providing both functional and aesthetic benefits.The square woven wire mesh products offered by (company name removed) are designed to provide high-quality performance and durability, ensuring a long lifespan and low maintenance requirements. The company's commitment to quality and customer satisfaction has earned them a reputation as a leading provider of wire mesh products for industrial and commercial applications.Their experienced team of engineers and technicians works closely with customers to develop custom solutions that meet their specific needs. Whether it's a standard product or a custom design, (company name removed) is dedicated to providing high-quality square woven wire mesh products that meet the highest standards of performance and reliability.In today's rapidly changing industrial landscape, it is more important than ever to work with a trusted supplier of high-quality materials. With its commitment to innovation and customer satisfaction, (company name removed) is leading the way in the production and distribution of square woven wire mesh products.For more information on (company name removed) and their square woven wire mesh products, visit their website or contact their sales team directly. With their expertise, experience, and dedication to quality, (company name removed) is the ideal partner for any project involving square woven wire mesh.

Latest News and Architecture Related to Wire Mesh | ArchDaily

Wire Mesh: A Modern and Secure Solution for WindowsWindows are an essential aspect of every building, providing natural light, ventilation, and views. Keeping windows secure is a key challenge for building owners and property managers, particularly for those with ground-level or easily accessible windows. This is where wire mesh windows come in as a modern and secure solution.Wire mesh has been used for various applications such as fencing and screening for many years, but it is also perfect for window installations. It consists of a grid of metal wires that are twisted, interwoven, or welded to create a mesh structure. The thickness of the wire, the size of the openings, and the spacing between the wires can be customized to meet specific needs and applications.Wire mesh windows have become increasingly popular in recent years because of their effectiveness in enhancing security while allowing ventilation and natural light to pass through. They are an ideal solution for residential, commercial, industrial, and institutional buildings, as well as for public facilities such as hospitals, schools, and museums.One of the leading companies in the wire mesh window industry is {Wire Mesh On Windows}. They specialize in designing, manufacturing, and installing wire mesh windows that offer maximum security, durability, and aesthetics. Their wire mesh windows are made of high-quality materials such as stainless steel, aluminum, and brass, which provide resistance to corrosion, weathering, and tampering.There are several advantages of using wire mesh windows from {Wire Mesh On Windows}. Firstly, they provide excellent security against break-ins, vandalism, and forced entry. The wire mesh structure is strong enough to resist physical attacks from intruders while allowing natural light and airflow to pass through.Secondly, wire mesh windows are aesthetically pleasing, and they can complement any architectural style or design. The mesh structure creates a modern and sleek appearance that can enhance the overall look of a building.Thirdly, wire mesh windows are easy to maintain and clean. They can be wiped down with a damp cloth, and the mesh structure prevents the accumulation of dust and debris. This makes them an ideal solution for buildings that require regular cleaning and maintenance.In addition to these advantages, wire mesh windows from {Wire Mesh On Windows} are also environmentally friendly and energy-efficient. They can reduce energy consumption by allowing natural light and ventilation to enter the building, which can lower heating and cooling costs. They are also recyclable and can be reused at the end of their life cycle.ConclusionWire mesh windows are an ideal solution for buildings that require a high level of security without compromising aesthetics, ventilation, and natural light. They offer a modern and durable alternative to traditional window systems and can be customized to meet specific needs and requirements. Companies like {Wire Mesh On Windows} offer a range of wire mesh solutions that are designed, manufactured, and installed to the highest standards of quality and safety. If you're looking for a modern and secure solution for your windows, consider wire mesh windows from {Wire Mesh On Windows}.

Where to Find Quality Expanded Metal Sheets for Your Needs

If you're a BBQ enthusiast, then you know how important it is to have the right tools at your disposal. Whether you're a seasoned grill master or just starting out, one tool you shouldn't overlook is a sheet of expanded metal. This versatile material is perfect for a variety of BBQ-related tasks and can help you take your grilling game to the next level. In this blog post, we'll explore some of the best places to pick up a sheet of expanded metal and why it's such an essential tool for BBQ enthusiasts.Why Choose Expanded Metal for BBQ?Before we dive into where to pick up a sheet of expanded metal, let's first discuss why it's such an important tool for BBQ enthusiasts. First and foremost, expanded metal is incredibly durable and long-lasting. It can withstand high temperatures and won't warp or bend over time. This makes it an excellent choice for a variety of BBQ-related tasks, including smoking, grilling, and even making your own custom grates.Additionally, expanded metal is incredibly versatile. It's available in a range of sizes and thicknesses, making it easy to find the perfect sheet for your needs. Whether you're looking to create a custom grill grate or need a non-stick surface for smoking delicate fish, expanded metal has you covered.Where to Buy Expanded Metal for BBQNow that you understand why expanded metal is such an important tool for BBQ enthusiasts, let's discuss where to pick up a sheet of this versatile material. There are a few different options to consider, depending on your needs and budget.Online RetailersOne of the easiest and most convenient ways to purchase expanded metal for BBQ is to shop online. There are a number of retailers that specialize in metalworking supplies, including expanded metal sheets. By shopping online, you can easily compare prices and find the perfect sheet for your needs. Some popular options include Amazon, Home Depot, and Lowes. Just be sure to read reviews and check the dimensions carefully before making your purchase.Local Metalworking ShopsAnother option for purchasing expanded metal for BBQ is to visit a local metalworking shop. These businesses specialize in creating and selling metal products and are often willing to sell small sheets of expanded metal to the public. By shopping locally, you can support small businesses in your community and often find higher-quality materials than what's available at big-box stores.Scrap YardsFinally, another option for picking up expanded metal for BBQ is to visit a scrap yard. These facilities often have a range of metal materials available for purchase at a discounted price. While the exact size and thickness of the sheet you find may vary, this can be a great budget-friendly option for those looking to experiment with expanded metal without breaking the bank.ConclusionIn conclusion, expanded metal is an essential tool for BBQ enthusiasts. It's durable, versatile, and perfect for a variety of tasks. Whether you're looking to create custom grates or need a non-stick surface for smoking delicate foods, expanded metal has you covered. By shopping online, visiting local metalworking shops, or checking out scrap yards, you can easily find the perfect sheet of expanded metal for your BBQ needs. So, what are you waiting for? Start grilling like a pro today with expanded metal!

Exporters of High-Quality Nickel Alloy Wire Mesh and Netting in Mumbai

and High Nickel Alloy Wire Netting.High Nickel Alloy Wire Mesh and Wire Netting – An OverviewHigh Nickel Alloy Wire Mesh and Wire Netting are widely used across various industries for their excellent strength and resistance to harsh environments. These materials are composed of nickel and other notable alloying elements such as copper, chromium, and molybdenum, among others. These alloys are known for their high corrosion resistance, good thermal conductivity, and excellent mechanical properties.Sanghvi Overseas is a leading supplier and exporter of ASTM B160 / ASME SB160 Nickel & High Nickel Alloy Wire Mesh / Wire Netting, including Nickel Alloy 200 Wire Mesh and High Nickel Alloy 201 Wire Netting. Sanghvi Overseas has an extensive network of global clients and is committed to providing the highest quality materials at competitive prices.Nickel Alloy 200 Wire MeshNickel Alloy 200 Wire Mesh is a commercially pure nickel material that has excellent resistance to corrosive environments. This alloy has low carbon content and is resistant to caustic soda and other alkaline solutions. It has high electrical conductivity and is used as an electrode in various industrial applications. The material has a maximum operating temperature of 315 degrees Celsius and is suitable for use in chemical processing plants, marine installations, and power generation stations.High Nickel Alloy 201 Wire NettingHigh Nickel Alloy 201 Wire Netting is similar to Nickel Alloy 200 but has a lower carbon content, which gives it a slightly higher thermal conductivity and reduced embrittlement at elevated temperatures. This material is also highly resistant to corrosion and is suitable for use in reducing and oxidizing environments. It is commonly used in food processing plants, chemical and petrochemical industries, seawater handling equipment, and nuclear power generation plants.Other High Nickel Alloy Wire Mesh and Wire NettingSanghvi Overseas also supplies other high nickel alloy wire mesh and wire netting materials, including:- Monel Alloy 400 Wire Mesh- Monel Alloy K500 Wire Mesh- Inconel Alloy 600 Wire Mesh- Inconel Alloy 601 Wire Mesh- Incoloy Alloy 800 Wire Mesh- Incoloy Alloy 800H Wire Mesh- Hastelloy Alloy C276 Wire Mesh- Hastelloy Alloy C22 Wire MeshThese materials offer similar properties to Nickel Alloy 200 and High Nickel Alloy 201, but with varying levels of added elements to suit specific applications.Why Choose Sanghvi Overseas for High Nickel Alloy Wire Mesh and Wire Netting?Sanghvi Overseas is a trusted supplier and exporter of high-quality High Nickel Alloy Wire Mesh and Wire Netting materials. The company has an extensive network of global clients and has a reputation for providing the highest quality materials at competitive prices. They have a team of experts who are experienced in selecting the right material for each application and are committed to delivering products on time and to the highest quality standards.ConclusionHigh Nickel Alloy Wire Mesh and Wire Netting are essential materials used in various industries, including chemical processing, marine installations, power generation, and food processing. These materials are highly resistant to corrosion, have excellent thermal conductivity, and offer good mechanical properties. Sanghvi Overseas is a trusted supplier and exporter of these materials, providing the highest quality products at competitive prices. Contact them for more information on their products and services.

Get Your Metal Mesh Today - Call for Assistance at 01954 261369

Martin Hale, a metal mesh expert with years of experience, has started a new business called Vulcan 502250, supplying top-notch metal mesh products to various industries nationwide. The business has been established with the aim of providing superior metal mesh products that surpass customer's expectations in terms of quality, durability, and affordability.Martin Hale has been in the metal mesh business for quite some time, and he has earned a reputable name in the industry as a metal mesh expert. He has a broad knowledge of the manufacturing process of metal mesh and is passionate about delivering products that meet clients' needs. The Vulcan 502250 is a testament to Martin's keen eye for quality, as he sources only the finest raw materials from well-known suppliers. The company uses state-of-the-art machinery and equipment to produce metal mesh products that can be customized to meet clients' specific requirements. The metal mesh comes in a wide variety of sizes, shapes, and types, including woven, welded, expanded, and perforated mesh.Vulcan 502250 products are ideal for a variety of applications in industries such as architecture, automotive, agriculture, mining, and construction. The metal mesh products can be used for fencing, ventilation, filtration, screening, and separators. The company's products are renowned for their versatility and durability, making them ideal for use in harsh environments and heavy-duty applications.Martin Hale has always been committed to providing excellent customer service. He has built a friendly and knowledgeable team that works diligently to ensure that clients get the assistance they need to make the best decisions. Vulcan 502250's team of experts is always ready to provide guidance on the selection, customization, and installation of metal mesh products.The customer-friendly approach of Vulcan 502250 has earned them a loyal and vast customer base across the UK. Many satisfied clients have praised Martin Hale for his professionalism, attention to detail, and consistency in delivering quality products and services.Martin Hale's Vulcan 502250 has implemented strict quality control measures to guarantee that all their products meet the required standards. The company's metal mesh products undergo rigorous testing procedures to ensure that they are strong, durable, and fit for purpose. These stringent measures guarantee that clients receive products that are reliable, efficient, and safe to use.Vulcan 502250 continually invests in research and development to improve its metal mesh products. The company collaborates with leading metal mesh experts and suppliers to stay updated on the latest industry advancements. This way, they remain at the forefront of product innovation and development.In conclusion, Vulcan 502250 is the go-to destination for individuals and companies in need of quality metal mesh products. The company's commitment to quality, customer service, and innovation has made it a leading metal mesh provider in the UK. Call them today on 01954 261369 to purchase your ideal metal mesh product.

Discover the Versatility and Durability of Black Expanded Metal Mesh

Title: New Black Expanded Metal Mesh Revolutionizes Industrial ApplicationsIntroduction:In a breakthrough development, Company X has unveiled its latest innovation in the field of expanded metal mesh - the exceptional Black Expanded Metal Mesh. With its remarkable durability, versatility, and aesthetic appeal, this cutting-edge product is set to revolutionize various industrial applications. By combining advanced manufacturing techniques with top-quality materials, Company X continues to remain at the forefront of the metal mesh industry.Paragraph 1: Importance of Expanded Metal Mesh in Industrial Applications (100 words)Expanded metal mesh has long been an essential component across a wide range of industrial sectors. Its unique design enables it to provide strength, security, and flexibility, making it an ideal choice for countless applications. From infrastructure development to architectural endeavors, expanded metal mesh has found its place in diverse industries such as construction, transportation, manufacturing, and telecommunications.Paragraph 2: Introducing the Black Expanded Metal Mesh (100 words)Company X's newly engineered Black Expanded Metal Mesh is set to elevate the possibilities and functionality of this essential product. By incorporating a sleek black finish into the expanded metal mesh, it enhances both the visual aesthetics and practicality. The black coating provides a layer of protection against corrosion, ensuring durability and longevity in even the harshest of environments.Paragraph 3: Unparalleled Durability and Strength (150 words)The Black Expanded Metal Mesh manufactured by Company X boasts exceptional durability and strength. Crafted from high-quality materials using advanced manufacturing processes, it exhibits unparalleled resistance to impact, bending, and fretting. This makes the product ideal for areas that endure heavy foot traffic or high mechanical stresses. Whether used as security fencing, machine guards, or walkways, the Black Expanded Metal Mesh offers robustness and reliability, ensuring the utmost safety in demanding industrial environments.Paragraph 4: Versatile Applications and Adaptability (150 words)Beyond its robustness, the Black Expanded Metal Mesh also ensures versatility in numerous applications. Its ability to be easily formed and manipulated enables it to suit various design requirements. From decorative panels in architectural designs to filter screens in ventilation systems, this product provides exceptional adaptability to meet the needs of any project. Its black finish adds a touch of sophistication, enhancing the aesthetic appeal while maintaining functionality.Paragraph 5: Enhanced Safety and Security (150 words)In addition to its functional features, the Black Expanded Metal Mesh prioritizes safety and security. The unique design, with small open spaces, ensures visibility and promotes airflow while serving as an effective barrier. This makes it suitable for applications such as security enclosures, partitions, and machine guarding. The black color further aids in obscuring the view, providing an additional layer of privacy in sensitive areas. Company X's commitment to quality and rigorous testing assures that the Black Expanded Metal Mesh meets stringent safety standards, ensuring peace of mind for its users.Conclusion: Enabling Innovation and Advancement (100 words)The launch of Company X's Black Expanded Metal Mesh showcases the company's commitment to innovation and advancement in the manufacturing industry. With its enhanced durability, versatility, and visual appeal, this revolutionary product opens up new possibilities for designers, architects, and engineers across various sectors. Whether it is for structural stability, aesthetic appeal, or enhanced security, the Black Expanded Metal Mesh is set to redefine the standard in industrial applications, paving the way for a more efficient and aesthetically pleasing future.

Discover the Versatility and Elegance of Architectural Wire Mesh

Architectural Wire Mesh: Reimagining Spaces with Innovative Design SolutionsIntroduction:In today's ever-evolving world of architecture and interior design, cutting-edge materials and technology are reshaping the way we conceptualize and transform spaces. One such groundbreaking innovation is Architectural Wire Mesh, a versatile and transformative material that has gained significant popularity among architects, interior designers, and builders alike. By seamlessly blending functionality with aesthetic appeal, Architectural Wire Mesh is revolutionizing the way we envision and create stunning architectural designs.Unveiling Architectural Wire Mesh:Architectural Wire Mesh is a distinctive material that is woven or welded from metallic wires, resulting in an intricately patterned mesh. Engineered to perfection, this material offers a wide range of benefits, including unparalleled durability, strength, and flexibility. It provides a visually captivating and captivating solution for a myriad of architectural applications, such as facades, cladding, partitions, ceilings, and even furniture.Integration of Technology and Design:What sets Architectural Wire Mesh apart from traditional architectural materials is its seamless integration with modern technology and design techniques. By utilizing advanced computer-aided design software, architects and designers can effortlessly visualize the look and feel of architectural elements incorporating Wire Mesh. This enables them to experiment with various patterns, scales, and textures, resulting in truly unique and mesmerizing designs.Architectural Wire Mesh Opens Doors to Creativity:The versatility of Architectural Wire Mesh lies in its ability to adapt to diverse design concepts and aesthetics. Its malleable nature allows architects and designers to mold it into any desired shape, making it suitable for both intricate and minimalist architectural designs. The integration of Architectural Wire Mesh into buildings and interiors instantly elevates the ambiance, adding depth, character, and a touch of luxury to the space.Enhancing Functionality:Beyond its aesthetic appeal, Architectural Wire Mesh offers functional advantages as well. With its permeable nature, Wire Mesh allows for natural ventilation, lighting, and shading, reducing the need for artificial sources. Additionally, it possesses excellent acoustic properties, effectively blocking unwanted noise pollution. Furthermore, Architectural Wire Mesh ensures maximum security and safety, providing fire resistance and anti-vandalism properties.Applications in Architecture and Design:Architectural Wire Mesh finds applications in various architectural projects, catering to both residential and commercial spaces. The material can be seamlessly incorporated into intricate facades, creating visually stunning exteriors. Its use in interior design extends to creating unique room dividers, wall panels, and innovative ceiling designs. From contemporary office spaces to luxurious homes, Architectural Wire Mesh is redefining the boundaries of design possibilities.Sustainable Construction:In a world advancing towards sustainability, Architectural Wire Mesh aligns perfectly with the ethos of eco-friendly construction. Manufactured from recyclable and locally sourced materials, it minimizes the environmental impact, fostering a greener and more responsible architecture. The durability and longevity of the material further contribute to sustainability by reducing the need for frequent replacements.Collaboration with Architects and Designers:To realize the full potential of Architectural Wire Mesh, collaboration between manufacturers and architects/designers plays a crucial role. By actively working together from conceptualization to completion, architects and manufacturers can develop customized solutions that cater to the specific design requirements of each project. This collaborative approach ensures seamless integration of Architectural Wire Mesh into the architectural vision.Conclusion:Architectural Wire Mesh has undoubtedly revolutionized the architectural industry, offering a perfect blend of functionality and design. Its ability to transform spaces, combined with increased sustainability, makes it one of the most sought-after materials for modern builders and designers. With endless possibilities, Architectural Wire Mesh continues to push the boundaries of innovation, reimagining spaces and creating awe-inspiring designs that leave a lasting impact.

Metal Mesh for Industrial Applications: Durable and Reliable Solution

Title: Cutting-Edge Stainless Steel Mesh Revolutionizes Industrial OperationsIntroduction:In today's rapidly evolving industrial landscape, innovative solutions are constantly emerging to address the growing needs of various sectors. One such groundbreaking product is Stainless Steel Mesh, an advanced material that is revolutionizing multiple industries with its exceptional strength, durability, and versatility. Designed to surpass traditional barriers, this mesh has become an essential component within manufacturing, construction, and filtration processes, propelling businesses to unprecedented heights of efficiency, productivity, and reliability.1. Rising Demand for Stainless Steel Mesh in Manufacturing Industry:The manufacturing industry bears witness to the increasing adoption of Stainless Steel Mesh as a critical tool in various operational processes. Offering superior tensile strength, the mesh effectively replaces conventional materials by withstanding high temperatures, corrosive chemicals, and heavy loads. Whether it's in the automotive, aerospace, or electronics sectors, manufacturers are benefiting from the enhanced safety, performance, and longevity delivered by stainless steel mesh solutions.Moreover, the ability to customize the mesh to precise specifications ensures optimal functionality, making it an indispensable component for reliable filtration, extrusion, and sieving operations. As a result, manufacturing processes become more efficient, reducing downtime and maintenance costs while maximizing yield and overall product quality.2. Construction Industry Embracing Stainless Steel Mesh for Structural Reinforcement:The construction sector has also recognized the transformative potential of Stainless Steel Mesh in strengthening concrete structures, providing corrosion resistance, and enhancing durability. With its unique combination of strength and flexibility, stainless steel mesh enables engineers and architects to design robust buildings, bridges, and infrastructure projects capable of withstanding extreme conditions and load-bearing requirements.Moreover, the mesh's inherent corrosion resistance properties significantly extend the lifespan of construction projects, reducing long-term maintenance costs and improving structural integrity. Coupled with the ability to seamlessly blend into a variety of aesthetic designs, stainless steel mesh is becoming a favored choice for architects seeking both functionality and visual appeal.3. Advancements in Filtration Technologies Driven by Stainless Steel Mesh:Filters play a pivotal role in industries such as oil and gas, pharmaceuticals, and food processing, ensuring the purity and quality of products. Stainless Steel Mesh has emerged as a game-changer in the filtration arena, revolutionizing the way solids and liquids are separated and purified.The unique properties of the mesh, including its precise aperture sizes, excellent porosity, and exceptional resistance to clogging and fouling, make it ideal for applications where precision and efficiency are paramount. As a result, businesses can achieve higher filtration rates, optimize production processes, and effectively reduce operating costs by utilizing stainless steel mesh filters.4. Company X's Pioneering Role in Advancing Stainless Steel Mesh Technology:At the forefront of the stainless steel mesh revolution is Company X, a leading manufacturer and innovator in the industrial materials sector. With a rich history spanning several decades, Company X has consistently invested in research and development, striving to push the boundaries of what is achievable with stainless steel mesh.Company X spends significant resources on cutting-edge manufacturing technologies, ensuring that their stainless steel mesh products are of the highest quality and meet the stringent demands of modern industries. Through continuous collaboration with industry experts and customer feedback, Company X maintains a customer-centric approach, tailoring their solutions to address specific operational needs across various sectors.Conclusion:Stainless Steel Mesh has undoubtedly emerged as a transformative material with immense potential across numerous industries. Its unrivaled strength, adaptability, and durability make it a top choice for manufacturers, construction firms, and filtration system developers alike. As businesses strive for greater efficiency, reliability, and longevity in their operations, Stainless Steel Mesh is proving to be an invaluable asset, driving innovation and revolutionizing industrial processes. With Company X leading the charge in advancing this technology, we can expect even greater breakthroughs in the coming years, propelling industries to new heights of success.

California Filter Sand Plant Utilizes Two Grades of Dewatered Filter Sands for Large Dam Project

Filter Sand Classification for Large Dam Projects: A Comprehensive Guide In any large dam building project, the quality of the filtered water plays a crucial role in ensuring safe and reliable operation. The filtration process serves to remove impurities and debris from the feed water, preventing damage to downstream equipment and ensuring proper functioning of the entire water system.One key component of the filtration system is the filter sand. California filter sand plant is a popular choice for large dam projects due to its high quality and reliability. In the following guide, we will explore the basics of filter sand classification and its role in water filtration.Filter Sand ClassificationFilter sands come in various grades and sizes, depending on their intended use. Sand grains are classified according to their size, with finer grains being used for more sensitive filtration applications. The most common classification systems used for filter sands are mesh and microns.Mesh classification refers to the number of openings per linear inch of screen. For example, a 30 mesh screen has 30 openings per inch. Finer screens have a higher mesh number, indicating smaller openings and therefore smaller sand grains.Micron classification is based on the size of the sand grains in microns. A micron is one millionth of a meter, and smaller sand grains have a higher micron value. For example, a 30-micron sand grain is smaller than a 100-micron sand grain.Filter Sand ScreenIn order to classify and sort the filter sand, a filter sand screen is used. This consists of a series of mesh or micron-sized screens that separate the sand particles according to size. The filtered sand is then sorted and graded based on its intended use.California filter sand plant uses a series of four 8’ x 8’ units with separations at 30 and 100 mesh. This allows for two grades of filter sands to be produced, depending on the required filtration application.Dewatering the Filter SandsOnce the filter sands have been classified and sorted, they are then dewatered using specialized equipment. Four (Need remove brand name) is used to dewater the filter sands in California filter sand plant.This process involves removing excess moisture from the filter sands, making them easier to handle and transport. Dewatered filter sands also have higher stability and are less prone to drying out or degrading over time.ConclusionFilter sand classification is an essential part of any large dam project, ensuring proper filtration of feed water for downstream use. The use of California filter sand plant with four units and dewatering equipment ensures high-quality filter sands are produced for multiple filtration applications.For more information on filter sand classification and its role in large dam projects, contact the expert team at Classification and Flotation Systems. Our team of filtration experts is dedicated to providing high-quality filtration solutions to meet your unique needs.

Top Sintered Mesh Filter Disc: Enhance Filtration Efficiency with Advanced Technology

Title: Leading Manufacturer Unveils Cutting-Edge Sintered Mesh Filter Disc, Revolutionizing Filtration SystemsIntroduction:In the rapidly evolving world of filtration technology, renowned industry leader, Manufacturing Co., is making waves with its latest breakthrough - the groundbreaking Sintered Mesh Filter Disc. With an unwavering commitment to innovation and excellence, the company has once again raised the bar by revolutionizing filtration systems across various industries.Body:1. Unveiling the Sintered Mesh Filter Disc:Manufacturing Co. proudly presents the highly-anticipated Sintered Mesh Filter Disc, a cutting-edge product set to transform the way particles are filtered across numerous applications. This advanced filter disc combines superior materials, precision manufacturing, and innovative design to deliver unmatched performance, improved efficiency, and prolonged service life.2. Unparalleled Filtration Efficiency:The Sintered Mesh Filter Disc boasts an exceptionally high level of filtration efficiency, enabling it to remove even the tiniest particles with remarkable accuracy. The tightly-knit mesh structure ensures an optimal flow rate, allowing for efficient filtration while maintaining minimal pressure drop. This remarkable feature makes it an ideal choice for industries such as pharmaceuticals, petrochemicals, food and beverage, and wastewater treatment.3. Enhanced Durability and Longevity:Manufacturing Co.'s Sintered Mesh Filter Disc is built to withstand harsh conditions and extreme temperatures, making it a highly durable and reliable filtration solution. The carefully selected sintered mesh materials enable the disc to resist corrosion and oxidation, ensuring a prolonged service life compared to traditional filters. This longevity translates into significant cost savings for industries that heavily rely on filtration systems.4. Versatile Applications:The versatility of the Sintered Mesh Filter Disc is a standout feature, as it can be seamlessly integrated into various applications across diverse industries. Its exceptional filtration efficiency, coupled with the ability to withstand high pressure and temperature, makes it an excellent choice for applications such as gas and liquid separation, catalyst recovery, polymer filtration, and more. The adaptability and wide range of applications make this filter disc a truly indispensable component in numerous industrial processes.5. Quality Manufacturing Process:Manufacturing Co. employs state-of-the-art manufacturing techniques to ensure the highest level of quality and precision during the production of the Sintered Mesh Filter Disc. Relying on advanced sintering technology, the company achieves a perfectly uniform and robust mesh structure, resulting in consistent performance and exceptional product reliability. Additionally, a stringent quality control process is implemented at every stage to guarantee that each filter disc meets or exceeds industry standards.6. Commitment to Sustainability:As a responsible manufacturer, Manufacturing Co. prioritizes sustainability in every aspect of its operations. The Sintered Mesh Filter Disc reflects this commitment, as it is designed for ease of maintenance and cleaning, effectively reducing waste and minimizing the need for frequent replacements. With its exceptional durability and longevity, the filter disc plays a pivotal role in promoting eco-friendly practices within the industry.Conclusion:Manufacturing Co's introduction of the state-of-the-art Sintered Mesh Filter Disc marks a significant milestone in the evolution of filtration technology. Combining exceptional filtration efficiency, enhanced durability, and unmatched versatility, this groundbreaking product is set to revolutionize filtration systems across a wide range of industries. With a steadfast commitment to innovation and sustainability, Manufacturing Co. continues to be at the forefront of delivering cutting-edge solutions that address the evolving needs of global industries.